On-site extraction, drainage and liquid collection process with auxiliary tunnels

A roadway, in-situ technology, applied in the improvement of process efficiency, mining fluids, ground mining and other directions, can solve the problems of long tail liquid collection time, long process cycle, harsh implementation conditions, etc., and achieve the improvement of rare earth resource recovery rate, The effect of increasing water content and increasing the recovery rate of rare earth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

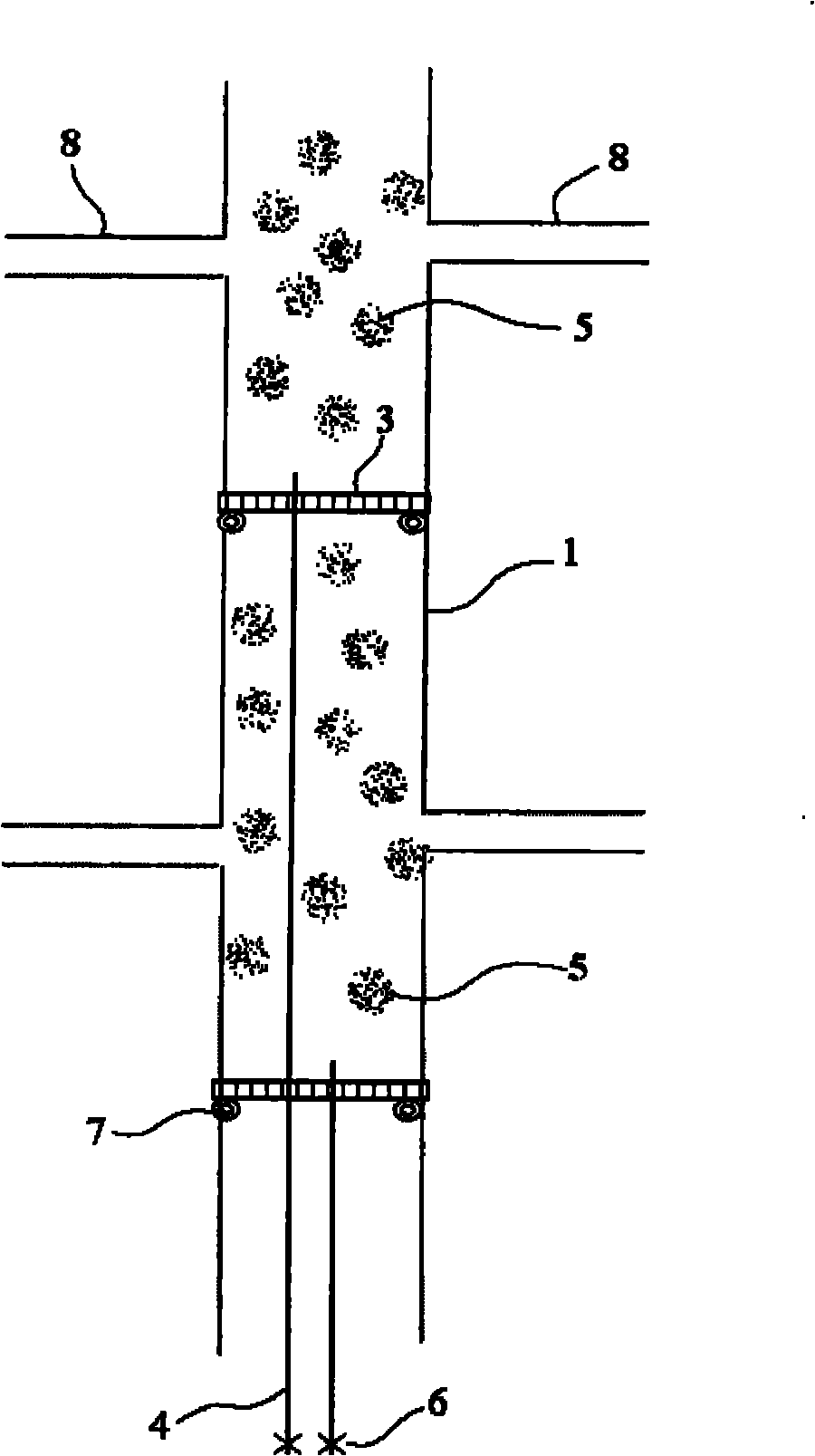

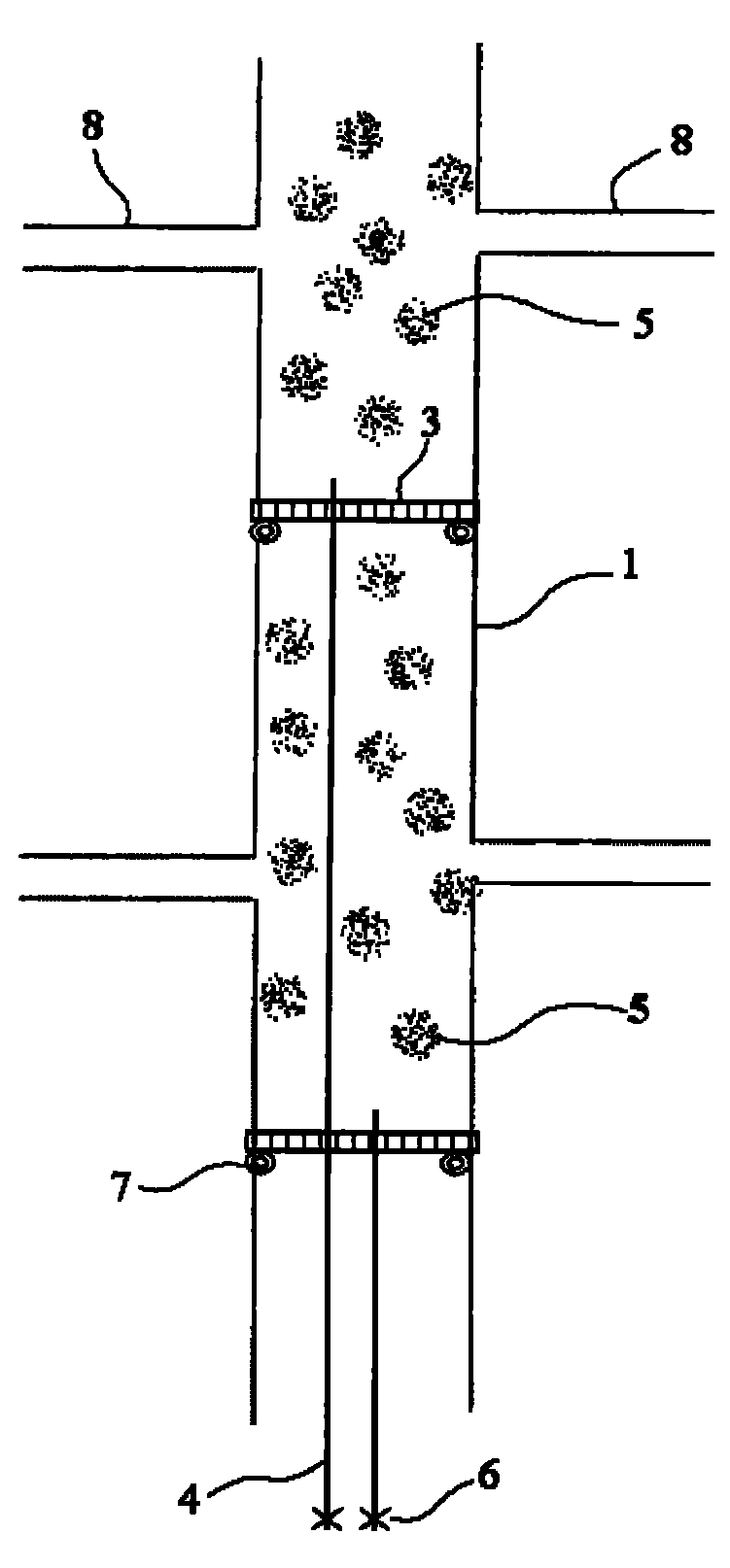

[0033] See attached figure 1 , the specific implementation method of the technical solution of the present invention is as follows: according to the ore body grade distribution and hydraulic principle, the height in the ore body is between 0.015%~0.02% at the bottom of the ore body, mainly along the direction or tendency of the mountain body, as far as possible Supplemented by the higher distribution of the passing grades on the plane, the liquid collection roadway 1 is set up with a slope of 1-2°. Auxiliary roadways 8 are set at intervals of 5-10 meters on both sides of the liquid-collecting roadway, and cement slurry seepage prevention measures can be implemented at the bottom of the roadway 1. A plurality of support pillars 7 can be arranged on both sides of the liquid collecting roadway 1 . After the construction of the liquid-collecting roadway 1 is completed, the sealing wall 3 is implemented every 20 to 30 meters and in front of the nearest support column 7, thereby di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com