Fuel switch

A fuel and switch technology, applied in liquid fuel feeders, mechanical equipment, engine components, etc., can solve the problem of low-pressure oil circuit air bubbles and fuel filtration problems that have not been completely solved, and it is difficult to set high-performance fuel oil. It can reduce the cost of application development and after-sales service, reduce structural design requirements, and facilitate and quick replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

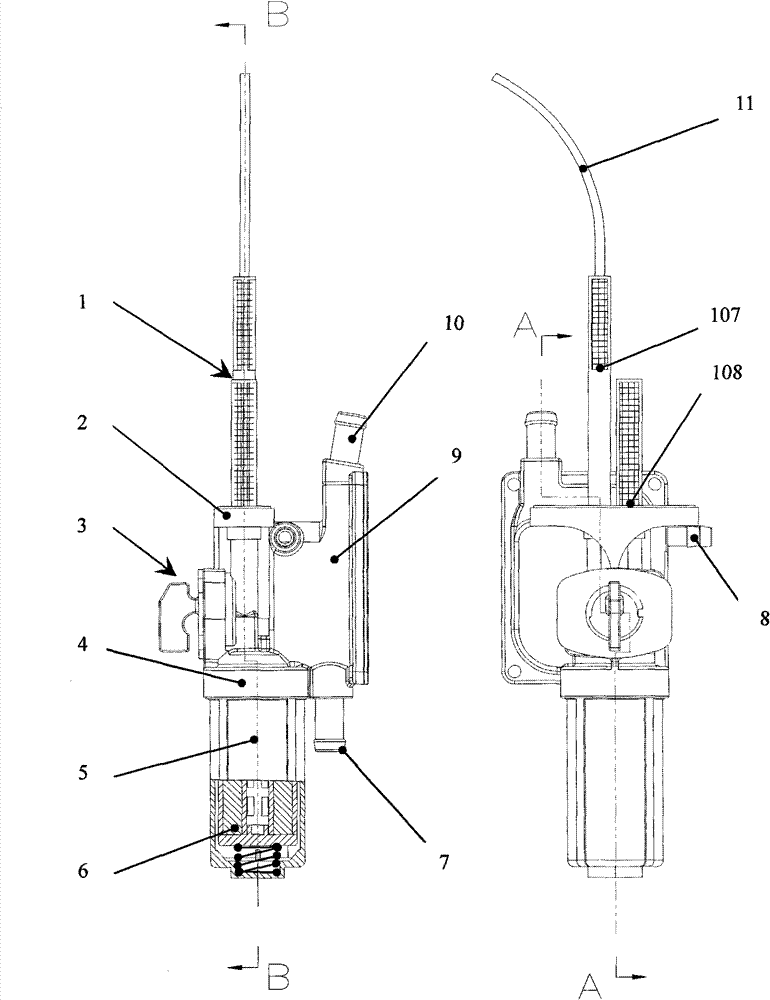

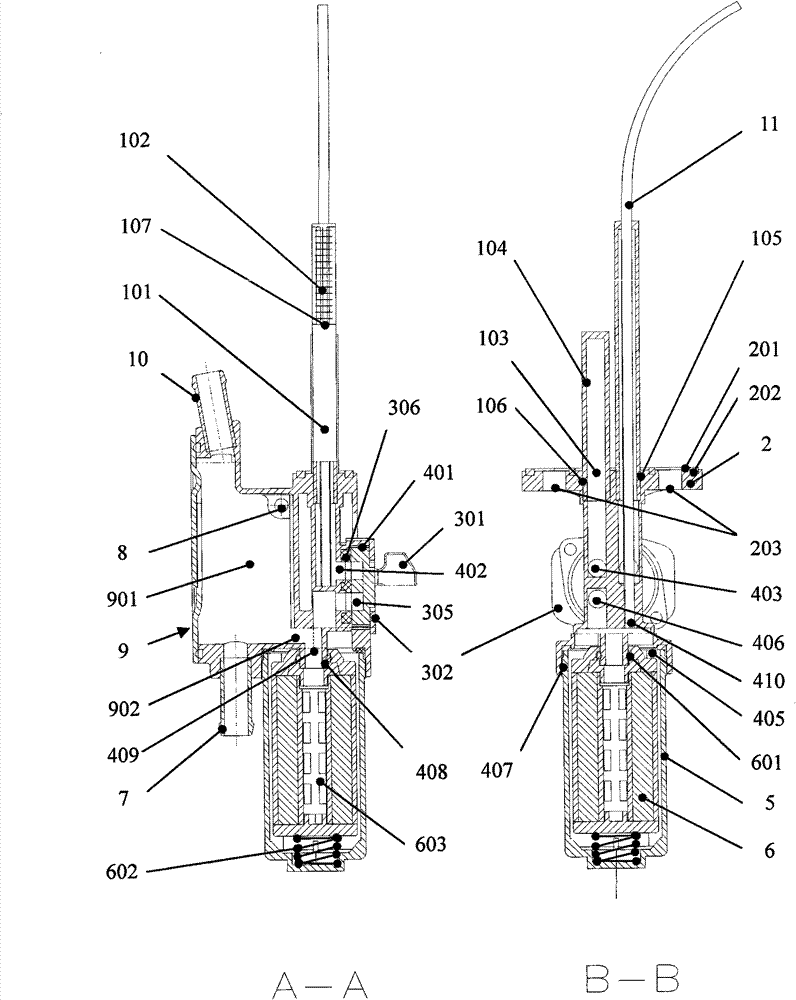

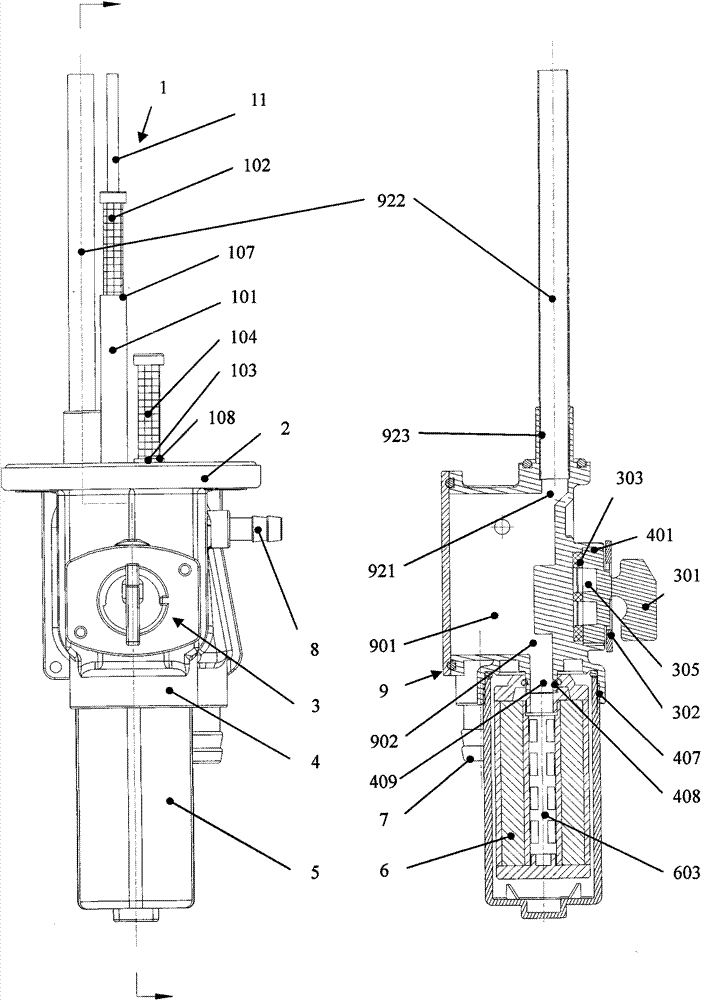

[0026] exist figure 1 In the shown embodiment, the fuel switch is mainly composed of the following parts: oil inlet assembly 1, connecting flange 2, switch assembly 3, switch body 4, fine filter oil cup 5, fine filter element 6 (in the fine filter oil cup 5), oil outlet nozzle 7, oil return nozzle 8, oil-gas separator 9, bubble exhaust nozzle 10, and small bubble exhaust tube 11.

[0027] Such as figure 1 and figure 2 As shown, the fuel inlet assembly 1 includes a common fuel oil supply pipe 101, a common fuel oil strainer 102, a spare fuel oil supply pipe 103, and a spare fuel oil strainer 104. The fuel supply pipe 101 and the coarse strainer 102 are injection molded together for The oil pipe 103 and the coarse filter 104 are injection molded together, the common fuel oil supply pipe 101 is tightly fitted and inserted into the hole 105 fixed on the connecting flange 2, and the spare fuel oil supply pipe 103 is tightly fitted and inserted into the hole 105 fixed on the conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com