Direct-current frequency conversion electric fan

A DC variable frequency, electric fan technology, applied in the direction of AC motor control, electrical components, non-variable-capacity pumps, etc., can solve the problem of insignificant energy-saving effect, and achieve obvious energy-saving effect, continuously adjustable speed, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

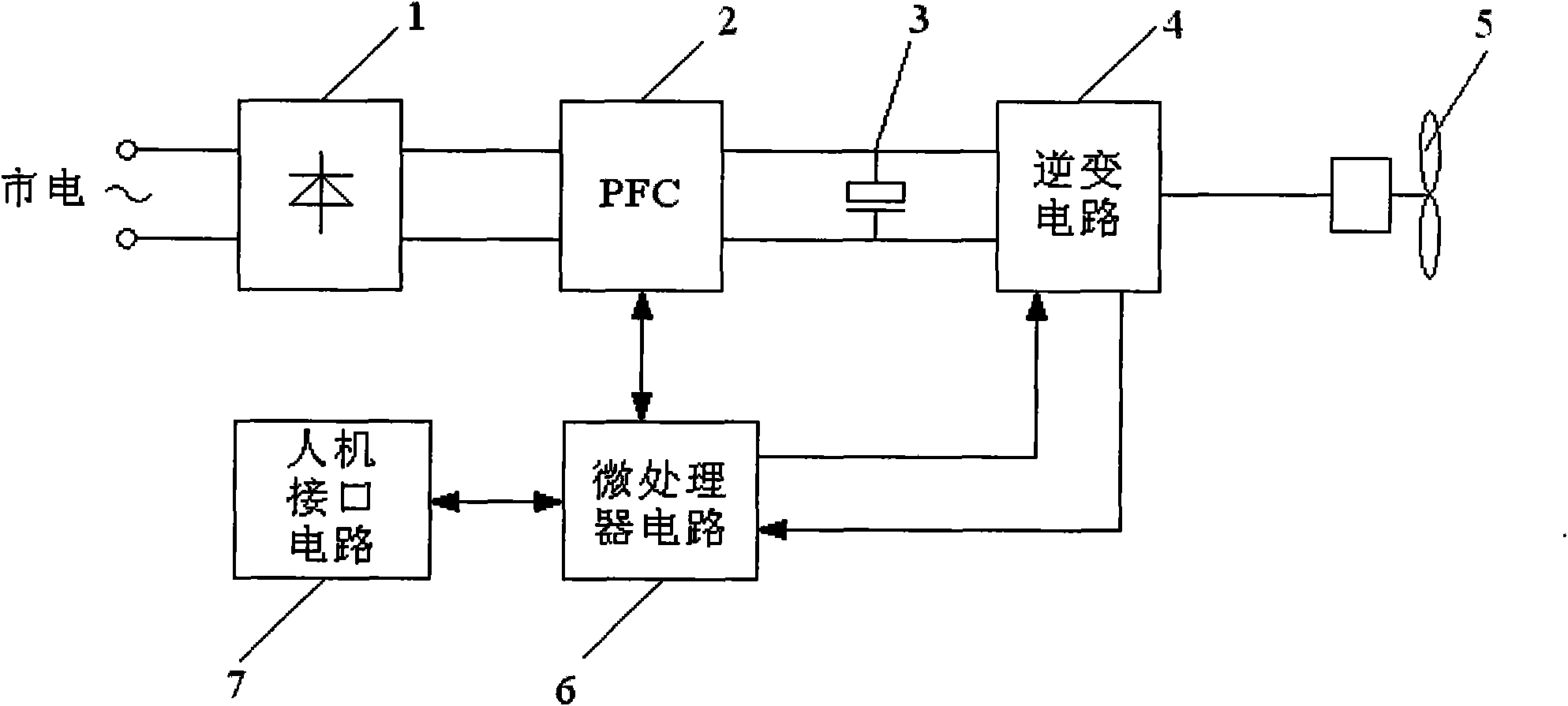

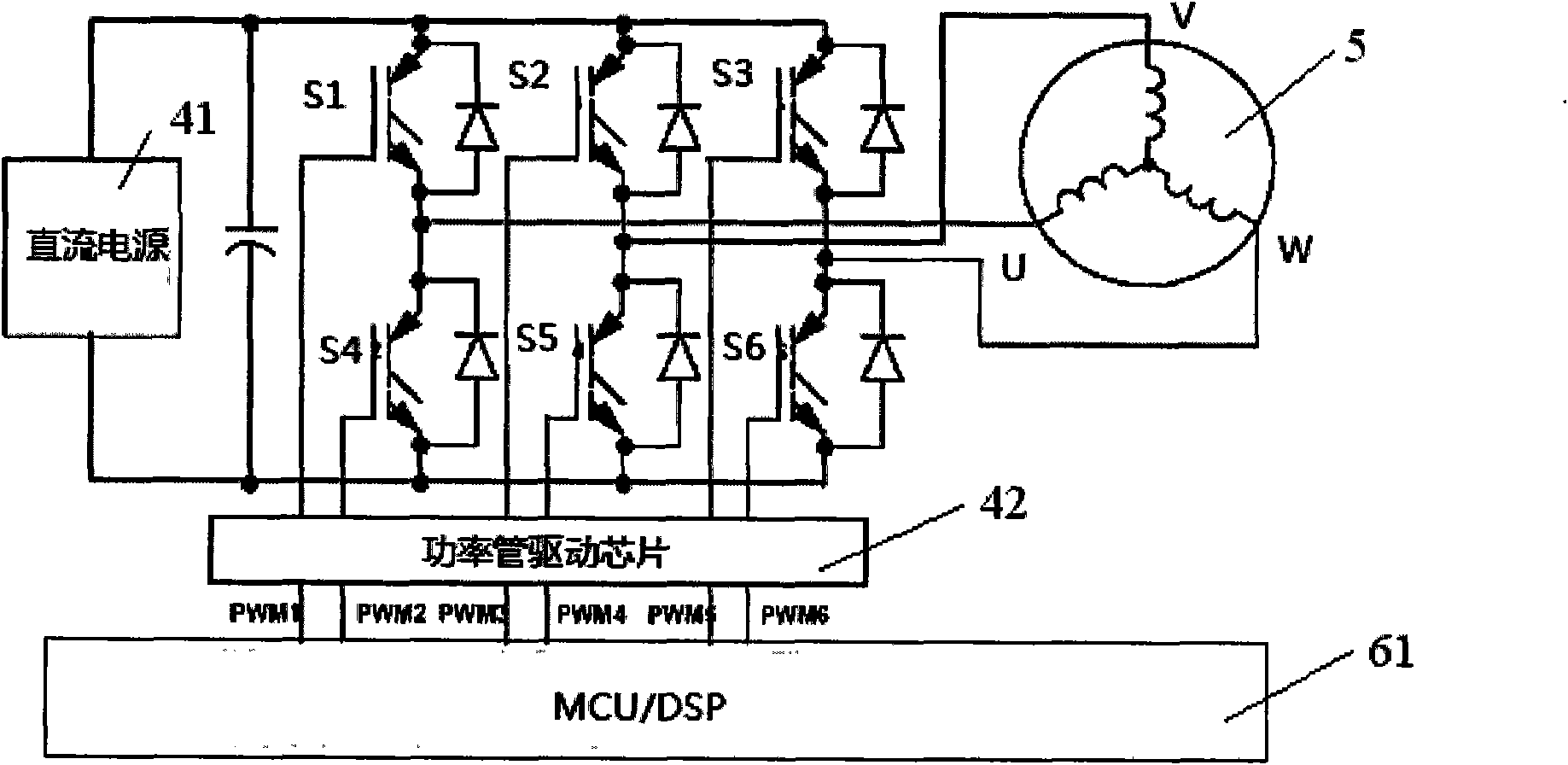

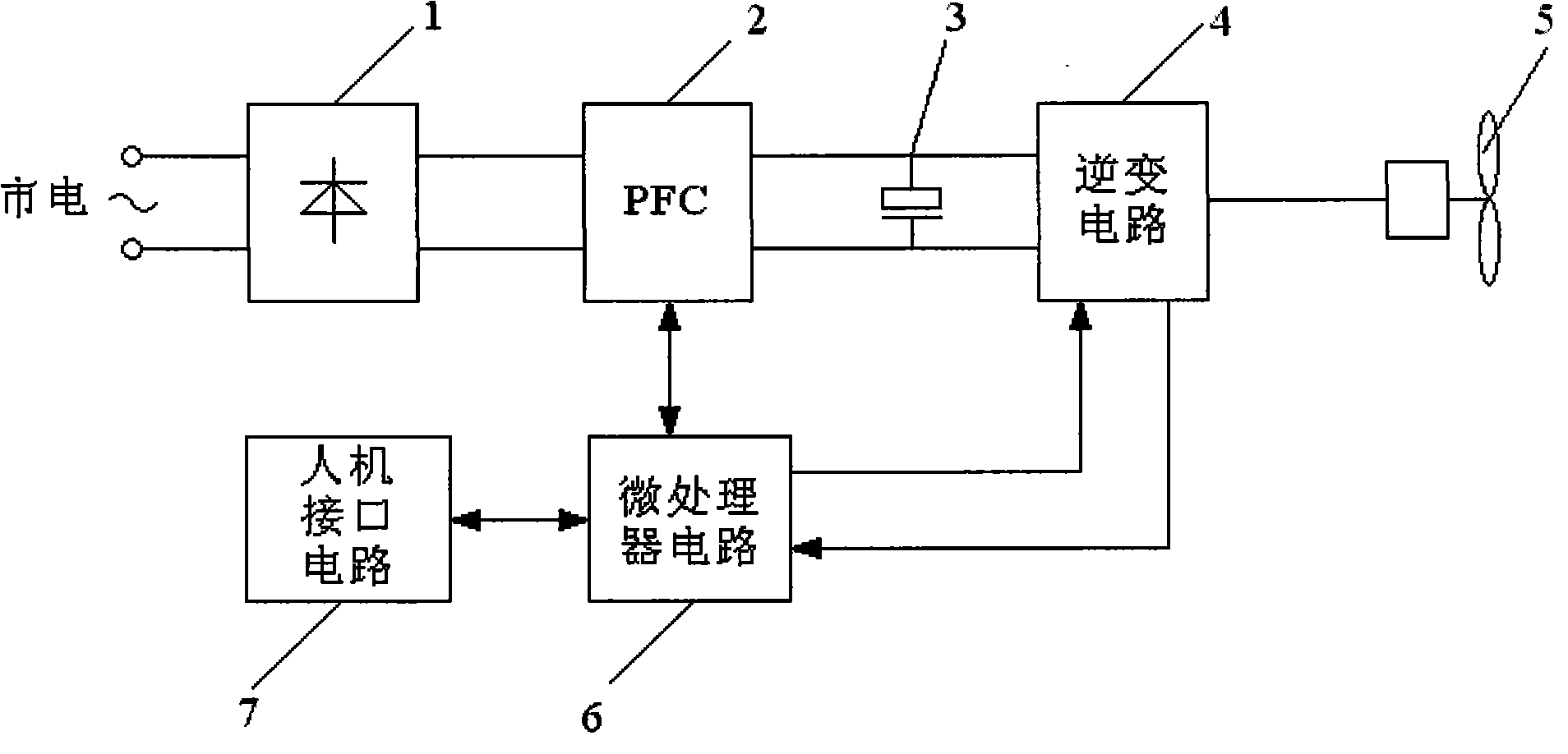

[0020] The invention can solve the technical shortcomings of the existing electric fan, and can achieve the purpose of greatly saving energy and improving comfort by applying microcomputer and power semiconductor technology. Its basic idea is to apply frequency converter technology to electric fans; and, in order to achieve better energy-saving effects, replace the motor with a three-phase motor.

[0021] This fan is preferably a permanent magnet motor variable frequency electric fan, and its motor can be a three-phase permanent magnet synchronous motor, a three-phase DC brushless motor, etc., commonly known as a DC variable frequency electric fan.

[0022] In order to further understand the basic principle and structure of the present invention, the present invention will be described below in conjunction with the accompanying drawings and embodiments.

[0023] see figure 1 , showing the composition of a preferred embodiment of the DC variable frequency electric fan of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com