A heat exchanger

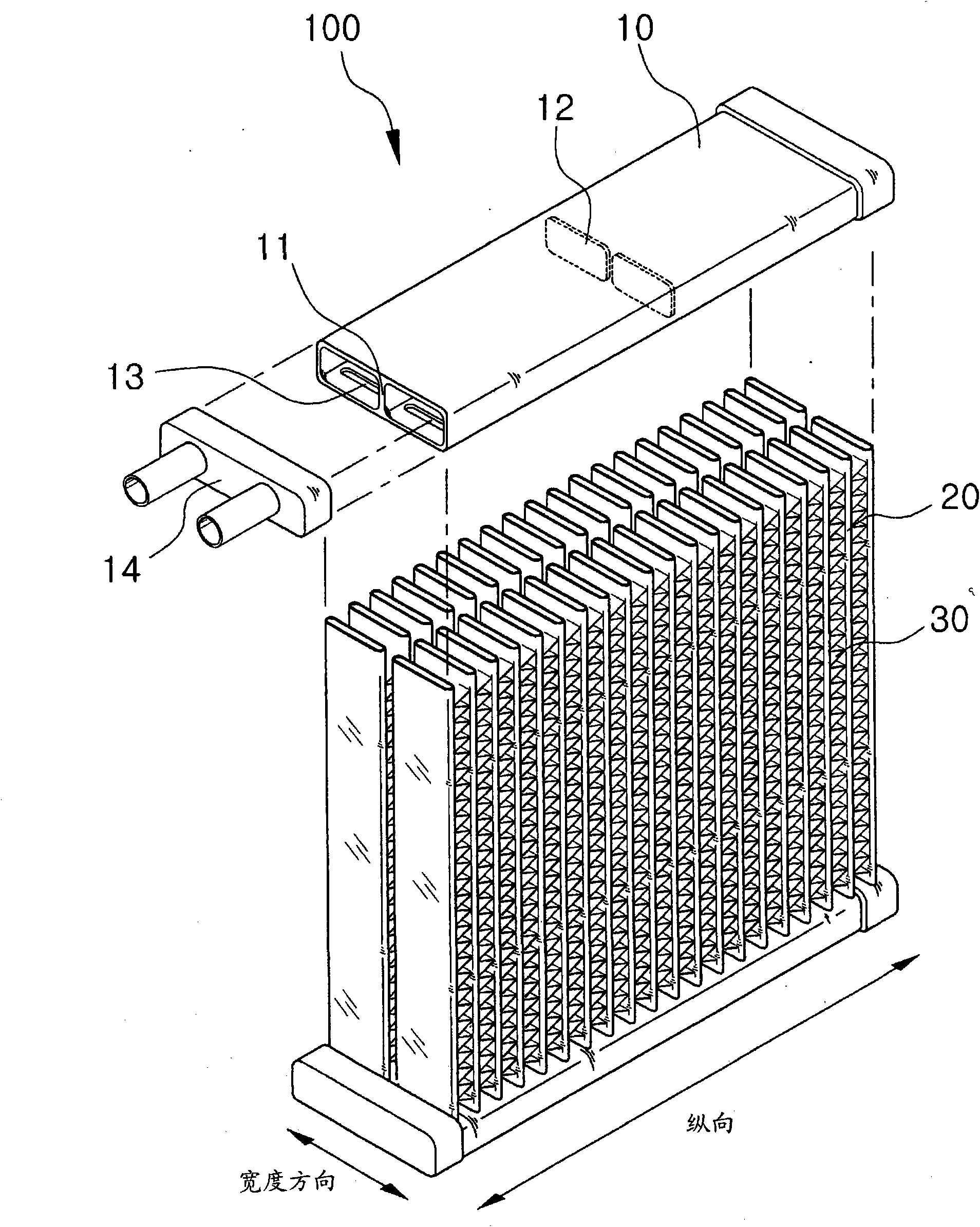

一种热交换器、散热片的技术,应用在热交换设备、换热器类型、换热器外壳等方向,能够解决热交换器结构复杂、热交换性能下降、温度分布不均匀等问题,达到提高热交换性能、改善流动、容易设计和制造的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

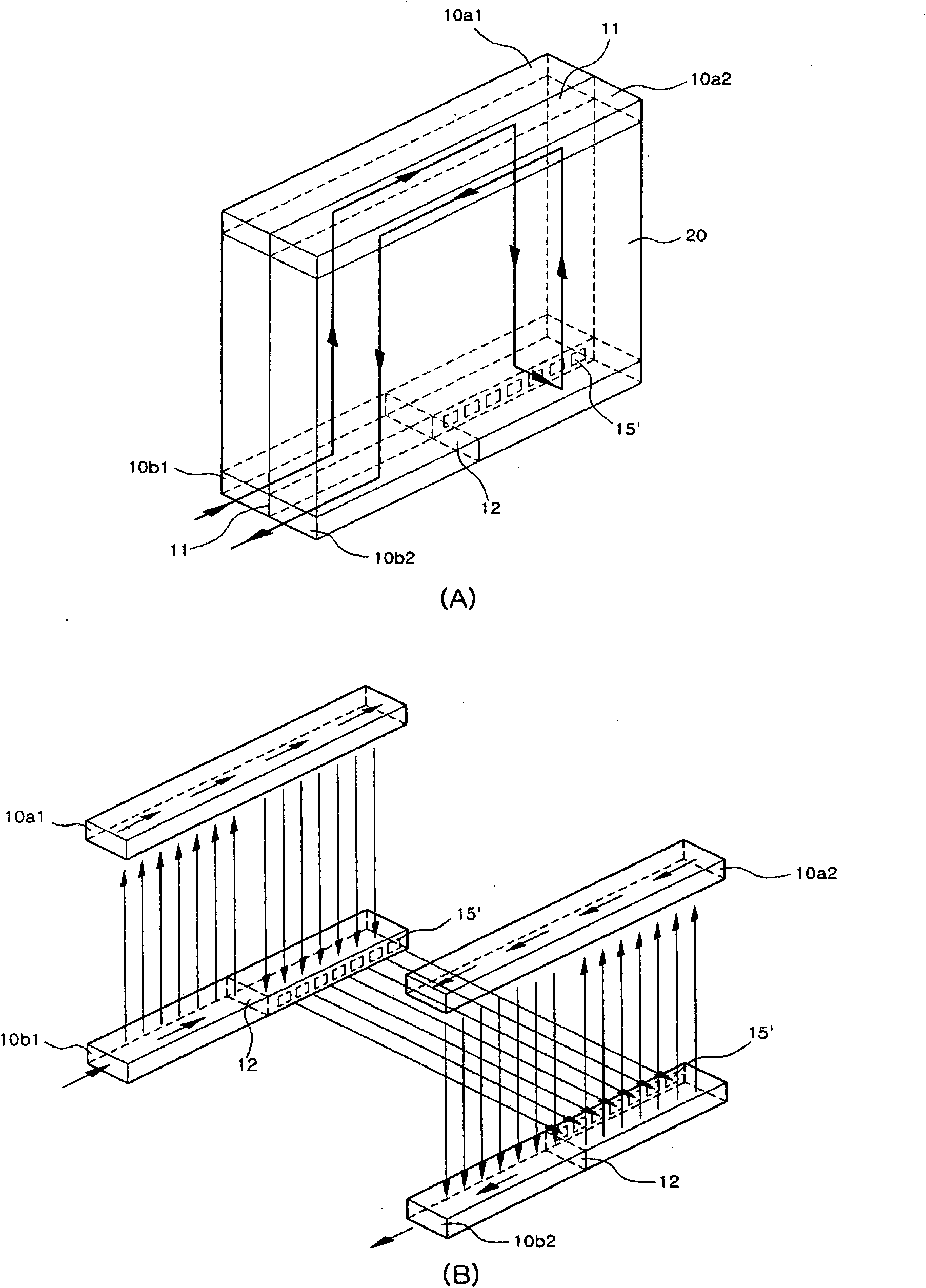

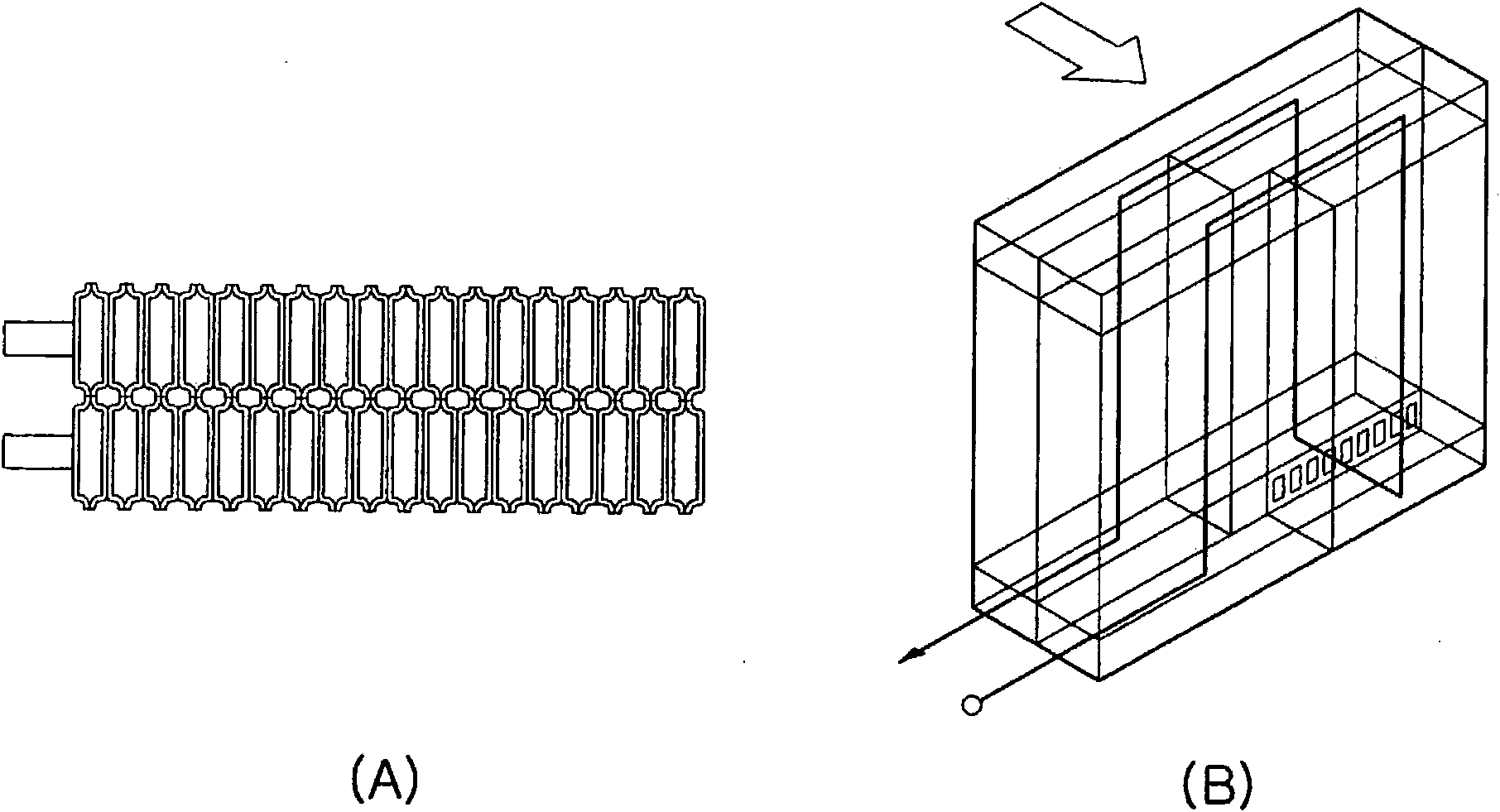

[0052] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0053] Figure 4 is a view showing the structure of the communication hole in the heat exchanger according to the present invention, wherein, Figure 4 A shows the structure of the communication hole according to the first embodiment of the present invention, Figure 4 B shows the structure of the communication hole according to the second embodiment of the present invention, Figure 4 C shows the structure of the communication hole according to the second embodiment of the present invention. As mentioned above, the heat exchanger switches the phase of the refrigerant through heat exchange (from liquid to gas in the evaporator and from gas to liquid in the condenser) and then discharges the refrigerant. In order to perform heat exchange efficiently, it is preferable that the core (ie, the portion including the tubes and fins) has a uniform temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com