A rotary self-excited circular piezoelectric vibrator generator

A piezoelectric vibrator, self-excited technology, used in generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve the problem of limited service life, power supply, and inability to pass cables problem, to achieve the effect of wide effective speed range, reasonable structural parameters and small torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

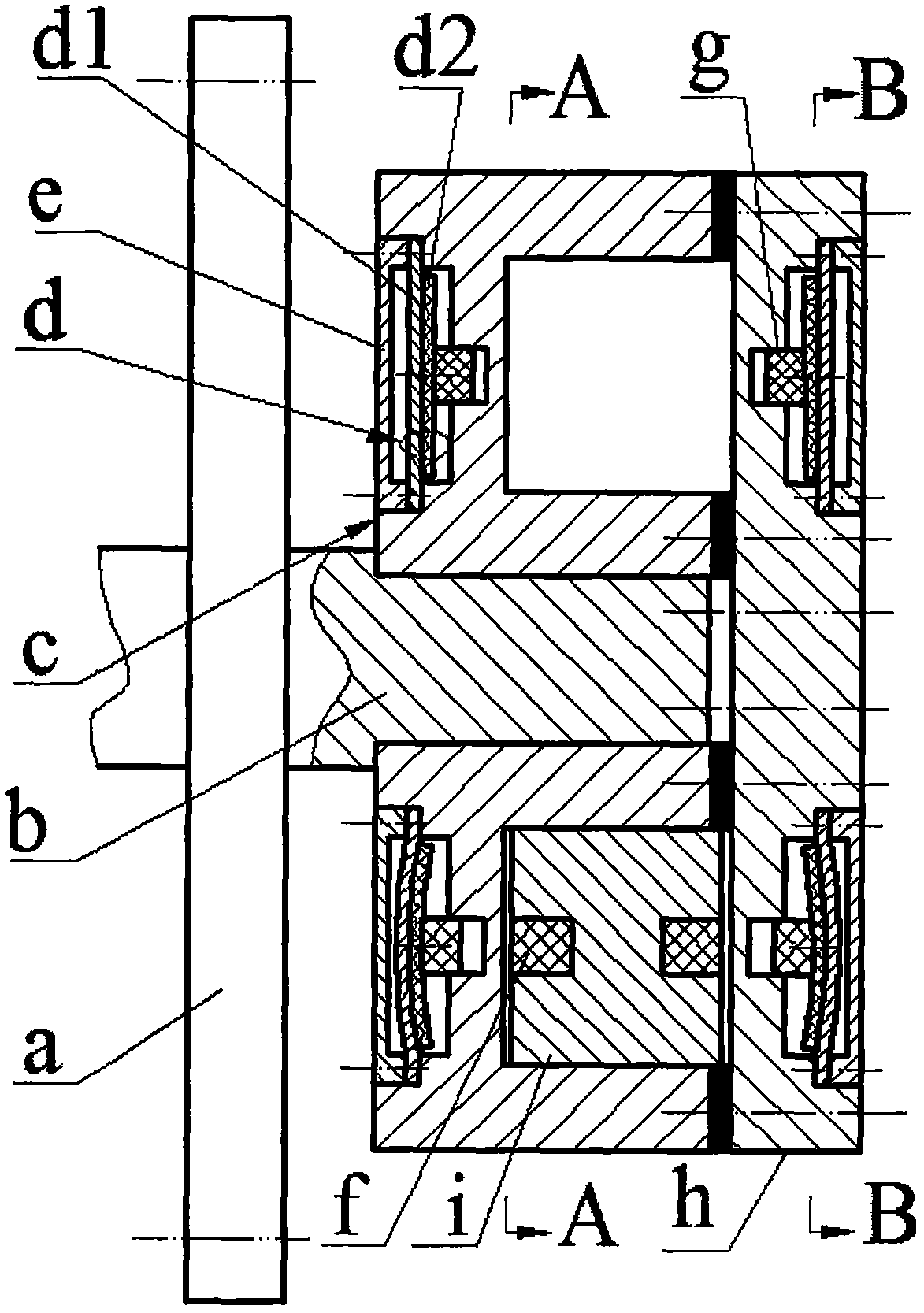

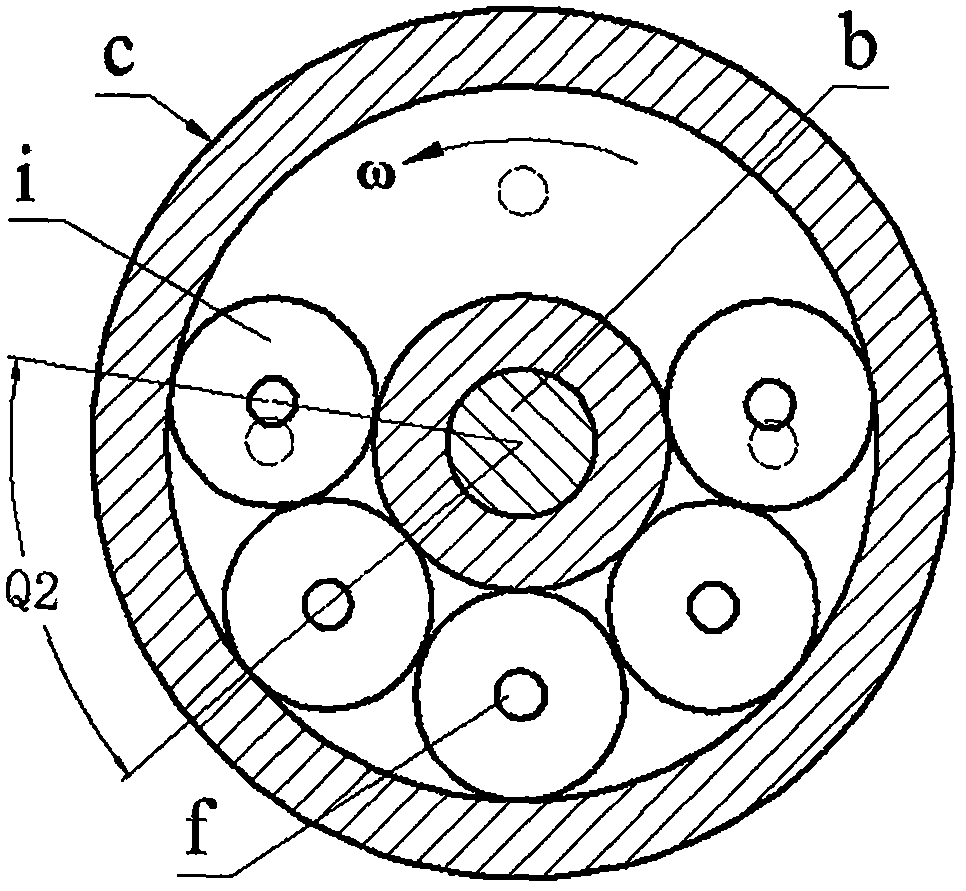

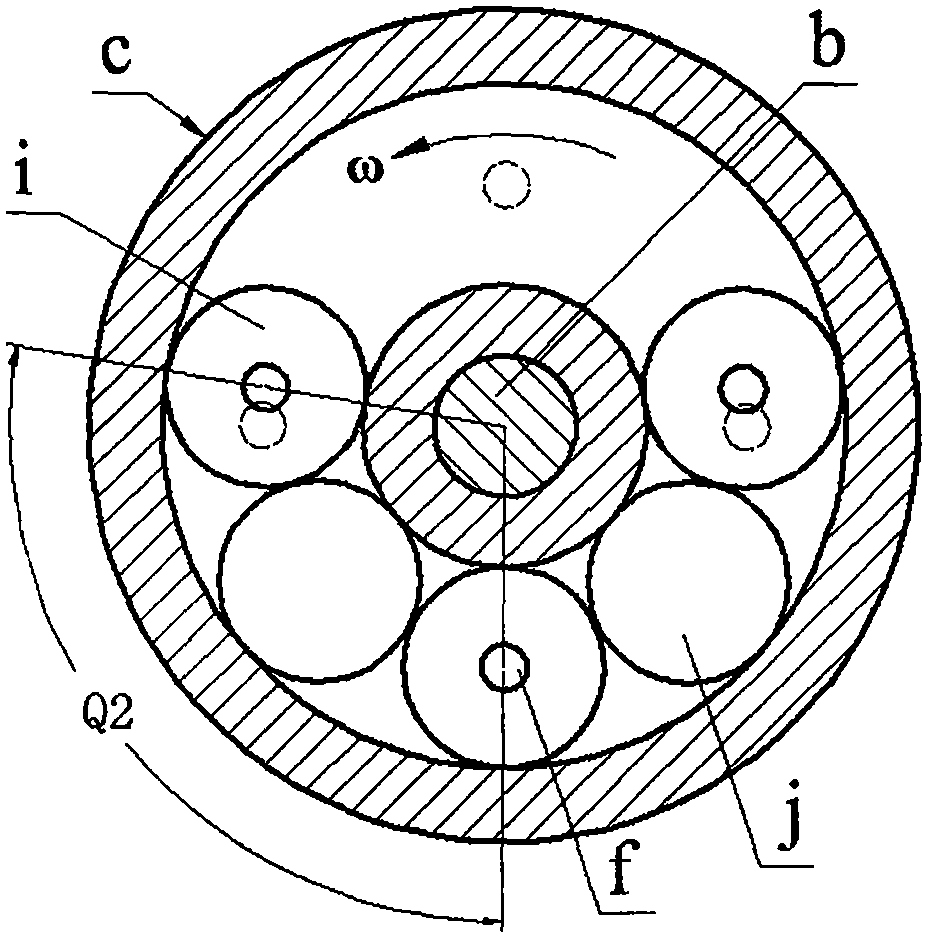

[0015] The cantilever shaft b of the gear a is placed in the central hole c4 of the disc body c. One side of the disc body c is provided with a disc sinking cavity c1 and a disc guide hole c2, and the other side is provided with a slideway c3; The end part is installed with a side plate h through screws, and the side plate h is connected with the cantilever shaft b through screws. The side plate h is provided with a side plate sink cavity h1 and a side plate guide hole h2; the plate body guide hole c2 and the side plate guide hole h2 Both are blind holes; the cavity c1 of the plate body and the cavity h1 of the side plate are installed with a piezoelectric vibrator d through screws and an end cover e, and the piezoelectric vibrator d is bonded by a metal substrate d1 and a piezoelectric chip d2; An excited magnet g is installed at the center of the electric vibrator d, and the excited magnet g is placed in the guide hole c2 of the plate body or the guide hole h2 of the side pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com