Concrete energy-saving hollow brick

A technology of hollow bricks and brick holes, which is applied in the direction of building components, buildings, building structures, etc., can solve the problems of small masonry mortar fullness, small bonding surface, and affecting compressive and shear strength, and achieve energy saving and construction Convenience and the effect of saving construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

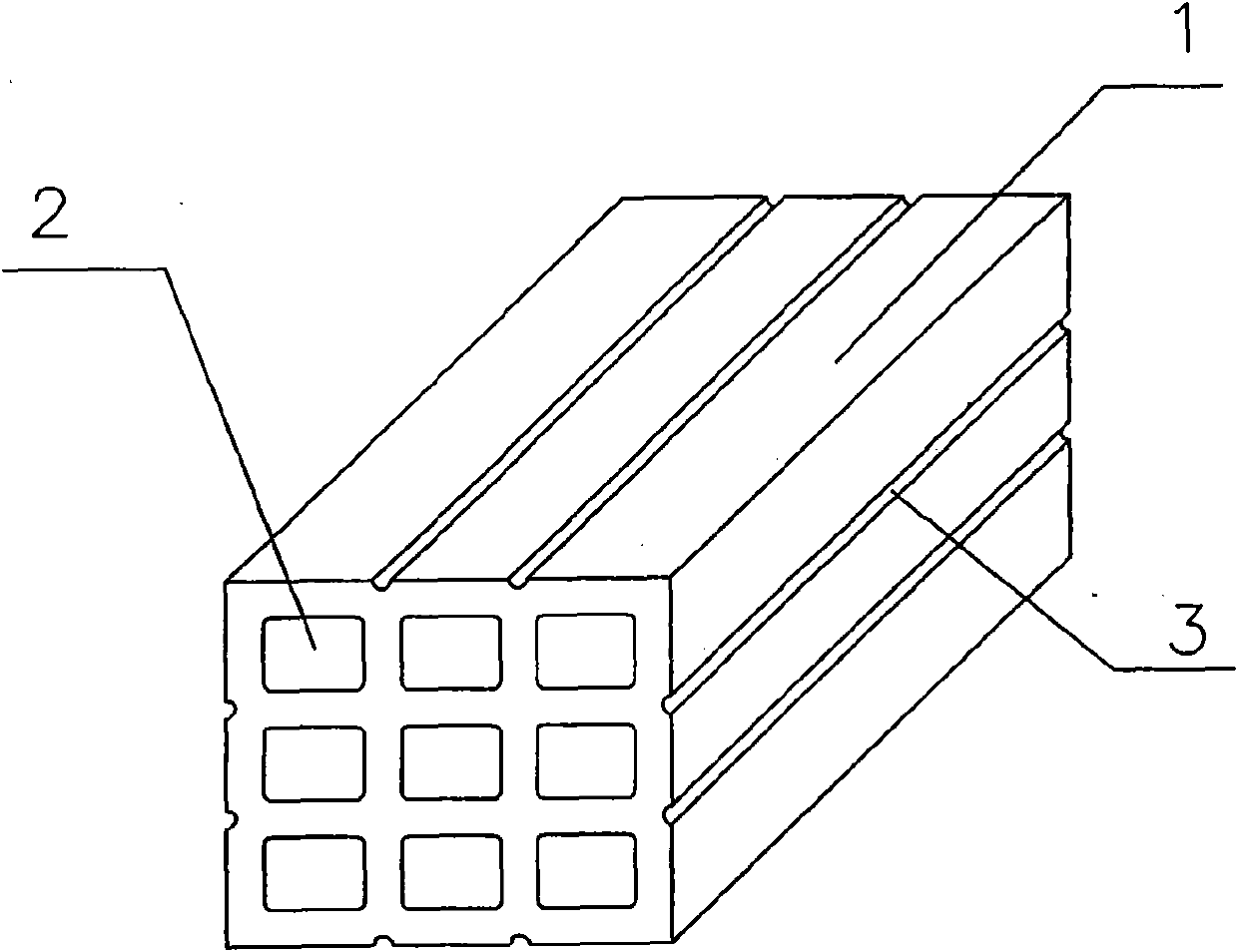

[0025] see figure 1 , a concrete energy-saving hollow brick includes a block 1 provided with brick holes, three rows of nine rectangular brick holes 2 are uniformly arranged in the length direction of the block 1, the rectangular brick holes are through holes, and the rectangular brick holes are arranged in the length direction of the block. Through, it is the main block A.

[0026] Two grooves 3 are evenly distributed on the four sides in the length direction of the block. The groove width of the groove is 10mm, and the groove depth is 6mm.

Embodiment 2

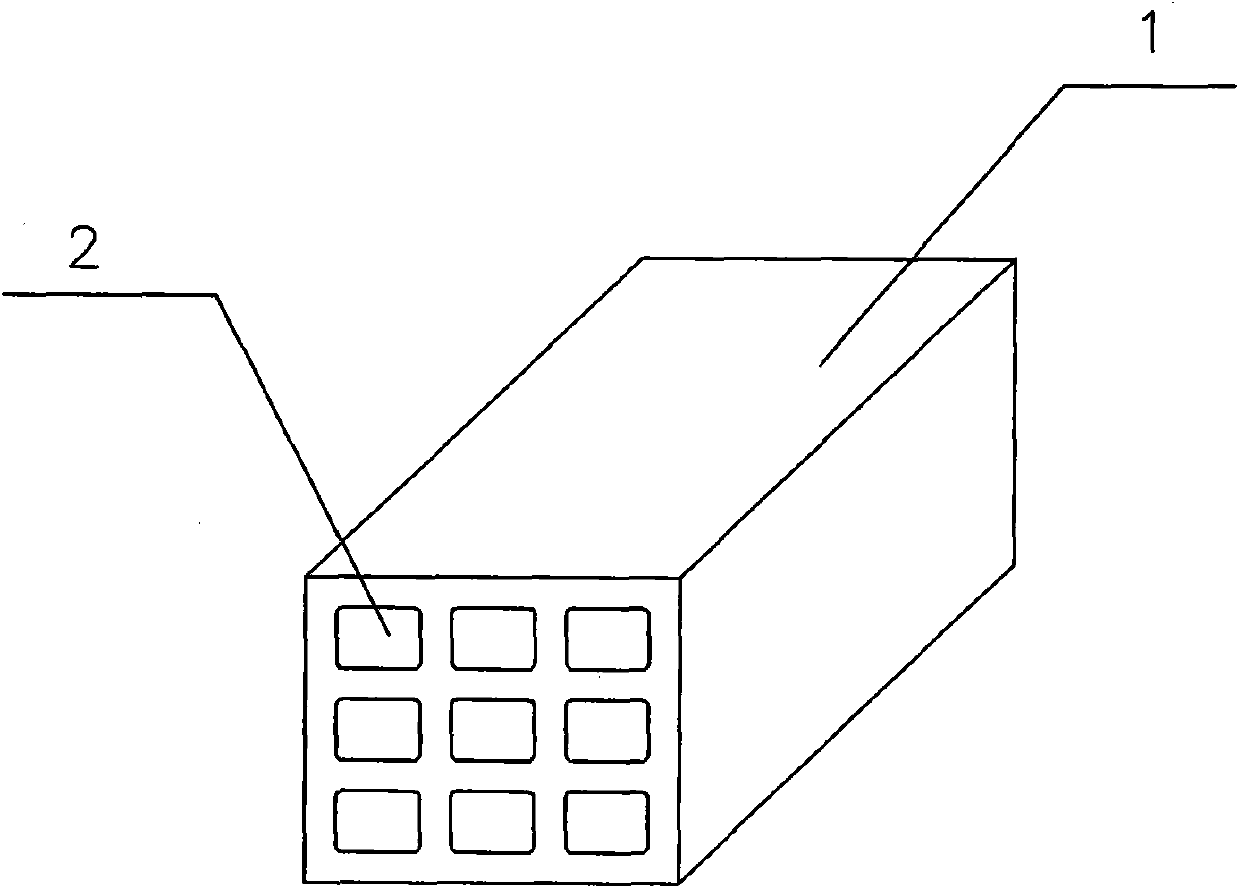

[0028] see figure 2 , the main block B structure, three rows of nine rectangular brick holes 2 are uniformly arranged in the length direction of the block 1, and the rectangular brick holes are through holes, and the rectangular brick holes run through the length direction of the block, which is the main block B.

[0029] Others are with embodiment 1.

Embodiment 3

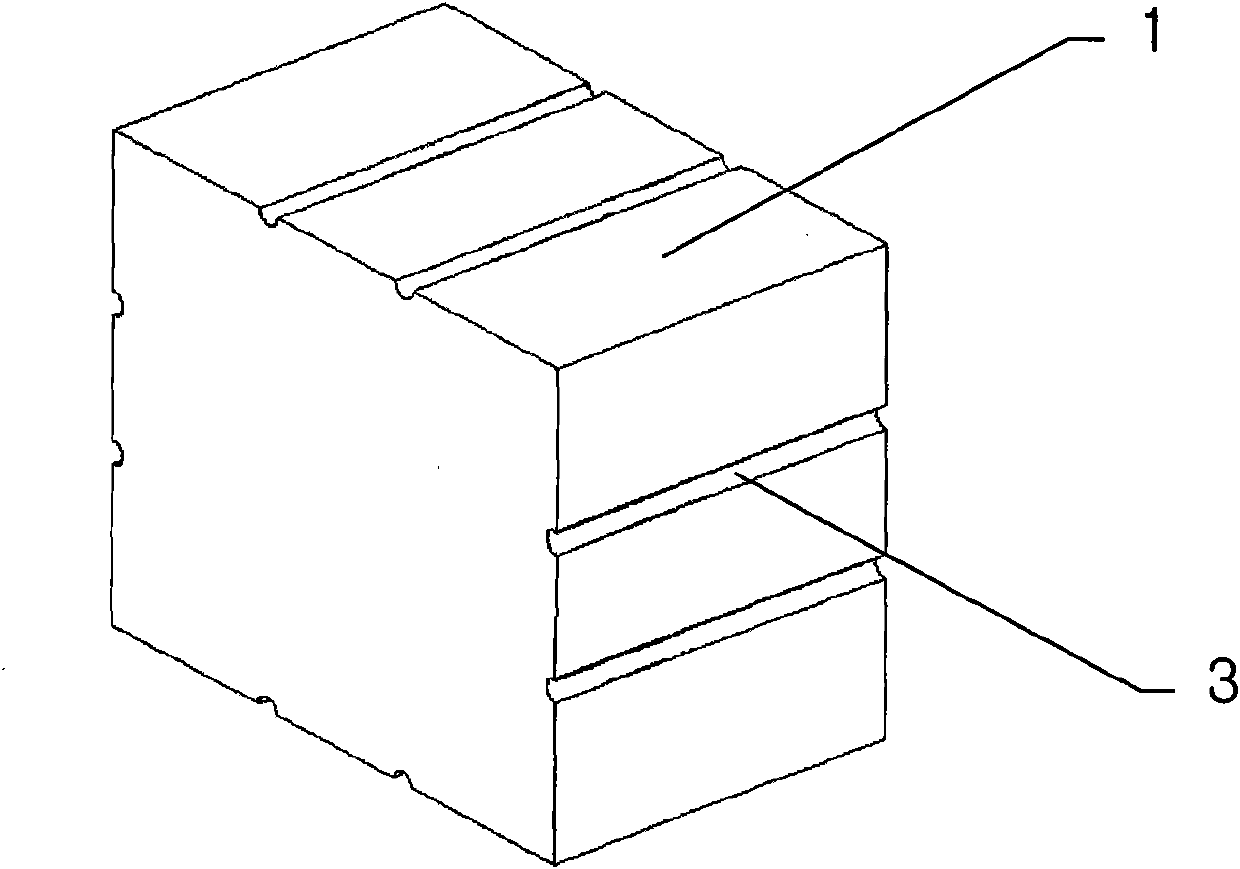

[0031] see image 3 , is the auxiliary block A structure, and its rectangular brick hole is a blind hole, that is, one end of the length direction of the block is closed. The length of the auxiliary block A is 3 / 4 of the length of the main block A, and the groove width of the grooves on the four sides of the block length direction is 5mm, and the groove depth is 4mm.

[0032] Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove width | aaaaa | aaaaa |

| Groove depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com