Air purifying agent

An air purifier, cobalt chloride technology, applied in other chemical processes, chemical instruments and methods, dispersed particle separation, etc., can solve the problem that the air purity and dryness cannot be accurately detected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

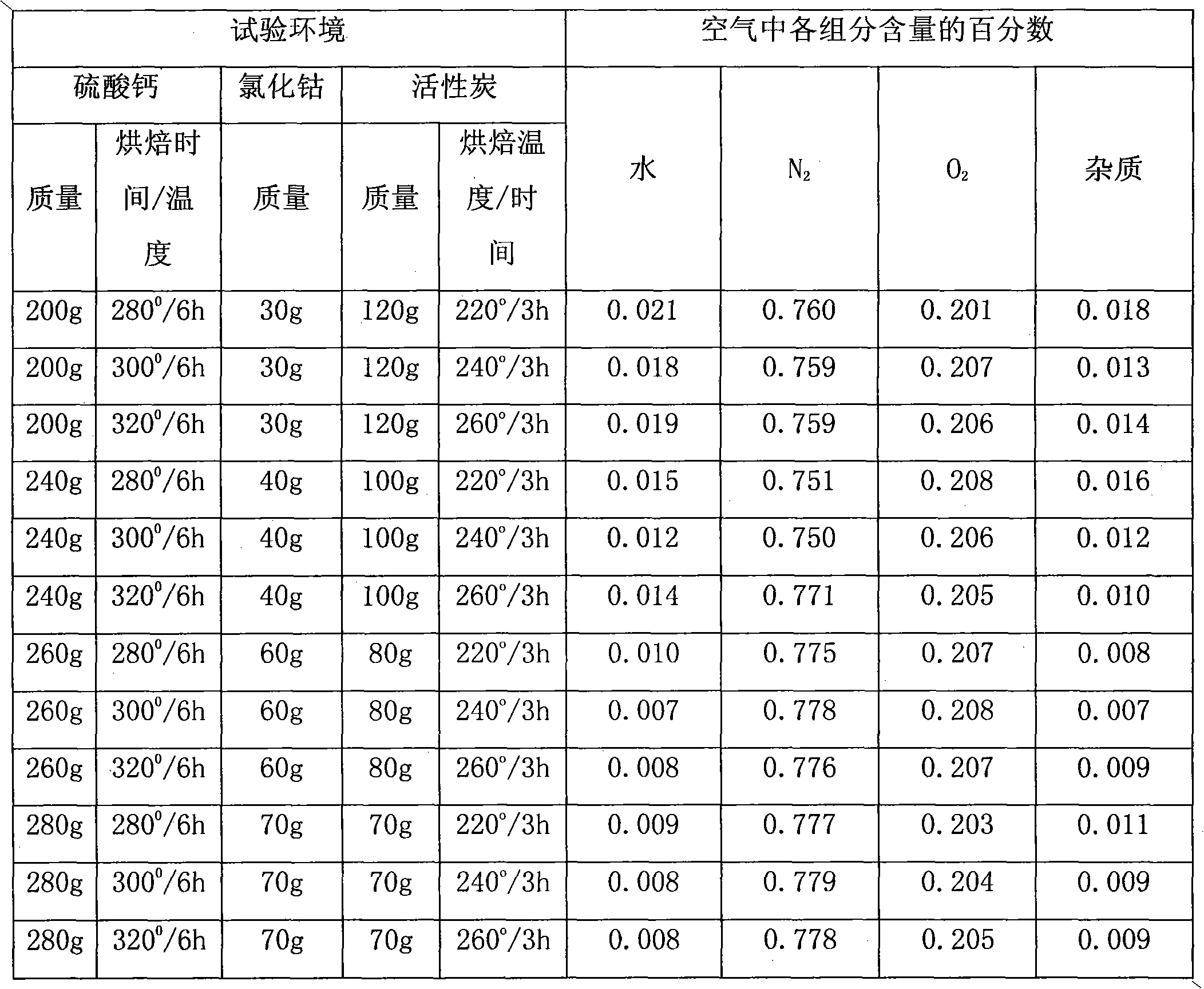

Method used

Image

Examples

Embodiment 1

[0017] The method comprises the following steps: a. Grinding calcium sulfate with a pulverizer, and sieving out too large or too small particles, taking 248g of calcium sulfate with a diameter of 0.8mm to 2mm and dyeing it with 45g of cobalt chloride, requiring uniform dyeing, The dyeing method is as follows: the dyeing is to dissolve cobalt chloride in water, put it into a watering can, put calcium sulfate into the drum, and spray the cobalt chloride solution into the calcium sulfate for dyeing while the drum is rotating. Bake the dyed calcium sulfate in an oven at 300°C for 6 hours, then seal it and place it at room temperature; b, take 92g of activated carbon and bake it in an oven at 240°C for 3 hours, then seal it and place it at room temperature; c. Mix the materials obtained in step a and step b evenly to obtain the air purifier of the present invention.

Embodiment 2

[0019] Comprise the following steps: a, calcium sulfate is ground with pulverizer, and sieve out too big or too small particle, get the calcium sulfate 278g after pulverizing and dye it with 45g cobalt chloride, require dyeing evenly, the dyed Calcium sulfate was baked in an oven at 260°C for 5.5 hours, and then sealed and placed at room temperature; b, 70g of activated carbon was baked in an oven at 210°C for 2.5 hours, and then sealed and placed at room temperature; c. The material obtained in a and step b is mixed evenly to obtain the air purifier of the present invention.

Embodiment 3

[0021] Comprise the following steps: a, calcium sulfate is ground with pulverizer, and sieve out too large or too small particle, get the calcium sulfate 240g after pulverizing and dye it with 75g cobalt chloride, require dyeing evenly, the dyed Calcium sulfate was baked in an oven at 290°C for 6 hours, and then sealed and placed at room temperature; b, 63g of activated carbon was baked in an oven at 290°C for 3.5 hours, then sealed and placed at room temperature; c. The material obtained in a and step b is mixed evenly to obtain the air purifier of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com