Ingot casting device for automatically clearing impurity and finishing appearance

A technology for automatic removal of impurities, which is applied to the field of automatic removal of impurities in the shape of the ingot casting device, can solve the problems of high labor intensity, low work efficiency, dangerous and difficult working environment, etc., to reduce labor intensity, improve work efficiency, improve Worker Dangerous Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical scheme of the present invention will be further described below in conjunction with the drawings.

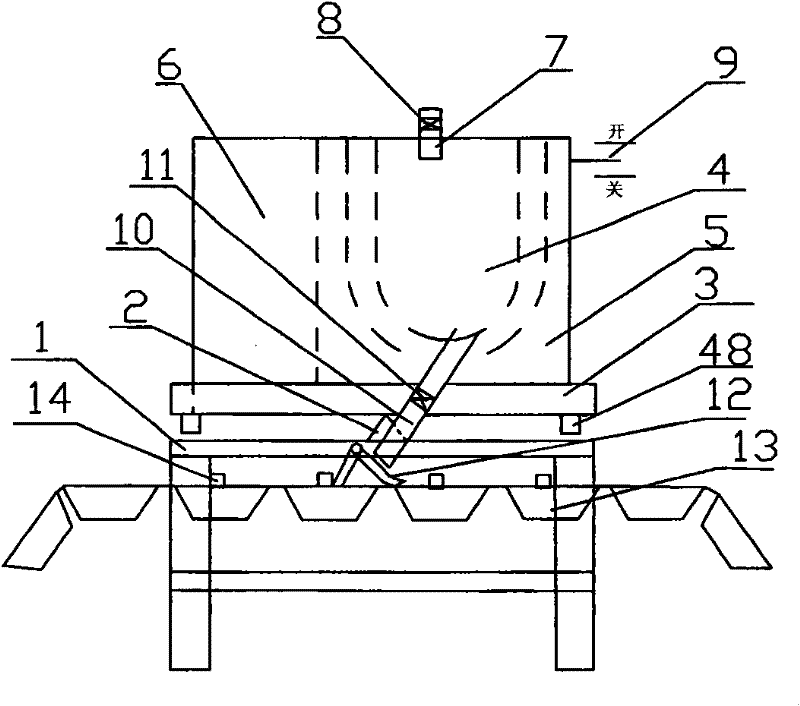

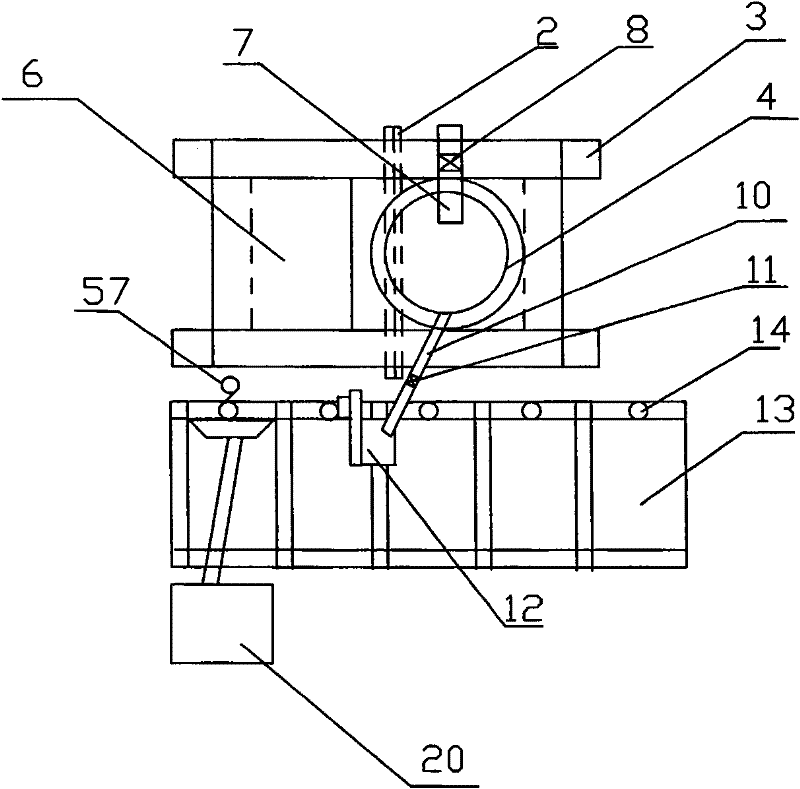

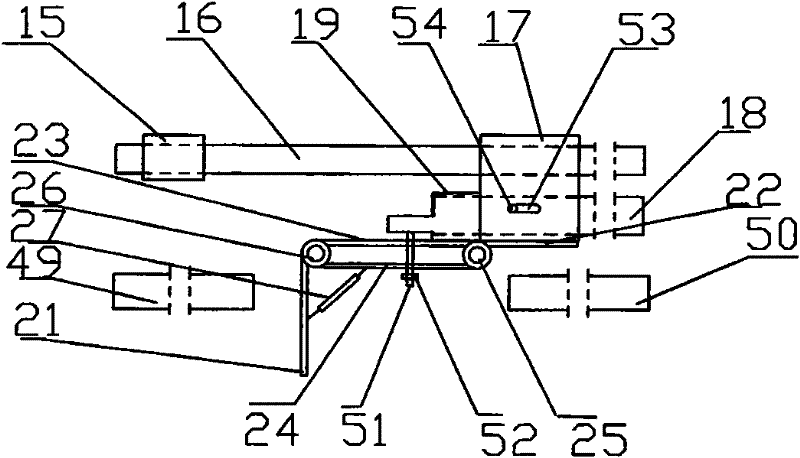

[0026] Such as figure 1 , figure 2 It is a schematic diagram of the structure of the casting part of the present invention. Such as figure 1 , figure 2 As shown, the casting part includes a base bracket (1), a triangular fulcrum (2), a channel steel base (3), a liquid storage pot (4) and a counterweight box (6); a liquid storage pot (4) and a counterweight box (6) Install the channel steel base (3), the channel steel base (3) is placed on the base support (1) through the triangular fulcrum (2), and the two ends of the channel steel base (3) are respectively provided with positioning fulcrums (48); The outer side of the pot (4) is provided with an insulation layer (5), one end is provided with a balance switch (9), the upper end is provided with an inlet pipe (7), and the inlet pipe (7) is provided with an inlet valve (8) and an inlet valve (8) Electrically c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com