Method for desalting sea sand and device for desalting sea sand with same

A sea sand and fresh water technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of cost increase, difficulty in meeting national standard requirements, and difficulty in further reducing sea sand chloride content, achieving low cost, Long service life, effect of improving desalination effect and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

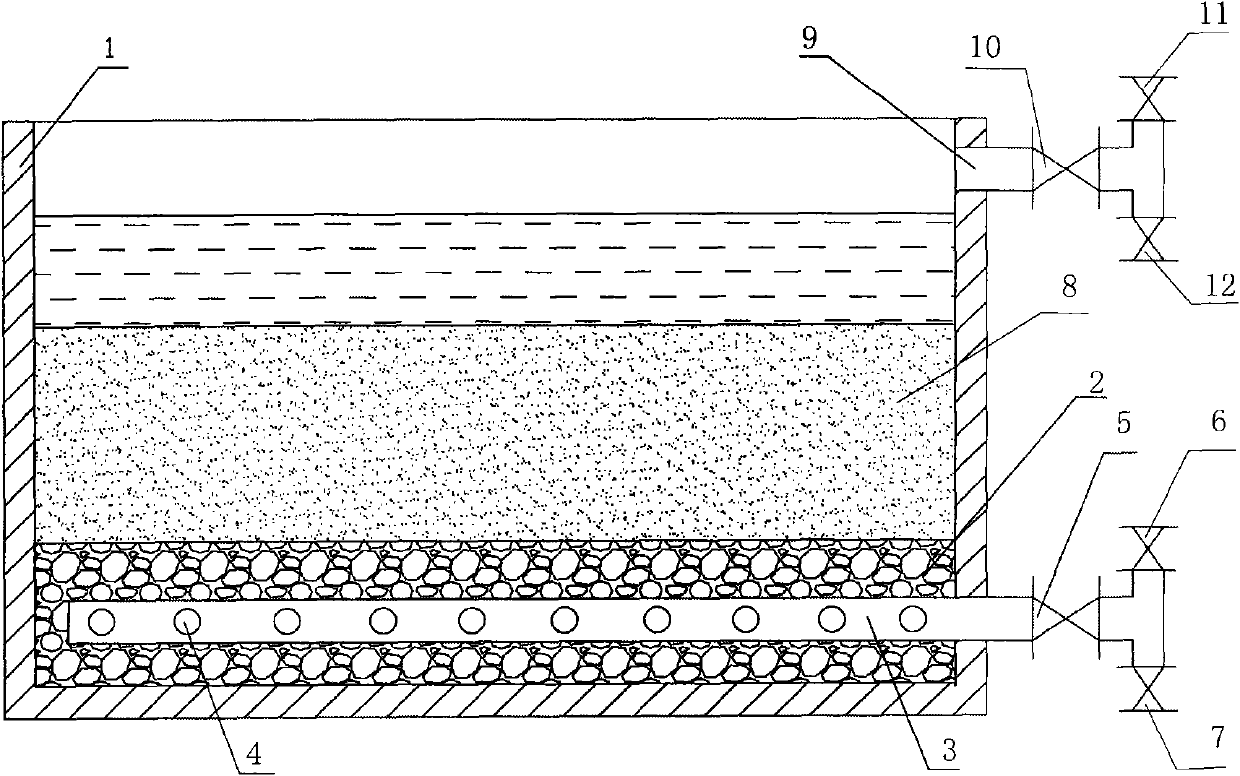

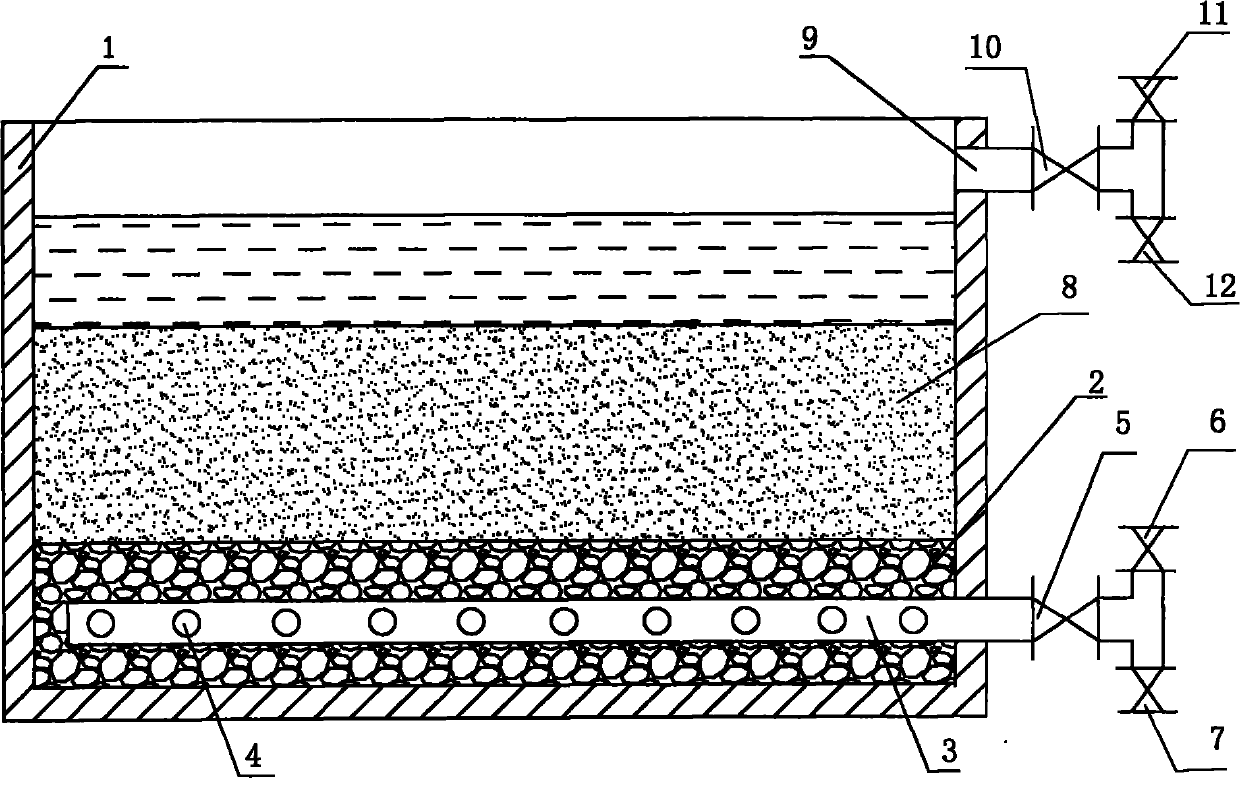

[0034] Such as figure 1The device for sea sand desalination shown in this example includes a desalination tank 1 with an upper opening, and a reverse filter layer 2 is laid on the bottom of the desalination tank 1, and the reverse filter layer 2 decreases step by step according to the particle size from bottom to top The principle is that it is laid step by step in the order of pebbles, gravel and sand. The water pipes are evenly arranged in the reverse filter layer 2, and the water pipes include a main water pipe 3 and a plurality of branch water pipes 4. One end of the branch water pipes 4 communicates with the main water pipe 3, and the other end opens in the reverse filter layer 2 as the water inlet and outlet of the branch water pipes. , the main water pipe 3 extends out of the desalination tank through the opening of the lower wall of the desalination tank, and communicates with the lower valve 5 through the outlet pipe, and the lower valve 5 communicates with the water ...

Embodiment 2

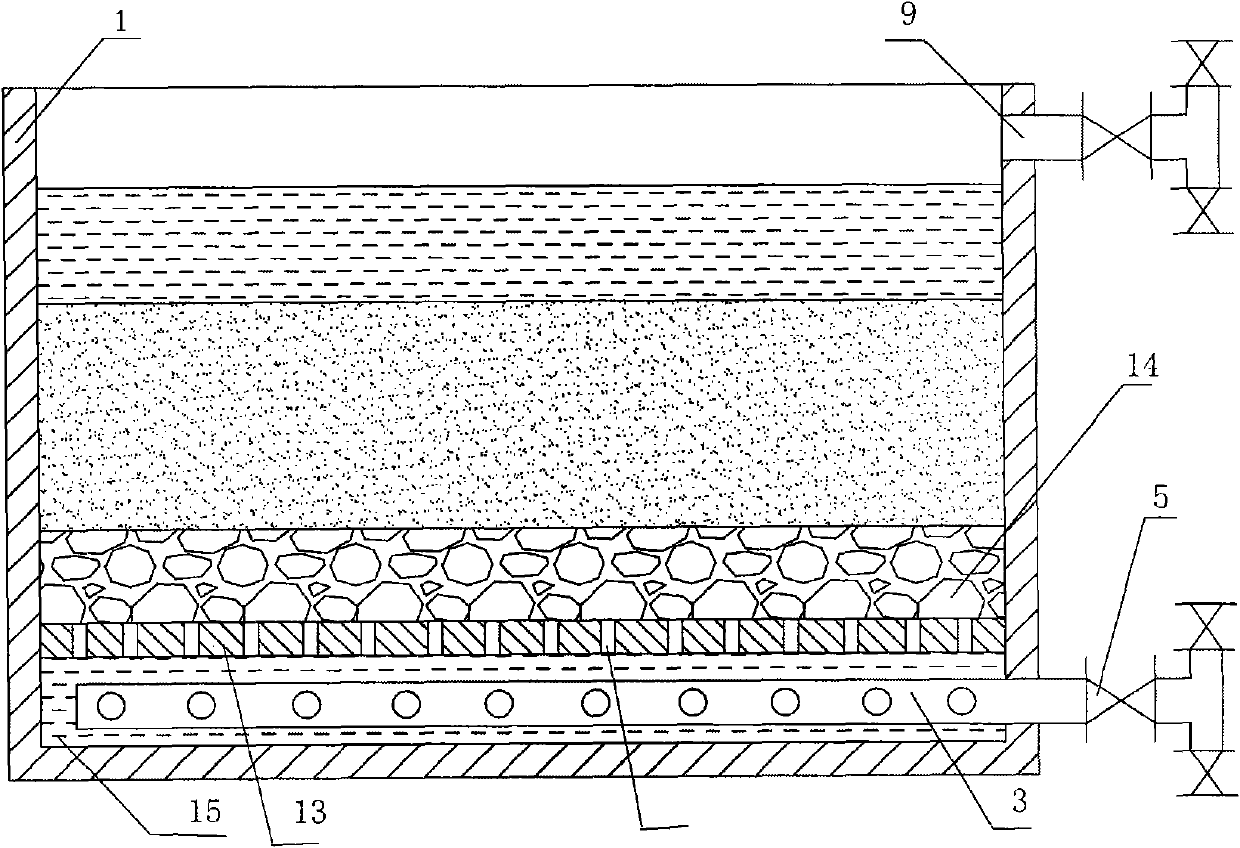

[0037] Such as figure 2 The device for sea sand desalination shown in this example includes a desalination tank 1 with an upper opening, the bottom of the desalination tank 1 is a reverse filter layer 2, and the reverse filter layer 2 includes an upper filter layer 14 separated up and down by a lining plate 13 and the lower interlayer 15; the liner 13 is densely covered with a plurality of through holes 16 spaced up and down; the upper filter layer 14 is gradually reduced in the order of pebbles, crushed stones and sand according to the principle that the particle size decreases step by step from bottom to top. The lower surface of the liner 13 and the upper surface of the pool bottom form a lower compartment 15 of a space, and water pipes are laid in the inner cavity of the lower compartment 15. The water pipes include the main water pipe 3 and a plurality of branch water pipes 4. One end of the branch water pipe 4 communicates with the main water pipe 3, and the other end o...

Embodiment 3

[0040] In this example, using figure 1 The device of sea sand desalination realizes sea sand desalination method of the present invention, specifically comprises the following steps:

[0041] (1) Transport the sea sand to the desalination tank, and fill it on the reverse filter layer of the desalination tank, determine the filling height according to the need, and push it flat by mechanical means.

[0042] (2) Close the lower valve, open the upper valve and the water source valve connected with it, then inject seawater into the desalination tank, and the seawater covers the top of the sea sand body;

[0043] (3) After immersion for more than 1 hour, open the upper valve and the water source valve connected to it, and inject fresh water for the second time. The water injection volume should not be less than the volume between the upper surface of the sand body and the upper surface of the immersion water, and should not be less than above the surface of the sand body. The wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com