Centralized lubricating system

A centralized lubricating and lubricating pump technology, which is applied in lubricating parts, engine lubricating, lubricating oil control valves, etc., can solve the problem of incomplete pressure relief, achieve the effects of simplifying the structure, avoiding excessive return, and facilitating production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

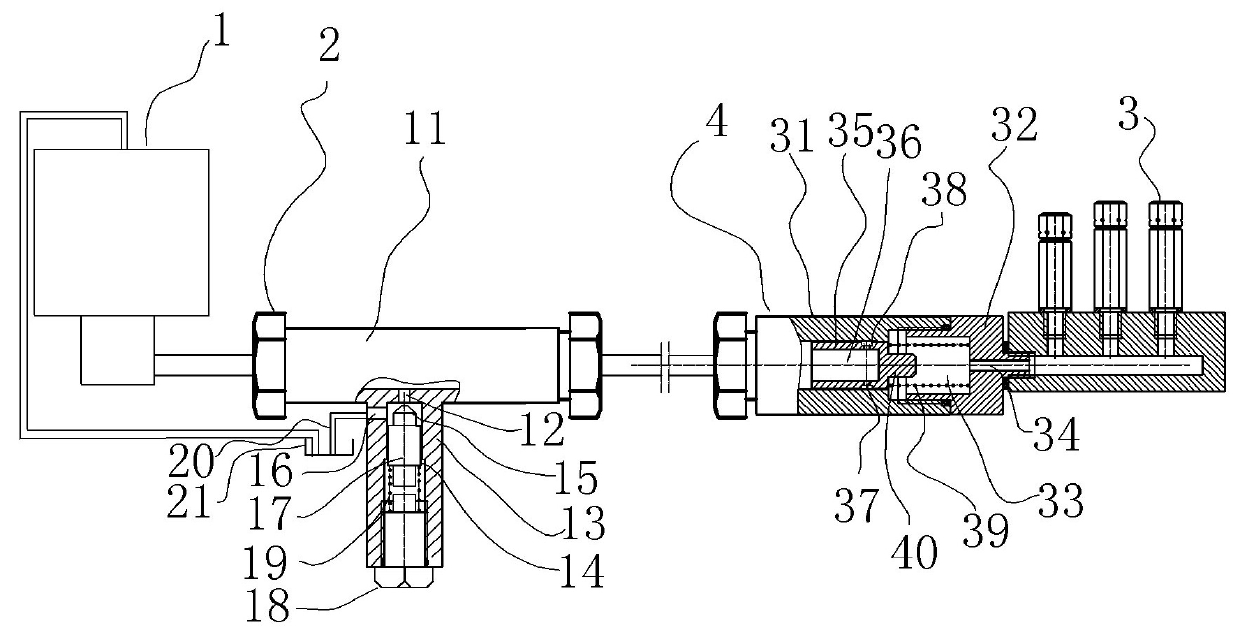

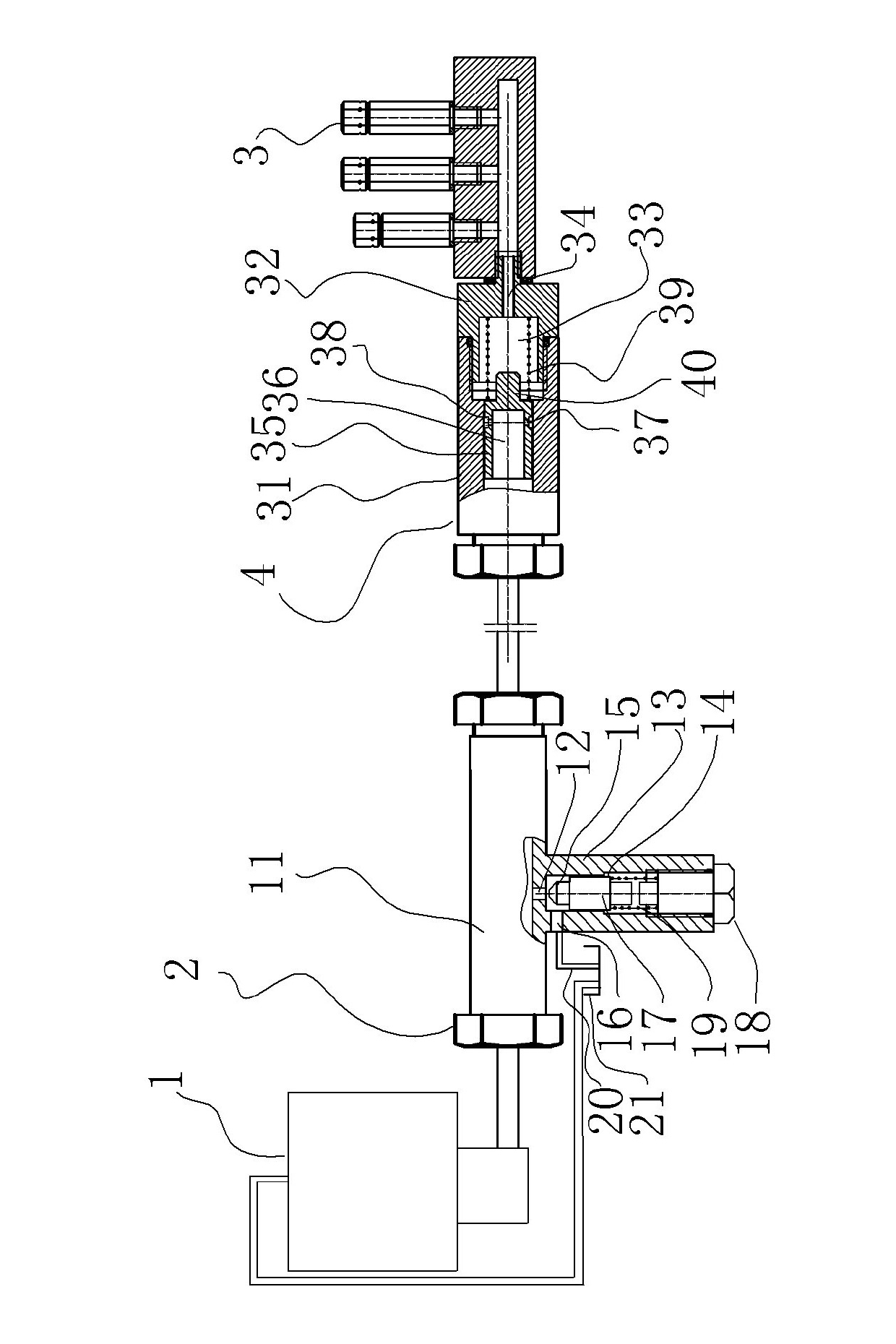

[0023] Embodiment 2 of the present invention, such as figure 2 As shown, the difference between this embodiment and embodiment 1 is that the difference between this embodiment and embodiment 1 is only that the auxiliary valve body body 1 has a useful The pressure relief spring 39 is top mounted between the auxiliary valve core 35 and the mating body 32 because of the limiting shoulder 41 constraining the return stroke of the auxiliary valve core 35 (of course, in other embodiments, a circlip may also be used).

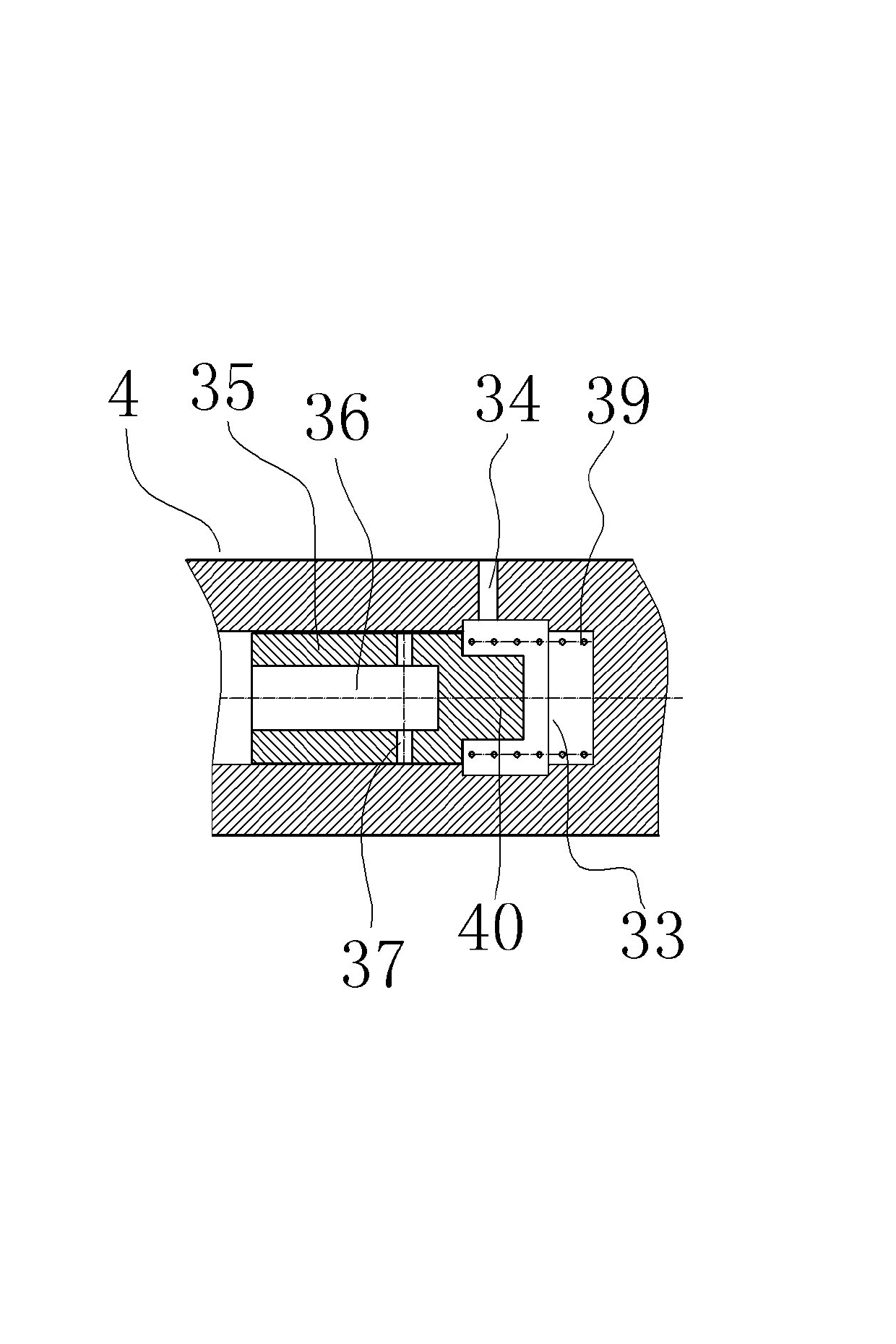

[0024] Embodiment 3 of the auxiliary pressure relief valve of the present invention, such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the auxiliary valve body is a cylindrical structure with one end open, the inner hole of the auxiliary valve body is a stepped hole, and the pressure relief spring 39 is arranged between the auxiliary valve core 35 and the auxiliary valve body. Between the sealing ends, the oil outlet hole 34 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com