Wire cut electric discharge machine with machining state discrimination function

A discharge processing machine and state judgment technology, which is applied to electric processing equipment, metal processing equipment, circuits, etc., can solve problems such as difficult discharge detection, difficult processing state discrimination, and inability to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

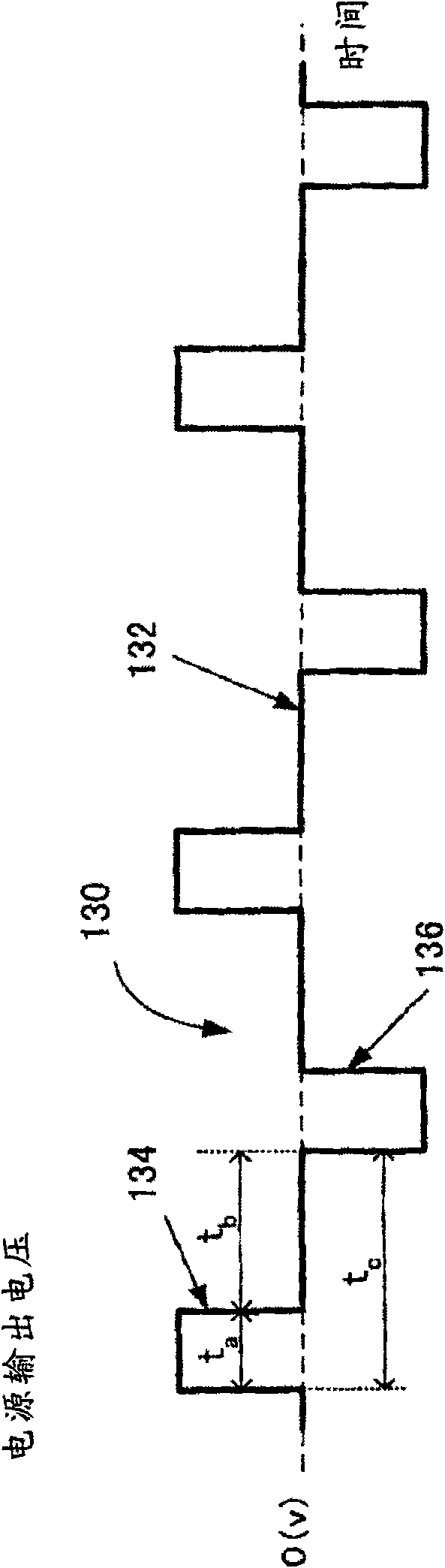

[0038] The present invention is characterized in that a rest time longer than the voltage application time is provided between positive and negative polarity voltage applications, and the voltage waveform is processed in a trapezoidal waveform, and each voltage application in each voltage application , by classifying the state between the poles into several categories (category), the processing state is identified independently of the average voltage.

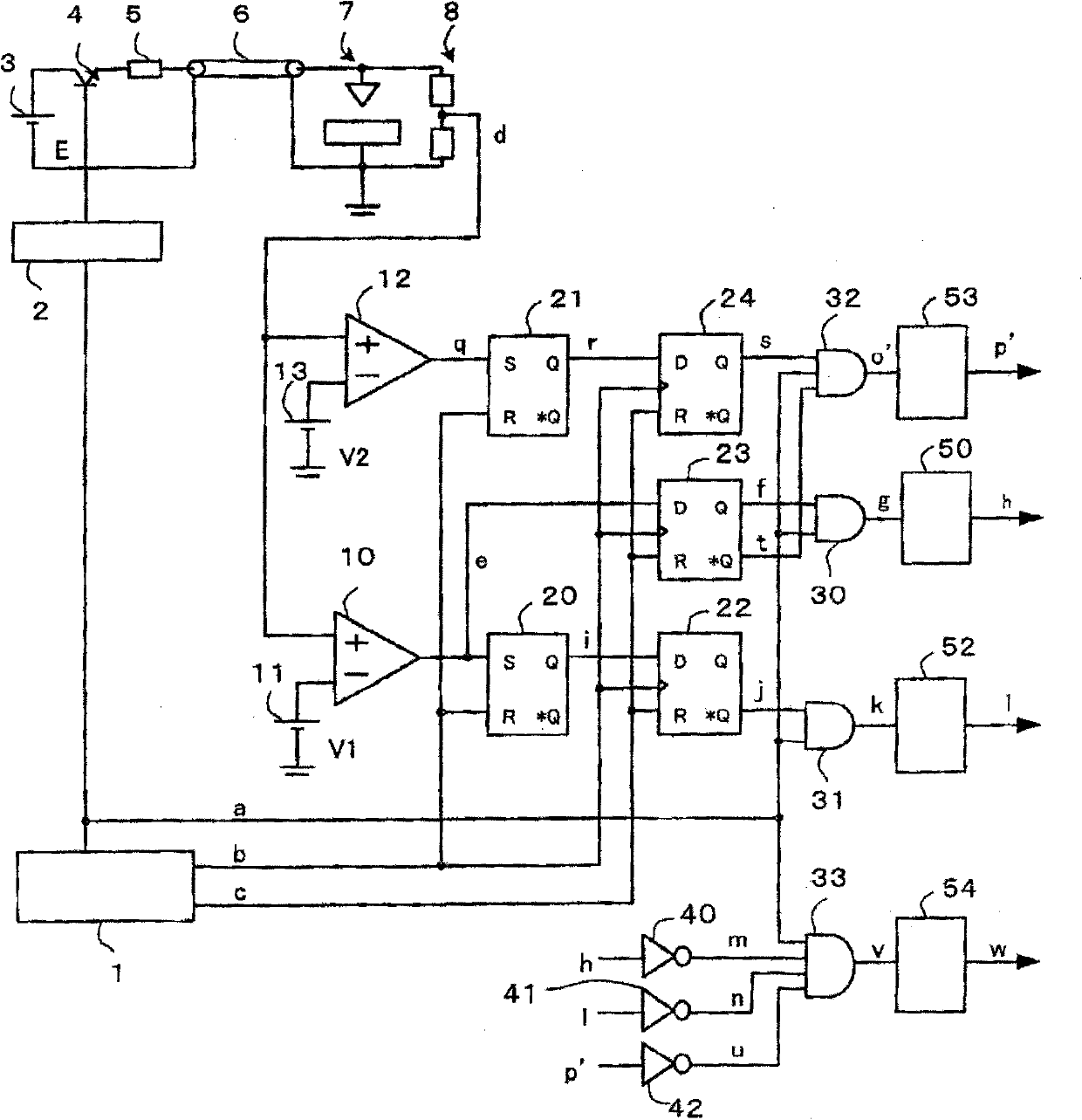

[0039] figure 1 An example of a bipolar voltage application circuit used in the embodiment of the present invention is shown.

[0040] The bipolar voltage applying circuit 9 includes: a pair of DC power sources 3 , a pair of switching elements 4 , a braking resistor 5 , and a power supply cable 6 . Symbol 7A is a wire electrode; symbol 7B is a workpiece, which is arranged at a predetermined interval with respect to the wire electrode 7A; and a gap 7 is formed between the wire electrode 7A and the workpiece 7B. By the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com