Method for testing fertilizer efficiency of fine garbage compost

A technology of waste composting and determination method, which is applied to the rational use of municipal solid waste composting and the determination of micronized waste composting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

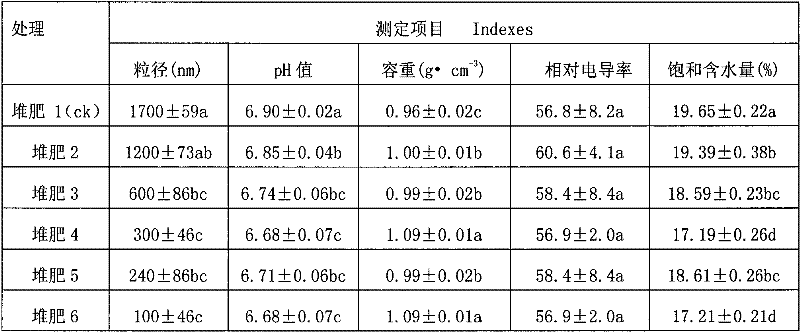

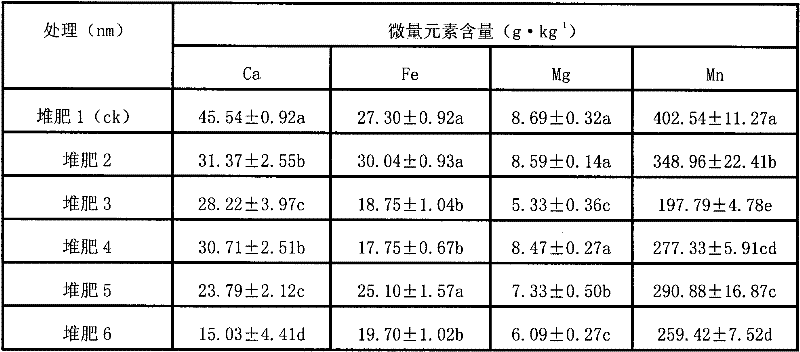

[0037] (1) The compost used in the experiment was first removed from impurities, then dried to a constant weight at 105°C, and the compost with a particle size of 1700nm was sieved;

[0038] (2) Pulverize the compost with a particle size of 1700nm at 24000 rpm for 9min, 6min, 3min, 2min and 1min respectively to prepare compost with different particle sizes, put the compost with different particle sizes into alcohol, and use The ultrasonic oscillator makes it evenly dispersed and becomes a suspension;

[0039] (3) Then use a toothpick to stick a little suspension, apply a layer on the surface of the sample table, dry it with electric hot air, then use a vacuum cleaner for half a minute, and finally use a S4800 field emission scanning electron microscope to measure the particle size. The obtained compost particles The diameters are 1700nm, 1200nm, 600nm, 300nm, 240nm and 100nm; the organic matter content in the compost is 22.00%, and the bulk density is 0.79g cm -3 , pH 7.62, p...

Embodiment 2

[0042] (1) The compost used in the experiment was first removed from impurities, then dried to a constant weight at 105°C, and the compost with a particle size of 1700nm was sieved;

[0043] (2) Pulverize the compost with a particle size of 1700nm at 24000 rpm for 9min, 6min, 3min, 2min and 1min respectively to prepare compost with different particle sizes, put the compost with different particle sizes into alcohol, and use The ultrasonic oscillator makes it evenly dispersed and becomes a suspension;

[0044] (3) Then use a toothpick to stick a little suspension, apply a layer on the surface of the sample table, dry it with electric hot air, then use a vacuum cleaner for half a minute, and finally use a S4800 field emission scanning electron microscope to measure the particle size. The obtained compost particles The diameters are 1700nm, 1200nm, 600nm, 300nm, 240nm and 100nm; the organic matter content in the compost is 22.00%, and the bulk density is 0.79g cm -3 , pH 7.62, p...

Embodiment 3

[0047] (1) The compost used in the experiment was first removed from impurities, then dried to a constant weight at 105°C, and the compost with a particle size of 1700nm was sieved;

[0048] (2) Pulverize the compost with a particle size of 1700nm at 24000 rpm for 9min, 6min, 3min, 2min and 1min respectively to prepare compost with different particle sizes, put the compost with different particle sizes into alcohol, and use The ultrasonic oscillator makes it evenly dispersed and becomes a suspension;

[0049] (3) Then use a toothpick to stick a little suspension, apply a layer on the surface of the sample table, dry it with electric hot air, then use a vacuum cleaner for half a minute, and finally use a S4800 field emission scanning electron microscope to measure the particle size. The obtained compost particles The diameters are 1700nm, 1200nm, 600nm, 300nm, 240nm and 100nm; the organic matter content in the compost is 22.00%, and the bulk density is 0.79g cm -3 , pH 7.62, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com