Hot rolled steel sheet having superior hot press forming property and high tensile strength, formed article using the steel sheet and method for manufacturing the steel sheet and the formed article

A high-tensile strength, hot-press forming technology, applied in the field of hot-rolled steel sheets, can solve the problems of expensive cold-rolled steel sheets, high cost burden, and low productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0054] Exemplary embodiments of the present invention will be described in more detail hereinafter.

Embodiment

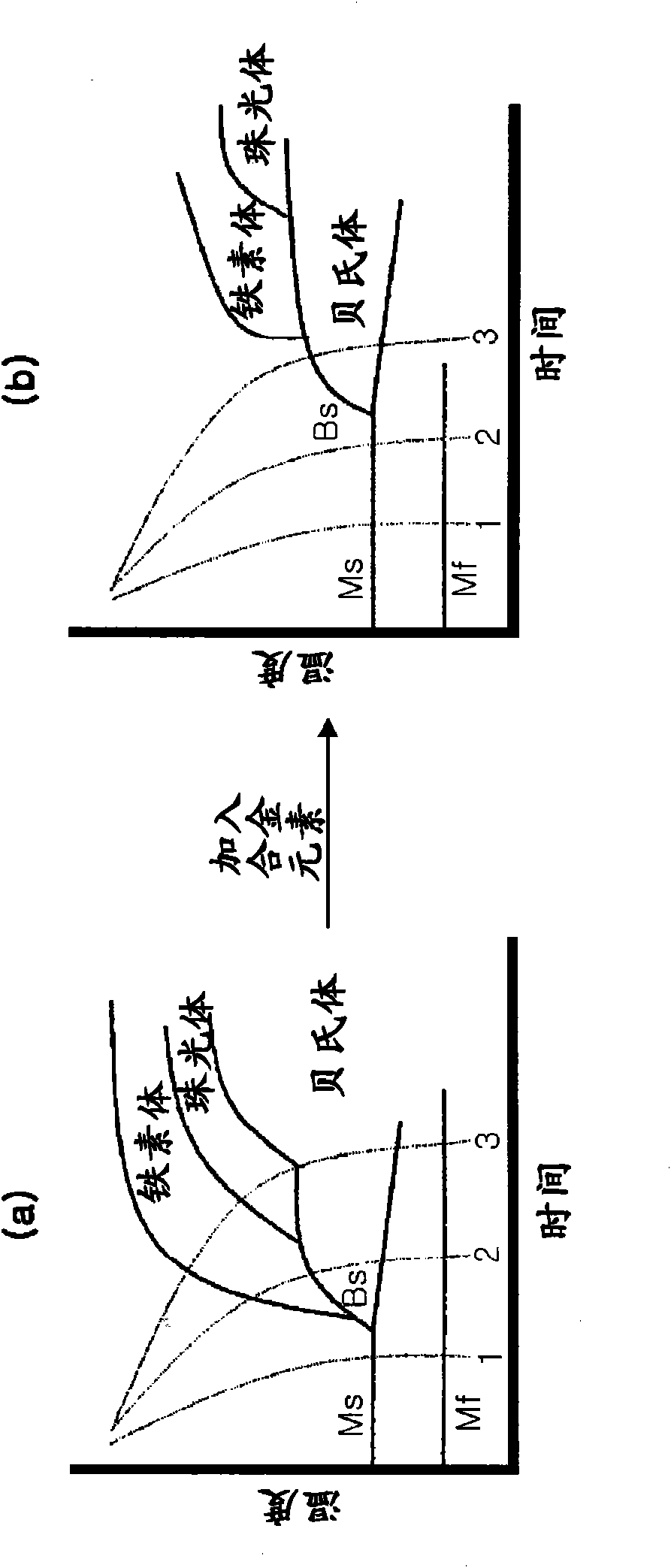

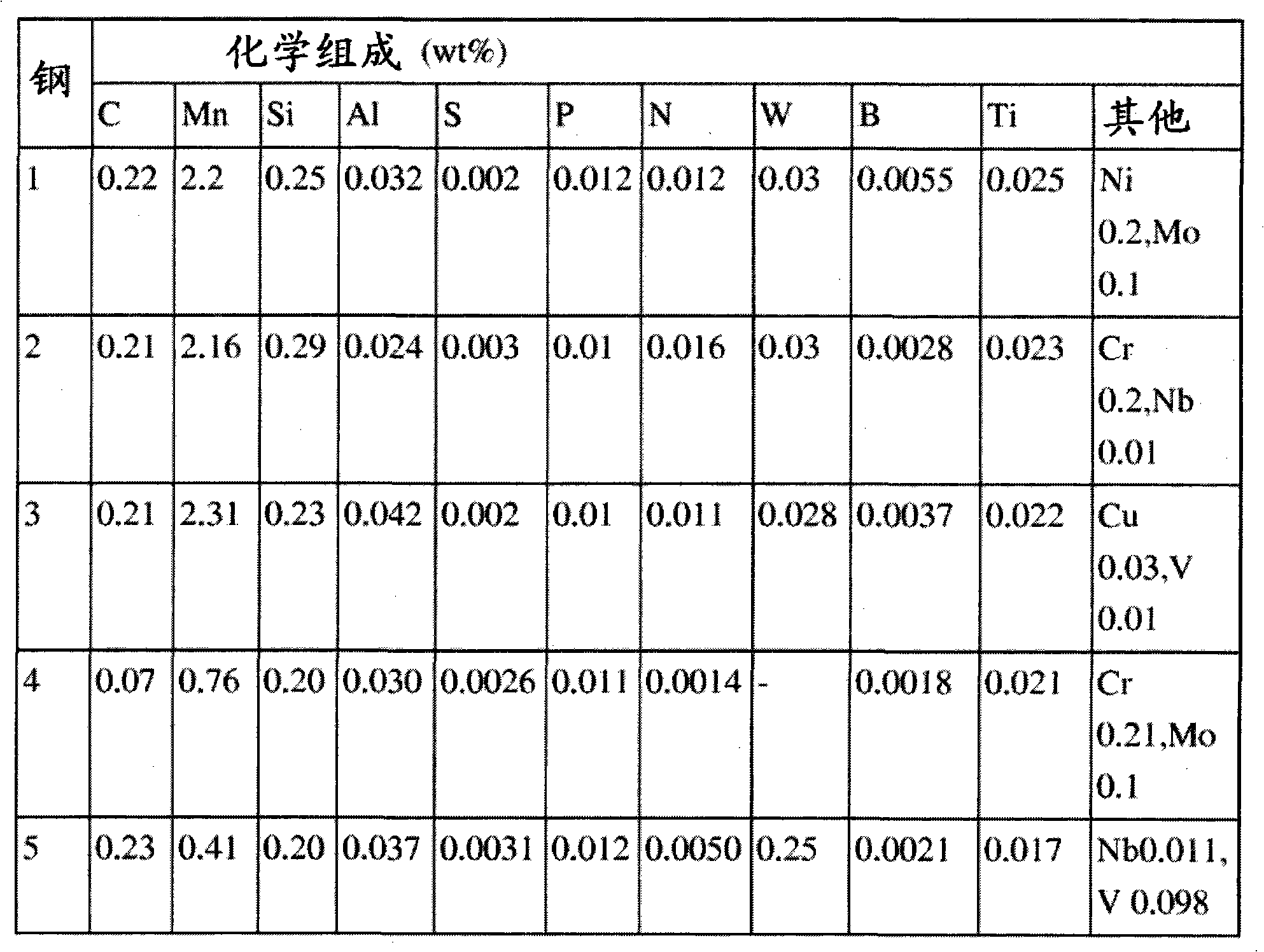

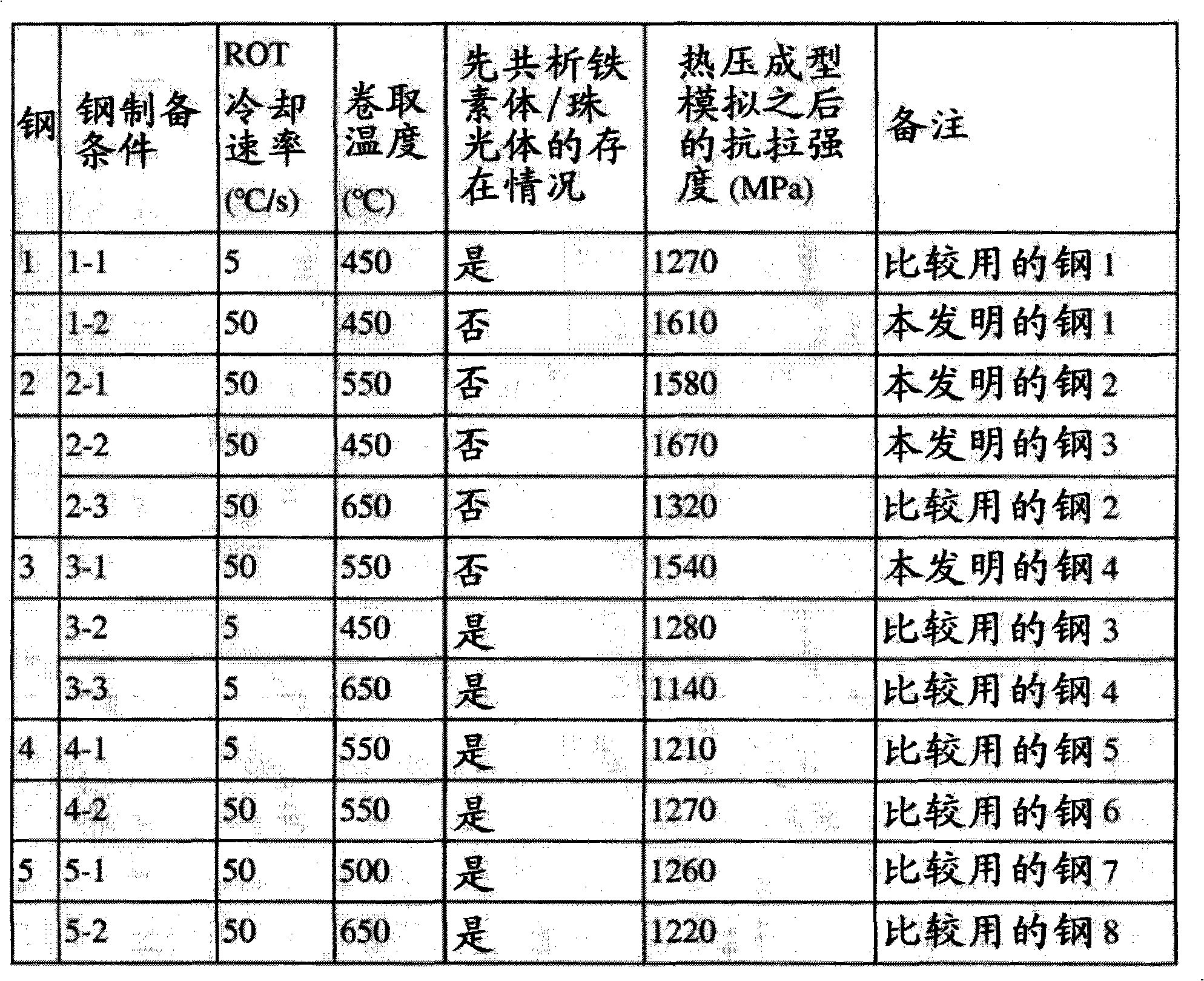

[0056] Steel ingots having the compositions listed in Table 1 below were prepared by vacuum induction melting. Herein, the prepared steel ingot has a thickness of 60 mm and a width of 175 mm. The steel ingot was reheated at 1200° C. for 1 hour, and hot rolled so that its hot rolled thickness was 1.6 mm. The hot rolling termination temperature is higher than the Ar3 transformation point. Then, the hot coiling process was simulated by cooling the reheated ingot to the desired hot coiling temperature at ROT cooling rates of 5°C / s and 50°C / s, keeping the cooled ingot In a furnace preheated to 400-650°C for 1 hour and cool the ingot in the furnace. The hot press forming simulation was performed using a dilatometer by cooling a steel ingot at a cooling rate of 20°C / s, and measuring the hardness of the steel ingot to calculate the tensile strength of the steel ingot. The results are listed in Table 2 below.

[0057]Among the steels listed in Table 1 below, Steels 1, 2, and 3 fall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com