High-pressure double suction pump

A double-suction pump, high-pressure technology, applied to pumps, pump components, non-variable pumps, etc., can solve the problems of long hydraulic strength test, easy failure of mechanical seal shaft holder, poor sealing effect of mouth ring, etc., to achieve Eliminate pop-up failure, improve fixation and mechanical seal performance, and increase flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

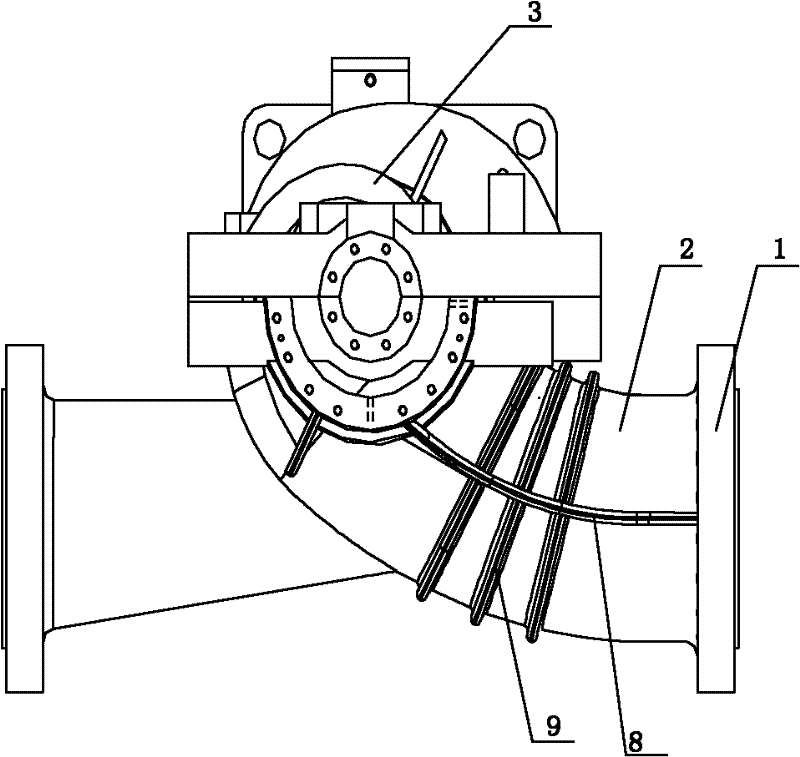

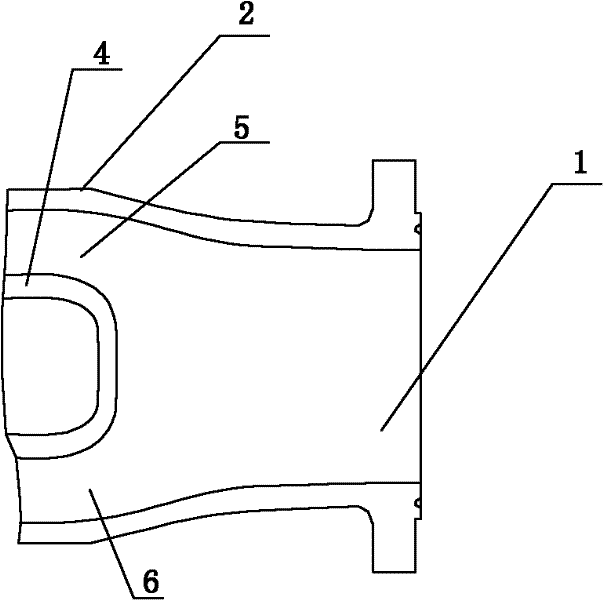

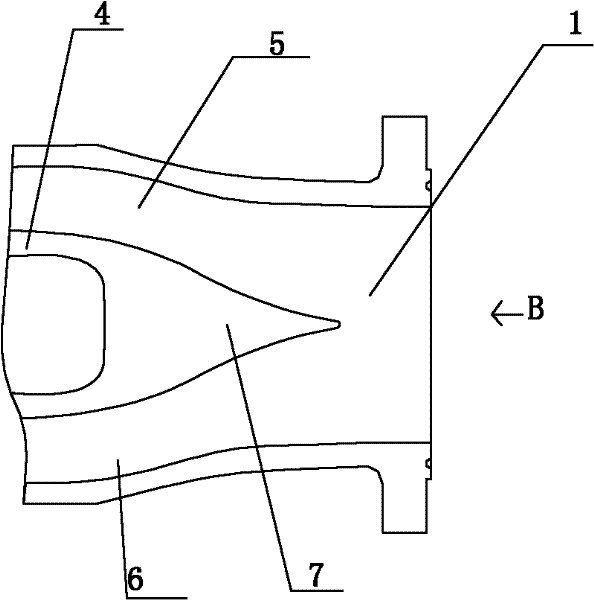

[0041] like figure 1 , image 3 , Figure 4 As shown, a high-pressure double-suction pump includes a suction chamber 1, a pump casing, an impeller, a shaft, a cartridge mechanical seal device 34 arranged between the pump casing and the shaft, an impeller mouth ring sealing device, and a mechanical seal flushing device , the suction chamber includes a suction inlet, a splitter section 2 and a spiral section 3, and the splitter section 2 includes a left runner 6, a right runner 5, and a volute wall 4 between the left runner 6 and the right runner 5, and the volute wall There is a water diversion tongue 7 extending toward the suction port; the left side of the water diversion tongue 7 and the right side of the left flow channel are connected together to form a smooth transition arc; the right side of the water diversion tongue 7 and the right flow The left sides of the road are connected together to form a smooth transitional arc surface. The water-distributing tongue 7 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com