Pneumatic tire and its manufacturing method

A technology for a pneumatic tire and a manufacturing method, which is applied to the reinforcement layer, tire parts, tires and other directions of the pneumatic tire, and can solve problems such as slippage and inability to travel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

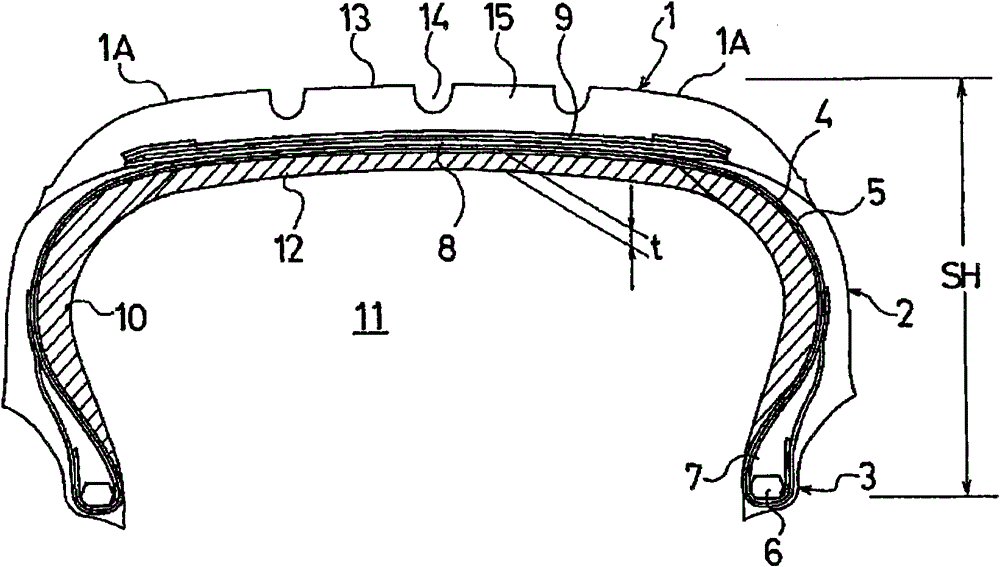

[0077] The tire size is the common size, namely 205×55R15. figure 1 In the tire 1 of the present invention (Example 1), a run-flat reinforcing layer made of rubber and having a crescent-shaped cross-sectional shape is arranged on the inner surface of the left and right sidewalls, and the inner surface of the tread is provided as shown in Table 1. The tread reinforcement layer is composed of thermoplastic elastomer composition (storage elastic modulus 60MPa). figure 1 In the tire 2 of the present invention (Example 2), a run-flat reinforcing layer composed of a thermoplastic resin (storage modulus of elasticity: 60 MPa) shown in Table 2 and having a crescent-shaped cross-sectional shape is disposed on the inner surfaces of the left and right side walls. , A tread reinforcement layer made of the same thermoplastic resin is also provided inside the tread portion. In addition, for the tire 1 of the present invention, a conventional tire (conventional tire) without a tread reinfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com