High-magnification three-dimensional imaging microscope based on double-light source off-axis illumination and imaging method

An off-axis illumination and three-dimensional imaging technology, which is applied in the field of optical instruments, can solve the problems of short working distance of high-magnification microscope objectives and insufficient space for installing two microscope objectives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

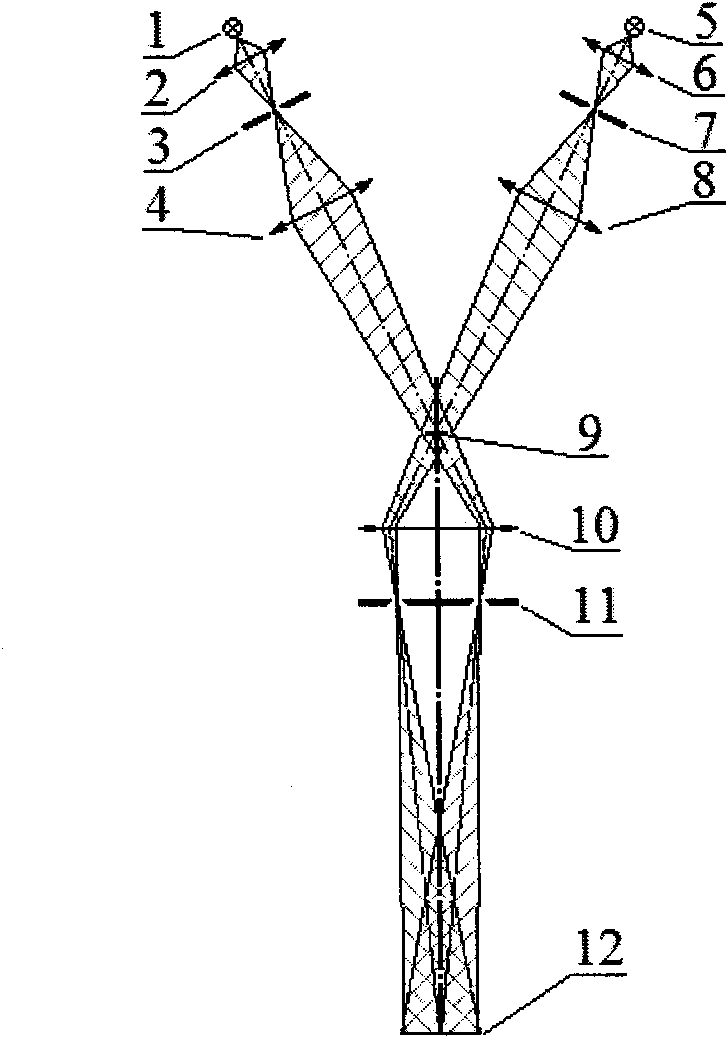

[0068] Embodiment 1: High-magnification three-dimensional imaging microscope (double-lens light source)

[0069] Such as figure 1 As shown, the high-magnification three-dimensional imaging microscope based on dual light source off-axis illumination provided by the present invention includes:

[0070] Two sets of light sources with the same structure on the left and right sides, the left light source includes a light bulb or LED light source 1, two sets of condenser lenses 2 and 4, and a pinhole diaphragm 3 between the two sets of condenser lenses; the right light source includes a light bulb or LED light source 5 in turn , two groups of condensers 6 and 8, and a pinhole diaphragm 7 between the two groups of condensers; the pinhole diaphragm is arranged on the exit pupil plane of the microscopic objective lens, and the center of the aperture diaphragm is between the optical axis of the illumination beam and the microscopic objective lens At the intersection of the exit pupil p...

Embodiment 2

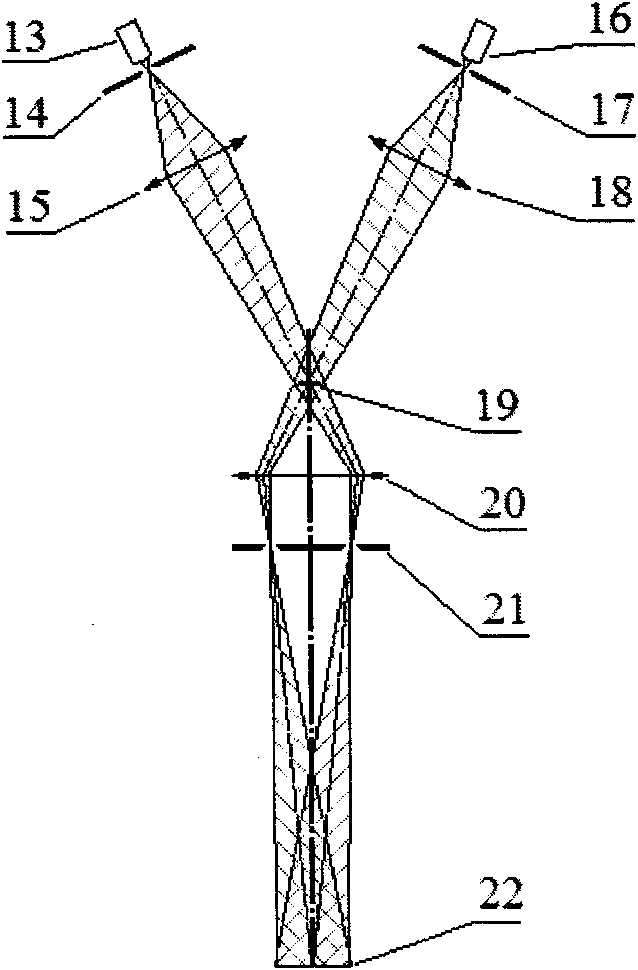

[0075] Embodiment 2: High magnification three-dimensional imaging microscope (single lens light source)

[0076] Such as figure 2 As shown, the left and right groups of light sources of the present invention can also be illuminated by monochromatic LEDs of the same structure, that is, the left light source includes a monochromatic LED light source 13, a pinhole diaphragm 14, and a group of condenser mirrors 15 in turn; the right light source sequentially It includes a monochromatic LED light source 16, a pinhole diaphragm 17 and a group of condenser lenses 18, and the rest of the structure is the same as that of Embodiment 1.

Embodiment 3

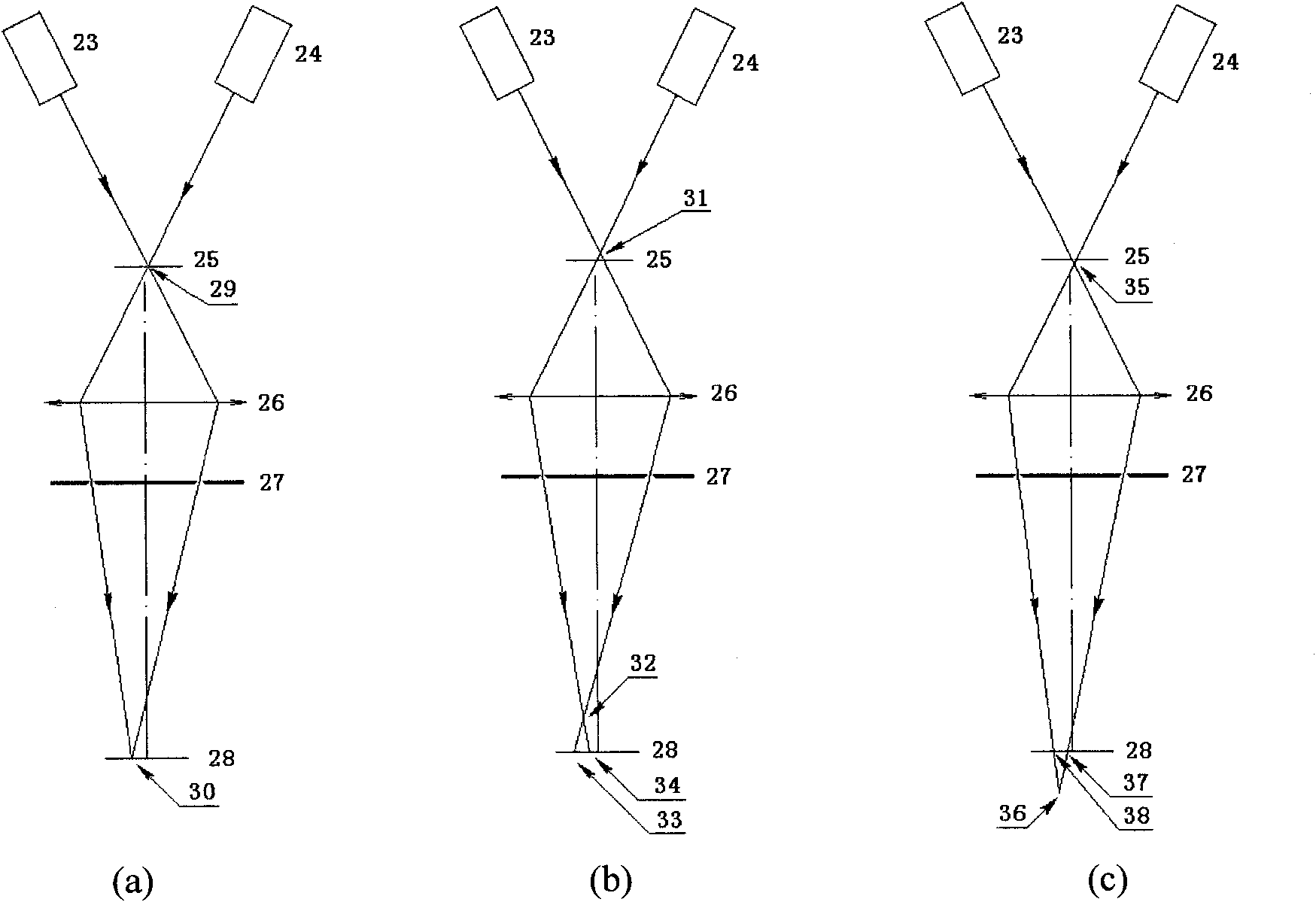

[0077] Embodiment 3: Imaging method for obtaining three-dimensional position information of an object with a three-dimensional imaging microscope

[0078] use the present invention figure 1 or figure 2 The shown device measures the three-dimensional coordinates of the object (the specific steps are as described in the summary of the invention), the left light source is illuminated by a red LED, the right light source is illuminated by a blue LED, the lateral magnification of the microscopic objective lens is 40 times, and the conjugate distance of the object image 195mm, NA=0.65, CCD effective imaging area 3.3mm×4.4mm, 1024×768 pixels.

[0079] 1. Use the reticle to calibrate the microscope

[0080] Adjust the reticle vertically to make the red and blue cross images overlap, determine the zero point of the z axis, take the zero point of the x and y axes on the axis corresponding to the center of the CCD, and move the reticle vertically, with a translation range of ±10 μm an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com