Plasma processing device and thimble lifting device thereof

A lifting device and plasma technology, applied in post-processing, post-processing details, crystal growth, etc., can solve problems such as complicated operation and poor leveling effect, and achieve the effects of improving reliability, avoiding lock-up, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The core of the present invention is to provide a thimble lifting device, which can avoid the lateral deviation of the central guide rod during the lifting process, thus having high reliability. Another core of the present invention is to provide a plasma processing equipment including the above-mentioned thimble lifting device.

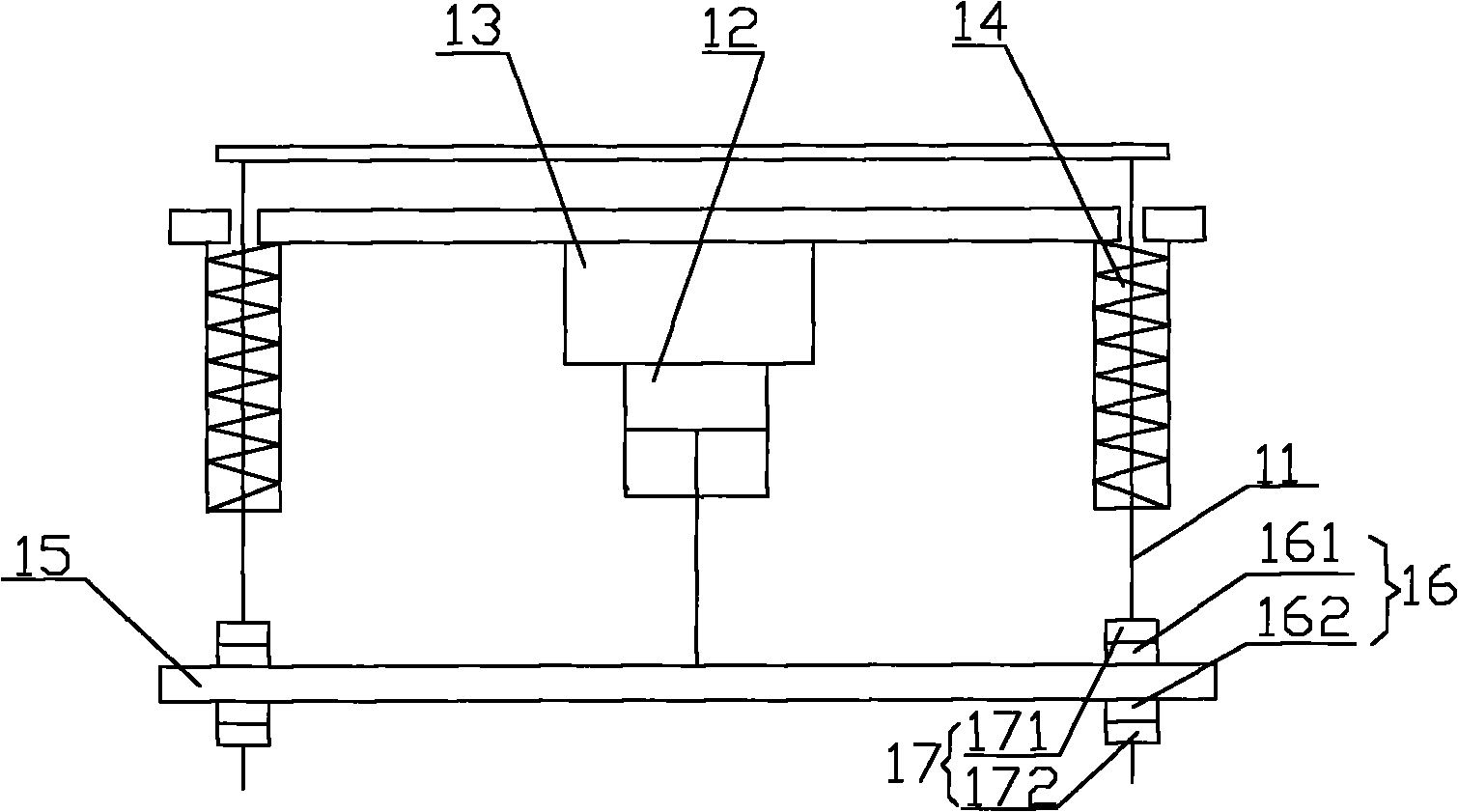

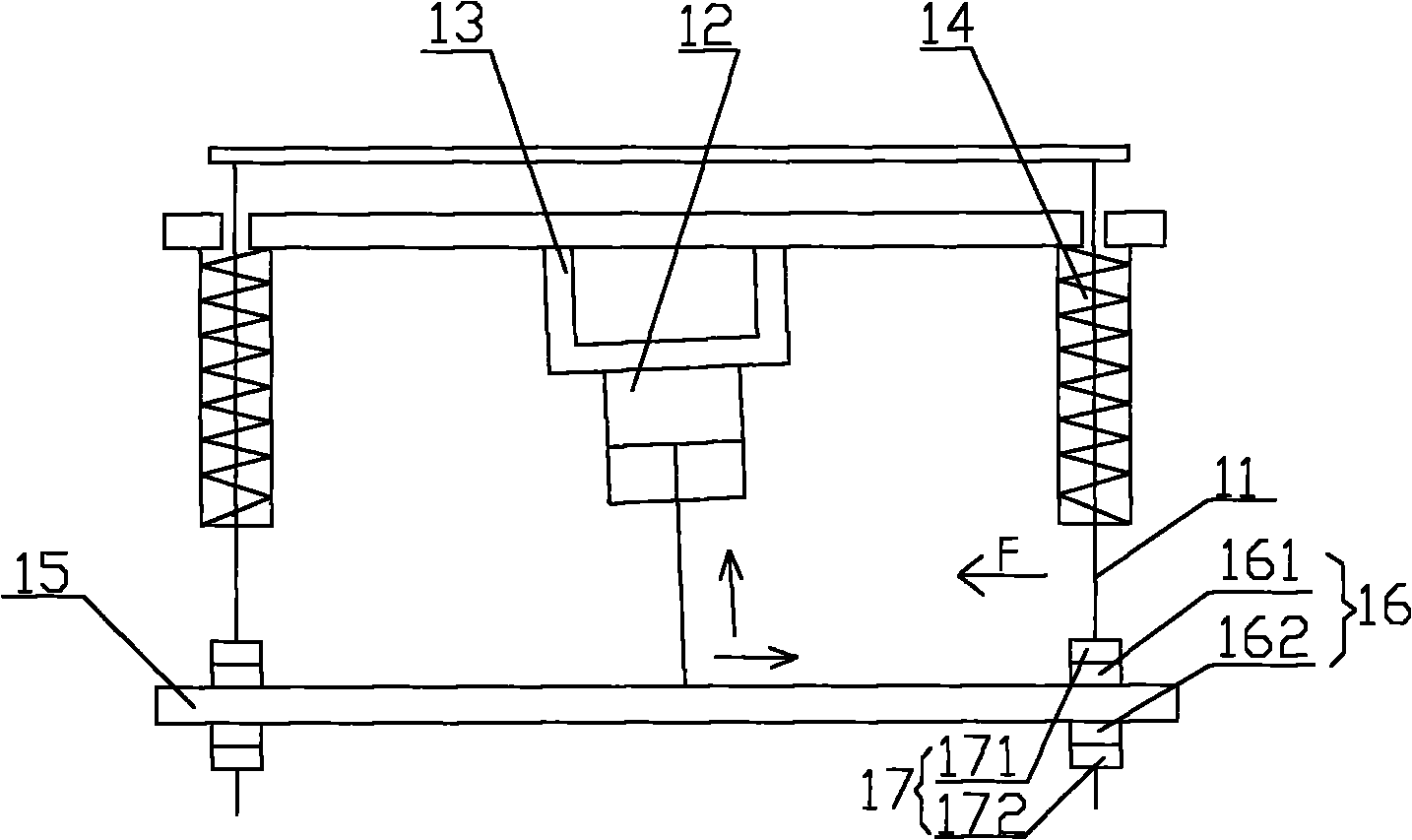

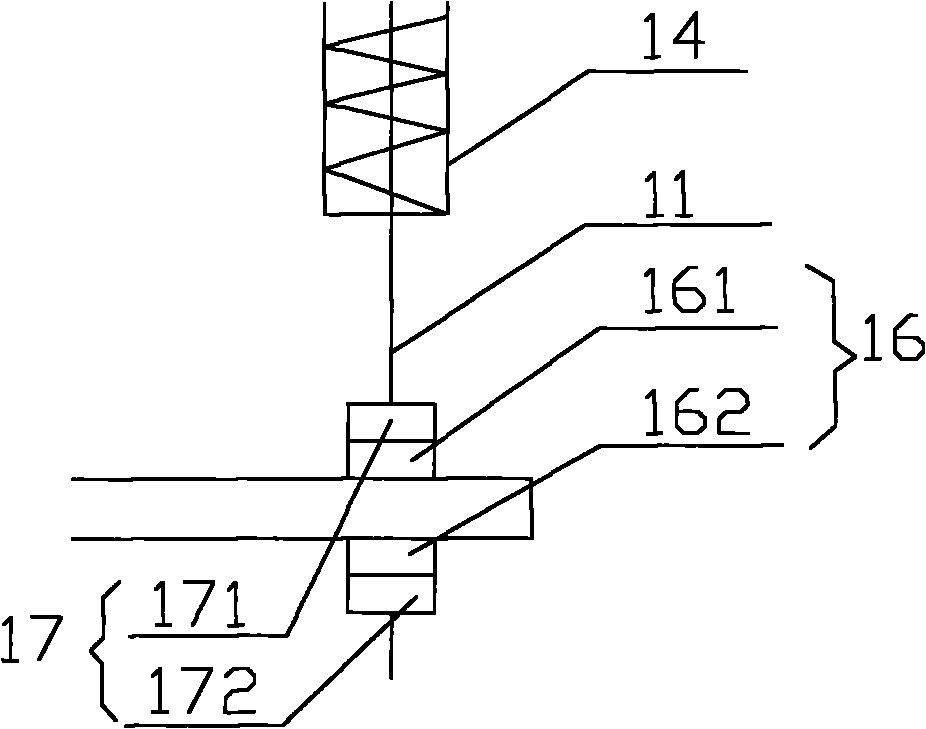

[0035] Please refer to Figure 4 , Figure 4 It is a structural schematic diagram of the first embodiment of the thimble lifting device provided by the present invention.

[0036]In the first specific embodiment, the thimble lifting device provided by the present invention includes a central guide rod 21 for connecting the thimble (not shown in the figure), and its lower end is movably connected to the outer end of the support arm 22, The inner end of the support arm 22 is fixedly connected with the output shaft of the driving part (not shown in the figure), and its extension direction is perpendicular to the direction of the above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com