Bonding pad, manufacturing method and bonding method thereof

A manufacturing method and bonding pad technology, which are used in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc. The effect of wire package failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

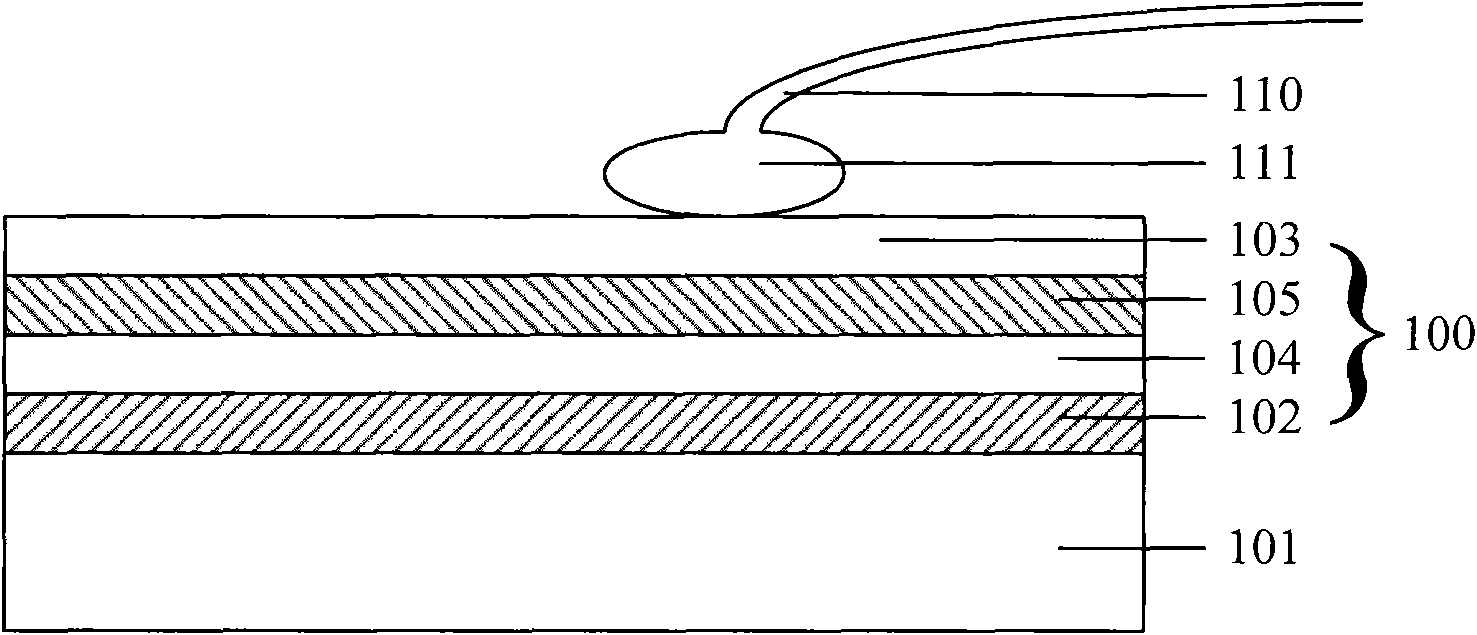

[0032] The inventors of the present invention found that in order to improve the hardness of the bonding pad and prevent the welding equipment from deforming the bonding pad during bonding, it is necessary to add an additional support metal layer with higher hardness to increase the hardness of the entire bonding pad. .

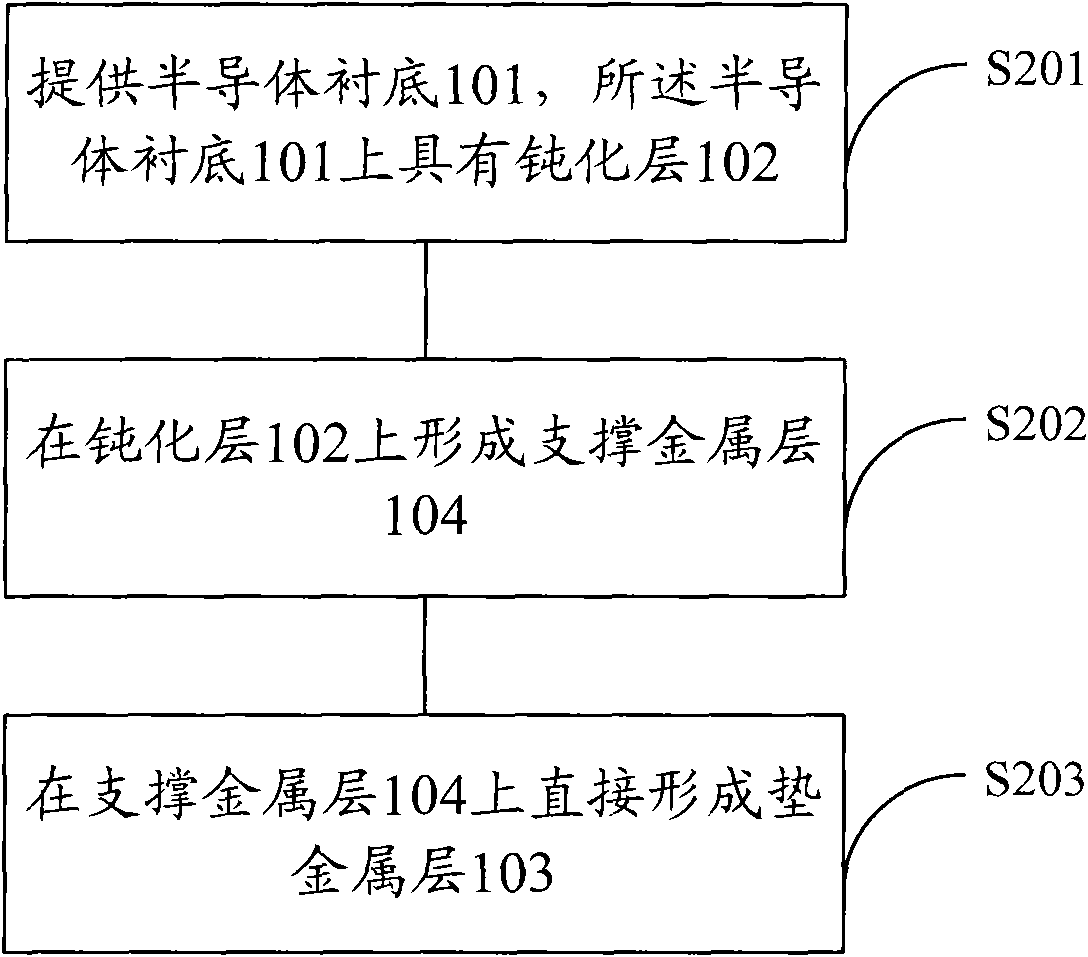

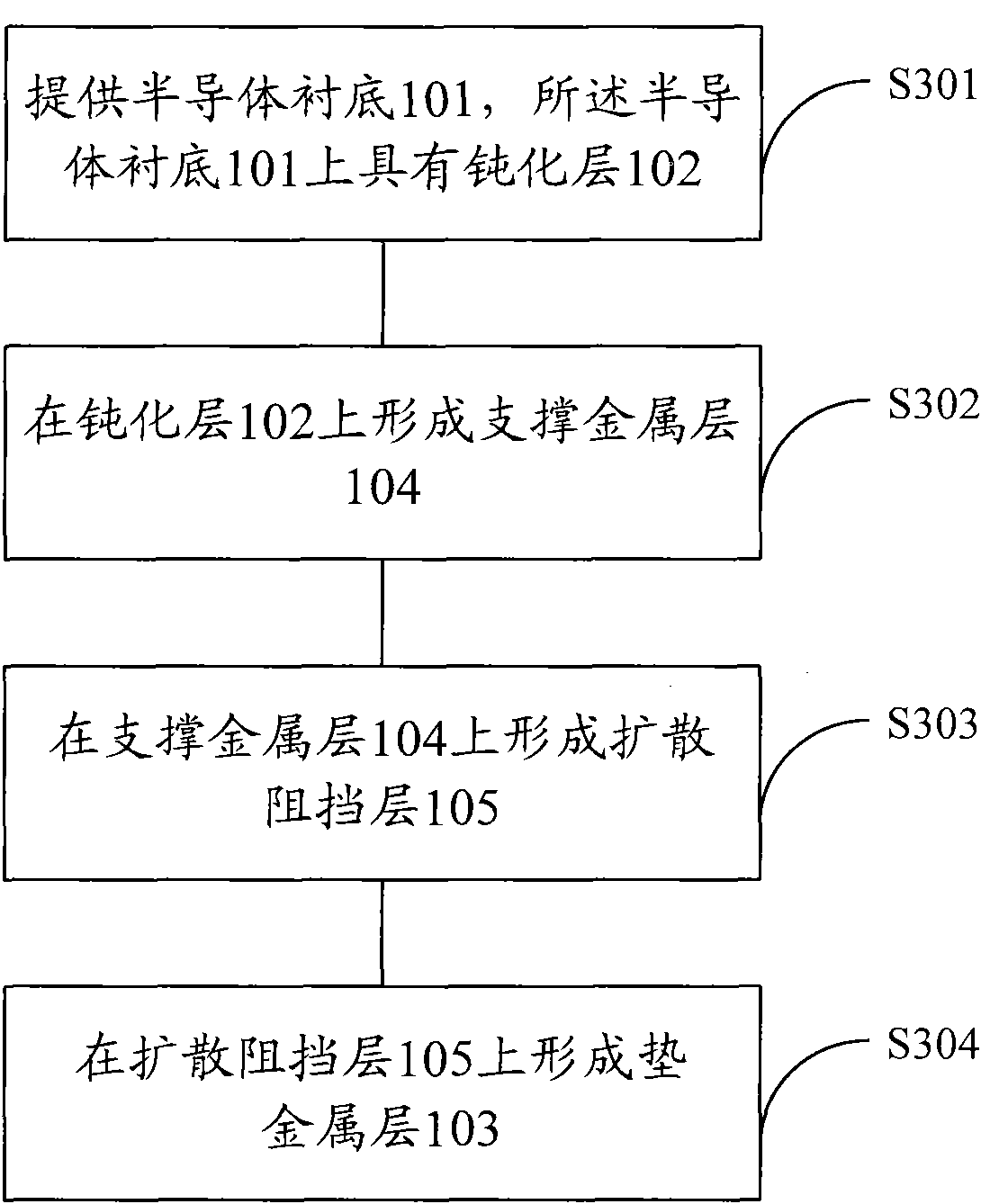

[0033] Therefore, if figure 1 As shown, the present invention provides a new bonding pad 100 for a semiconductor chip, which includes a passivation layer 102 on a semiconductor substrate 101 and a pad metal layer 103 on the passivation layer 102 . In addition, the bonding pad 100 further includes a support metal layer 104 disposed between the pad metal layer 103 and the passivation layer 102 .

[0034] Wherein, the pad metal layer 103 is used for direct bonding with the wire 110. In one embodiment of the present invention, the material of the wire 110 is Au. Correspondingly, the material of the pad metal layer 103 can be preferably bonded with Au. And lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com