Method for assembling lugs of lithium ion battery

A lithium-ion battery and assembly method technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of low assembly quality and efficiency of tabs, and achieve the effects of improving assembly quality and efficiency and preventing displacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

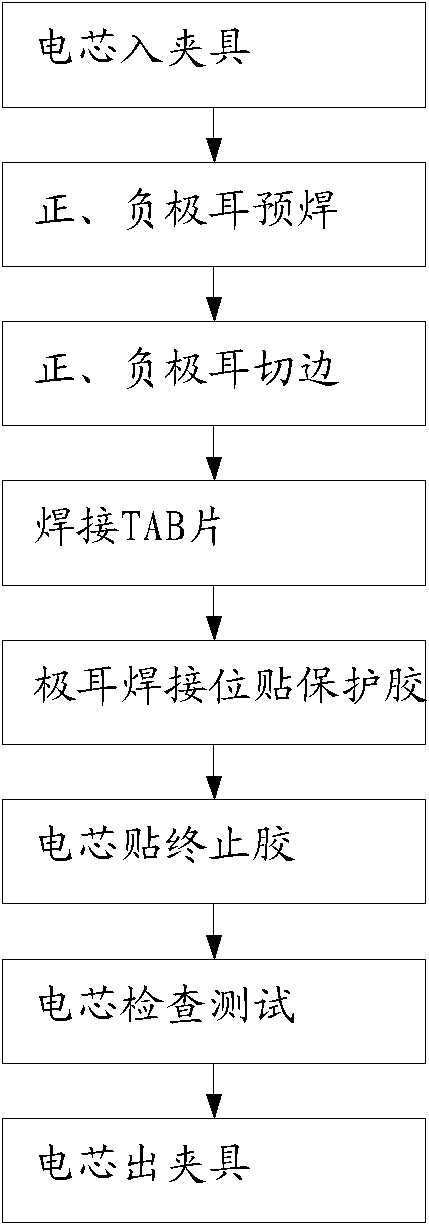

[0019] Such as figure 1 The shown method for assembling the tabs of a lithium ion battery includes the following steps:

[0020] Step one, insert the battery into the fixture.

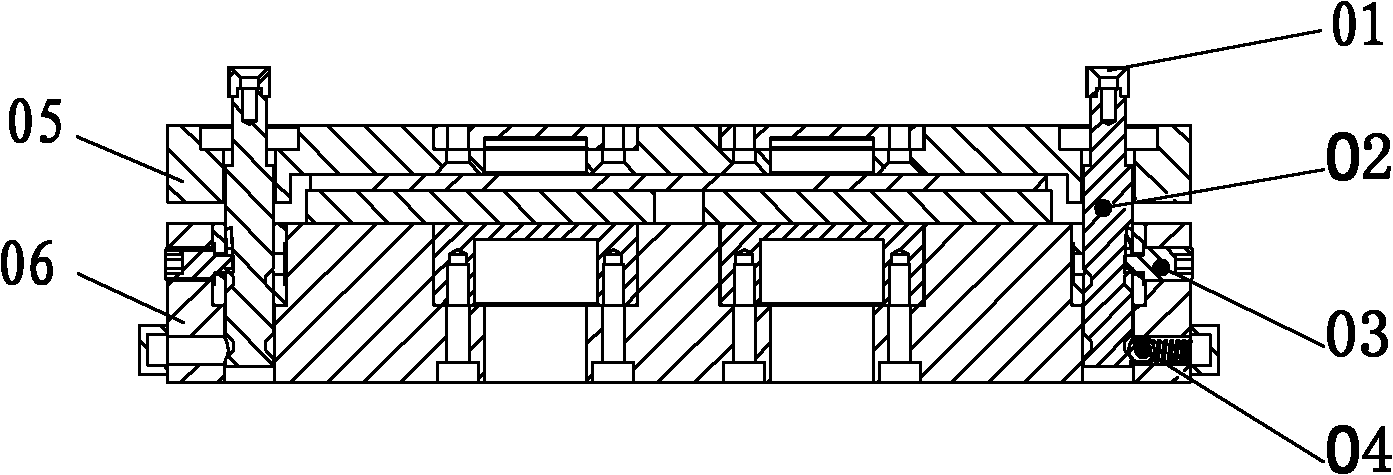

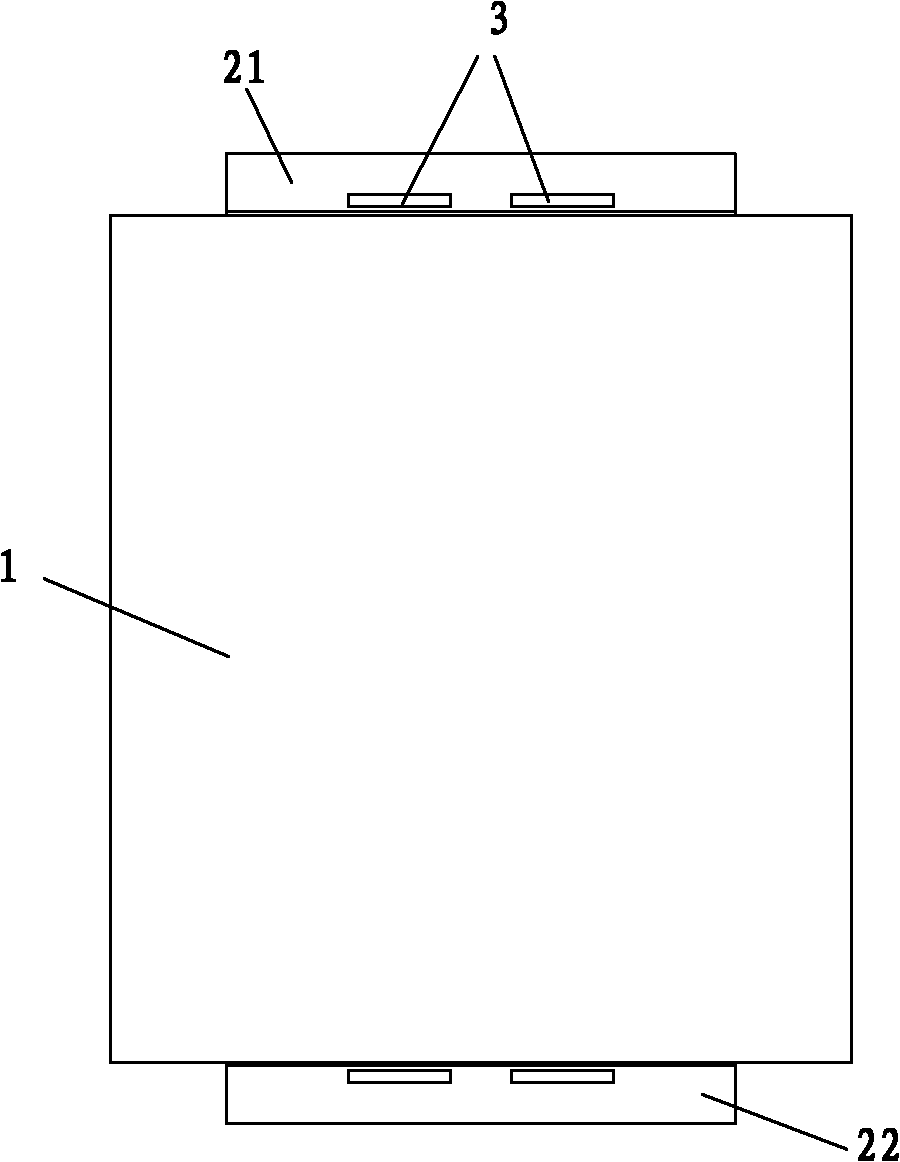

[0021] After the positive and negative plates of the lithium-ion power battery are laminated by the automatic laminator, a rectangular bare cell with a certain thickness is formed. The cell with the outer diaphragm is pasted with a piece of adhesive tape on the overlap of the outermost layer. In order to ensure that the diaphragm does not loosen, at this time, the alignment of the positive and negative electrodes or the alignment with the diaphragm is up to the standard. To ensure that the alignment of the battery will not be affected in the subsequent process steps, The cell is fixed in the fixture, and the actions of each station are completed step by step. The fixture is not opened until the entire cell has been glued. Such as figure 2 As shown, the clamp includes a clamp cover 05, a download tool 06, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com