Carbon fiber-resin composite core for overhead cable

A resin composite material and composite material core technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of low transverse strength, complicated manufacturing process, etc., achieve the effect of reducing weight per unit length and improving flattening resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

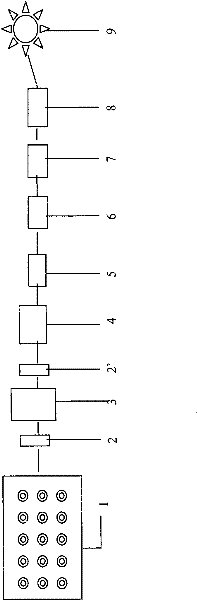

Image

Examples

Embodiment

[0036] Raw material specifications:

[0037] Carbon fiber: Torayca T700SC-12K, tensile strength 4900MPa, tensile modulus 235GPa, strain 2.1%, monofilament diameter 7μ;

[0038] Epoxy resin system: viscosity 1200-2000cP at 25℃, density 1.2g / cm at 25℃ 3 ;

[0039] Glass fiber mat: MFS-50;

[0040] Fiberglass stitched felt: GF / 960-50-35.

[0041] figure 1 It is a schematic diagram of the production equipment for producing the composite core of the present invention. like figure 1 As shown, the carbon fibers are unwound from the creel 1 with the tension adjustment device at a constant tension, pass through the yarn guide plate 2 in sequence, and pass through the preheating box 3 in parallel, where the moisture is removed and softened by heating Sizing agent on carbon fiber surface to improve resin infiltration effect. Then pass through the yarn guide plate 2' and enter the glue tank 4. After sufficient infiltration, it enters the preform mold 5 . At this stage, the excess...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com