Membrane type flow quantity adjusting valve with circulation

A flow control valve, diaphragm type technology, applied in valve details, multi-port valves, valve devices, etc., can solve the problems of high installation accuracy, inapplicability, flow control valve failure, etc., and achieve reasonable valve core structural parameters. , compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

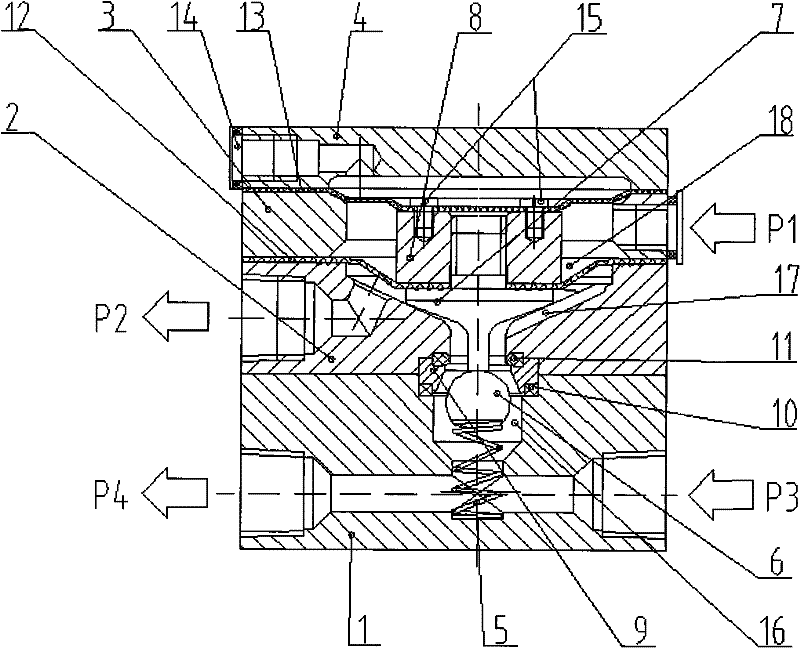

[0027] Diaphragm flow regulating valve with circulation adjusts the position of the spherical valve core and the conical valve core by the gas pressure input into the gas chamber to realize the adjustment of the liquid outlet P of the first valve block 2 The function of the size of the liquid flow.

[0028] Control air inlet P 1 Connect the gas source with controllable pressure, the pressure control range of the gas source is preferably 0~0.3MPa; the liquid inlet P 3 Connect to a stable hydraulic source, the pressure of the hydraulic source should not exceed 0.6MPa; flow adjustment outlet P 2 Connect hydraulic components that need to adjust the flow rate; liquid circulation outlet P 4 After being filtered, it returns to the stable hydraulic source mentioned above to complete the oil circulation function.

[0029] The spring is tensioned between the spherical valve core and the bottom cover; in the initial state, the spring is compressed, and during the movement of the spher...

specific Embodiment 2

[0032] The diaphragm type flow regulating valve described in the specific embodiment 1, in use, will circulate the liquid outlet P 3 Plugged to form a flow regulating valve without circulating liquid, this implementation does not affect the flow regulating outlet P 4 flow characteristics, but the liquid inlet P 2 flow is greatly reduced.

specific Embodiment 3

[0033] The diaphragm type flow regulating valve described in specific embodiment 1, in use, closes the control gas inlet and connects the control gas to the plug hole, and can also realize the flow control of the diaphragm type flow regulating valve, and control the gas inlet P 1 Pressure P and flow adjustment outlet P 2 The flow Q has a similar change.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com