Simulated ore drawing method of miniature vibration ore drawing machine based on indoor simulated ore drawing

A kind of mining machine and miniature technology, which is applied in the field of simulating ore drawing, to achieve the effect of convenient placement, increasing visual effects and working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

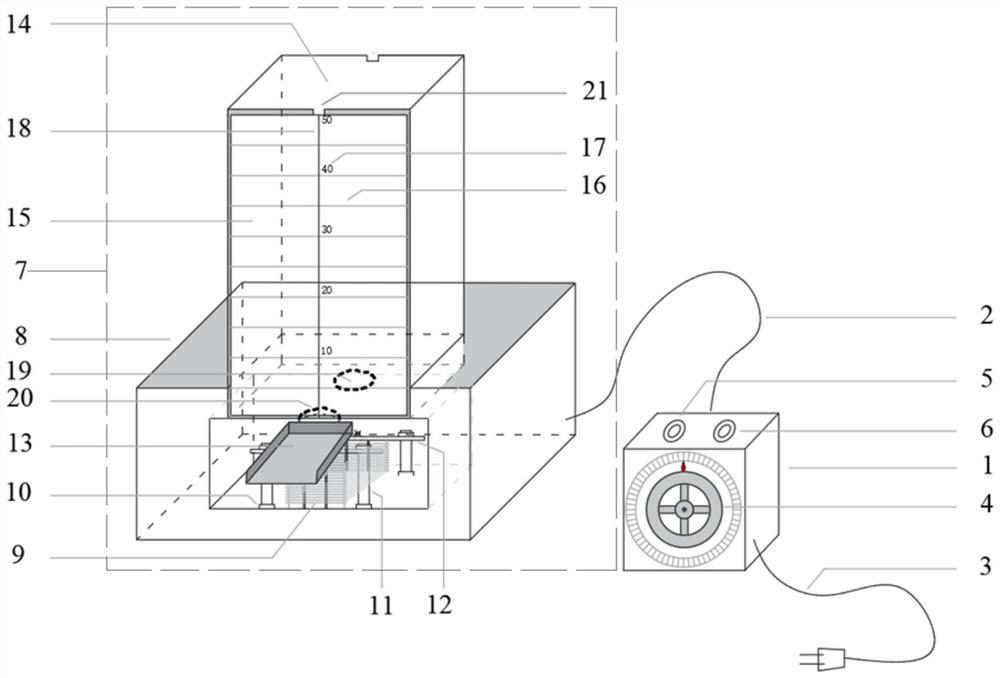

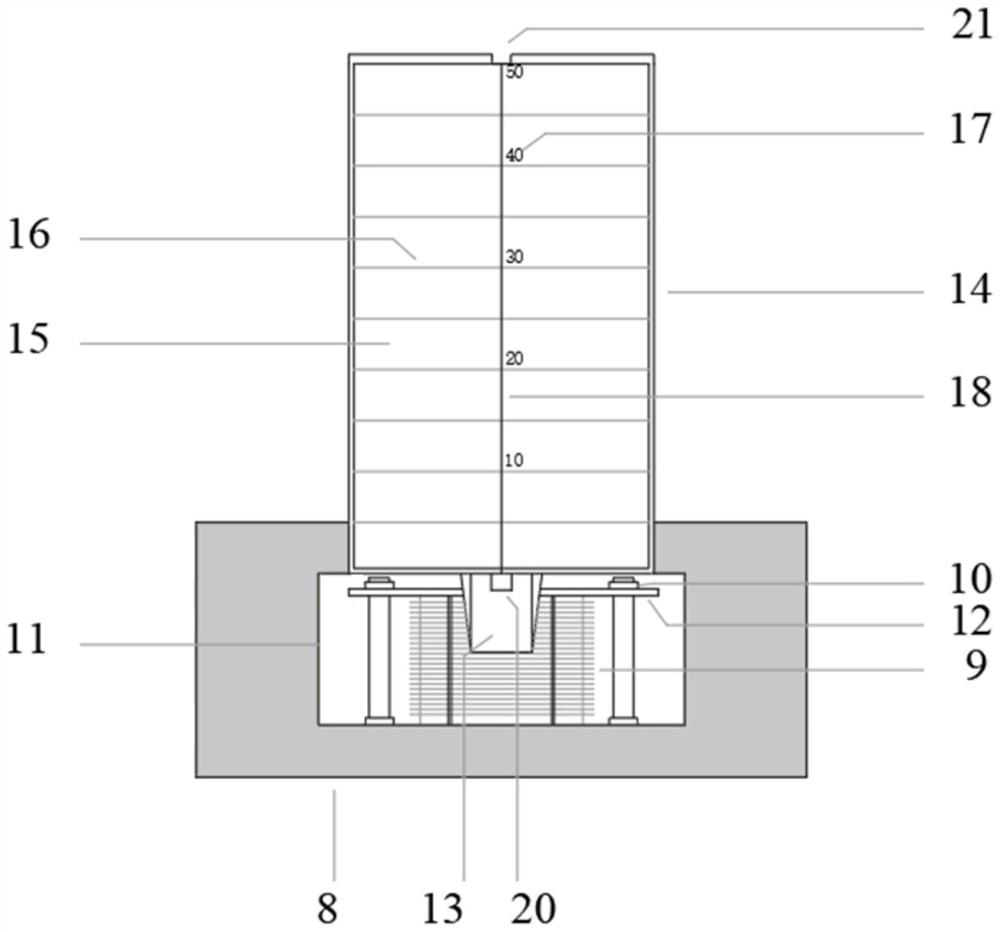

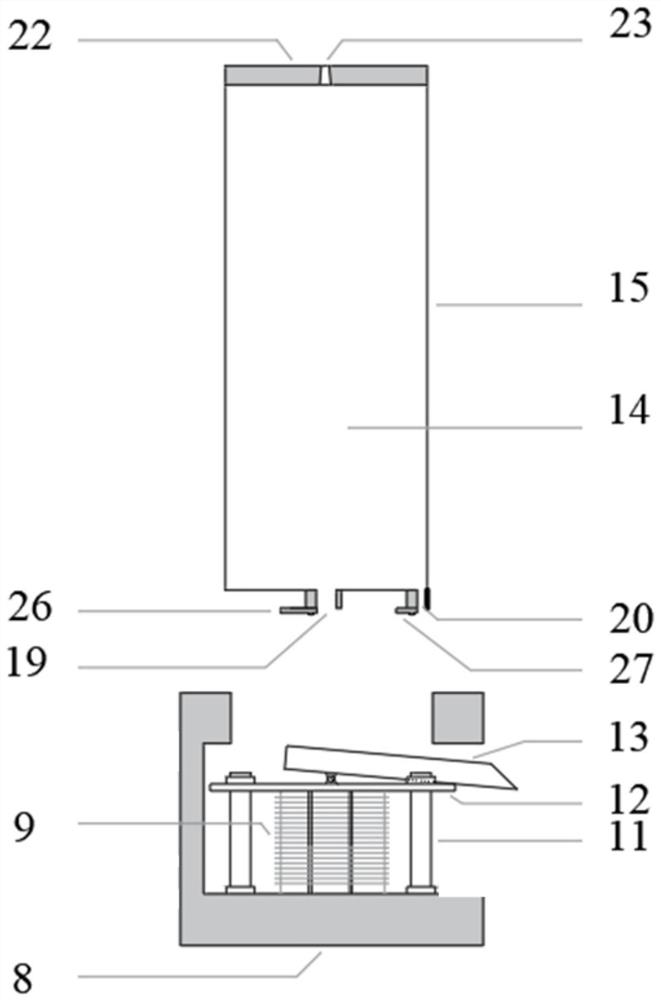

[0052] Embodiment 1: as Figure 1-8 As shown, a kind of miniature vibrating mining machine for indoor simulation of ore drawing,

[0053] Including controller 1, mining machine 7, mining machine 7 includes base 8, vibrator 9, ore receiving skip 13, ore loading bin 14, ore receiving bucket 25, vibrator 9 is fixedly arranged on the bottom of base 8, connected to The ore skip 13 is obliquely arranged in the base 8 and the ore-connecting skip 13 is positioned above the vibrator 9, the ore-connecting bucket 25 is arranged at the outlet of the ore-connecting skip 13, the ore loading bin 14 is fixedly arranged on the base 8, and the ore loading The bottom of the bin 14 extends into the base 8. A central funnel 19 is provided in the center of the bottom plate of the ore loading bin 14. A half-wall funnel 20 is provided at the junction of the front plate 15 and the bottom plate of the ore loading bin 14. The center of the half-wall funnel 20 is the ore loading bin. The center point of...

Embodiment 2

[0064] Embodiment 2: When the present embodiment adopts the miniature vibrating ore-discharging machine of embodiment 1 to simulate ore-drawing indoors to simulate ore-drawing and measure the discharge body parameters, the following specific steps are included:

[0065] (1) Close the center funnel and the half-wall funnel, and place the ore-connecting bucket under the outlet of the ore-connecting skip;

[0066] (2) Use ore particles to fill the center funnel until the upper surface of the ore particles is flush with the bottom plate of the ore loading bin, set the positioning device on the top of the ore loading bin, and turn on the laser light to locate the center position, and lay the marking particles of the same color on the center position , recorded as color 0;

[0067] (3) Lay the first layer of ore, scrape the plane of the first layer of ore layer until the top surface of the ore layer is on the same level as the first layer of horizontal scale line on the front plate ...

Embodiment 3

[0073] Embodiment 3: When the present embodiment adopts the miniature vibrating ore-discharging machine of embodiment 1 to simulate ore drawing in the room to simulate the formation of the funnel busbar, the following specific steps are included:

[0074] (1) Close the center funnel and the half-wall funnel, and place the ore-connecting bucket under the outlet of the ore-connecting skip;

[0075] (2) Fill the half-walled funnel with ore particles until the upper surface of the ore particles is flush with the bottom plate of the ore loading bin, and lay the marking particles of the same color on the central axis of the front plate of the ore loading bin, and record it as color 0;

[0076] (3) Lay the first layer of ore, scrape the plane of the first layer of ore layer until the top of the ore layer is on the same level as the first horizontal scale line of the front plate of the ore loading bin, at the junction of the top of the ore seam and the front plate of the ore loading bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com