Flexible printed paper battery anti-counterfeiting label

A flexible printing and paper battery technology, applied to battery components, circuits, seals, etc., can solve problems such as unsuitable for large-scale use, difficult anti-counterfeiting, automatic failure, etc., to achieve simple and effective identification methods and high accuracy of counterfeiting , The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

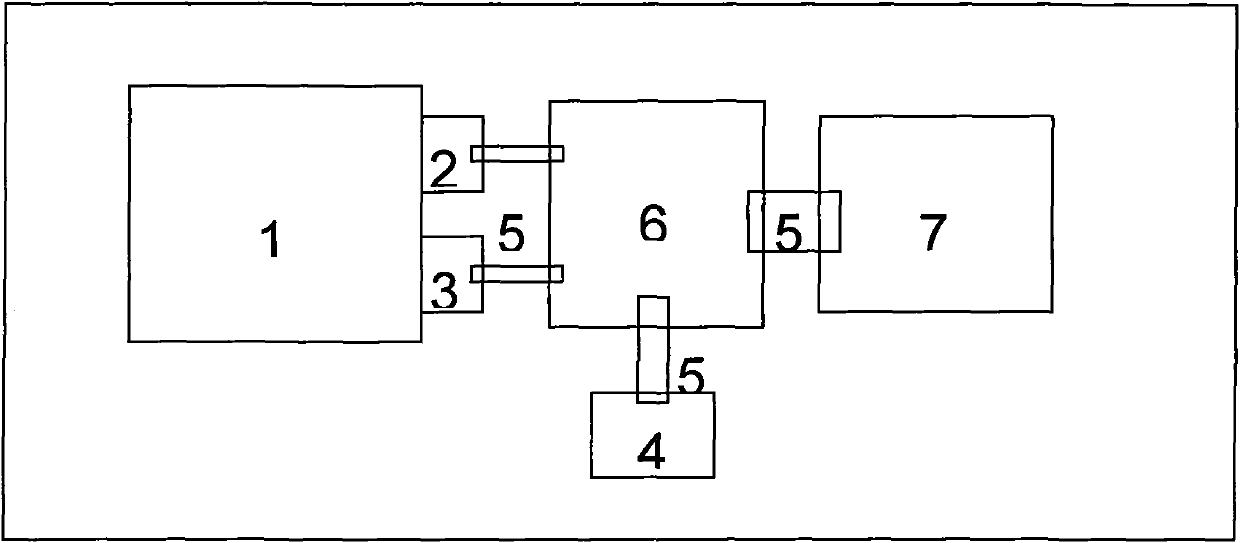

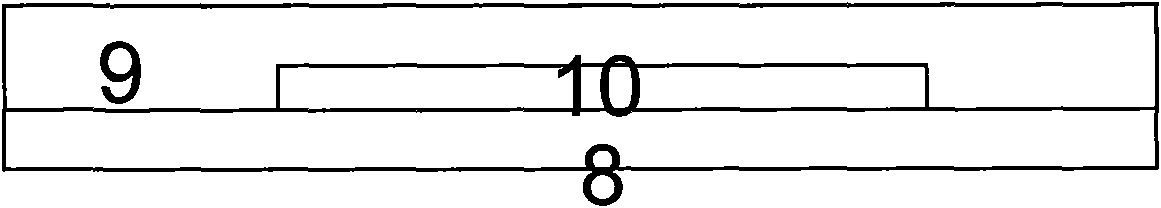

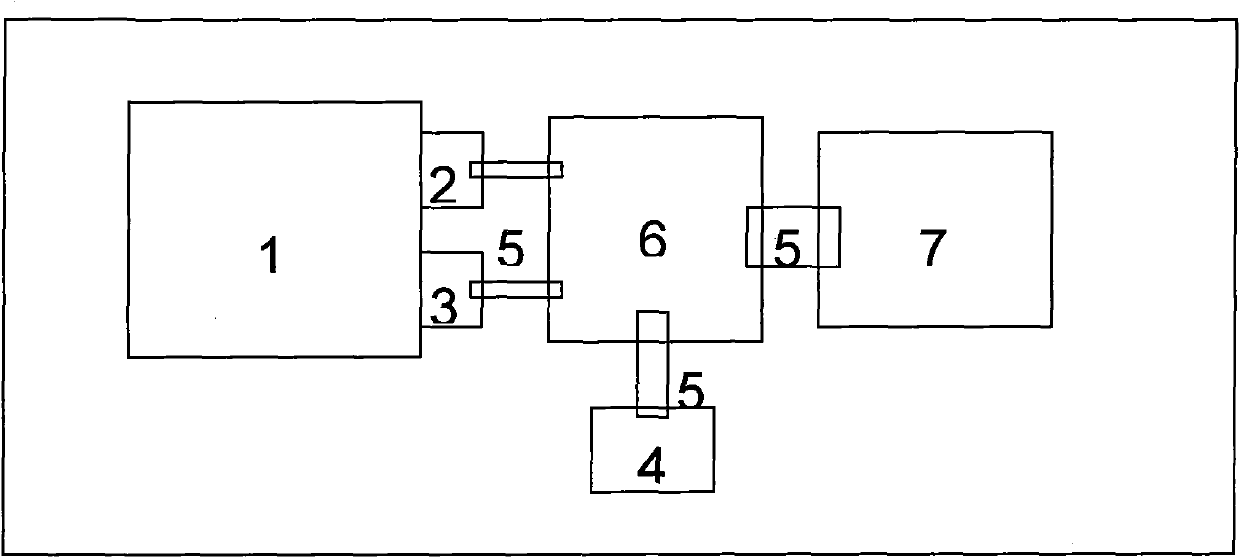

[0023] Embodiment: a kind of flexible printed paper battery anti-counterfeiting label (see figure 1 , figure 2 ), the outer packaging material of the anti-counterfeiting label adopts film plastics, i.e. the lower layer of film plastic 8 and the upper layer of film plastic 9, which are bendable and easy to stick or place on commodities or other articles of various materials and surface shapes. The front paper battery 10, which is a component of the anti-counterfeit label, is uniformly printed on a large area by a printing machine and matching special printing material ink cartridges and inkjet equipment, and is cut into an anti-counterfeit label of required size and shape by a die-cutting machine. The paper battery part is mainly composed of thin film battery main body 1 (Power paper STD-20 paper battery, Power paper official website http: / / www.powerpaper.com ) and battery positive and negative poles 2 and 3, with a thickness of 0.7 mm, a DC power supply voltage of 1.5 volts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com