Method for improving luminous intensity of light-cumulating luminous slurry

A technology of luminous intensity and light storage type, applied in luminescent materials, chemical instruments and methods, optics, etc., can solve the problems of low luminous efficiency and intensity, and achieve the effect of improving luminous intensity and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

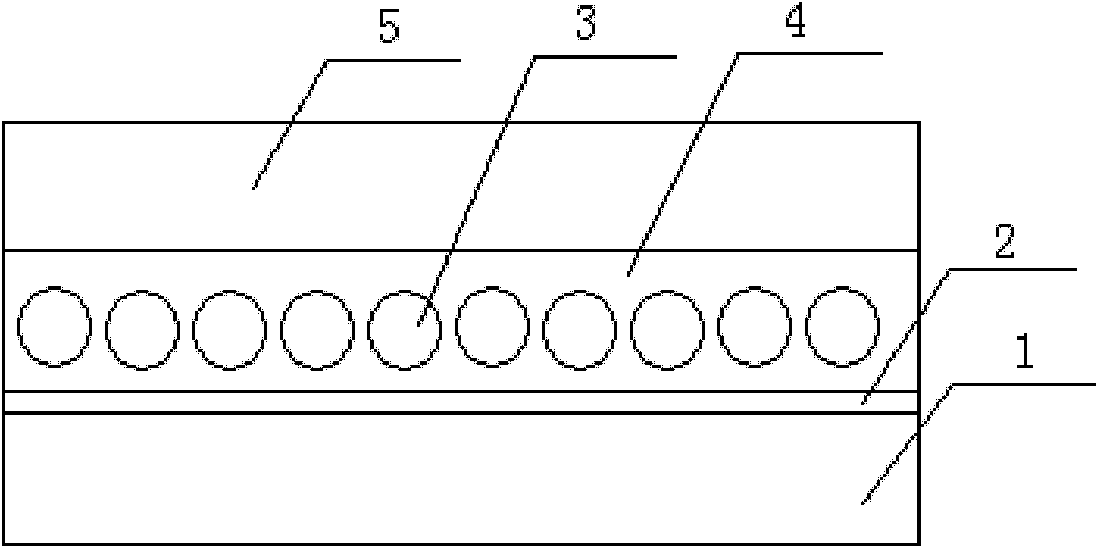

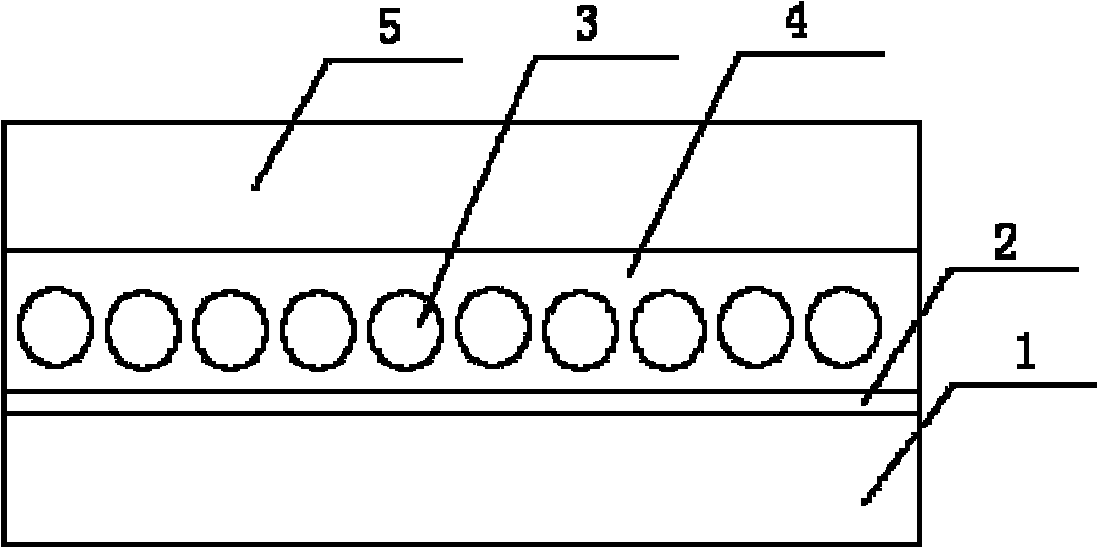

[0020] 1) The prepared substrate TiO 2 The slurry is printed on a PET film substrate through a 100-mesh screen, and dried at 120°C.

[0021] 2) After drying, printed with TiO 2 The base material is printed on the glass bead reflective layer slurry through a 100-mesh screen, and dried at 120°C after printing.

[0022] 3) Finally, after the reflective layer is completely dry, the luminescent paste is printed on the basis of the reflective layer through an 80-mesh screen, and dried at 130° C. after printing.

Embodiment 2

[0024] 1) The prepared metal reflective layer slurry is printed on a PET film substrate through a 120-mesh screen, and dried at 120°C.

[0025] 2) After drying, the substrate printed with the metal reflective layer is printed with the glass bead reflective layer slurry through a 100-mesh screen, and dried at 120° C. after printing.

[0026] 3) Finally, after the reflective layer is completely dry, luminescent paste is printed on the basis of the reflective layer through a 100-mesh screen, and dried at 130° C. after printing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com