Automatic production and assembly method of internal memory connector

A technology of automatic production and assembly method, which is applied in the assembly/disassembly, connection, circuit/collector parts and other directions of contacts, which can solve the problems of high personnel expenses, discontinuous production, and high defect rate, and achieve a large reduction in Manpower requirements, product quality improvement, and the effect of reducing defective rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further achieve the intended purpose and effects of the present invention, the following will be combined with the accompanying drawings and the embodiments thereof to describe in detail the specific implementation, structure, features and effects of the memory connector automatic production and assembly method proposed according to the present invention. illustrate.

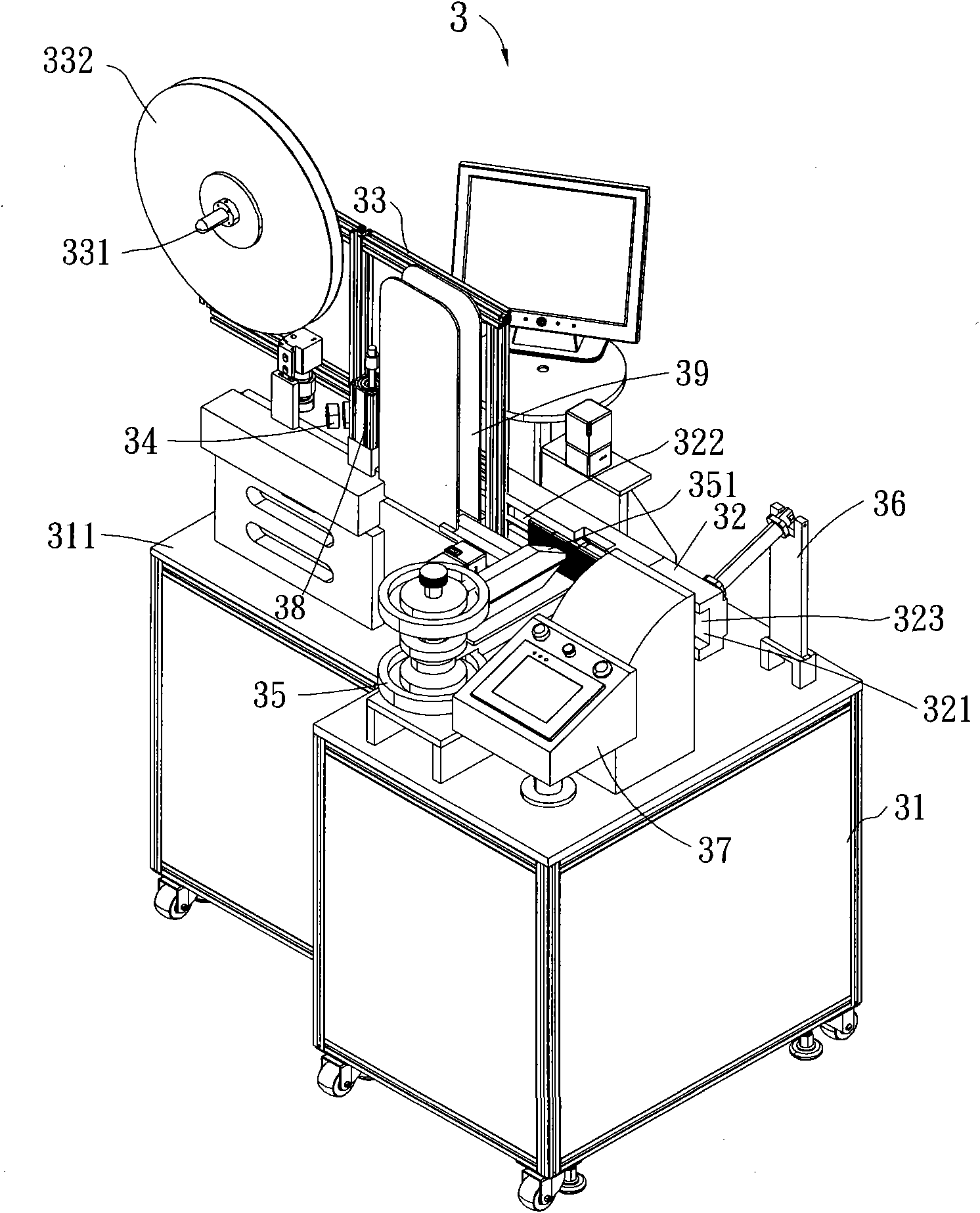

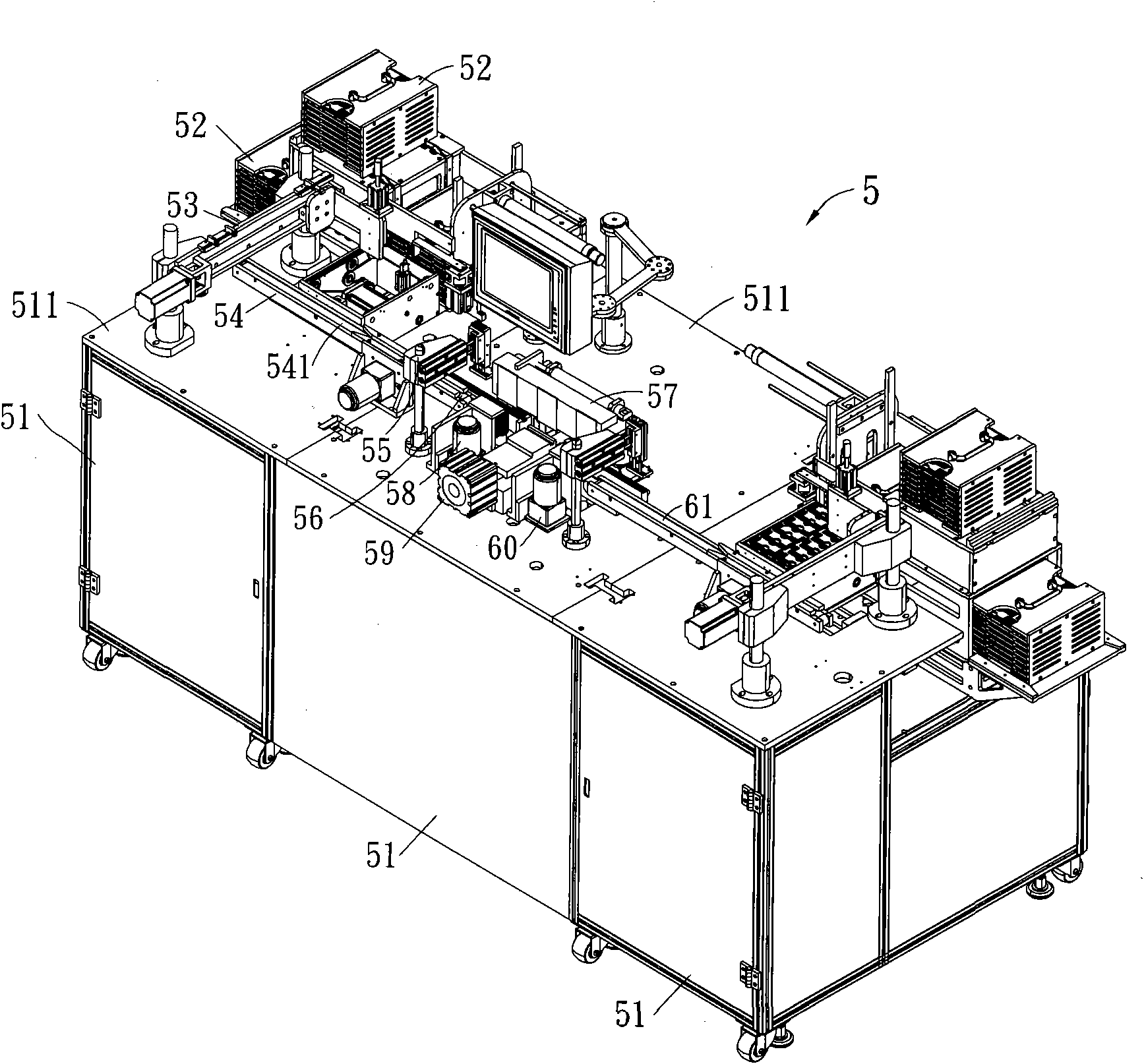

[0022] Please refer to Figure 2 to Figure 5 As shown, it is an automatic machine for realizing the automatic production and assembly of memory connectors according to the present invention. The automatic production of memory connectors passes through automatic pin insertion machine 3, pin pressing and automatic dust removal machine 5, test type automatic machine 7, and insertion and pressing lock arm Automata 8.

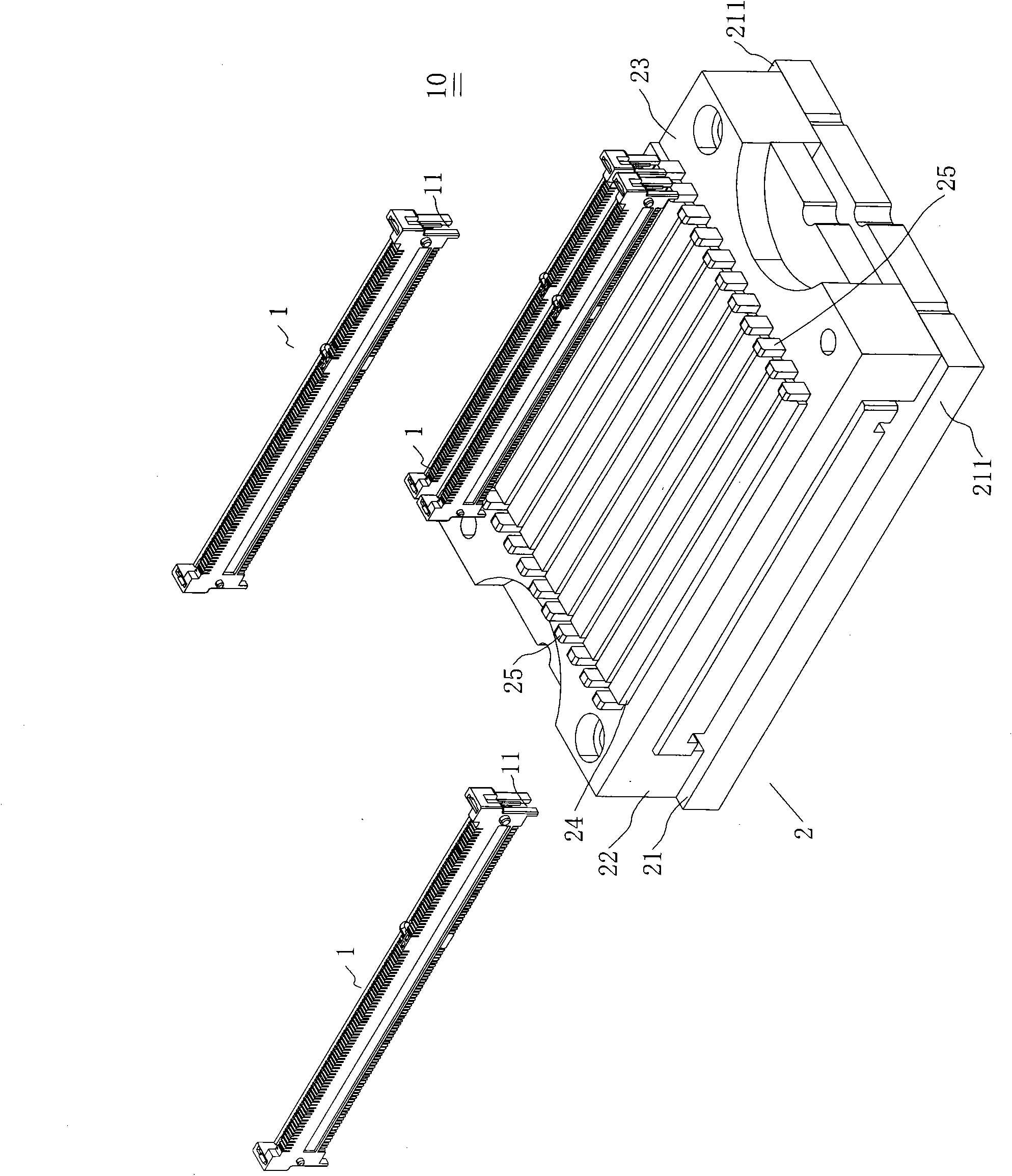

[0023] Before starting the automatic production assembly machine, it needs to make relevant preparations. Such as figure 1 As shown, it includes a memory connector base 1 and a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com