Potato extracted starch refiner

A refiner and starch technology, applied in grain processing and other directions, can solve the problems of large loss rate, large water consumption and discharge, large space occupation, etc., and achieve the effects of reducing power consumption, improving the extraction rate of starch, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

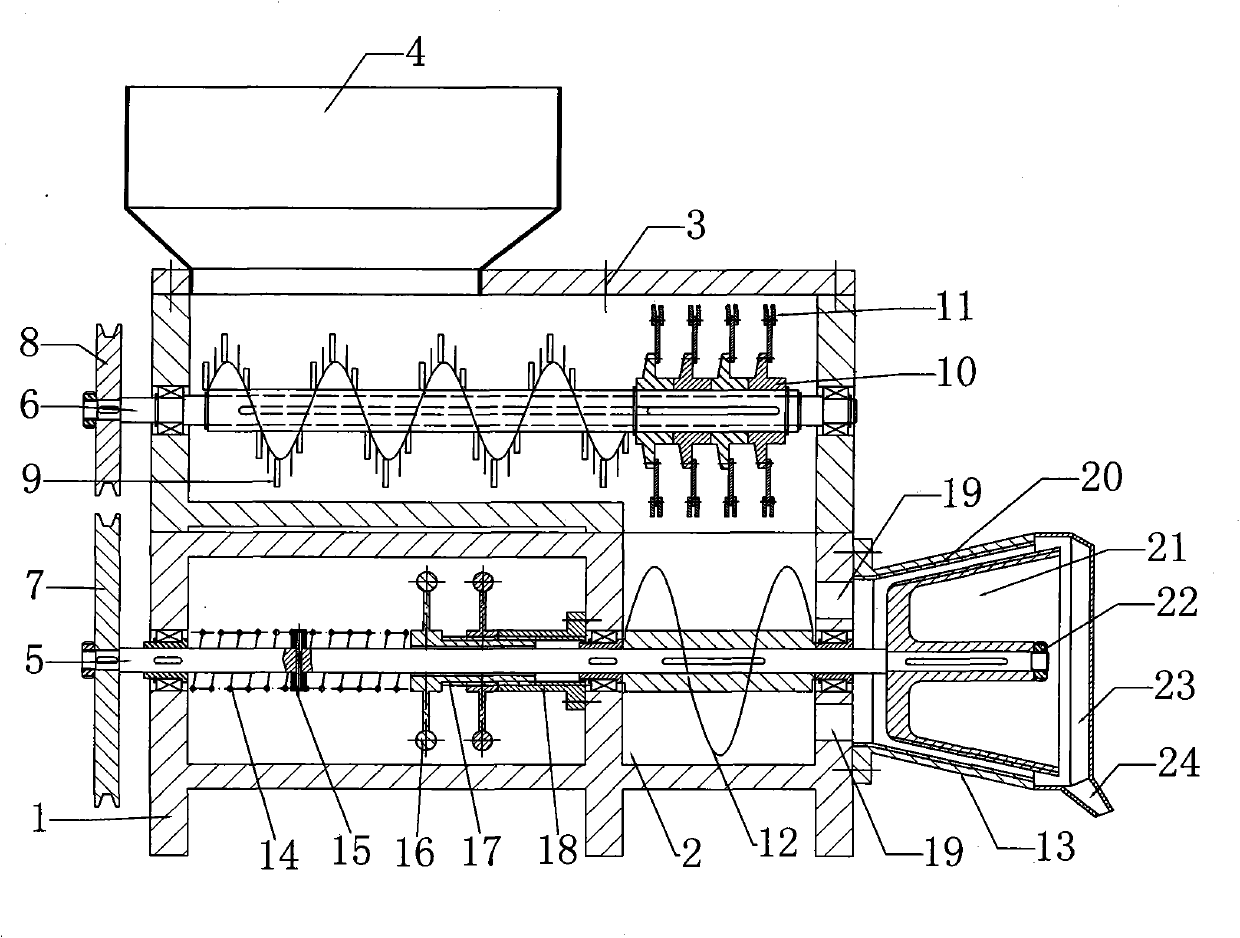

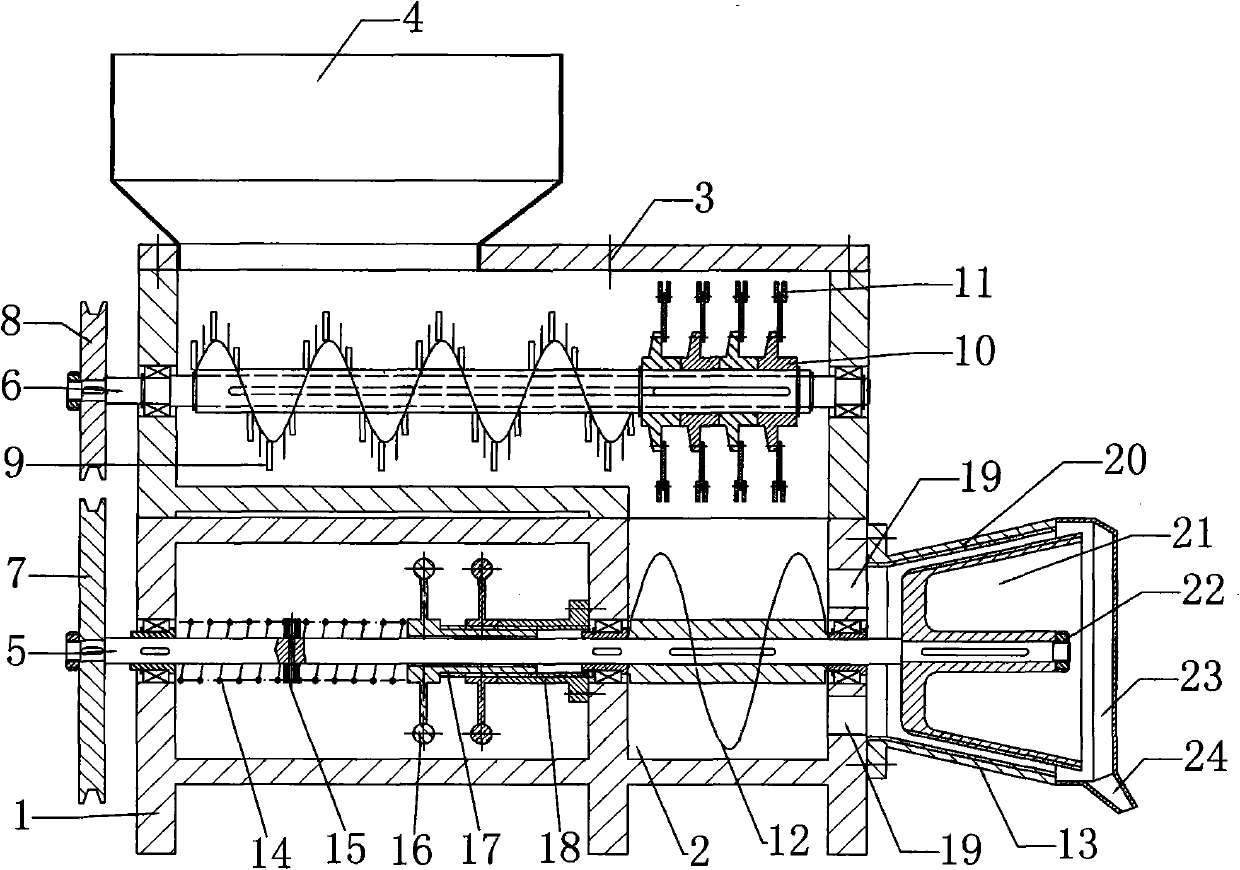

[0011] Accompanying drawing is a kind of specific embodiment of the present invention. The potato extracting starch refiner includes a frame 1, which is characterized in that: a refining mechanism 2 is installed on the frame 1, a crushing mechanism 3 is installed above the refining mechanism 2, and a feeding hopper 4 is installed above the crushing mechanism 3, The main machine shaft 5 and the crushing shaft 6 are respectively installed in the refining mechanism 2 and the crushing mechanism 3, and the main machine wheel 7 and the pulley 8 are respectively installed at the front ends of the main machine shaft 5 and the crushing shaft 6, and the main machine wheel 7 and the pulley 8 are connected by a belt. The shaft 5 is connected to the power input, and the crushing mechanism 3 includes a slice conveying device and a crushing device installed on the crushing shaft 6. The slice conveying device communicates with the feed hopper 4 and is located below it. A plurality of agitatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com