Packaging technology and packaging device of non-refrigerated infrared focal plane array device

A focal plane array and uncooled infrared technology, which is applied in the process of producing decorative surface effects, manufacturing microstructure devices, decorative arts, etc., can solve the problems of cumbersome process, complex structure, high cost, etc., and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

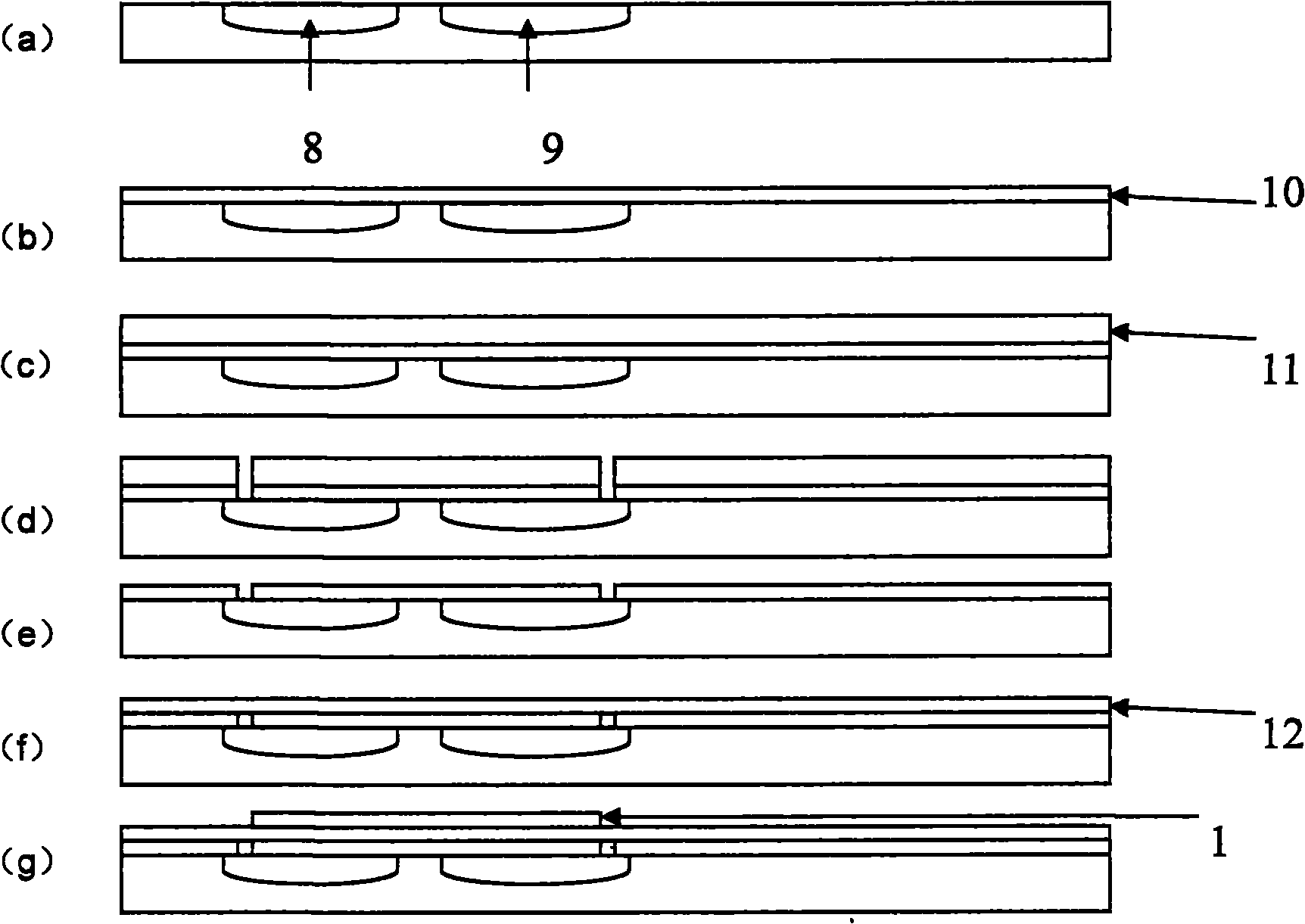

[0036] The preparation of the body is the most critical and complicated part of the process. In the field of packaging, it mainly includes three aspects: the semiconductor refrigerator, the negative temperature coefficient sensor, and the preparation of the welded metal frame.

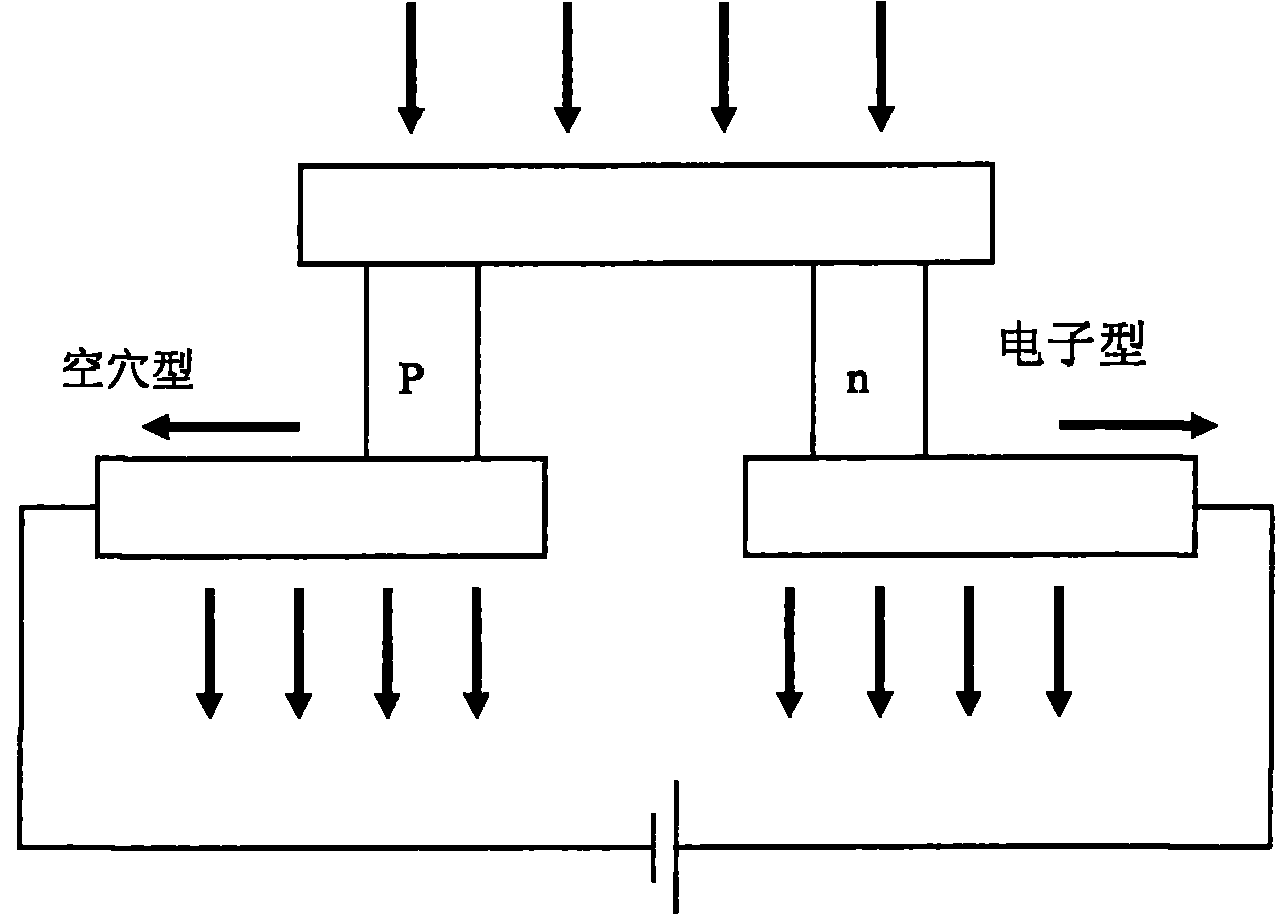

[0037] The semiconductor cooler is an integral part of the infrared focal plane, and its main function is to keep the temperature of the focal plane stable and the temperature distribution uniform. Its basic principle is to use the Peltier effect in semiconductors, such as figure 2 As shown, a galvanic pair is formed by welding an N-type and a P-type semiconductor particle with a metal connecting sheet. When the direct current flows from the N pole to the P pole, the upper end of the two will absorb heat, which is called the cold end, and the lower end will generate heat release, which is called the hot end. If the direction of the current is reversed, the hot and cold ends will switch to each other. ...

Embodiment 1

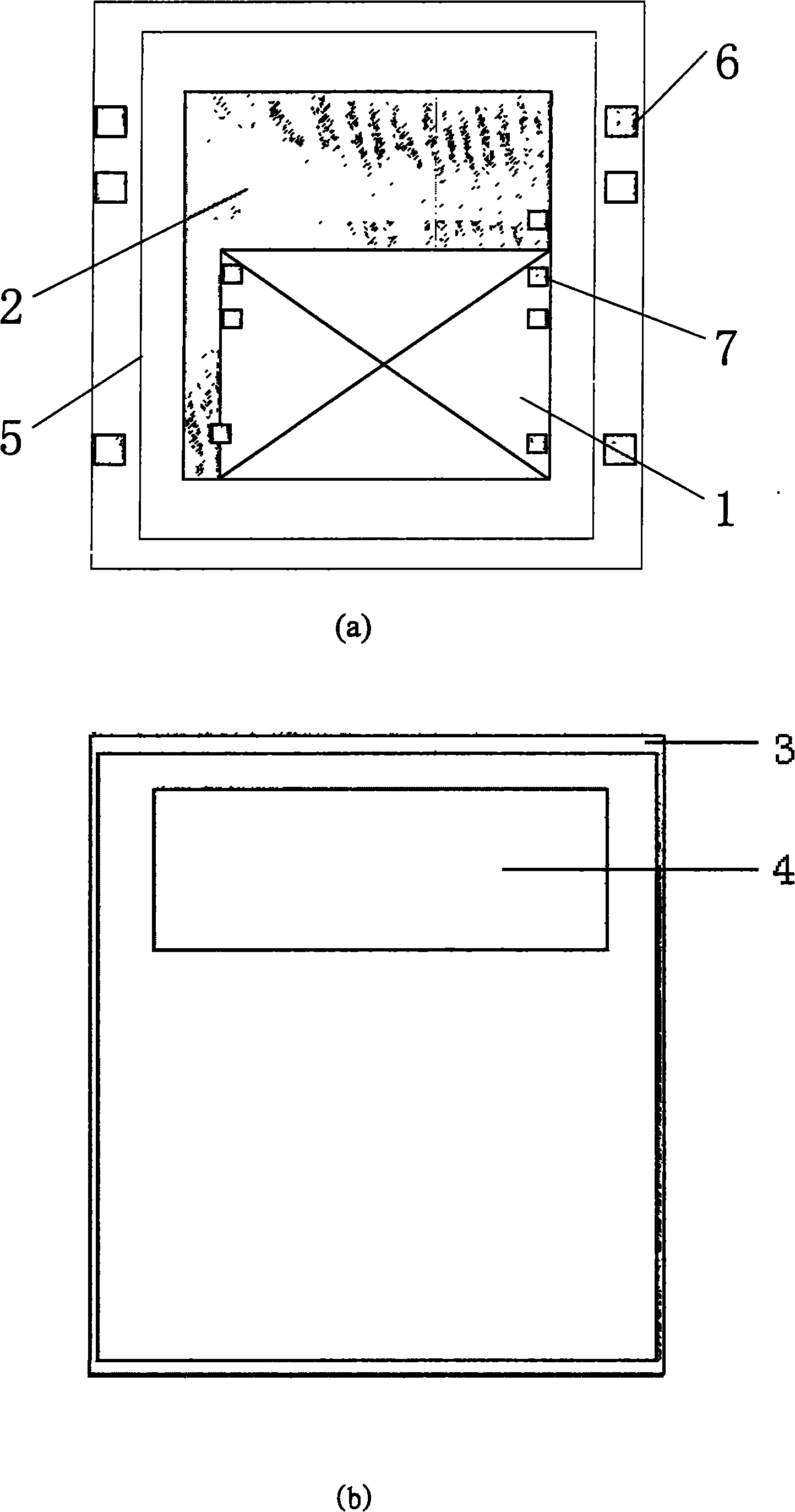

[0048] An uncooled infrared focal plane device, consisting of 320×240 uncooled infrared focal plane units, each uncooled infrared focal plane unit is 50um×50um in size, the array area is 16mm×12mm in size, and the integrated readout circuit is 22mm in size ×25mm, the readout method is the column gating method. Prepare 241 thermistors in the production, P, N injection according to 4mm×16mm, and 8mm×16mm specifications and connect with aluminum layer, the metal pattern is concentric with the chip, the size is 18mm×20mm. The cover area is 20mm×22mm.

Embodiment 2

[0050] An uncooled infrared focal plane device, consisting of 640×480 uncooled infrared focal plane units, each uncooled infrared focal plane unit is 15um×15um in size, the array area size is 9.6mm×7.2mm, integrated readout The size of the circuit is 15mm×18mm, and the readout method is the row strobe method. Prepare 641 thermistors in the production, P, N injection according to the specifications of 3.2mm×7.2mm, and 6.4mm×7.2mm and connect with aluminum layer, the middle gap is 50um, the metal pattern is concentric with the chip, and the size is 12mm×13mm. The cover size is 13mm×16mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com