Precision full-floating drum brake

A drum brake and full-floating technology, which is applied in the direction of mechanically driven drum brakes and brake parts, can solve problems such as uneven friction surfaces, improve driving safety, achieve better braking effects, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

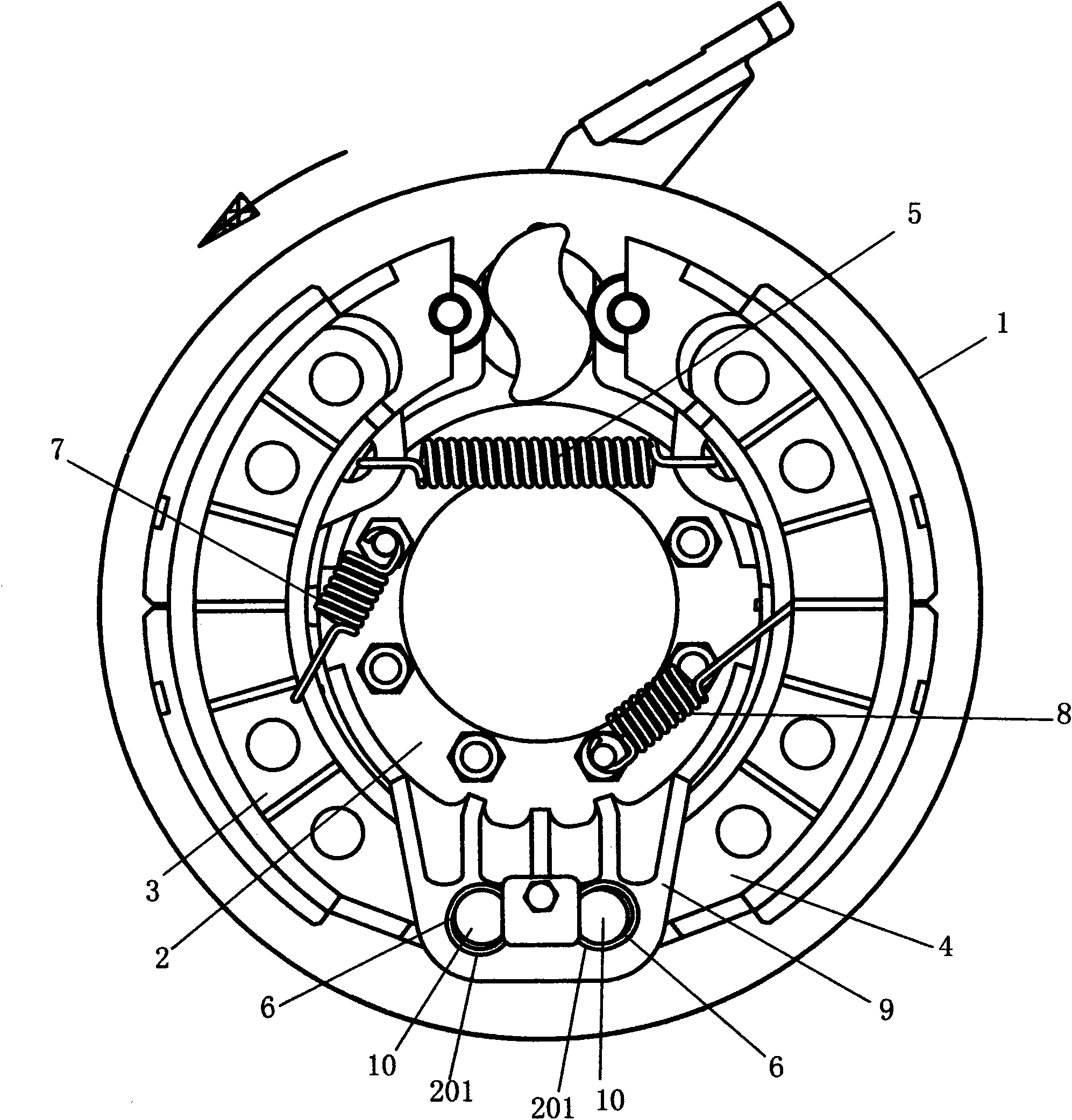

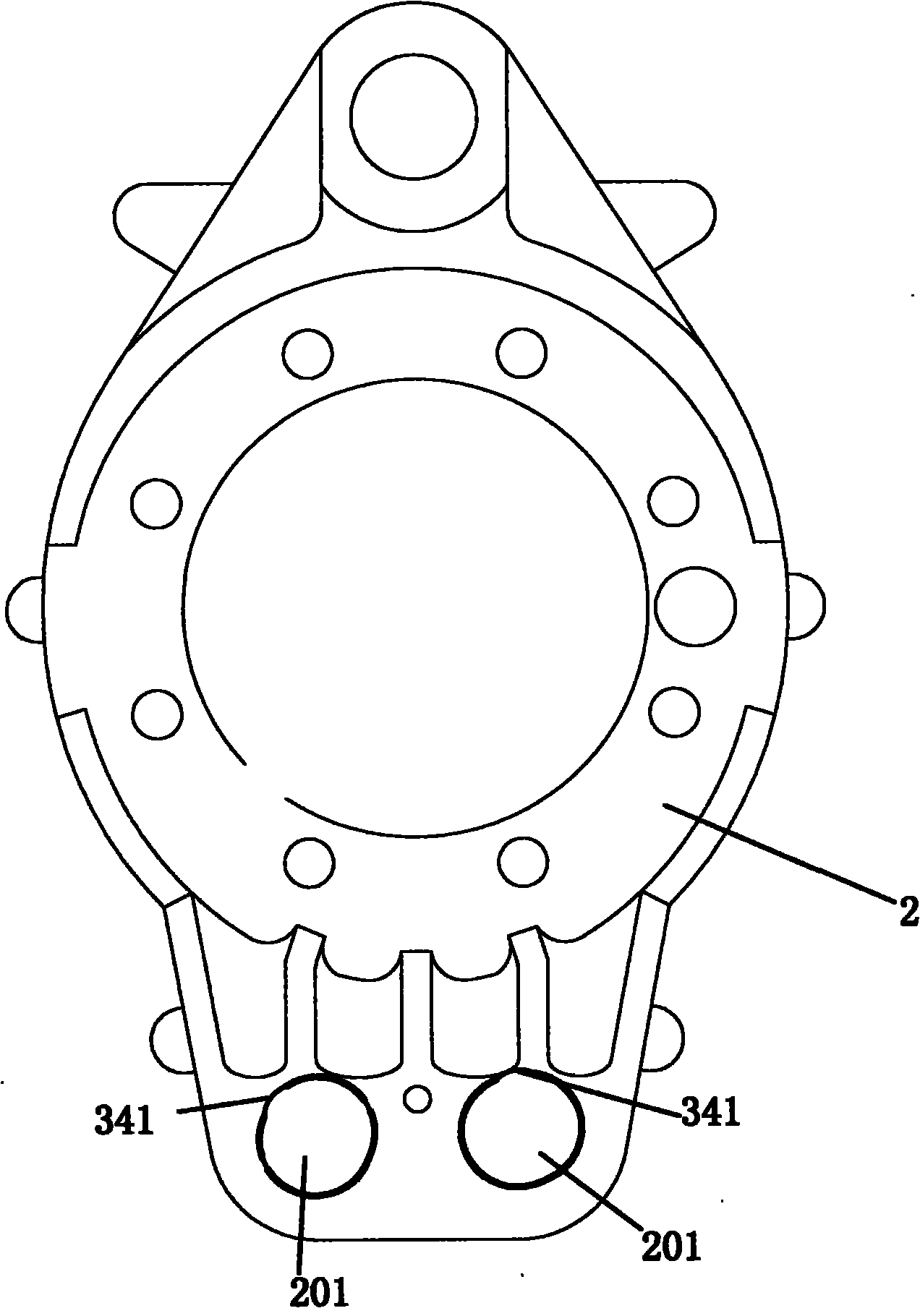

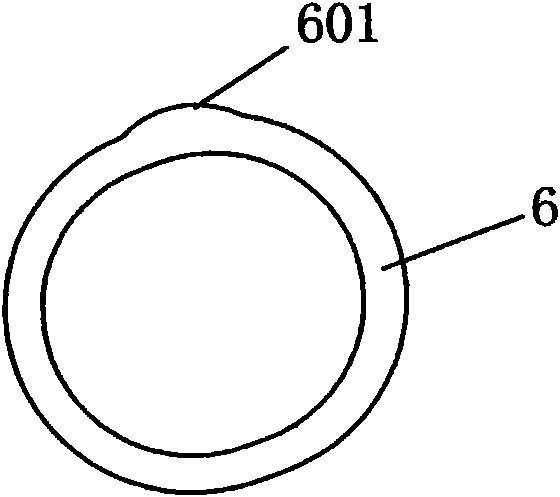

[0032] Such as Figures 1 to 4 Shown: a precision full-floating drum brake, including a brake drum 1, a brake base plate 2, master and slave brake shoes 3 and 4 symmetrically arranged on the brake base plate 2, master and slave brake shoes 3 The supporting end connection holes 301, 401 of , 4 are axially connected with the clamping part 9 at one end corresponding to the brake base plate 2, the open ends of the main and slave brake shoes 3, 4 are free ends, and one camshaft passes through the brake base plate 2 and the other The through hole of the convex part at one end is in contact with the rollers at the free ends of the master and slave brake shoes 3 and 4, and one end of the rollers located at the master and slave brake shoes 3 and 4 is provided with a return spring 5, and the clamping part 9 of the above-mentioned brake base plate 2 It is arranged as upper and lower splints, with a gap left in the middle. A pair of positioning holes 201 are opened on the corresponding po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com