Improved continuous variable-voltage and variable-frequency soft starter

A technology of soft starter and inverter, which is applied to the starter of a single multi-phase induction motor, motor generator/starter, etc. It can solve the problems of fewer stages and cannot meet the requirements of soft start, and achieve overload capacity strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

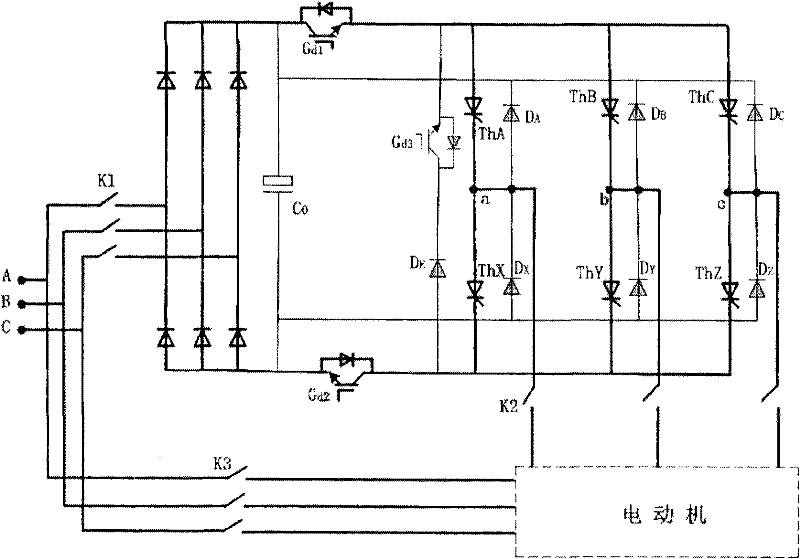

[0029] The soft starter used for the continuous variable frequency variable voltage of electric motor in specific embodiment 1 is as figure 1 shown.

[0030] The soft starter includes a mechanical switch K1 connected to the three-phase grid power supply, and also includes an inverter and two fully-controlled high-frequency electronic switches Gd 1 、Gd 2 A series circuit consisting of Gd 1 、Gd 2 respectively connected to the upper and lower ends of the series circuit, the series circuit and the capacitor C 0 The two ends connected in parallel to the output of a three-phase diode rectifier bridge; the mechanical switch K1 is connected to the input end of the three-phase diode rectifier bridge; the inverter consists of the following two parts:

[0031] (1) Six thyristors ThA, ThB, ThC, ThX, ThY, ThZ on the AC side of the inverter and six diodes D A 、D B 、D C 、D X 、D Y 、D Z 3 pairs of bridge arms together; each bridge arm contains a thyristor and an anti-parallel diode,...

specific Embodiment 2

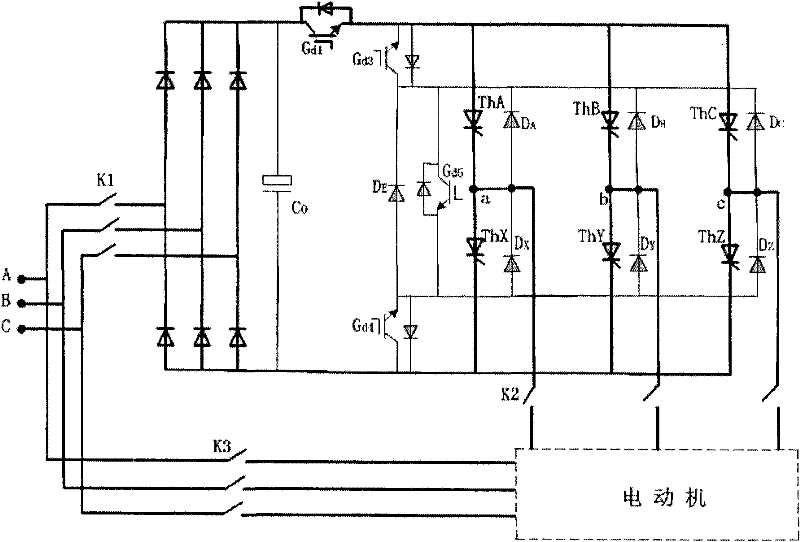

[0043] Such as image 3 As shown, the soft starter includes a mechanical switch K1 connected to the three-phase grid power supply, and also includes an inverter and a fully-controlled high-frequency electronic switch G d1 A series circuit composed of G d1 Connected to the upper end of the series circuit, the series circuit and the capacitor C 0 The two ends connected in parallel to the output of a three-phase diode rectifier bridge; the mechanical switch K1 is connected to the input end of the three-phase diode rectifier bridge; the inverter consists of the following two parts:

[0044] (1) Six thyristors ThA, ThB, ThC, ThX, ThY, ThZ on the AC side of the inverter and six diodes D A 、D B 、D C 、D X 、D Y 、D Z 3 pairs of bridge arms together; each bridge arm contains a thyristor and an anti-parallel diode, where: the cathode of ThA is connected to the anode of DA to become the upper bridge arm of the first pair of bridge arms, that is, the A bridge arm, ThX Anode and D X ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com