Overall regulation and water spraying atomization steam temperature reducing device

An overall regulation and steam technology, applied in the direction of liquid injection device, injection device, injection device, etc., can solve the problems of complex structure, many accessories and high manufacturing cost of the desuperheating system, so as to broaden the application range, simplify the internal structure and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

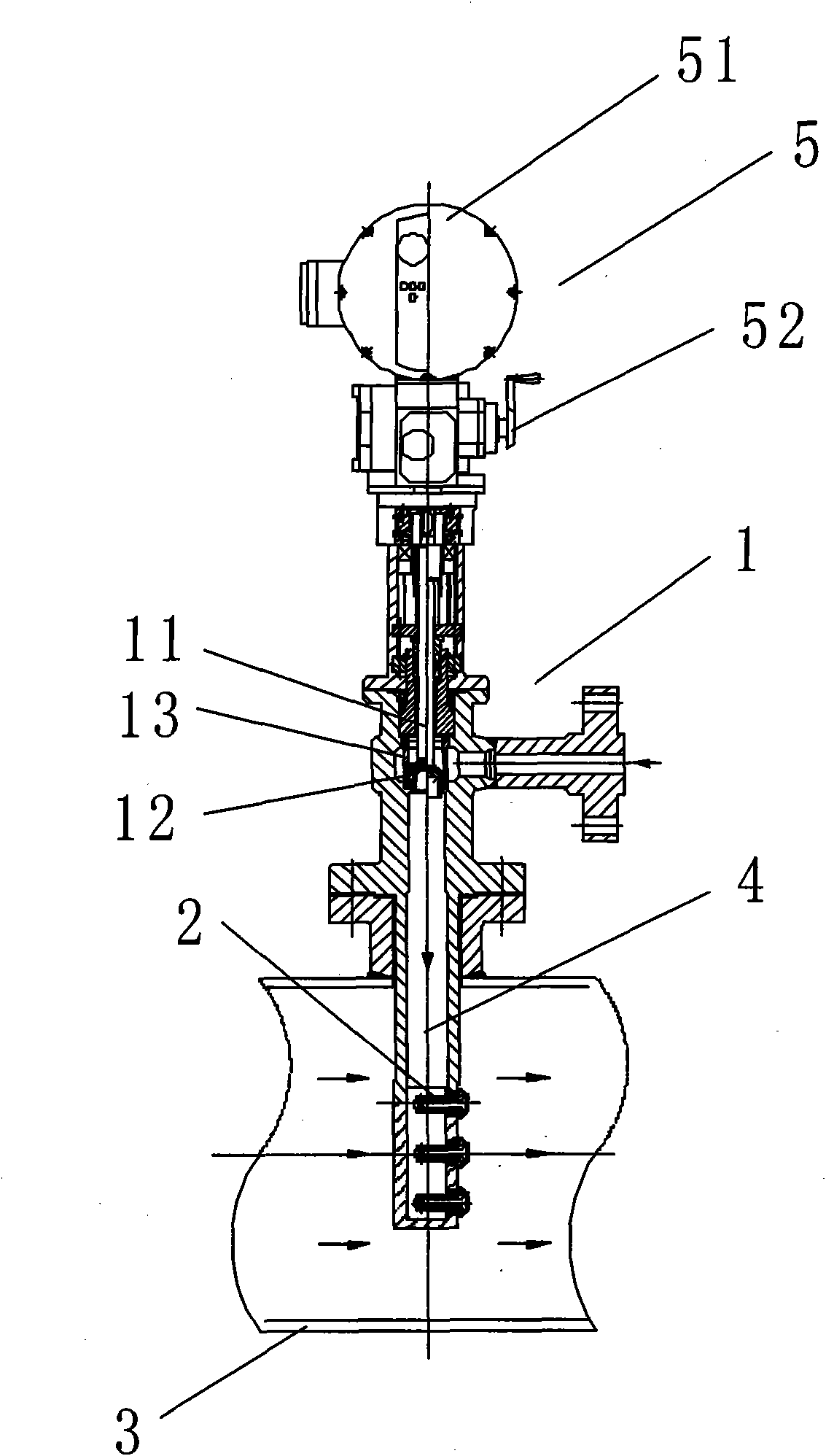

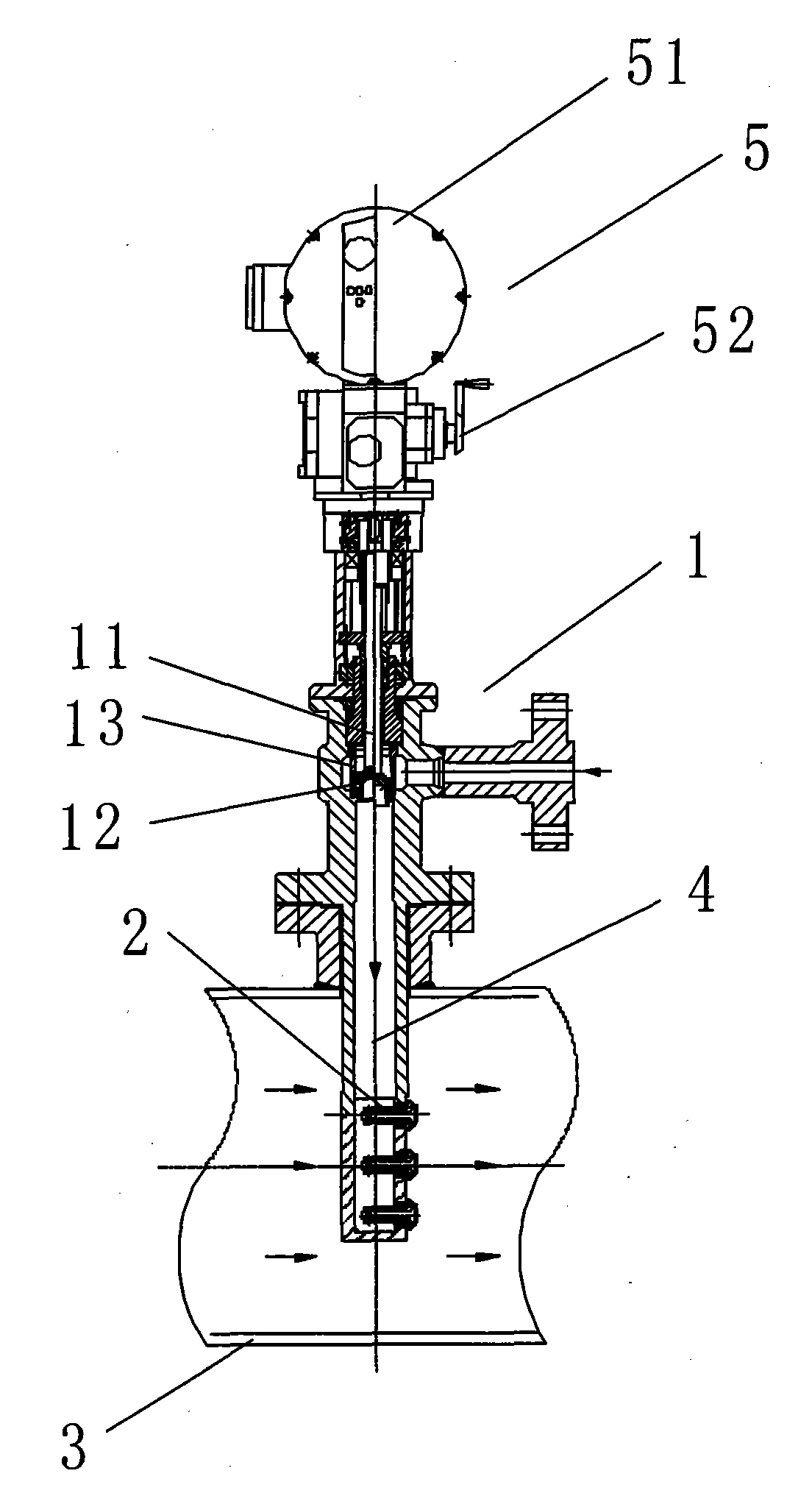

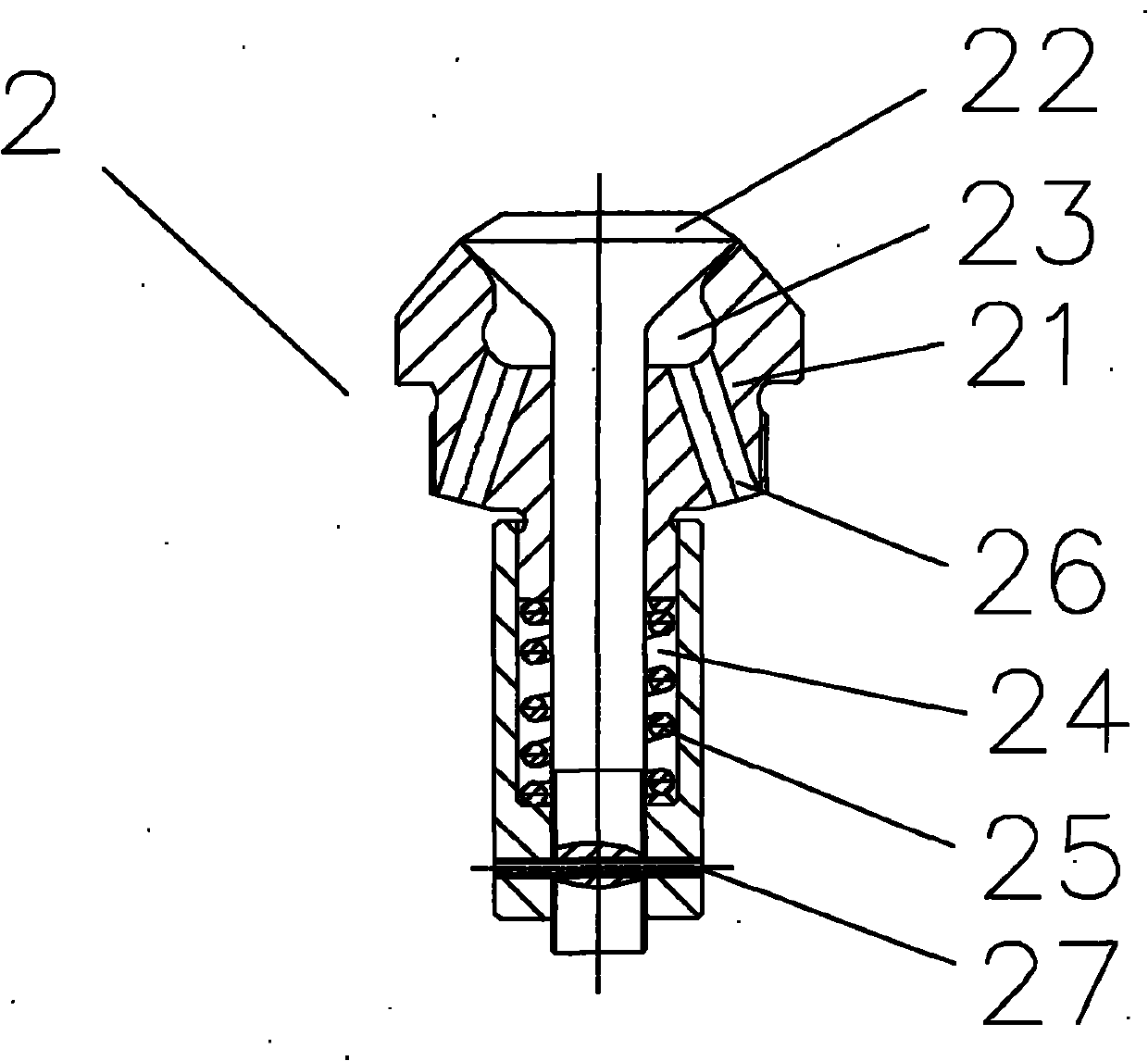

[0020] The accompanying drawings disclose the specific structures of the embodiments of the present invention without limitation, and the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] Depend on figure 1 It can be seen that the embodiment of the present invention includes a regulating valve 1 and a nozzle 2 fixedly installed on the desuperheating water pipe 4 in the steam pipeline 3, wherein:

[0022] The valve stem 11 of the regulating valve 1 is connected to the valve core 12. The regulating valve 1 is provided with a regulating sleeve 13, and at least two sections of the regulating sleeve are provided with small holes. The water entering the regulating valve 1 can only pass through the The small hole of the adjustment sleeve 13 enters; the valve core 12 blocks or opens the small hole on the adjustment sleeve 13 when the valve core 12 slides up and down in the inner cavity of the adjustment sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com