Patents

Literature

30results about How to "Manual operation is not required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

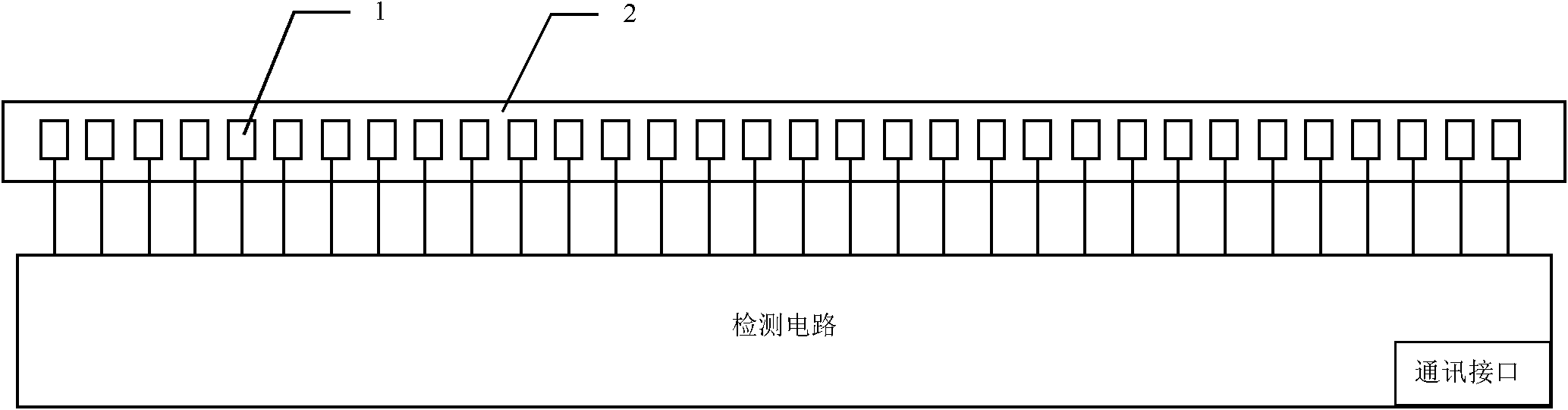

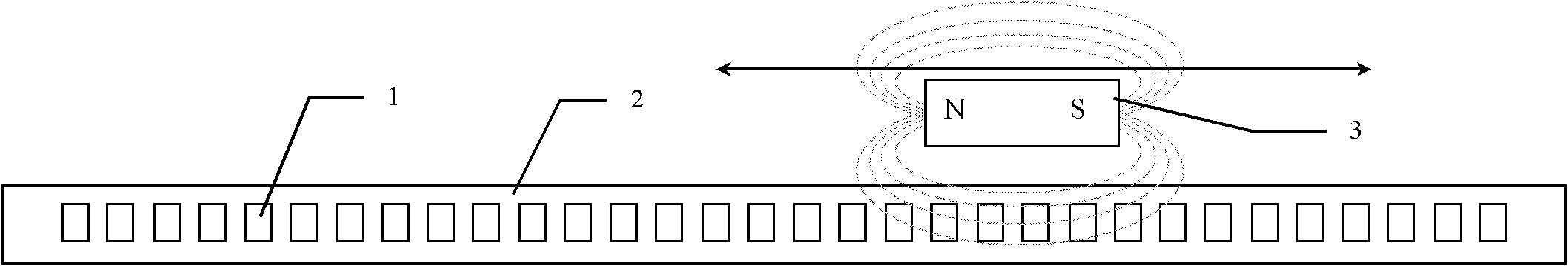

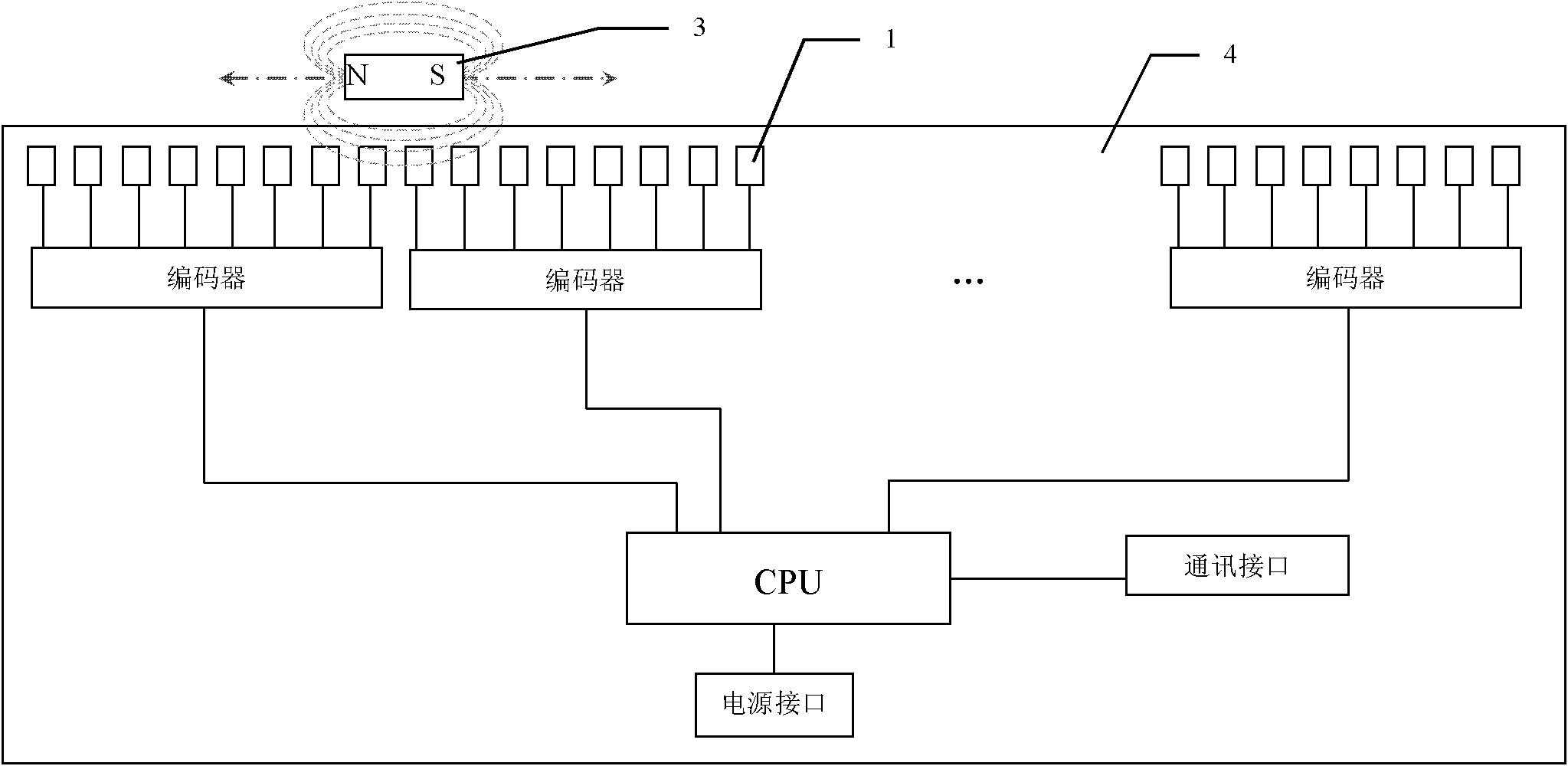

Magnet displacement sensor

InactiveCN102519349ASimple structureLow costUsing electrical meansCommunication interfaceLinear arrays

The invention relates to a magnet displacement sensor, which is used for measuring displacement of a magnet without contacting with the sensor and comprises a plurality of magnetic sensitive elements, a strip-shaped supporting part and a detecting circuit. The magnetic sensitive elements are fixedly arranged on the strip-shaped supporting part and are arranged at certain intervals along a length direction to form a uniformly distributed linear array, each interval ranges from 1 millimeter to 20 millimeters, an input end of the detecting circuit is connected with the magnetic sensitive elements so as to detect output statuses of the magnetic sensitive elements within a range of a magnetic field effect when the magnet moves along the length direction parallel to the strip-shaped supporting part, and an output end of the detecting circuit is provided with a communication interface. The magnet displacement sensor can realize automatic intelligent measurement, and has the advantages of simplicity in structure and low cost.

Owner:CHINA GEOKON INSTR

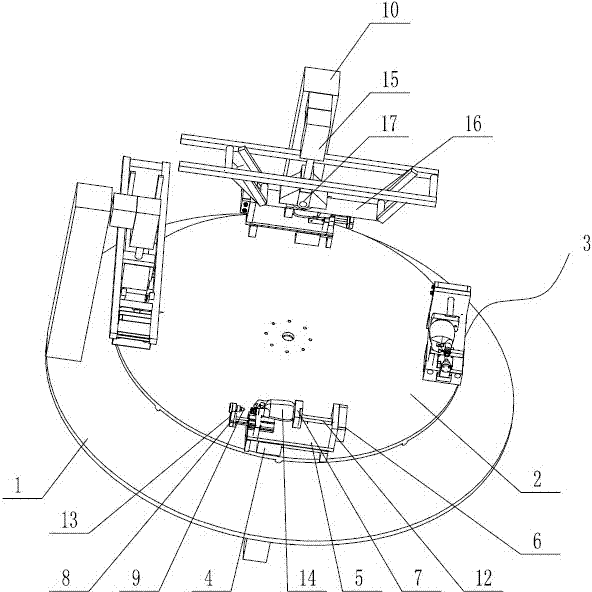

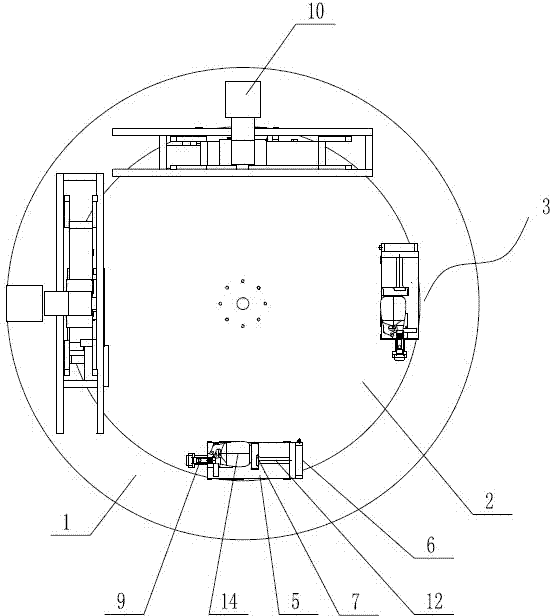

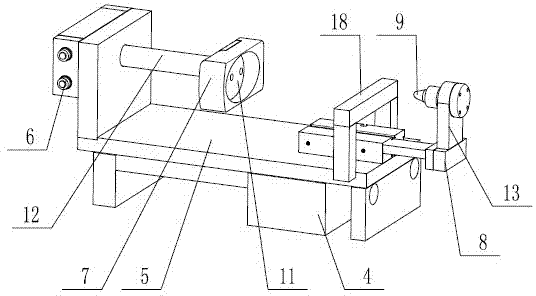

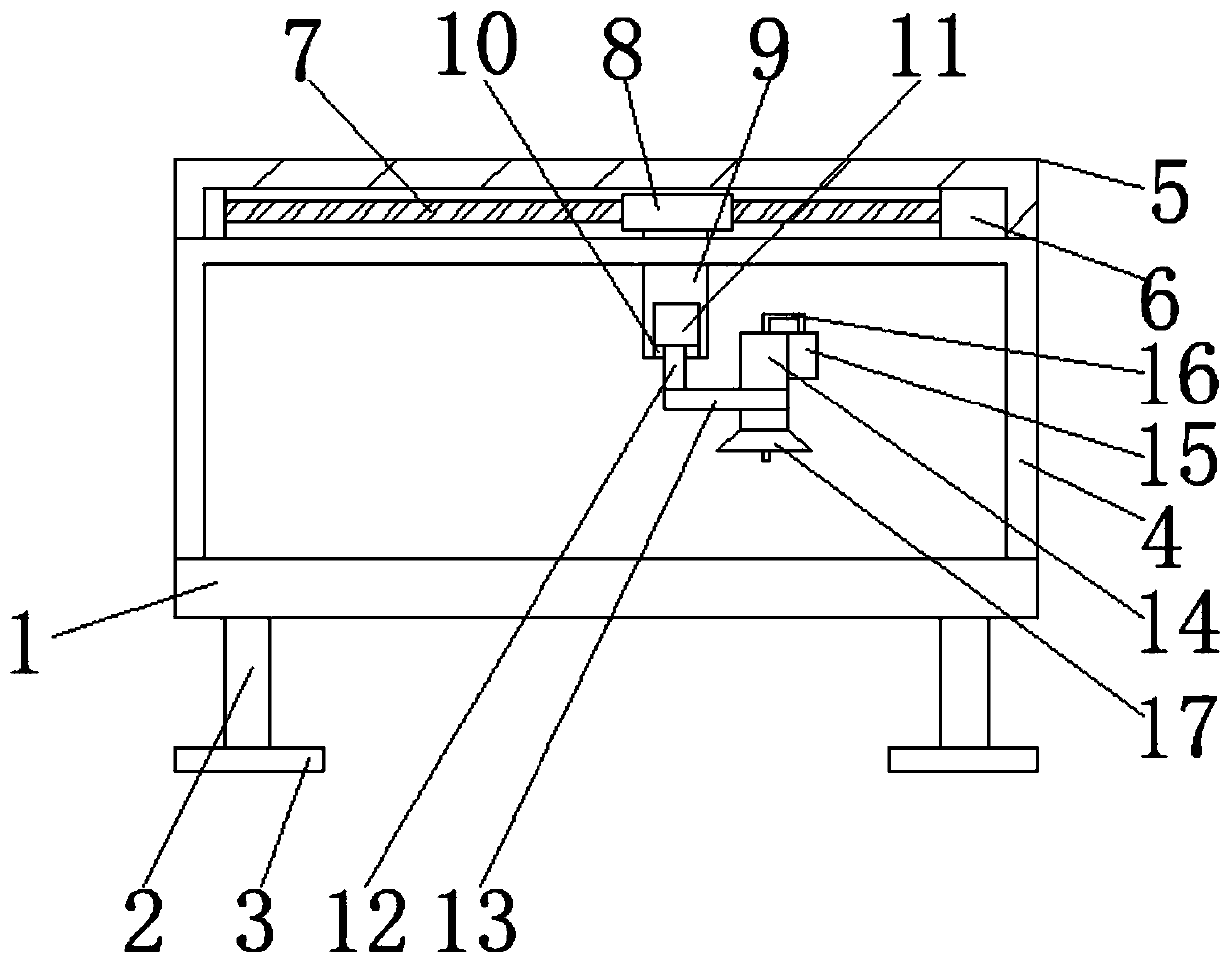

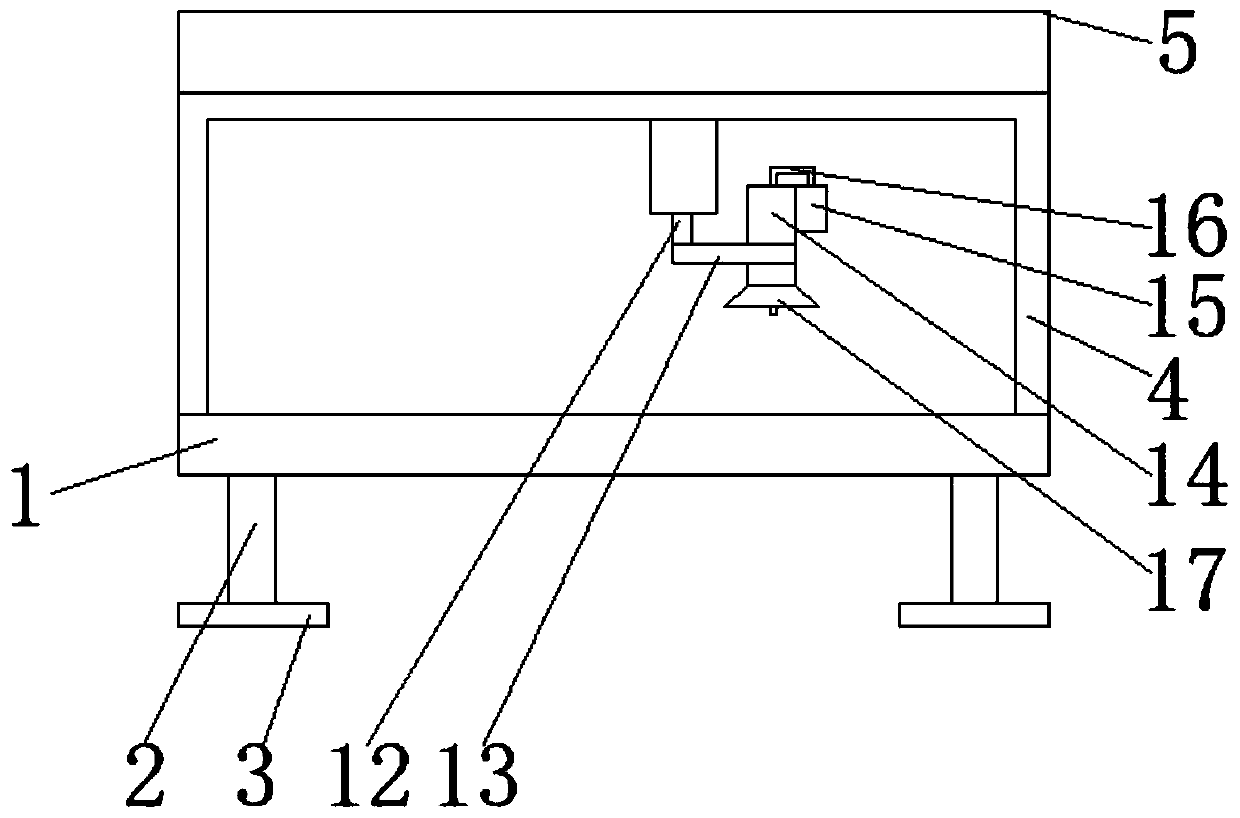

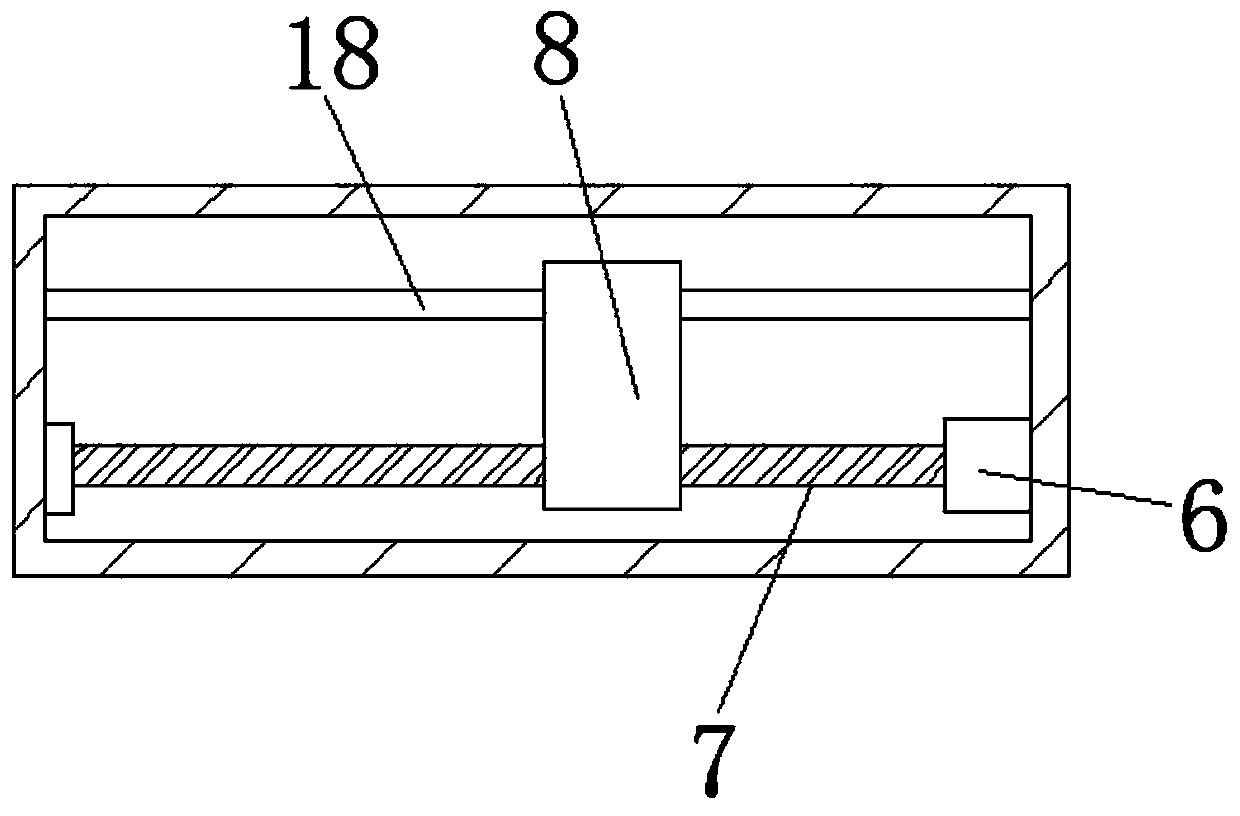

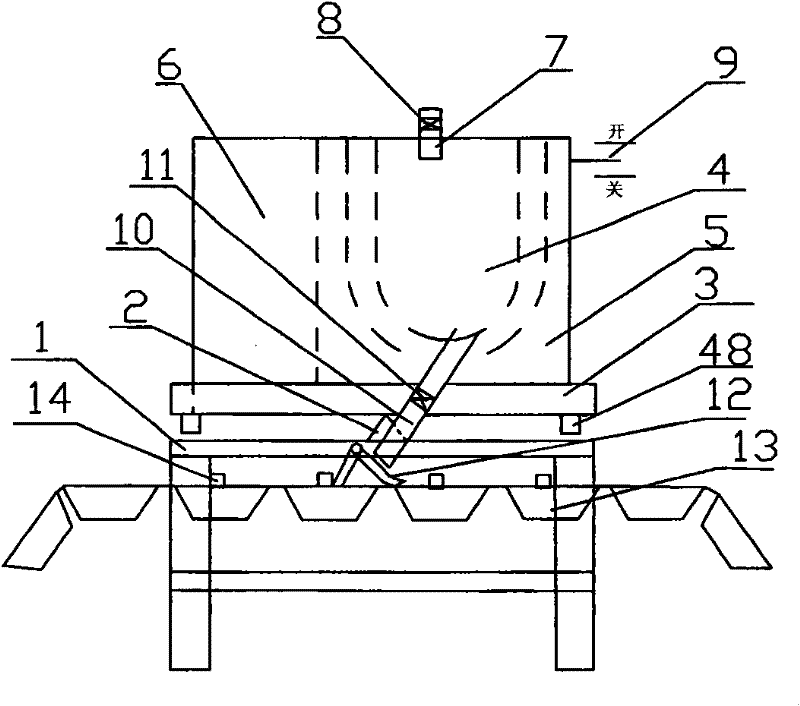

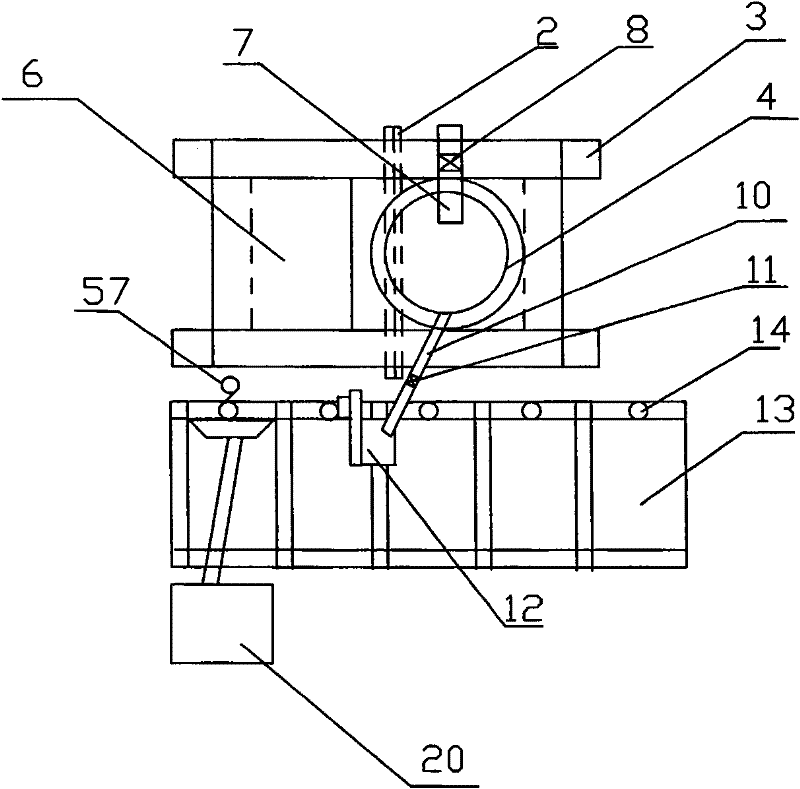

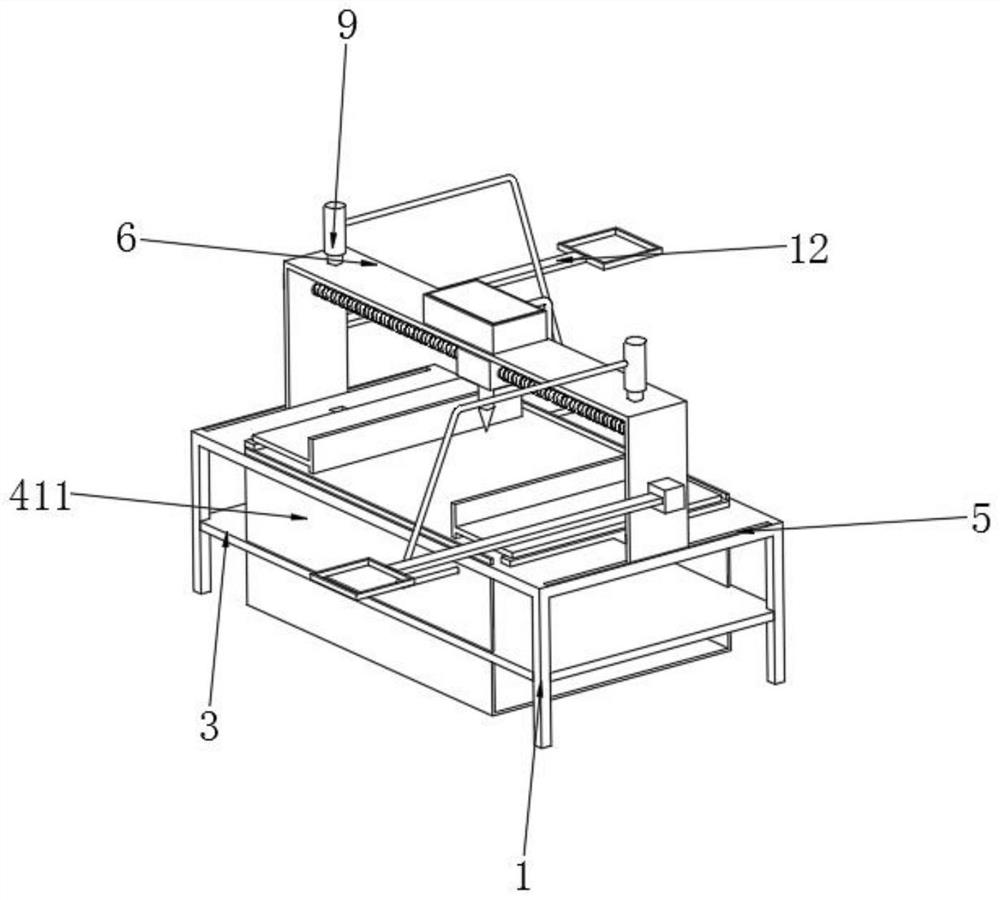

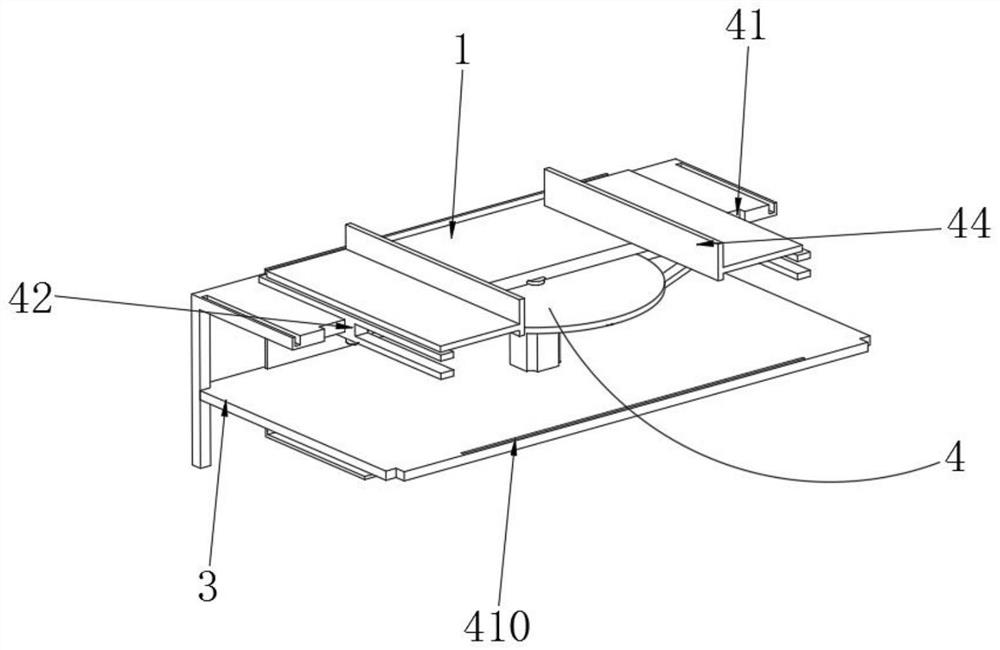

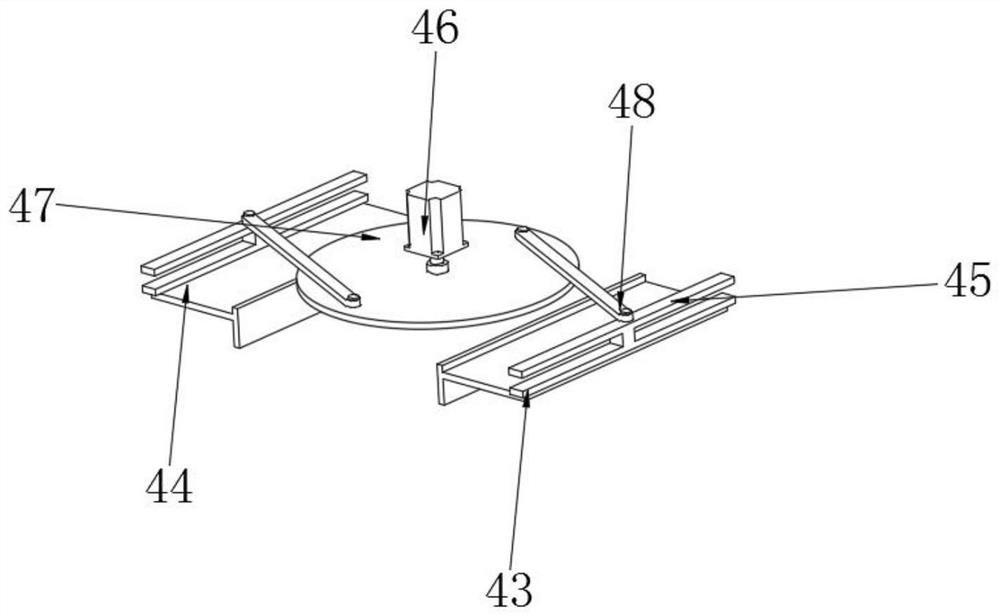

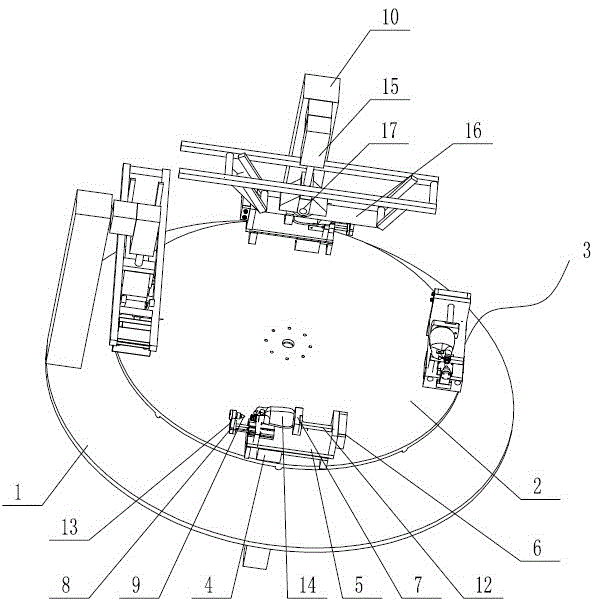

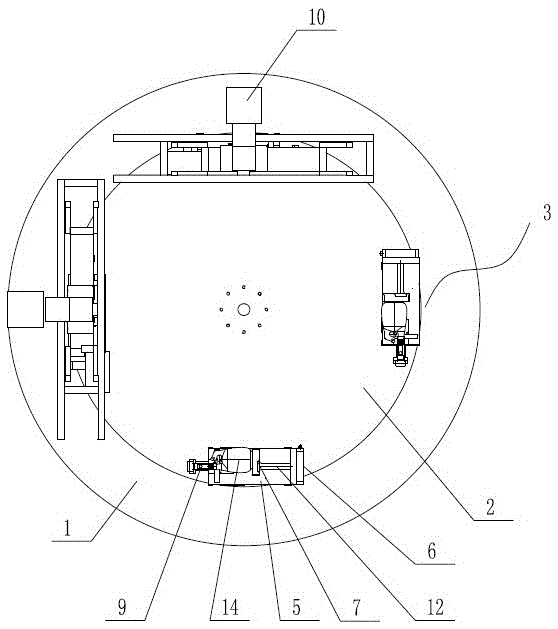

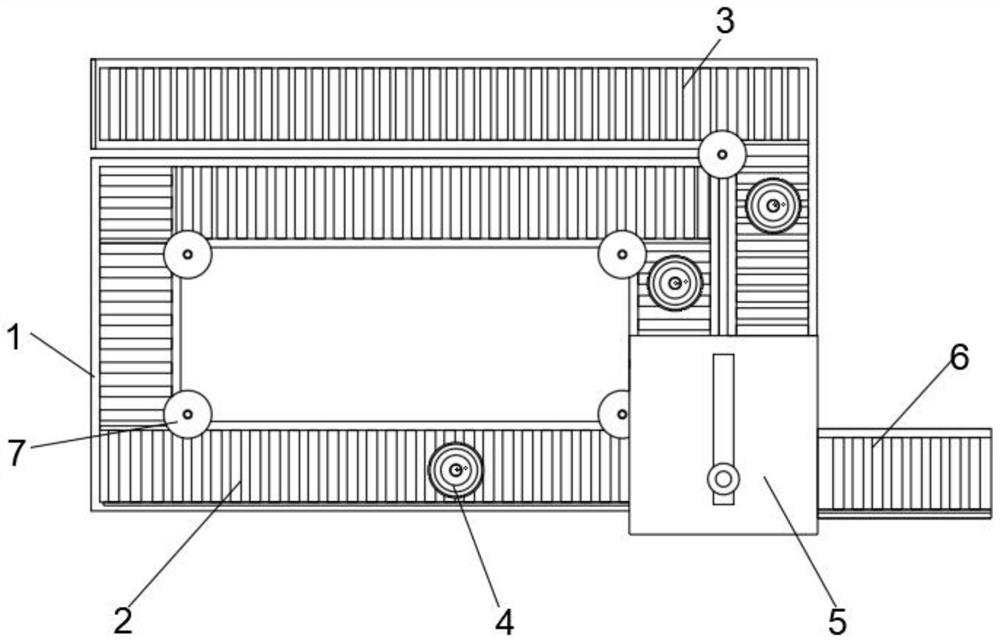

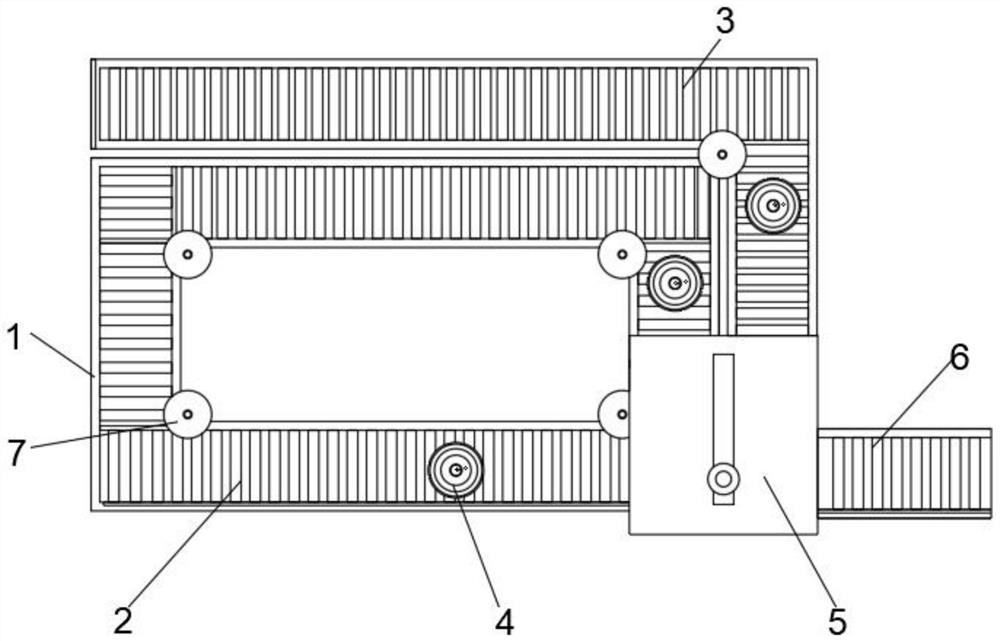

Special-shaped glass bottle double-sided brand offset printing device

ActiveCN103935115APrecise positioningGuaranteed positive contactTransfer printingProduction lineEngineering

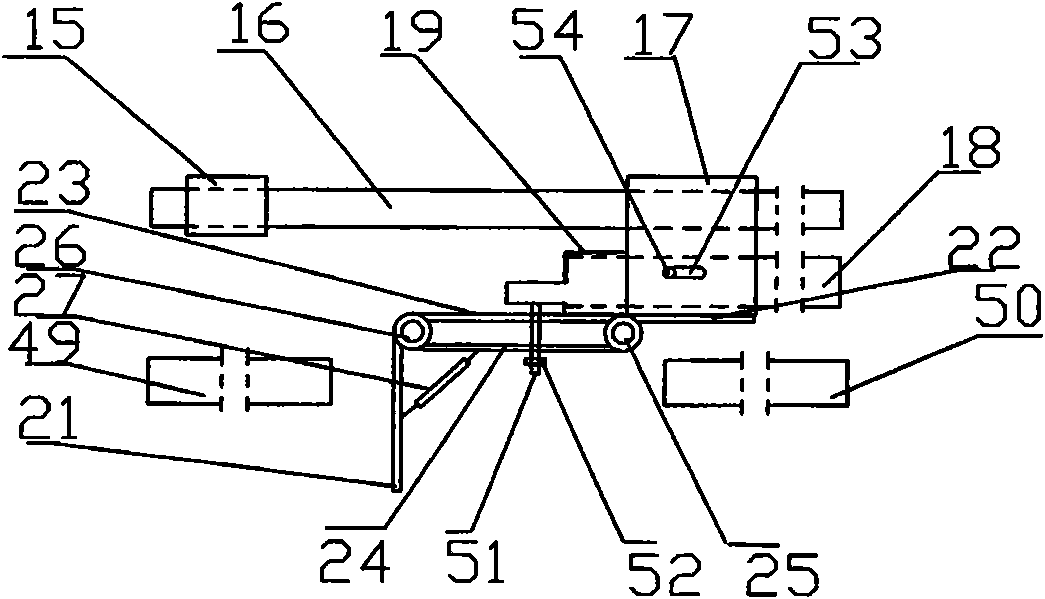

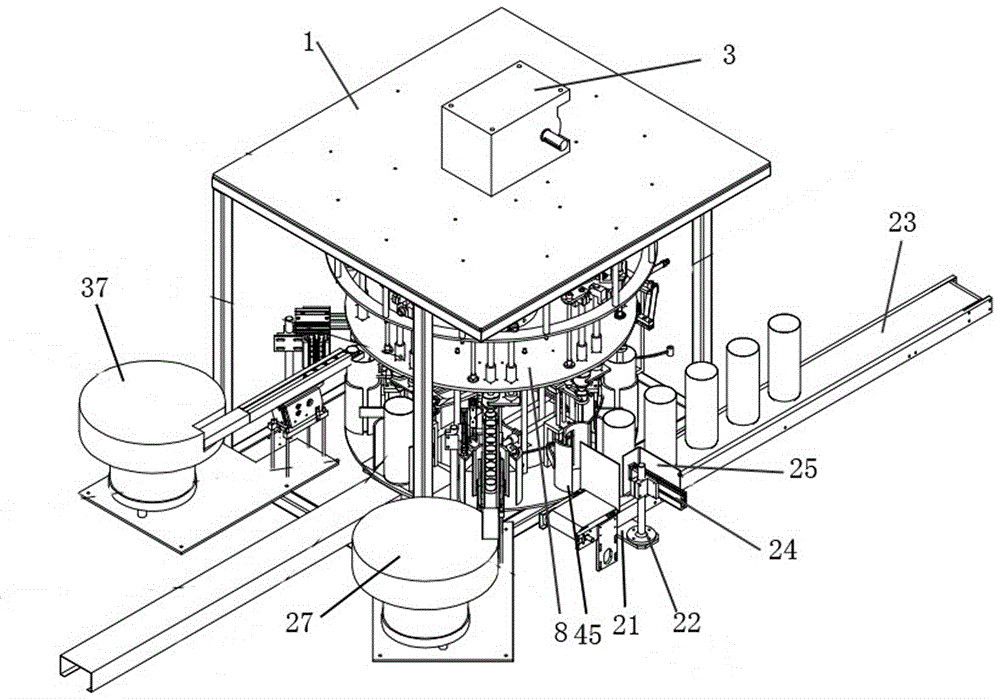

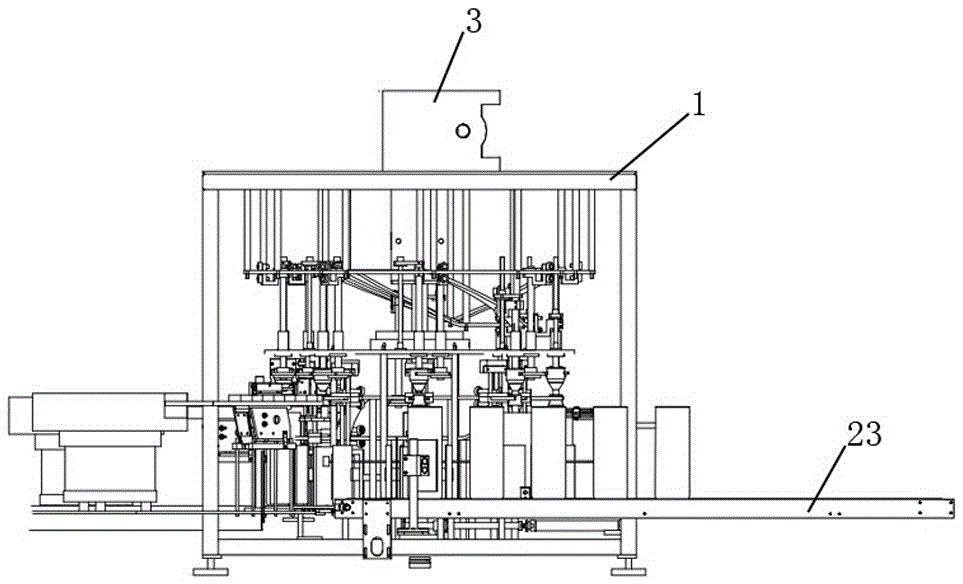

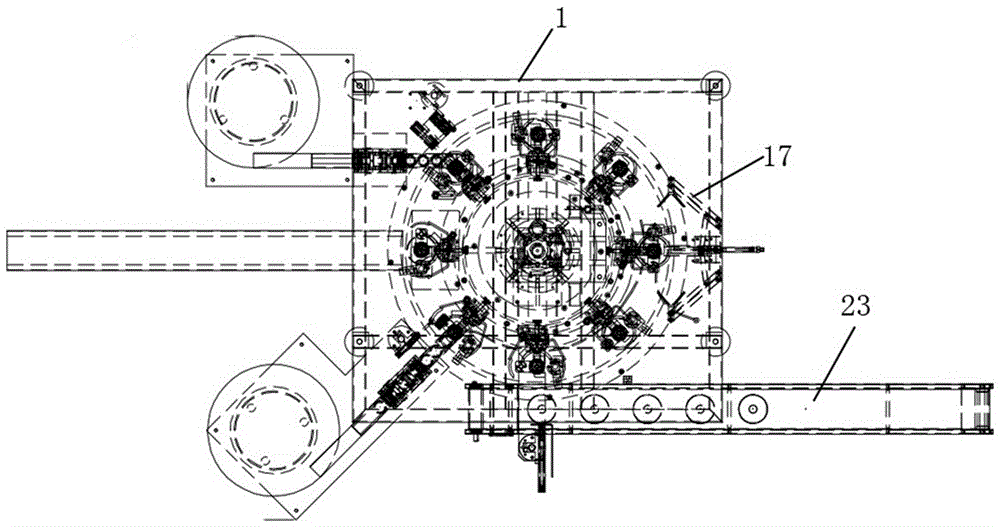

The invention discloses a special-shaped glass bottle double-sided brand offset printing device which comprises a working table. A rotating disc and a cam indexer are arranged on the working table. A plurality of special-shaped bottle clamping mechanisms are evenly distributed on the edge of the rotating disc. Each special-shaped bottle clamping mechanism comprises a horizontally-moving air cylinder, wherein a bottle body containing base frame is arranged on the horizontally-moving air cylinder, a bottle body turning shaft and a bottle bottom bearing bottom plate are installed at the tail end of the bottle body containing base frame, a pit is formed in the bottle bottom bearing bottom plate, a bottle opening bearing frame is arranged on the bottle body containing base frame, a turning driving device is connected with the outer end of the bottle body turning shaft, an ejecting air cylinder and an ejecting head are arranged at the front end of the bottle body containing base frame, and thermal printing units are correspondingly arranged at the fixed positions of the two special-shaped bottle clamping mechanisms on the working table respectively. By means of the special-shaped glass bottle double-sided brand offset printing device, manual operation is greatly reduced, production efficiency is high, the percent of pass is greatly increased, energy consumption is low, the quality is controllable, labor intensity of workers is low, and the device is suitable for automatically controlling a production line and easy to popularize.

Owner:SHANDONG HAIDA ROBOT TECH CO LTD

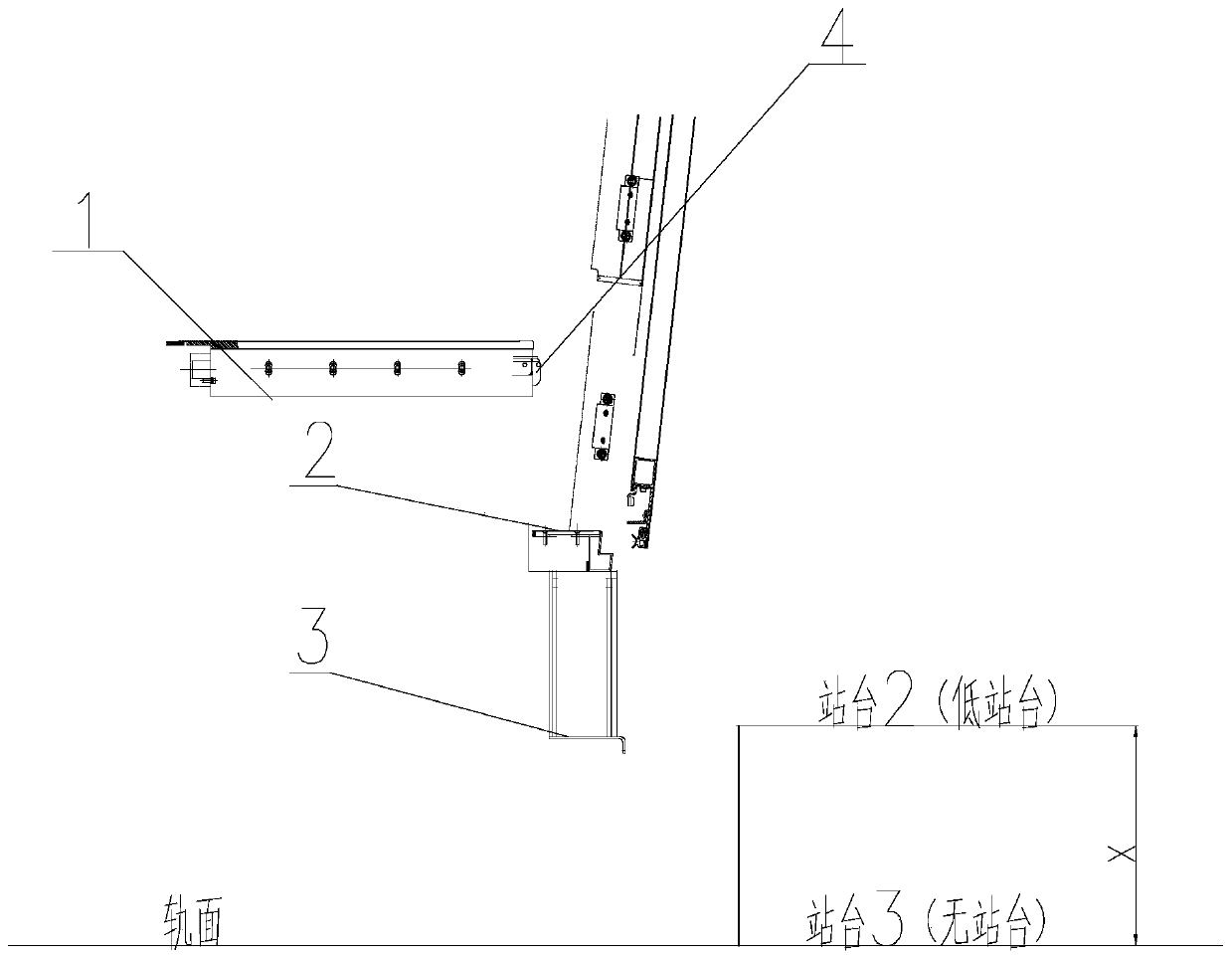

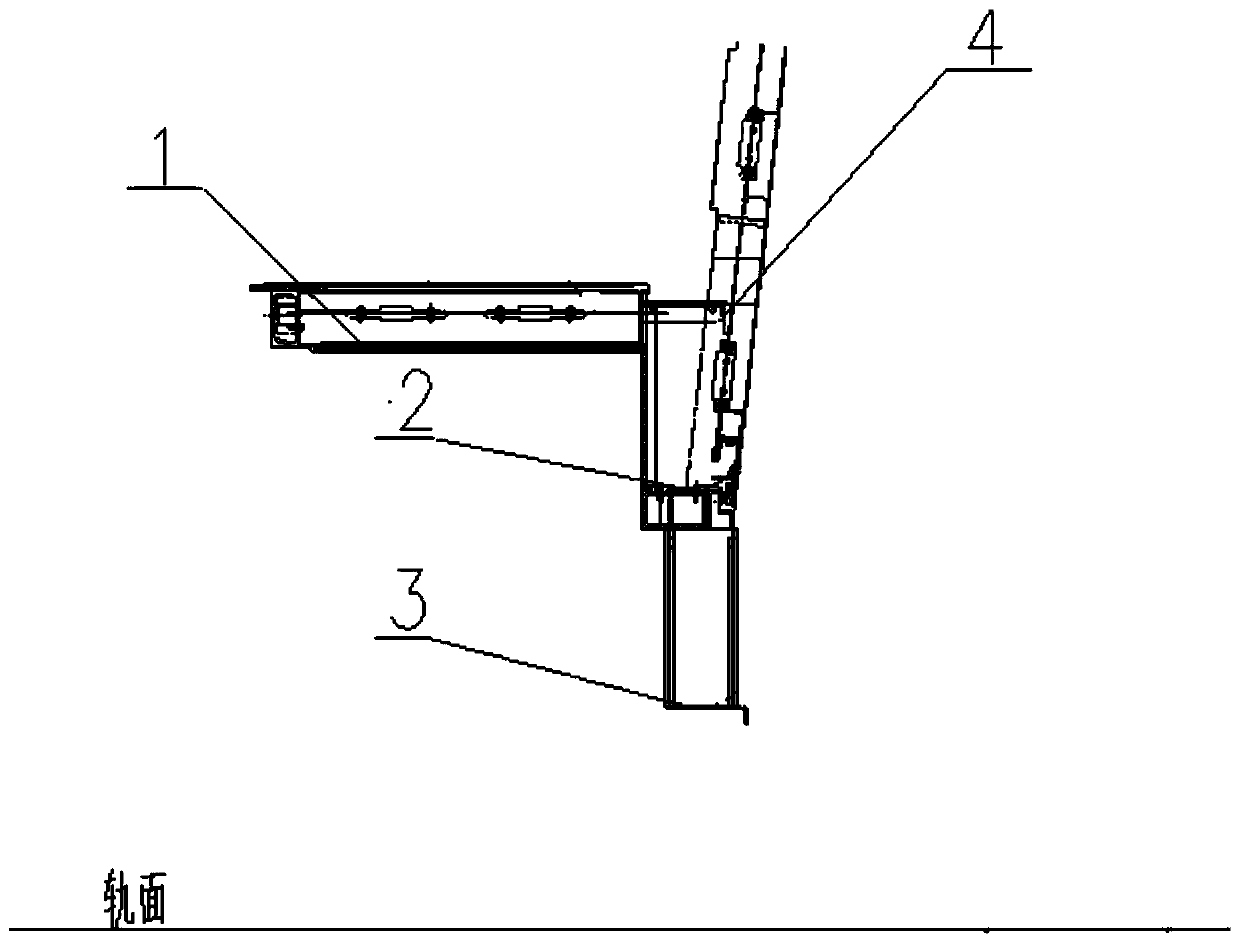

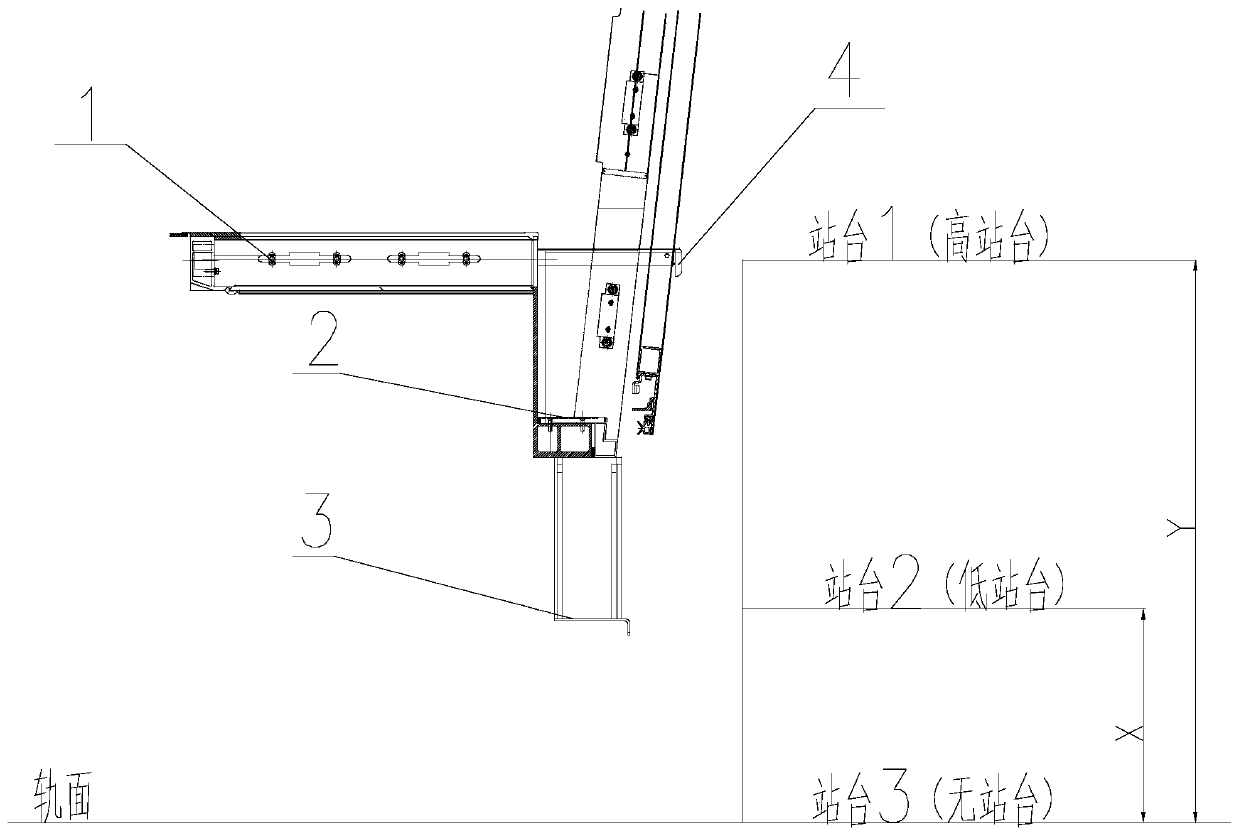

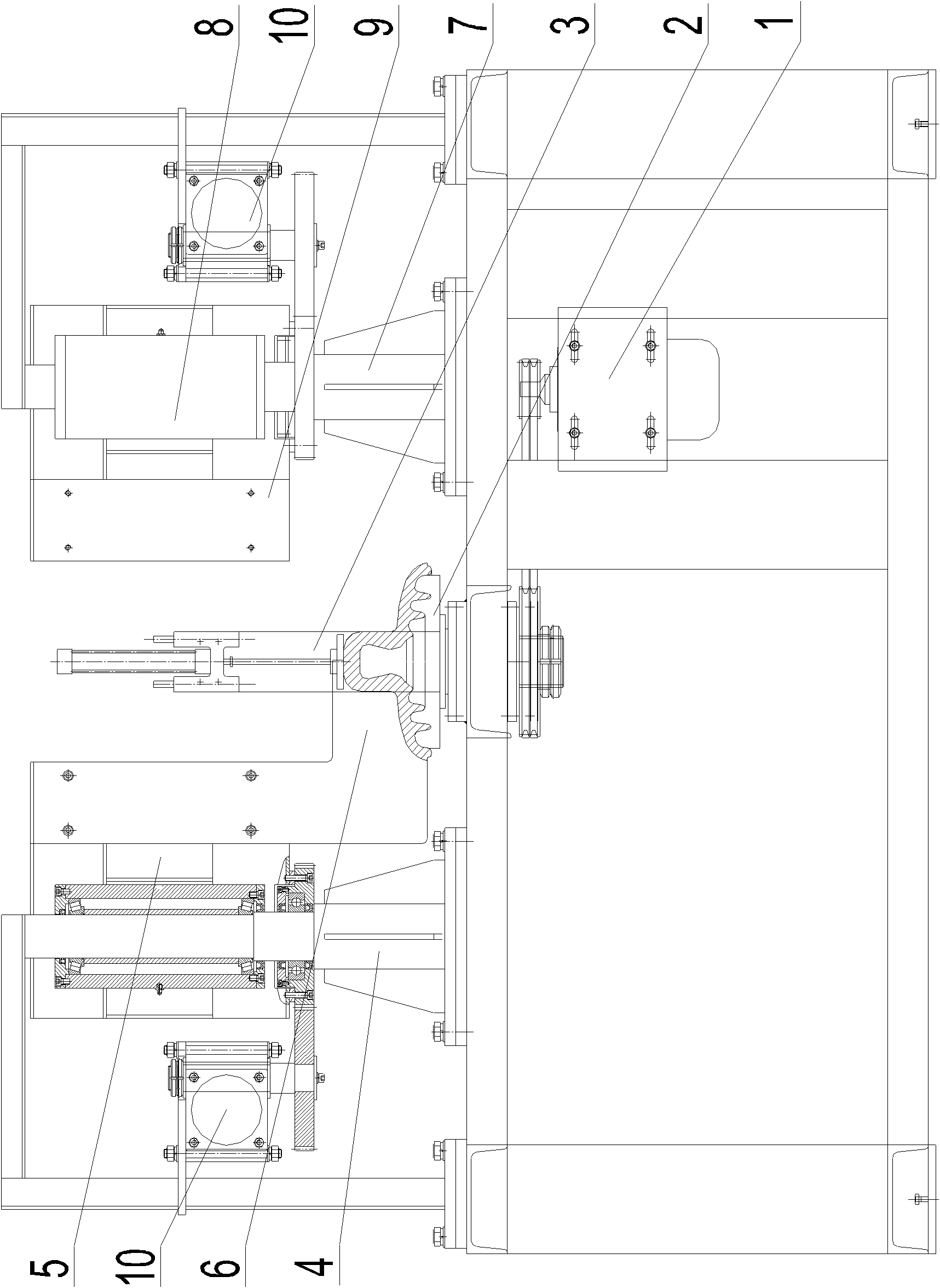

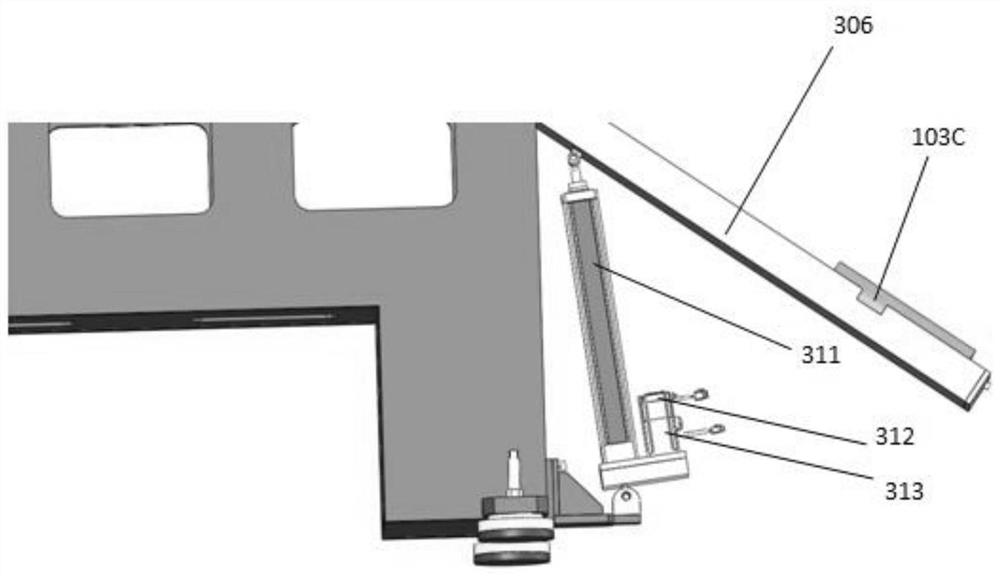

Railway track train and train door entrance step structure thereof

InactiveCN110696841APrevent fallingEasy to get on and offRailway componentsRailway stationControl theoryMechanical engineering

The invention discloses a railway track train and a train door entrance step structure thereof, the train comprises a fixed step fixed on a train body and close to the bottom of the train; a telescopic step forming a continuous step with the fixed step, wherein the telescopic step is far away from the train bottom and comprises a step body fixed to the train body and a movable pedal capable of extending out of the step body, and when the train is in butt joint with the high platform, the movable pedal extends out of the step body to make up for a gap between the step body and the high platform; when the train is in butt joint with a low platform or no platform, the movable pedal retracts to the step body; when the train is in a door closing state, the movable pedal extends to a door closing position to compensate a gap between the step body and a train door leaf; and the train further includes a driving device which drives the telescopic position of the movable pedal. Movement of the movable pedal is controlled through the driving device, and manual operation is replaced. The train door entrance step structure can adapt to platforms with different heights, passengers are preventedfrom falling into gaps, manual operation is not needed, and the labor intensity is reduced.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

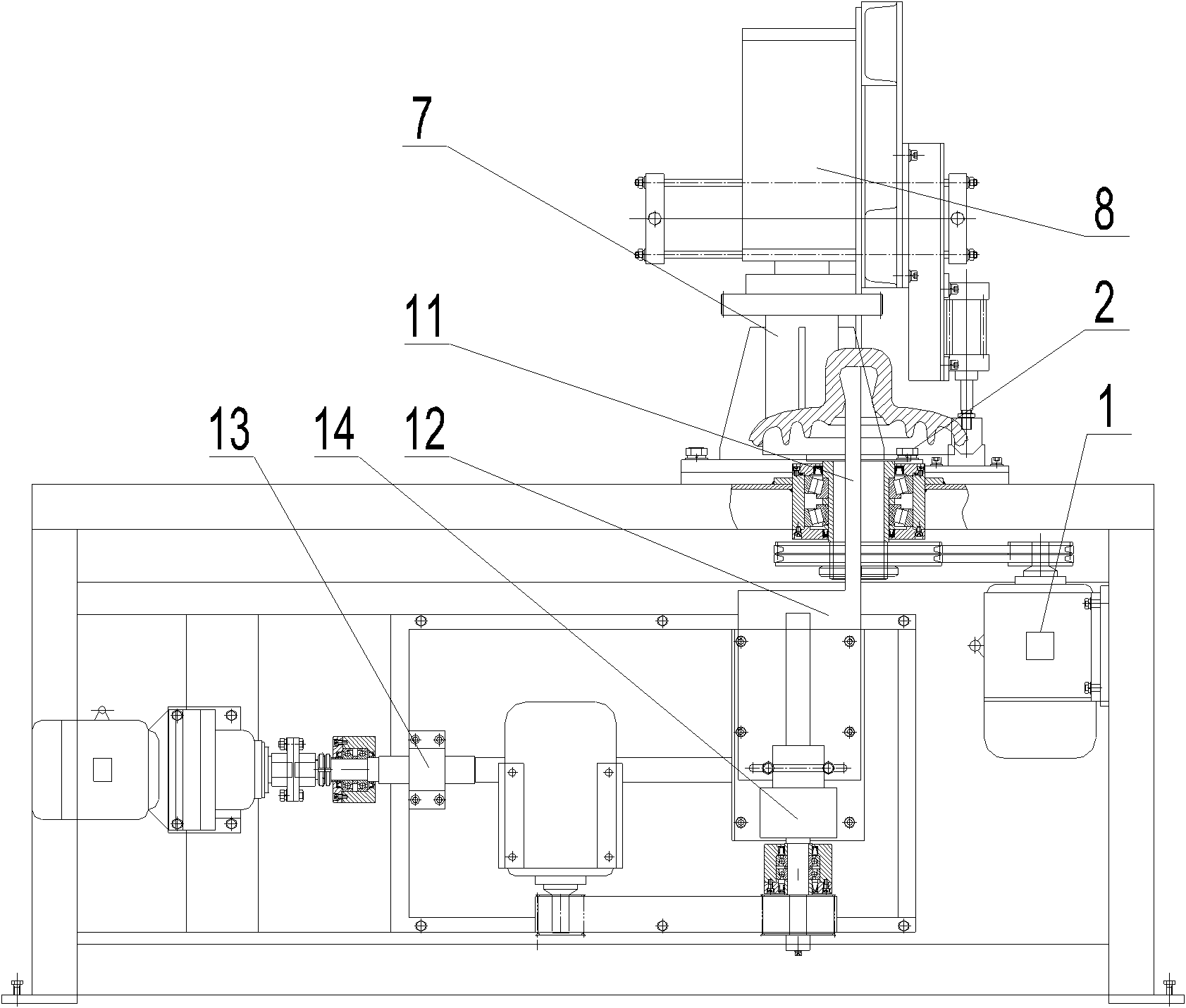

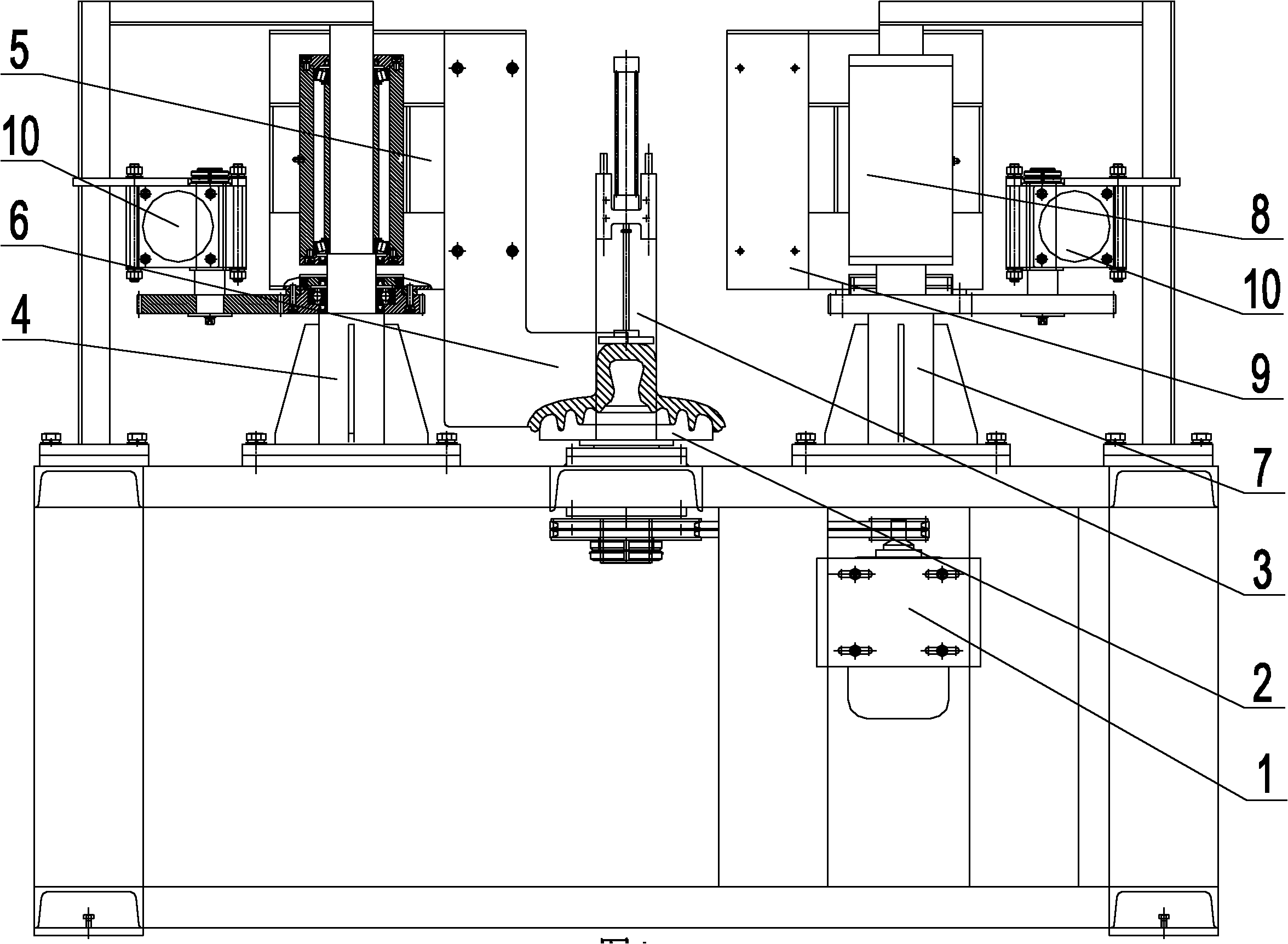

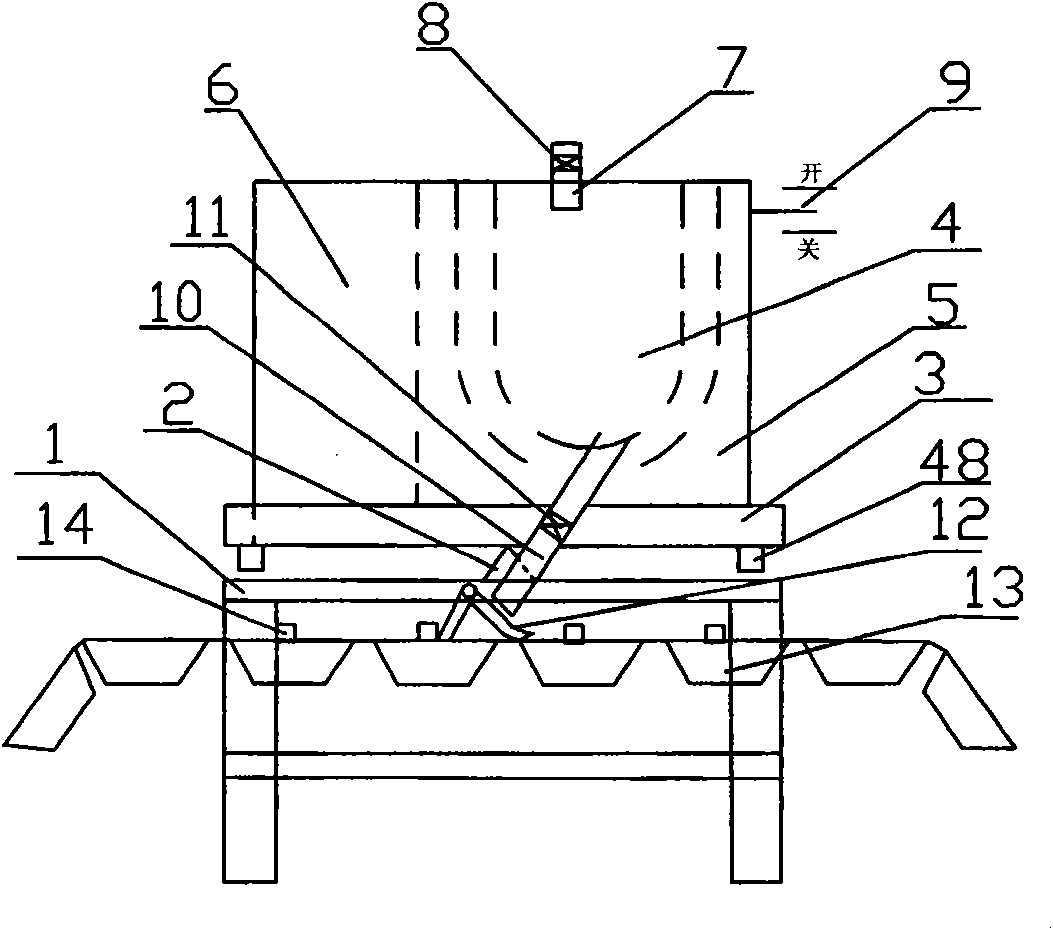

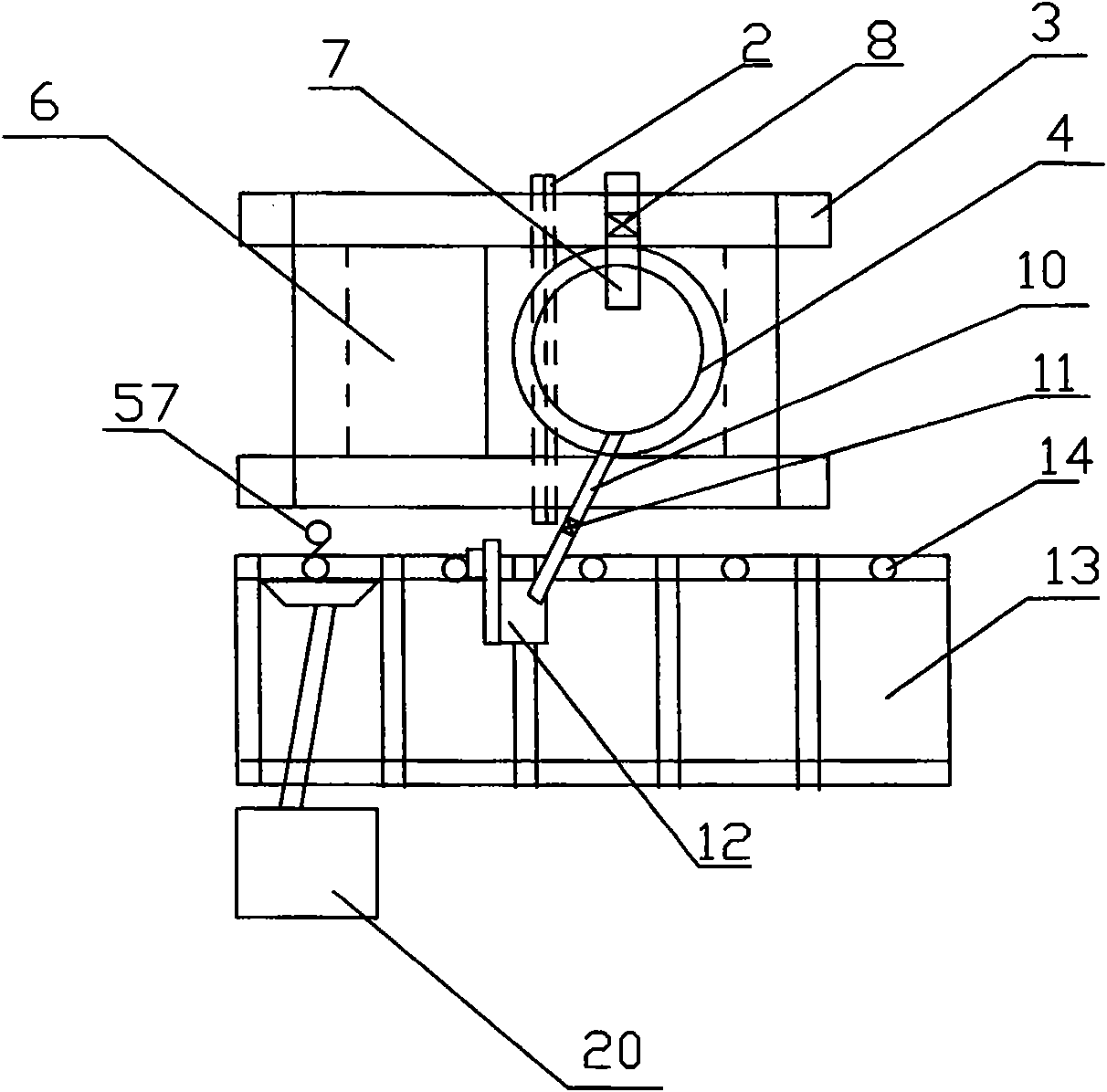

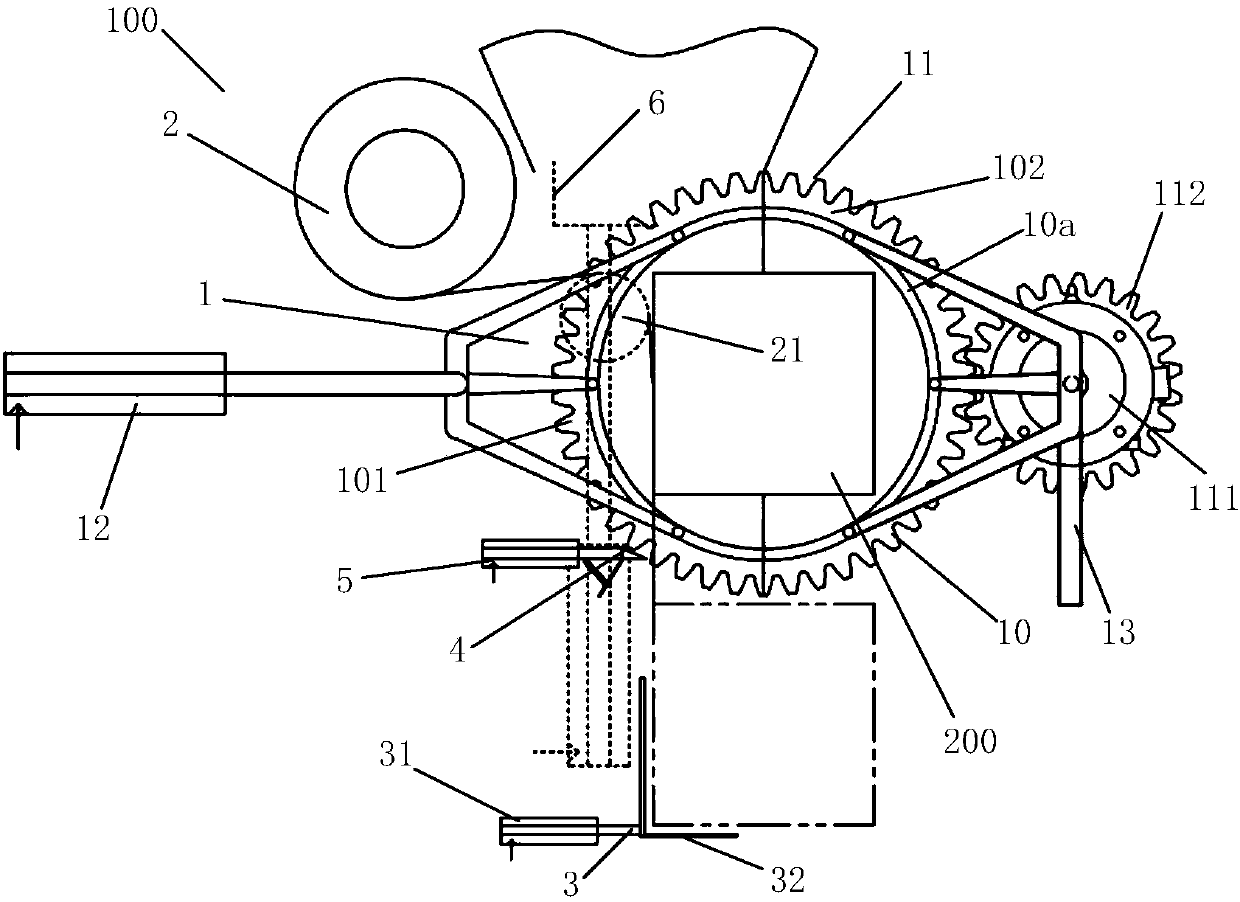

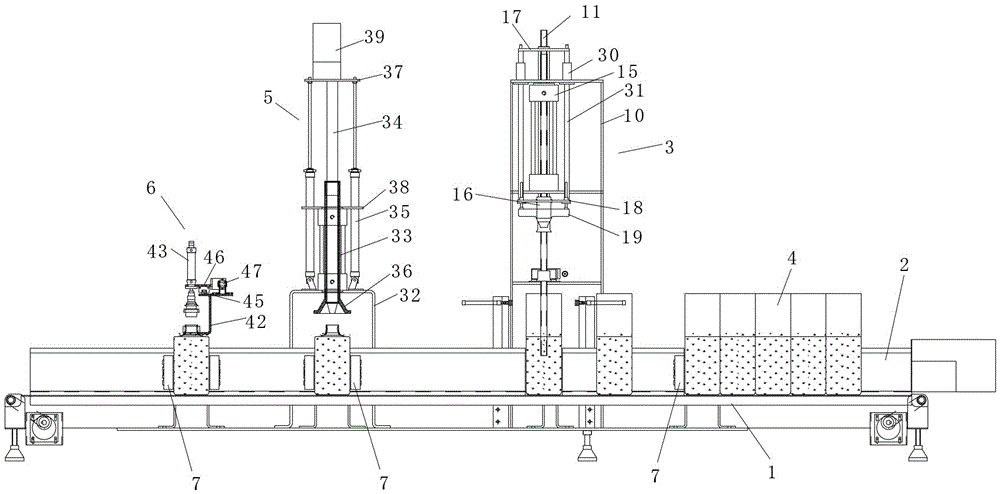

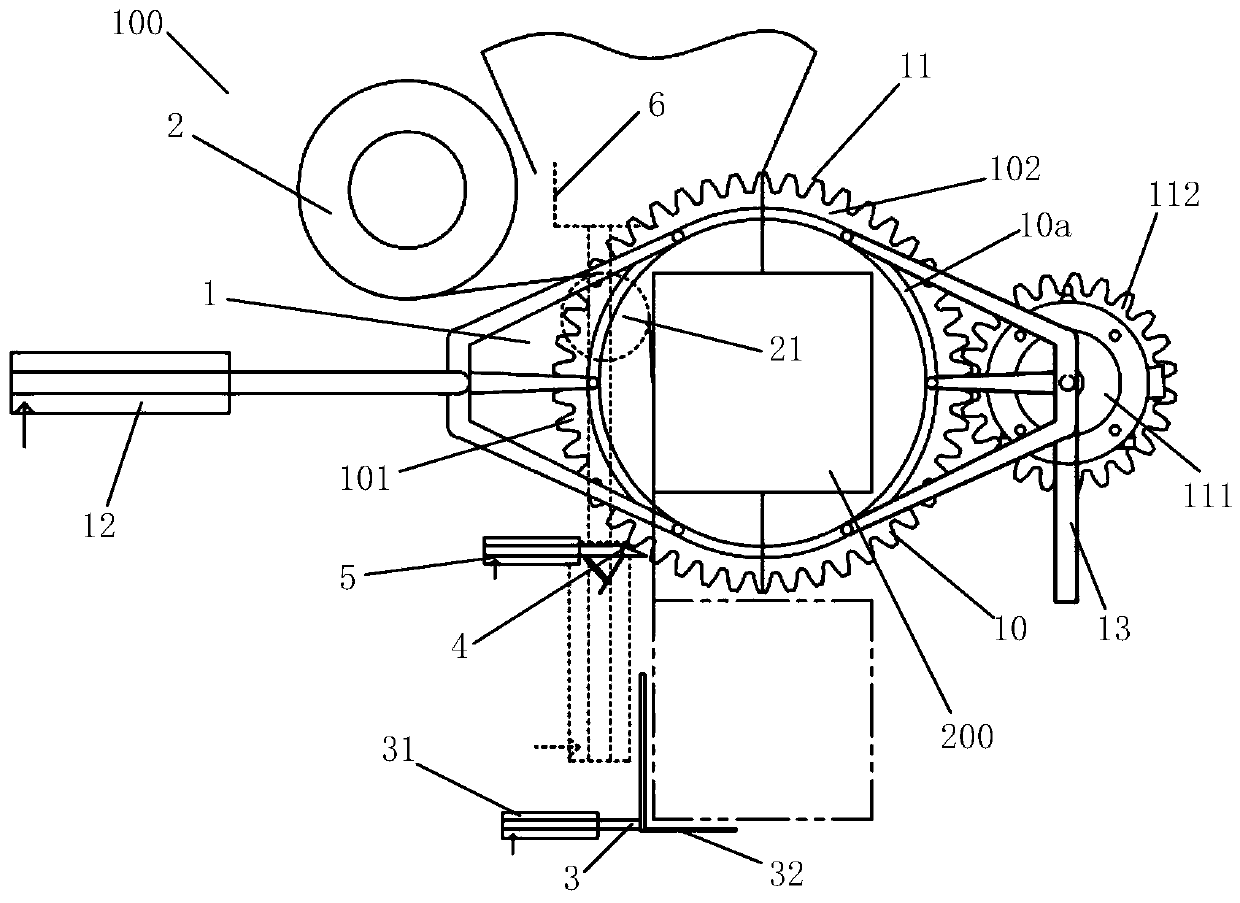

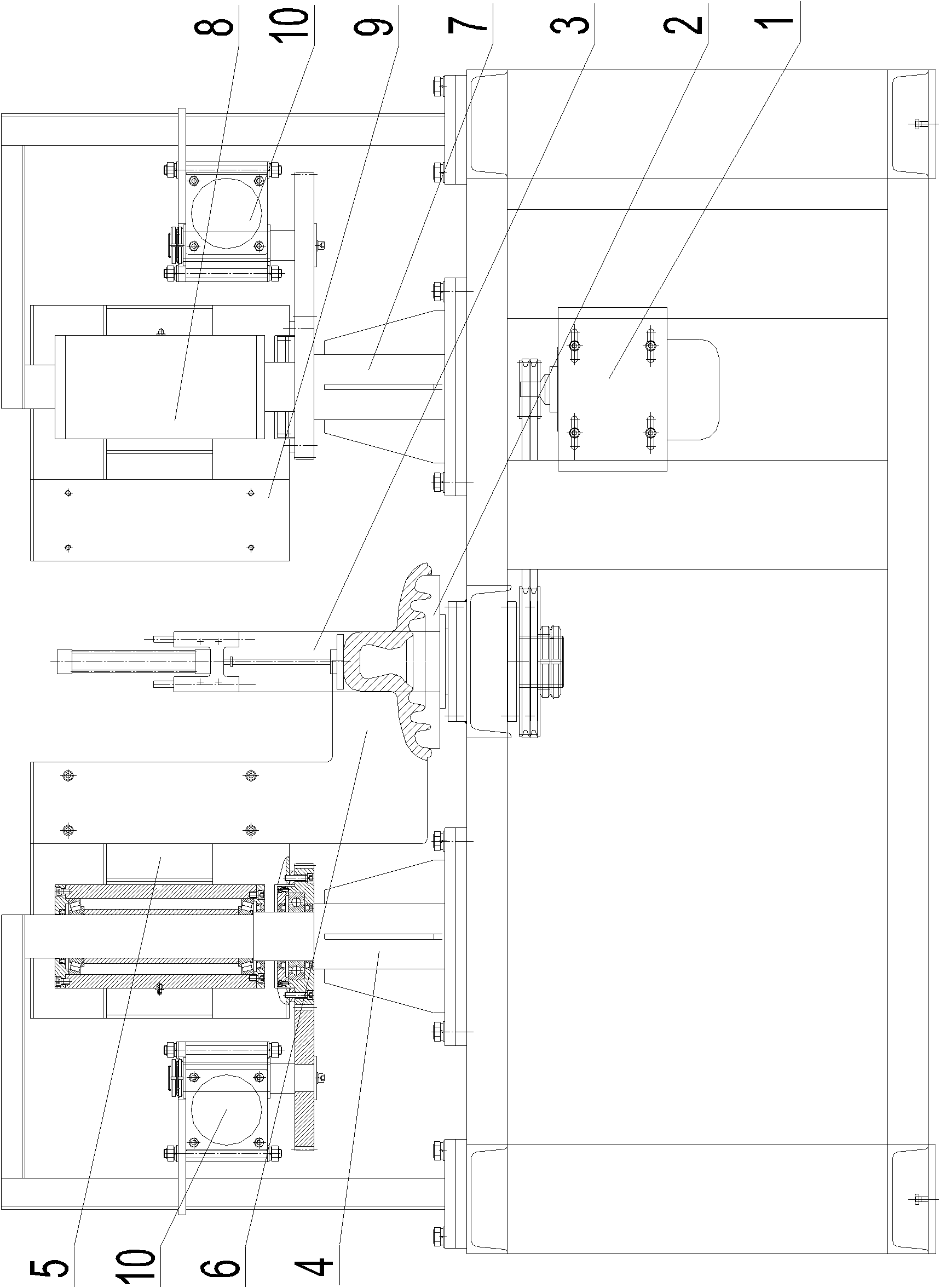

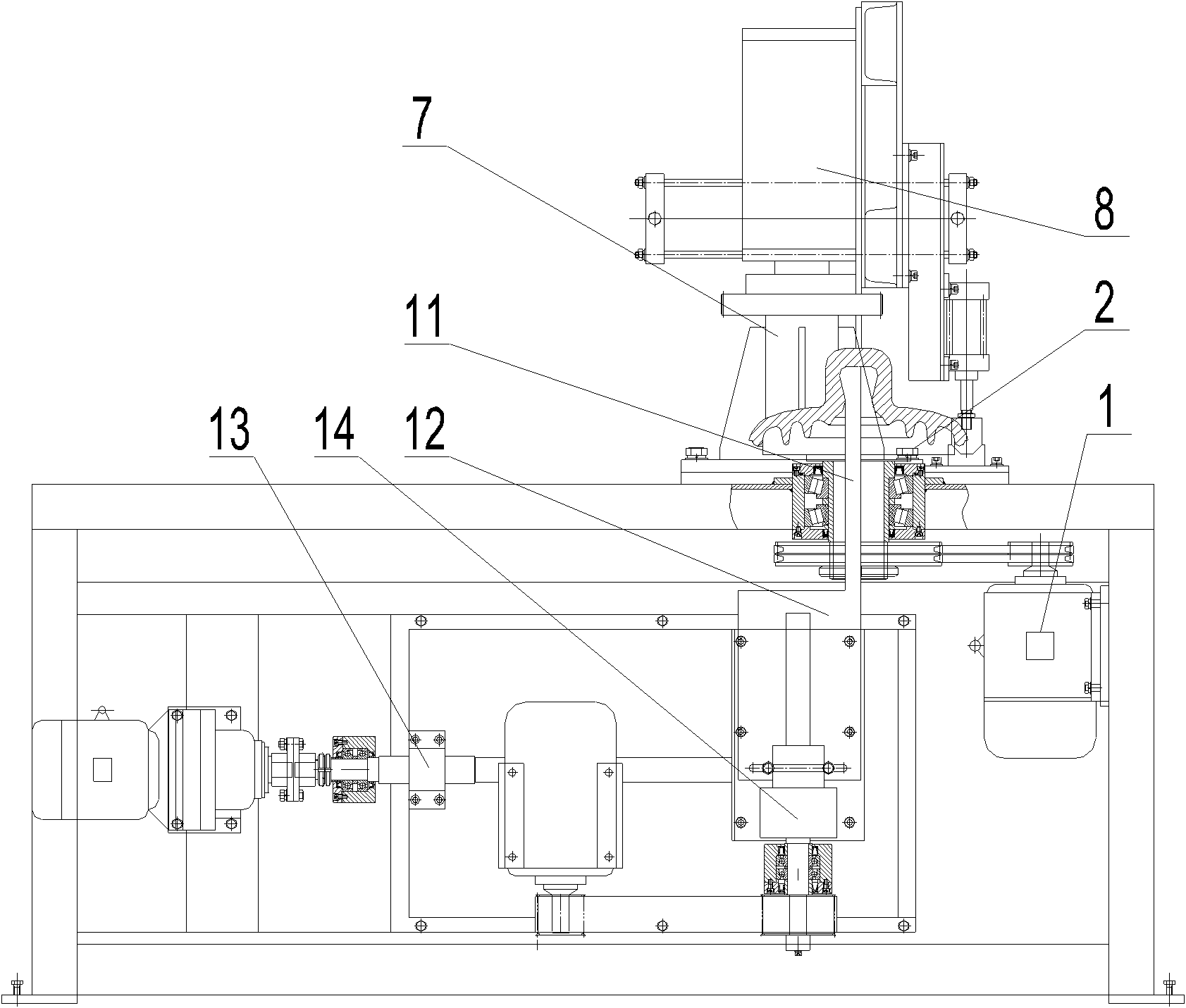

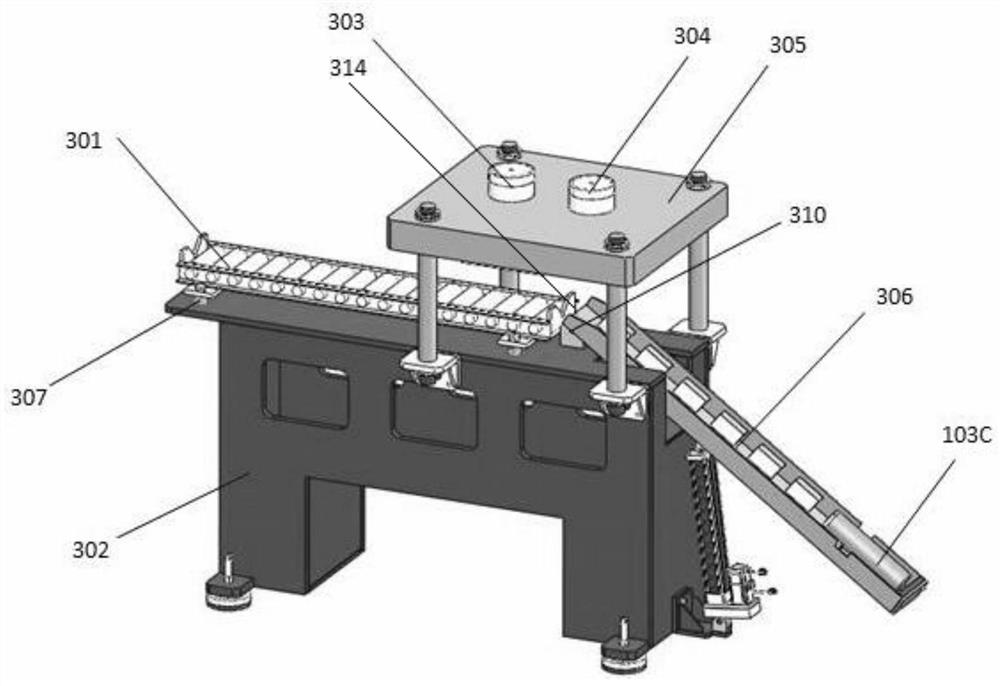

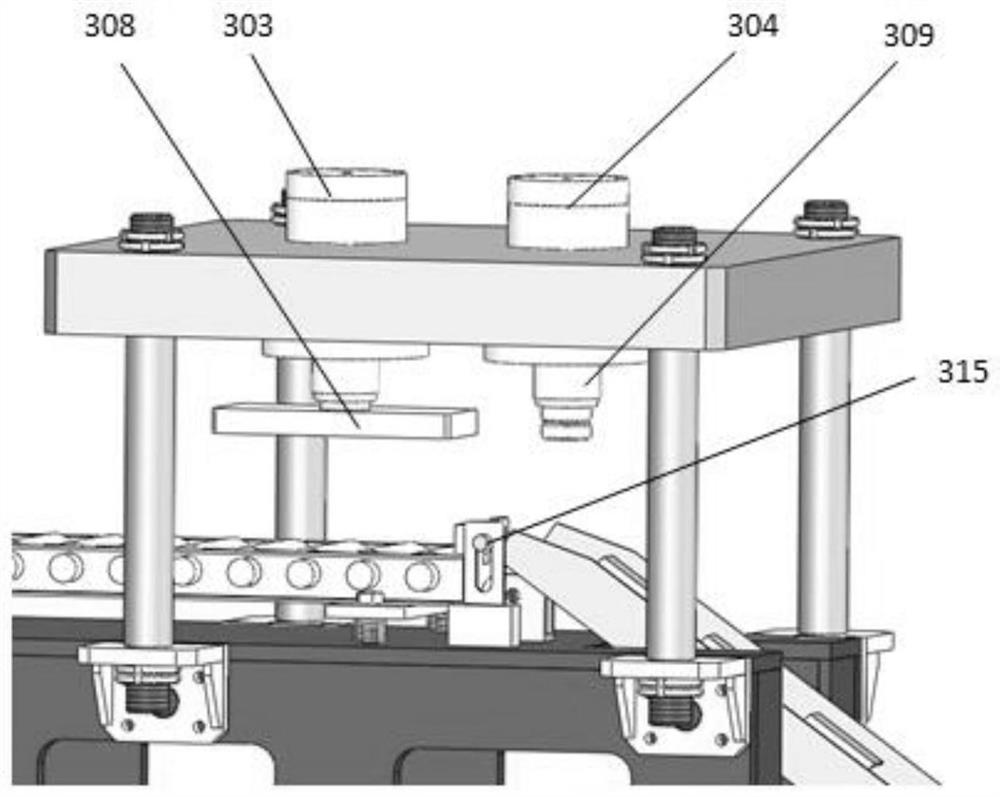

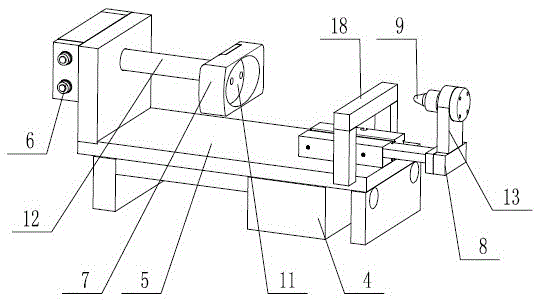

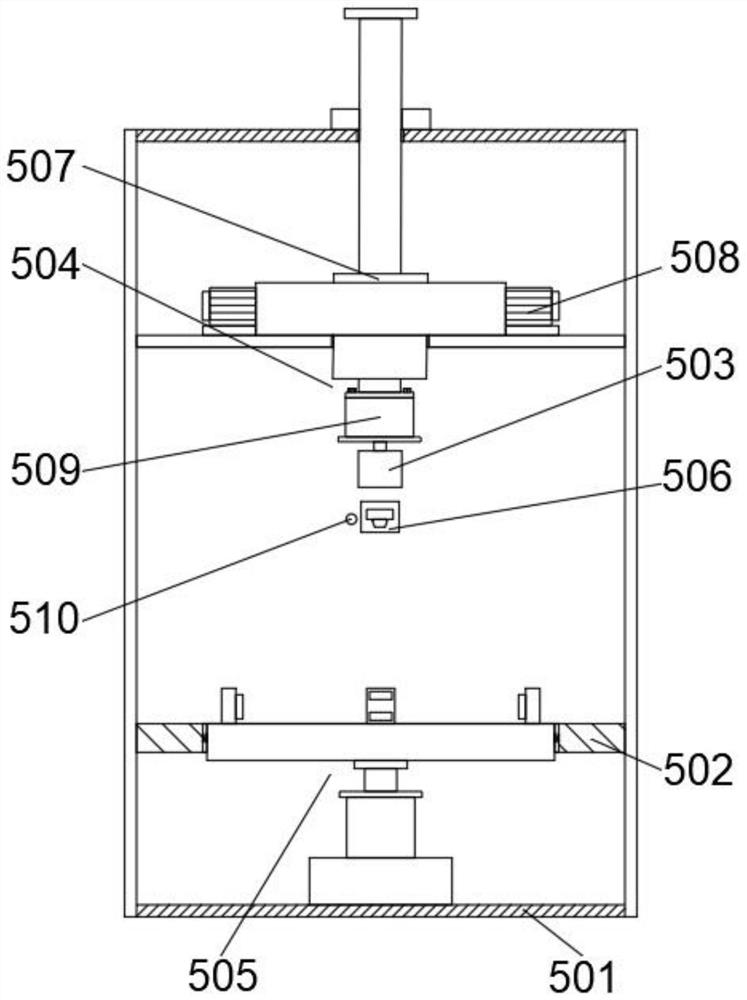

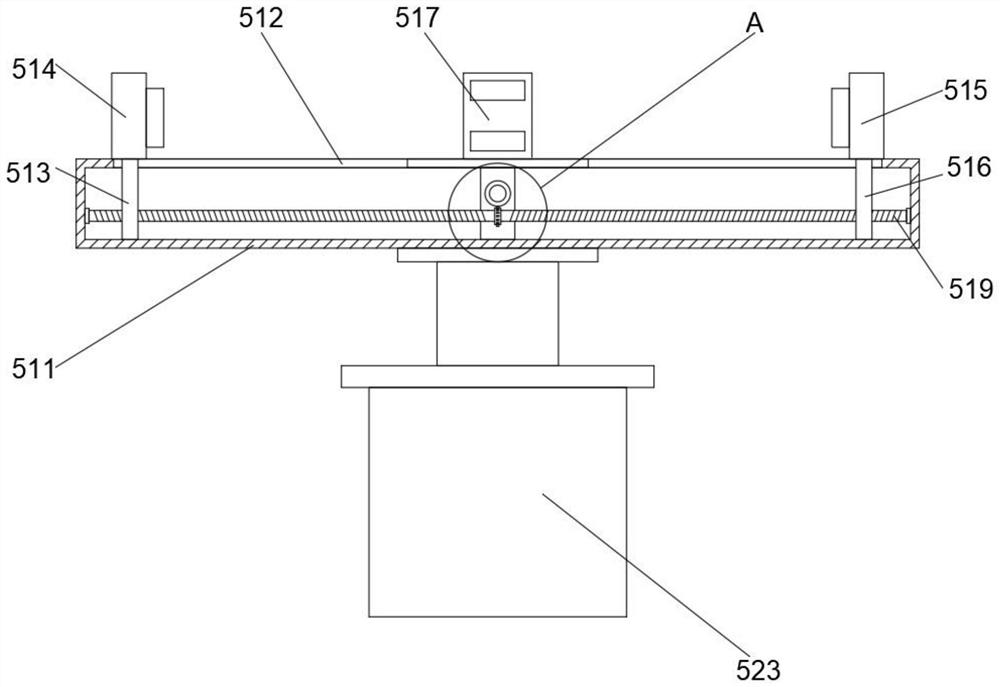

Porcelain insulator trimming method and device

InactiveCN102485452AQuality improvementHigh degree of automationCeramic shaping apparatusElectric machineryEngineering

The invention discloses a porcelain insulator trimming method and device, which is characterized in that: a porcelain insulator blank is put on a base (2) and is fixed by a compressing cylinder (3), a rotating motor (1) drives the base (2) and the blank to rotate, and a first forming cutter (6) and a second forming cutter (9) swing to gradually touch the external surface and head of the blank, so that the external surface of the blank is formed by repairing. Compared with the prior art, the invention has the following advantages: (1) the degree of automation is high, and manual operation is not needed; (2) the obtained product has high accuracy and stable quality; (3) by replacing the forming cutters and adjusting process parameters, multiple porcelain insulator blanks can be processed to be suitable for multiple products; (4) fully-mechanical operation is realized, and the production efficiency is high; and (5) manpower and production time are saved, and the product cost is low.

Owner:贵州建新南海科技股份有限公司 +2

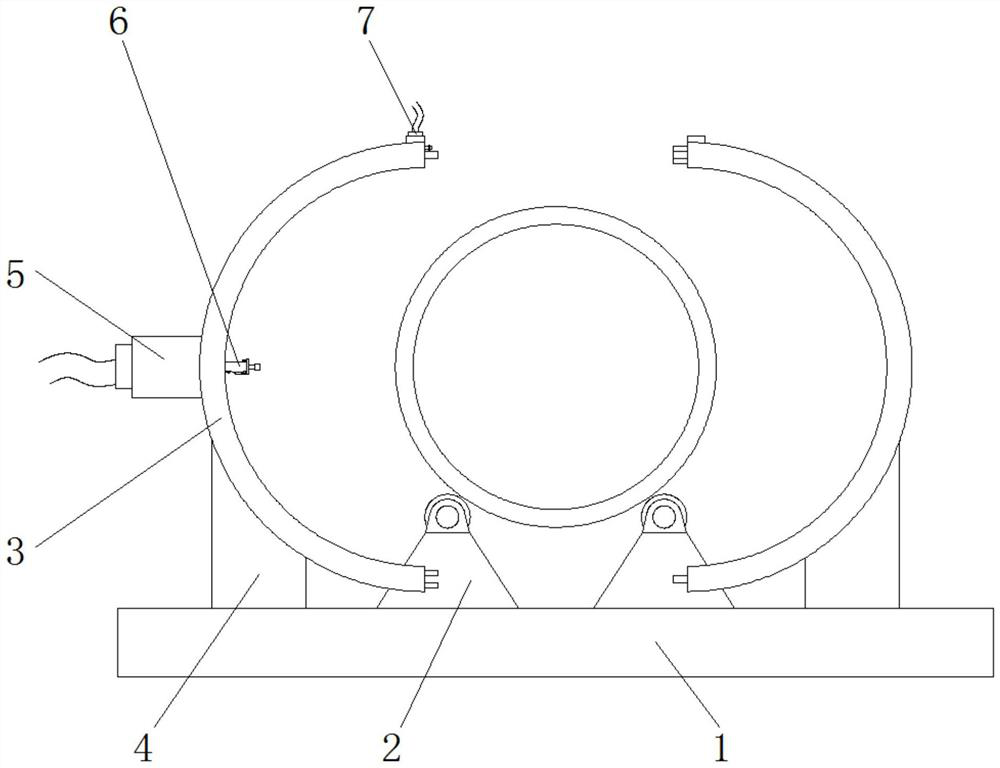

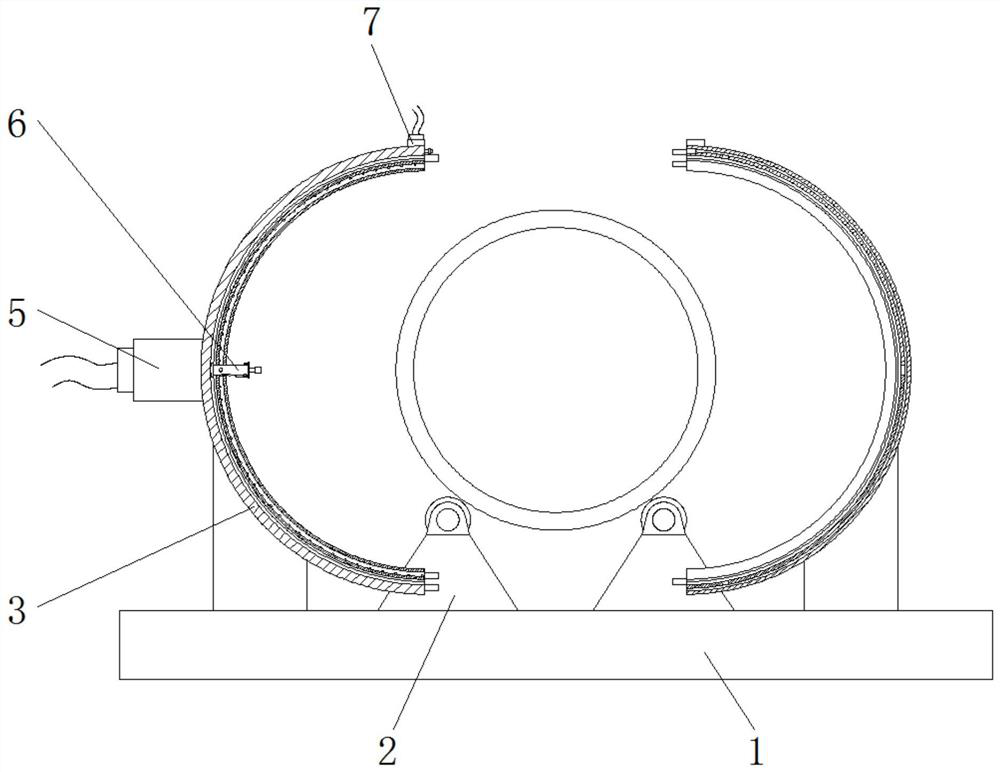

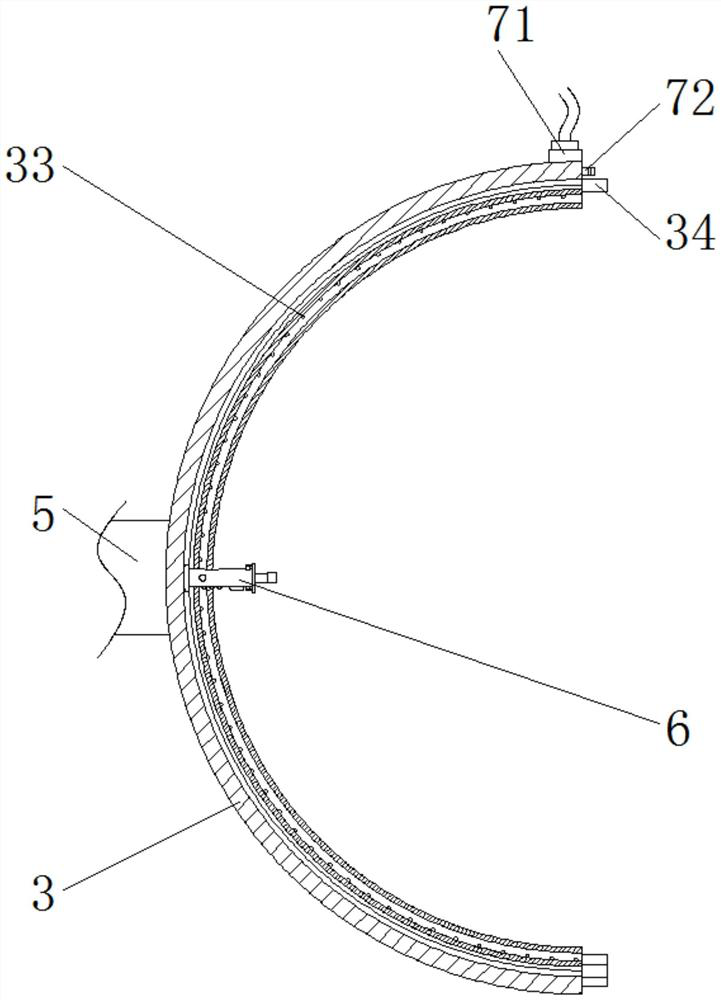

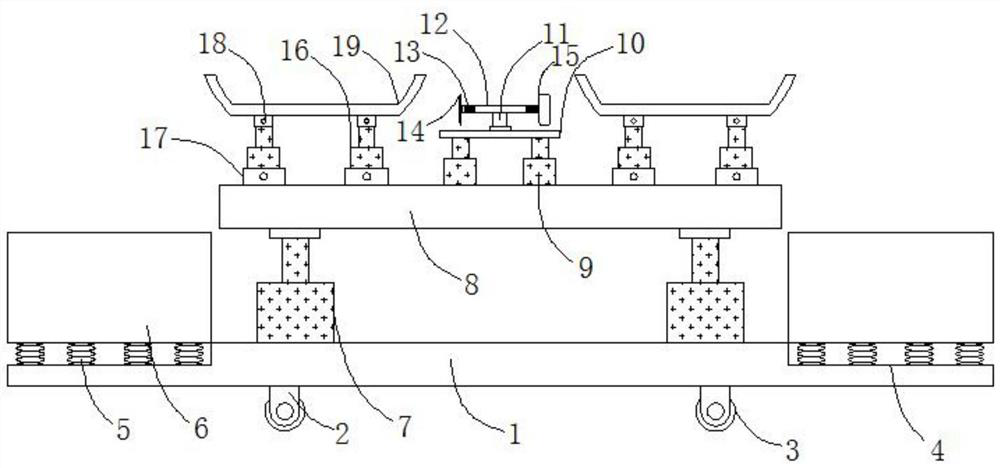

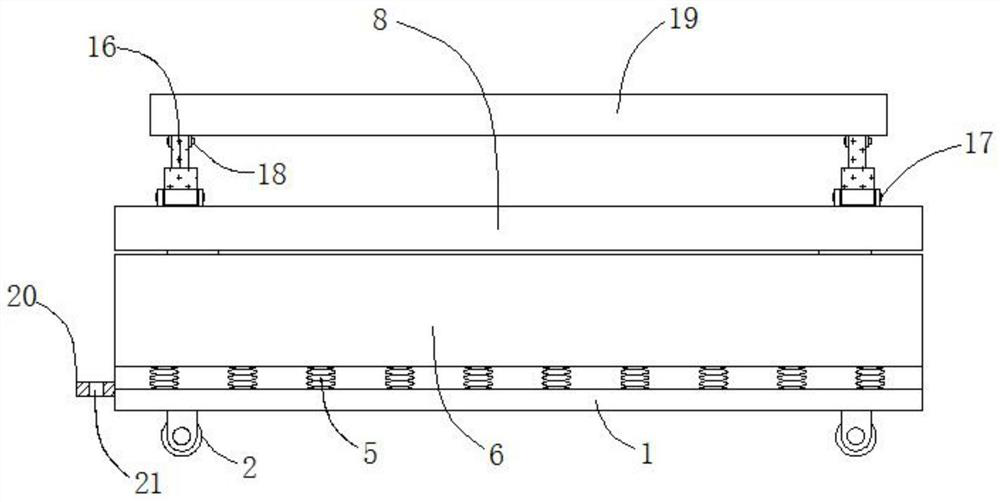

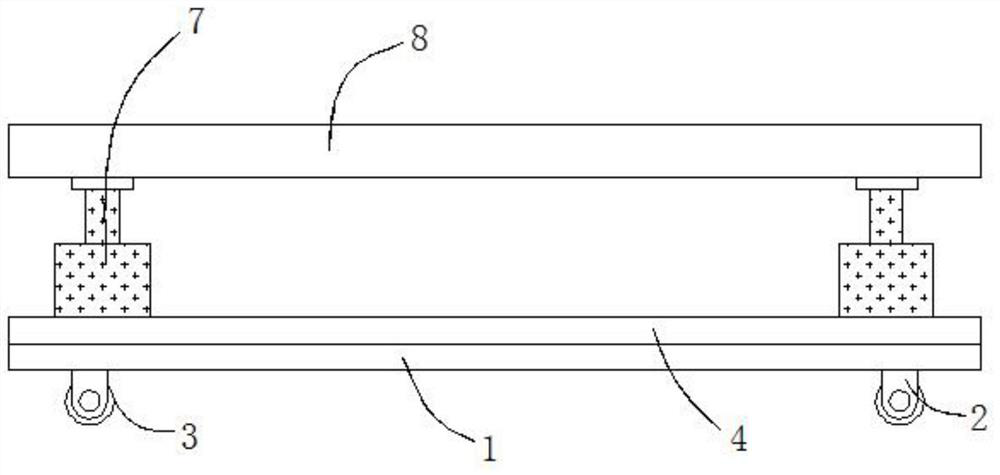

Wind power generation tower barrel welding device

PendingCN114850739AManual operation is not requiredGuarantee welding qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachining

The invention discloses a wind power generation tower barrel welding device, and relates to the technical field of welding equipment.The wind power generation tower barrel welding device comprises a machining base, a plurality of sets of auxiliary supporting frames installed at the upper end of the machining base and used for assisting in supporting a wind power generation tower barrel and a welding device body used for welding the wind power generation tower barrel, and the welding device body comprises a welding machine main body and a welding head; a guide rail assembly used for assisting in driving the welding head to rotate is slidably arranged on the upper end face of the machining base. According to the wind power tower drum surface welding machine, through the welding machine body, the welding head and the guide rail assembly used in cooperation with the welding machine body and the welding head, the welding head can be driven to do annular motion around the wind power tower drum, the surface of the wind power tower drum is automatically welded, manual handheld operation is not needed, and meanwhile through the cooling assembly, in the welding process, welding efficiency is improved. And air cooling is carried out on the welding position, and the welding quality is ensured.

Owner:易磊

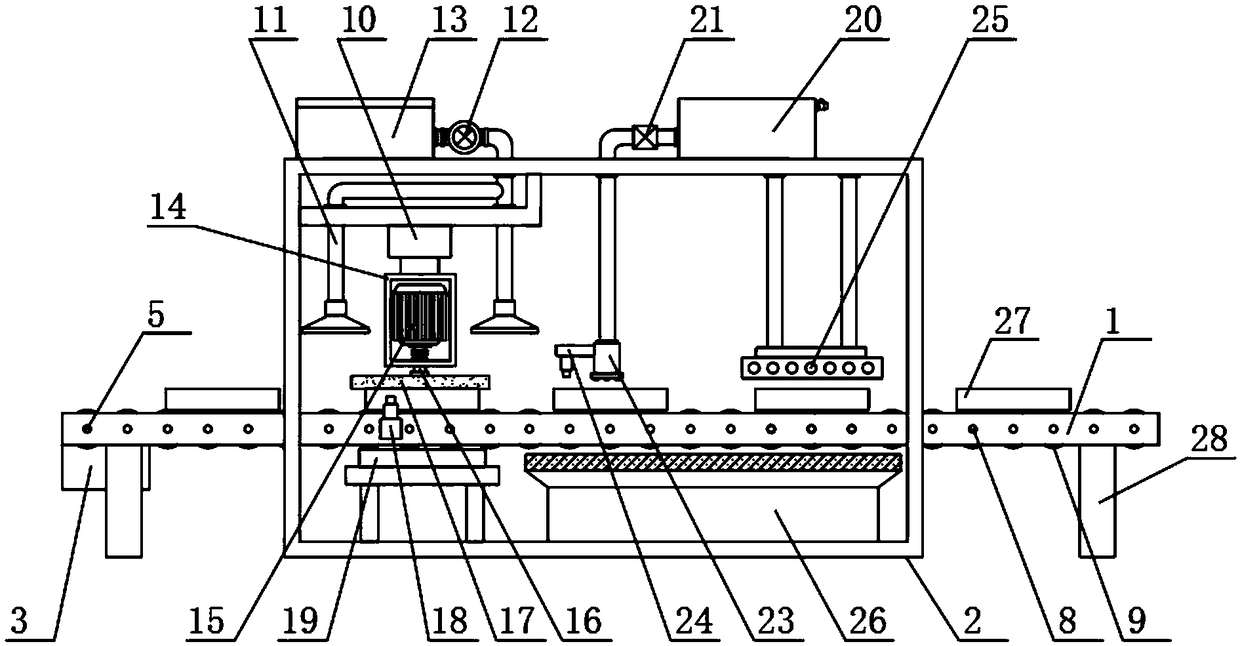

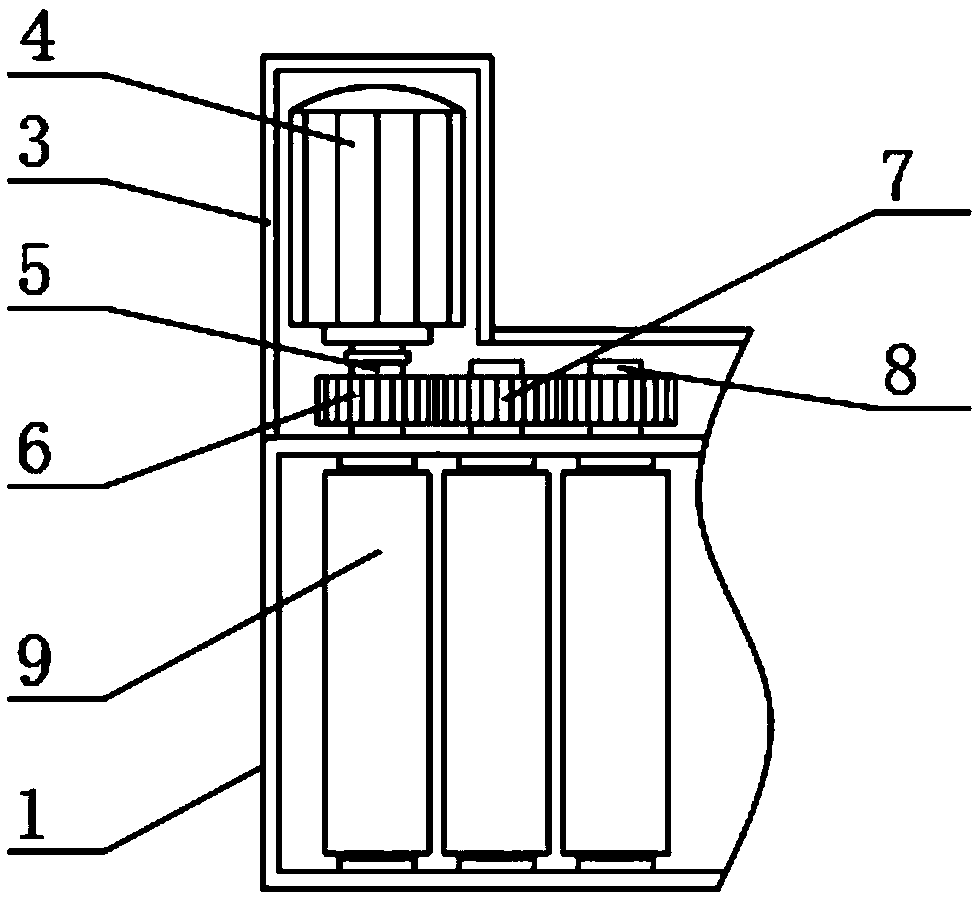

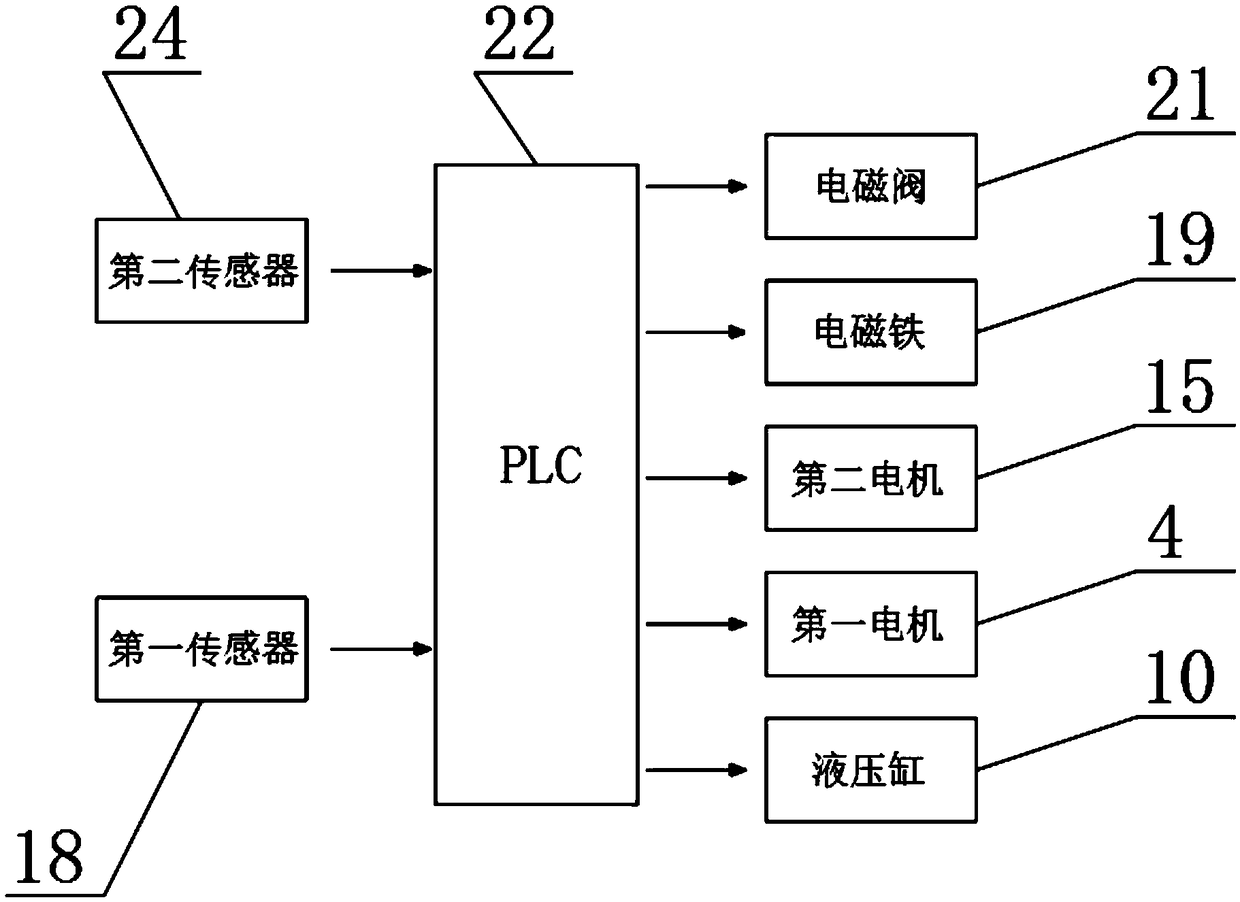

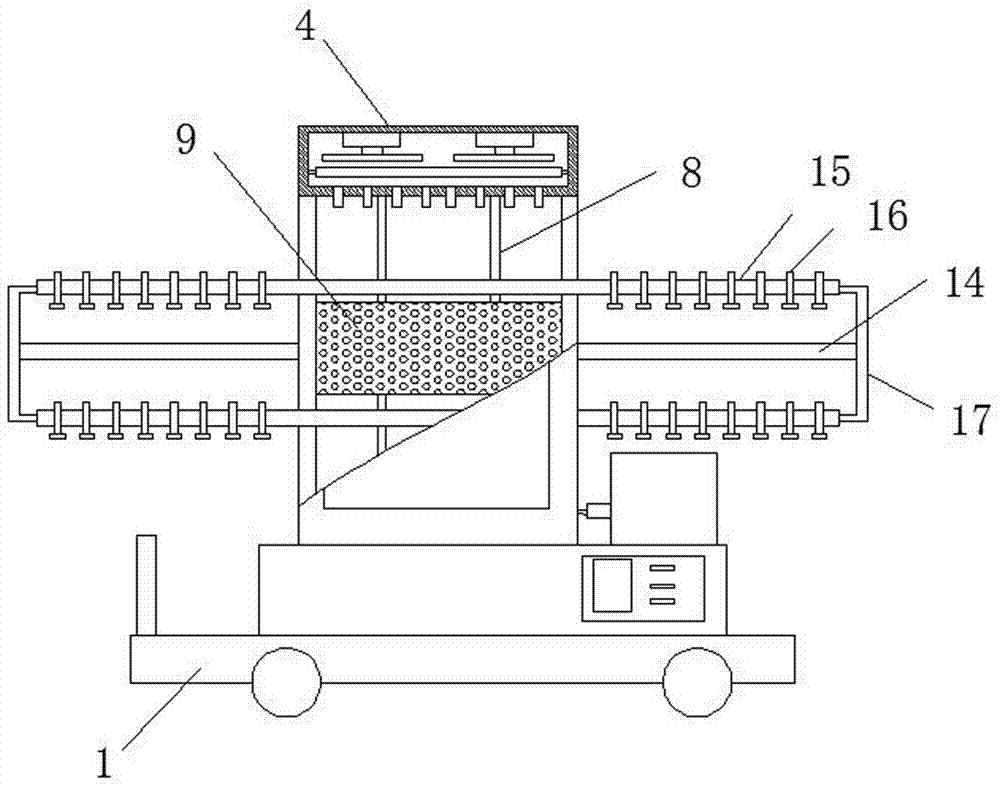

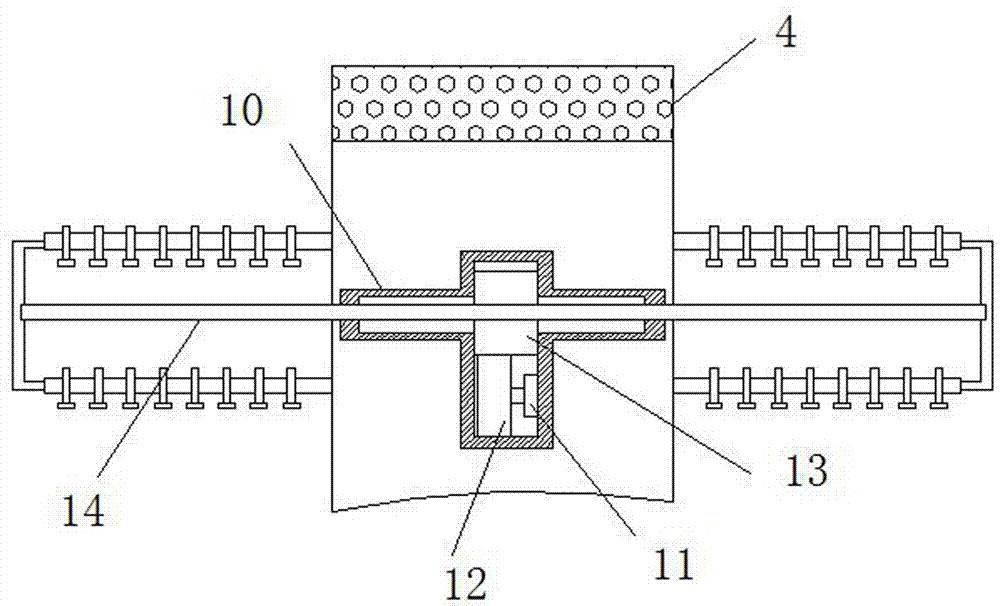

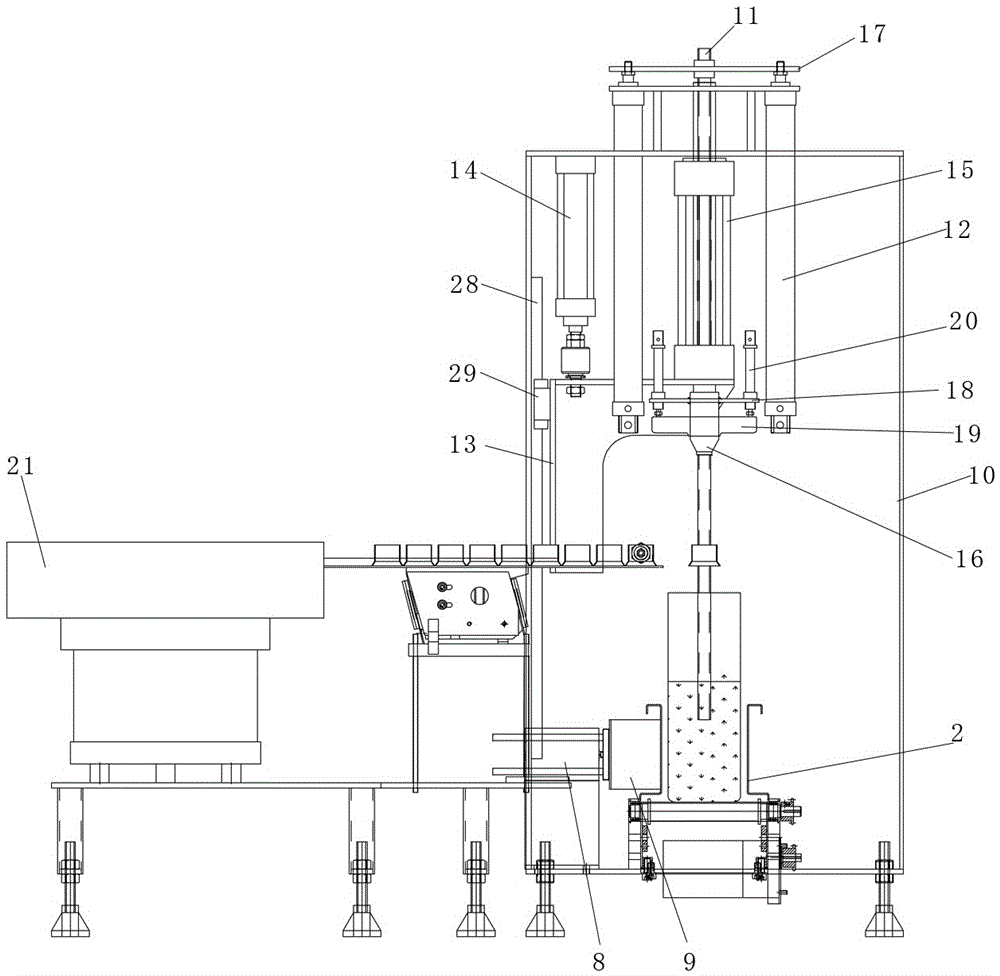

Integrated processing device for concrete tubular pile end plate without manual operation

PendingCN109382746AReduce labor intensityAvoid wastingGrinding machinesAutomatic grinding controlEngineeringIntegrated processing

The invention relates to the technical field of tubular pile end plate processing devices and discloses an integrated processing device for a concrete tubular pile end plate without manual operation.The device comprises a support frame and a PLC, a protection box is arranged in the middle of the support frame, a protection cover disposed on the left side of the protection box is fixedly mounted on the back face of the support frame, a first motor is fixedly mounted in the protection cover, an output shaft of the first motor is fixedly connected with a driving shaft, a mother gear located in the protection cover fixedly sleeves the driving shaft, and the right end of the mother gear is meshed with child gears. According to the integrated processing device for the concrete tubular pile endplate without manual operation, through arrangement of the PLC, the PLC is adopted for controlling the first motor, a hydraulic cylinder, a second motor, an electromagnet and a solenoid valve, integration and automation of processing processes without manual work are achieved, and the labor intensity of workers is reduced.

Owner:TAIZHOU RUNWEI MACHINERY

Ingot casting device for automatically clearing impurity and finishing appearance

The invention belongs to the field of non-ferrous metal melting equipment, and relates to an ingot casting device for automatically clearing impurity and finishing appearance. The device comprises a casting part, a baffle plate, a scraper assembly, an edge scraping assembly and an ingot mold, wherein the casting part adjusts the flow by using the dynamic balance principle; the scraper assembly removes oxide layers and impurity; and the edge scraping assembly finishes the ingot casting appearance. The device has the advantages that: because of the adoption of the technical scheme, the device automatically controls the flow and the weight, clears the impurity and finishes the appearance by electric and mechanical automatic control combination; and the device replaces manual operation, improves the dangerous and hard working environment of workers, reduces the labor intensity, improves the work efficiency, has a simple structure, and does not use manual operation.

Owner:施长智

Strain bag capping machine

ActiveCN104285676BLess susceptible to infectionSimple structurePackagingCultivating equipmentsEdible mushroomPulp and paper industry

The invention relates to a strain bag cover arranging machine, and belongs to the technical field of edible mushroom production. To solve the technical problem, the strain bag cover arranging machine which is convenient to operate and high in production efficiency and replaces manual operation through machinery is provided. According to the technical scheme, a center shaft is arranged in the center inside a rack, a cam indexing unit is arranged at the top of the rack, the output of the cam indexing unit is connected with the center shaft, the cam indexing unit controls an upper rotating disc and a lower rotating disc to rotate and stop, in cooperation with the mechanical structure motion and air cylinder action, circulating working from the first station to the eighth station is achieved, and relative actions of ferrule arranging, automatic strain bag feeding, automatic strain bag binding off, ferrule sleeving, inner plug arranging and automatic strain bag output are finished. The strain bag cover arranging machine is easy and convenient to operate, high in working efficiency and capable of being widely used for arranging covers of strain bags.

Owner:ZHANGZHOU CITY XINGBAO MACHINERY

Environment detection equipment and detection method for improving detection precision

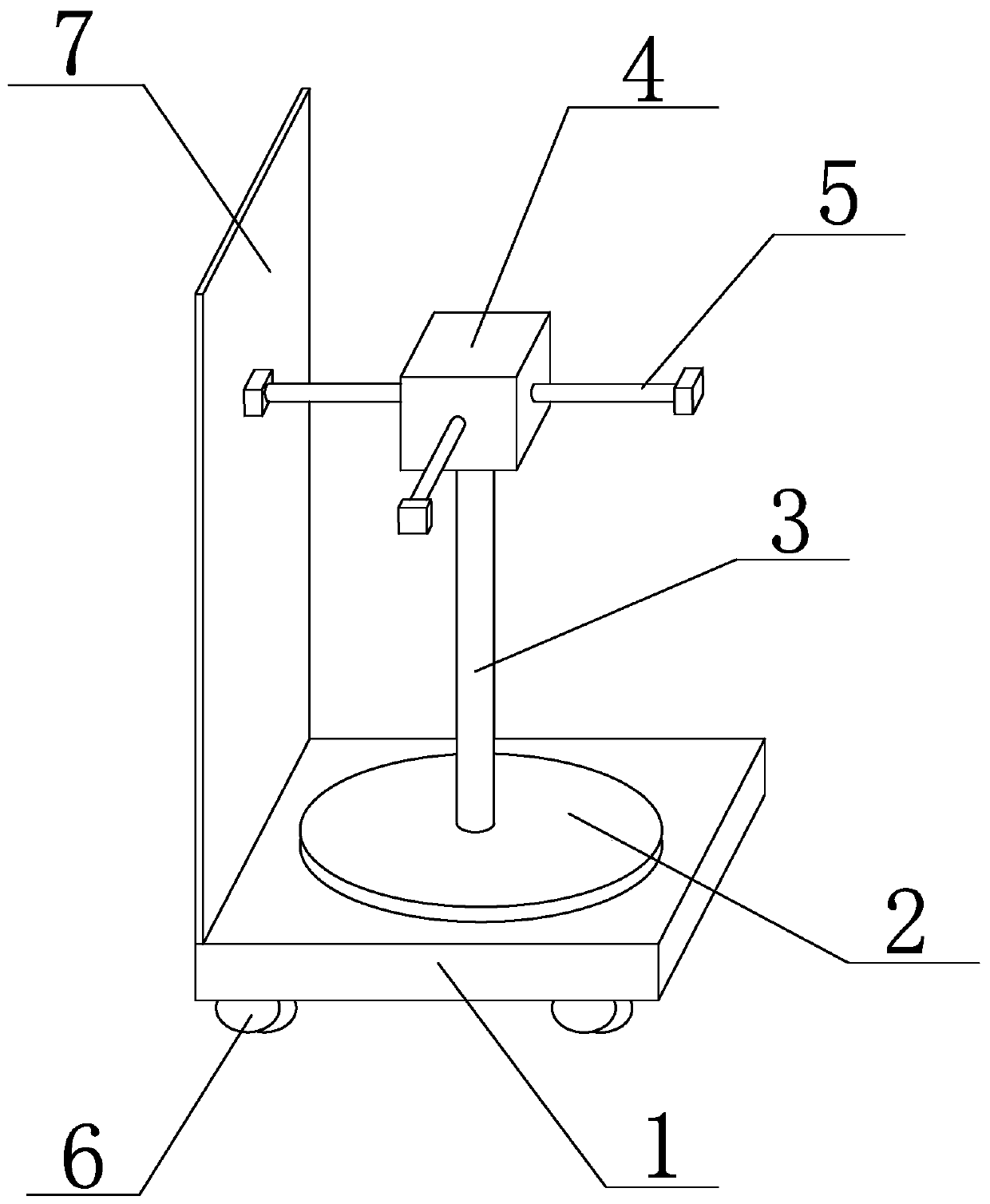

InactiveCN111257514AReduce mistakesImprove detection accuracyGas analyser construction detailsStructural engineeringMoisture sensor

The invention discloses environment detection equipment and a detection method for improving detection precision. The equipment includes a base, a horizontally arranged turntable is arranged on a surface of the base; the turntable can rotate around the axis of the turntable along the surface of the base; a strut is vertically arranged in the center of the turntable surface; a mounting block is arranged at a top end of the strut; a plurality of moving rods are vertically mounted on peripheral side walls of the mounting block; a humidity sensor, a carbon dioxide sensor, a carbon monoxide sensorand a formaldehyde sensor are installed at front ends of the moving rods, the moving rods and the strut are provided with telescopic structures, a first driving mechanism can drive the moving rods toextend or retract in the axis direction, and a second driving mechanism can drive the strut to extend or retract in the vertical direction. According to the detection equipment, the continuous detection of different point locations in one range can be achieved, multiple sets of data can be collected, the accuracy and low errors of environment detection data are achieved, manual handheld operationis not needed, the equipment is easier and more convenient to use, and shaking can be avoided.

Owner:四川以勒科技有限公司

Oral cavity cleaning nursing device for neurological patients

The invention discloses an oral cavity cleaning nursing device for a neurological patient, and effectively solves the problems that oral cavity cleaning operation for the patient is tedious, time-consuming and labor-consuming. Comprising a support, a fixed box is arranged at the right end of the upper side of the support, the lower end of the fixed box is connected with a buccal box through a fixed frame, a crankshaft is arranged in the buccal box, a moving column is arranged in the buccal box, a rotating ring is rotationally connected in the buccal box, a rotating ring is coaxially and rotationally connected in the rotating ring, and the rotating ring and the rotating ring are each provided with a chute and a swing frame. A sliding frame is slidably connected in the swing frame, a tooth brushing box is hinged to the upper end of the sliding frame, tooth brushing plates are arranged on the upper and lower side walls of openings in the left and right sides of the tooth brushing box respectively, bottom plates are arranged on the inner side walls of the openings in the left and right sides of the tooth brushing box respectively, a plurality of silica gel brush heads are arranged on the bottom plates and the tooth brushing plates, and a water supply pipeline and a waste liquid pipeline are arranged in the tooth brushing box; the teeth of a patient can be comprehensively cleaned by putting the teeth of the patient into the opening of the tooth brushing box.

Owner:PEOPLES HOSPITAL OF HENAN PROV

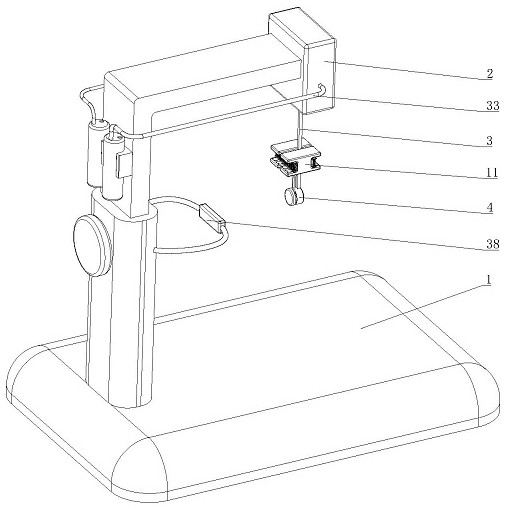

Intelligent biopsy sampling device for gastroenterology department

InactiveCN111544057AEasy to adjust the positionEasy to useSurgical needlesVaccination/ovulation diagnosticsElectric machineryEngineering

The invention provides an intelligent biopsy sampling device for the gastroenterology department, and relates to the field of sampling devices. The intelligent biopsy sampling device for the gastroenterology department comprises a bed body; the upper surface of the bed body is fixedly connected with a bracket; the top of the bracket is fixedly connected with a shell. A first motor is fixedly connected to the interior of the shell; the output end of the first motor is fixedly connected with a screw rod; the outer surface of the screw rod is in threaded connection with a moving block, the lowersurface of the moving block is fixedly connected with a cantilever, and a mounting groove is formed in the lower surface of the cantilever; a second motor is fixedly connected into the mounting groove, the output end of the second motor is fixedly connected with a rotating shaft, and the bottom of the rotating shaft is fixedly connected with an adjusting rotary table. Through the design of a multi-angle adjusting mechanism, the position of the device can be simply and conveniently adjusted, the device is more convenient to use, manual handheld operation is not needed, and the device is more accurate and sanitary during sampling.

Owner:李之慧

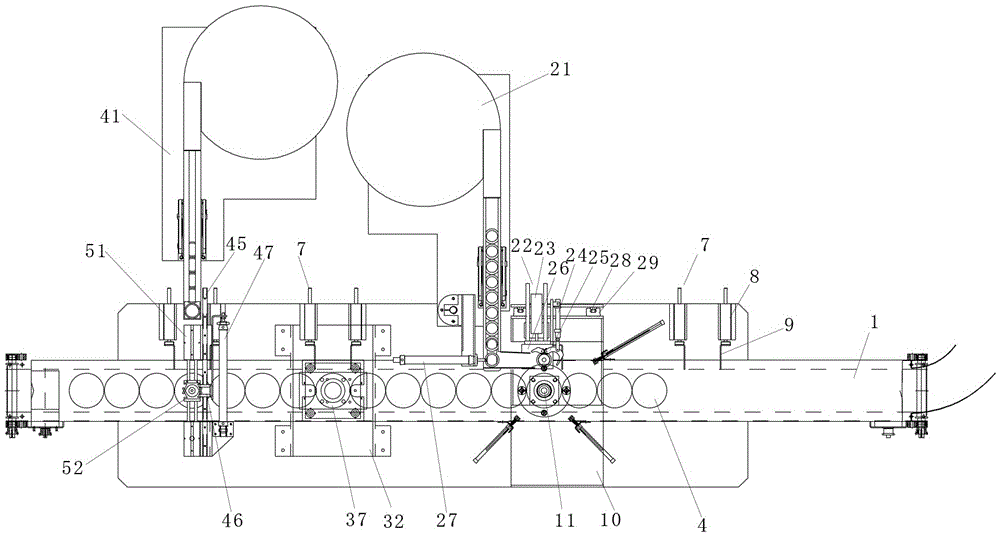

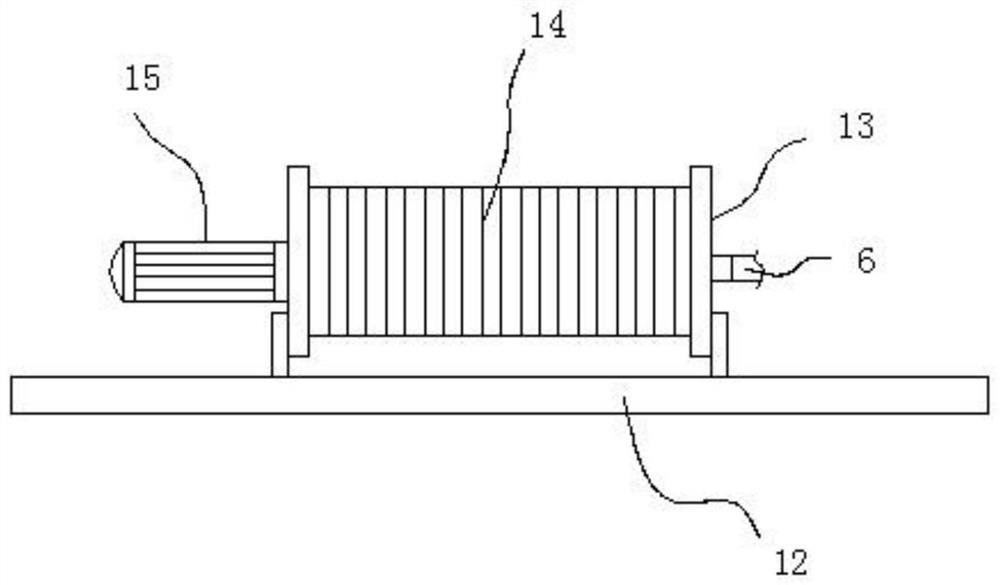

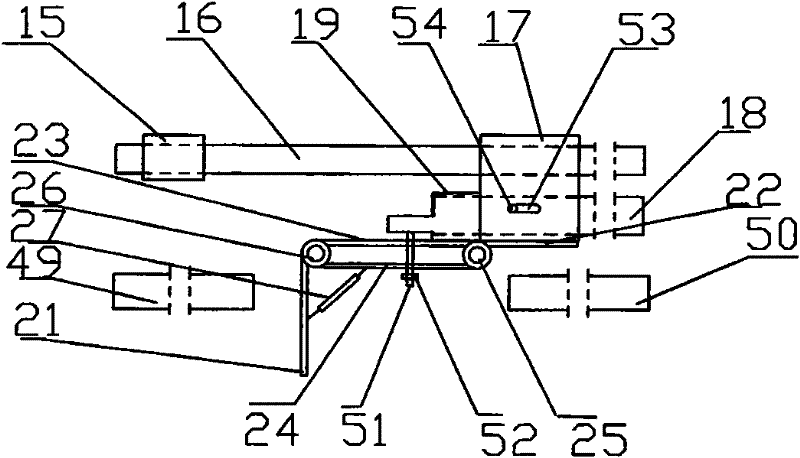

Automatic adhesive tape winding system for gypsum board filler strips

ActiveCN109693308ARealize automatic receivingAchieve rotationAuxillary shaping apparatusEngineeringUltimate tensile strength

The invention provides an automatic adhesive tape winding system for gypsum board filler strips. The system includes an induction device and a split type rotation device. The induction device and thesplit type rotation device are electrically connected to each other. The induction device is used for inducing the position of a gypsum board filler strip. The split type rotation device is used for receiving the gypsum board filler strip and driving the gypsum board filler strip to rotate to realize automatic winding of an adhesive tape. The gypsum board filler strip automatic adhesive tape winding system provided by the invention adopts a split type hollow rotating wheel to realize automatic receiving, rotating and lowering of the gypsum board filler strip, improves the degree of automation,does not need manual hand-held operation, reduces safety hazards to workers, effectively reduces the labor intensity, and improves the production efficiency.

Owner:BEIJING NEW BUILDING MATERIALS PLC +1

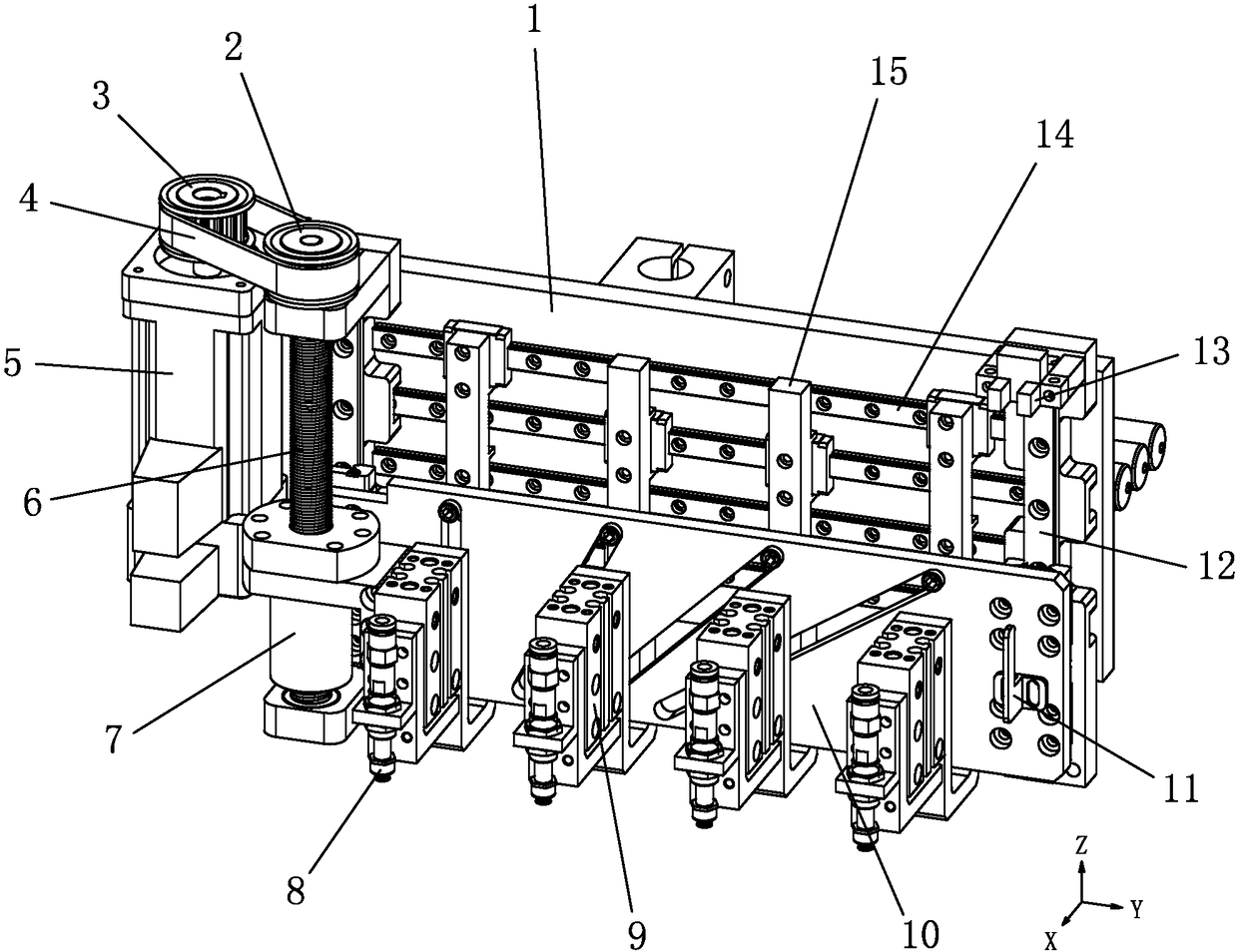

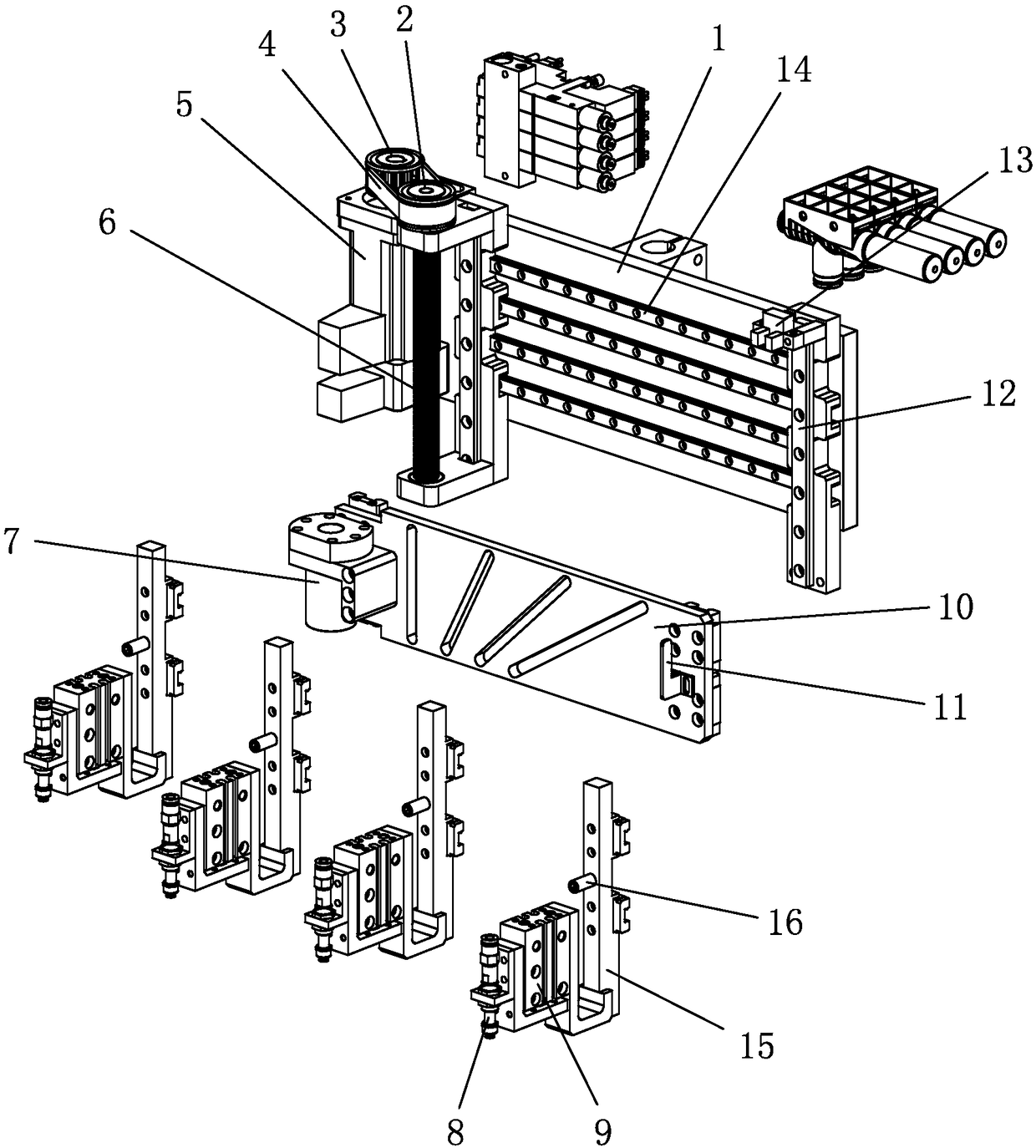

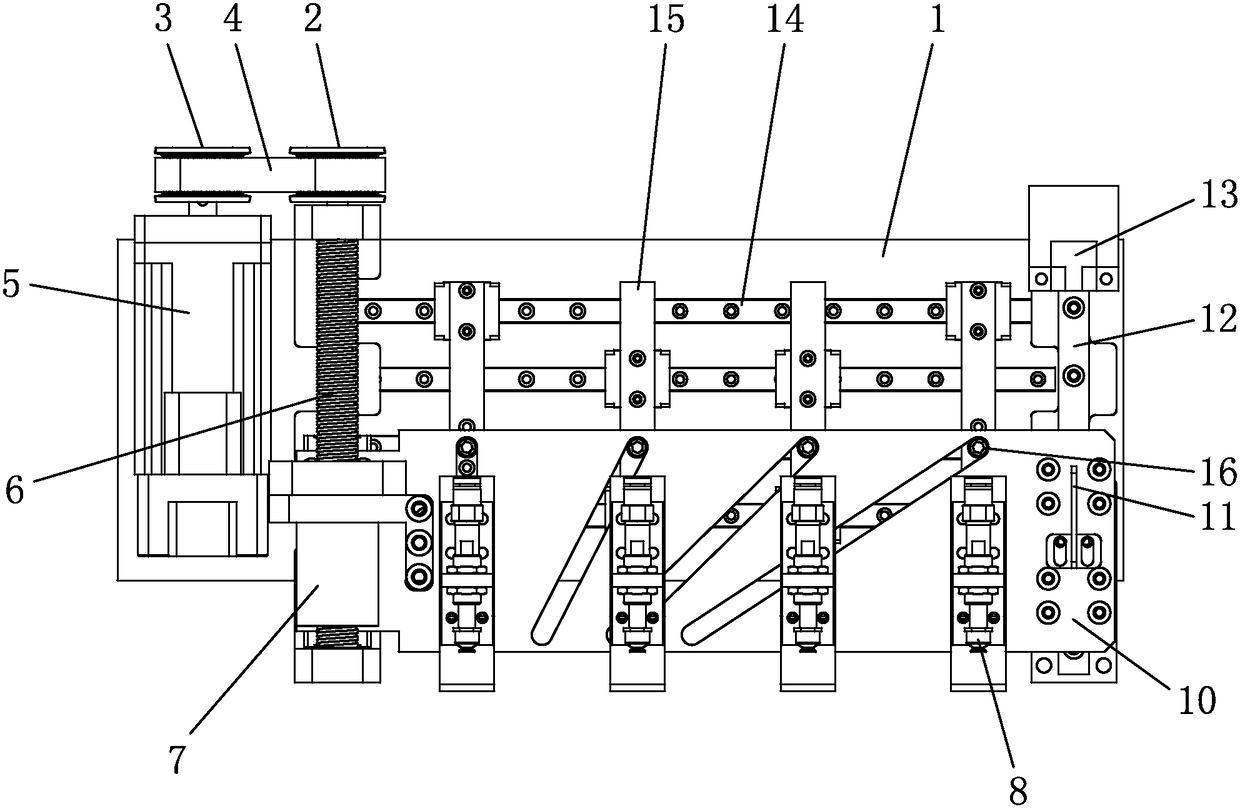

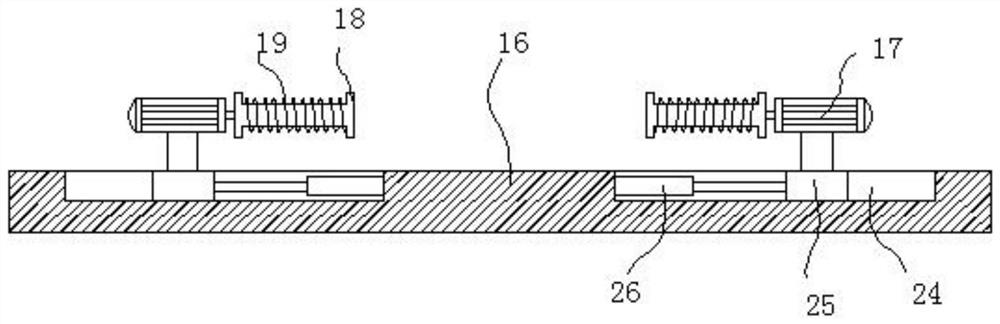

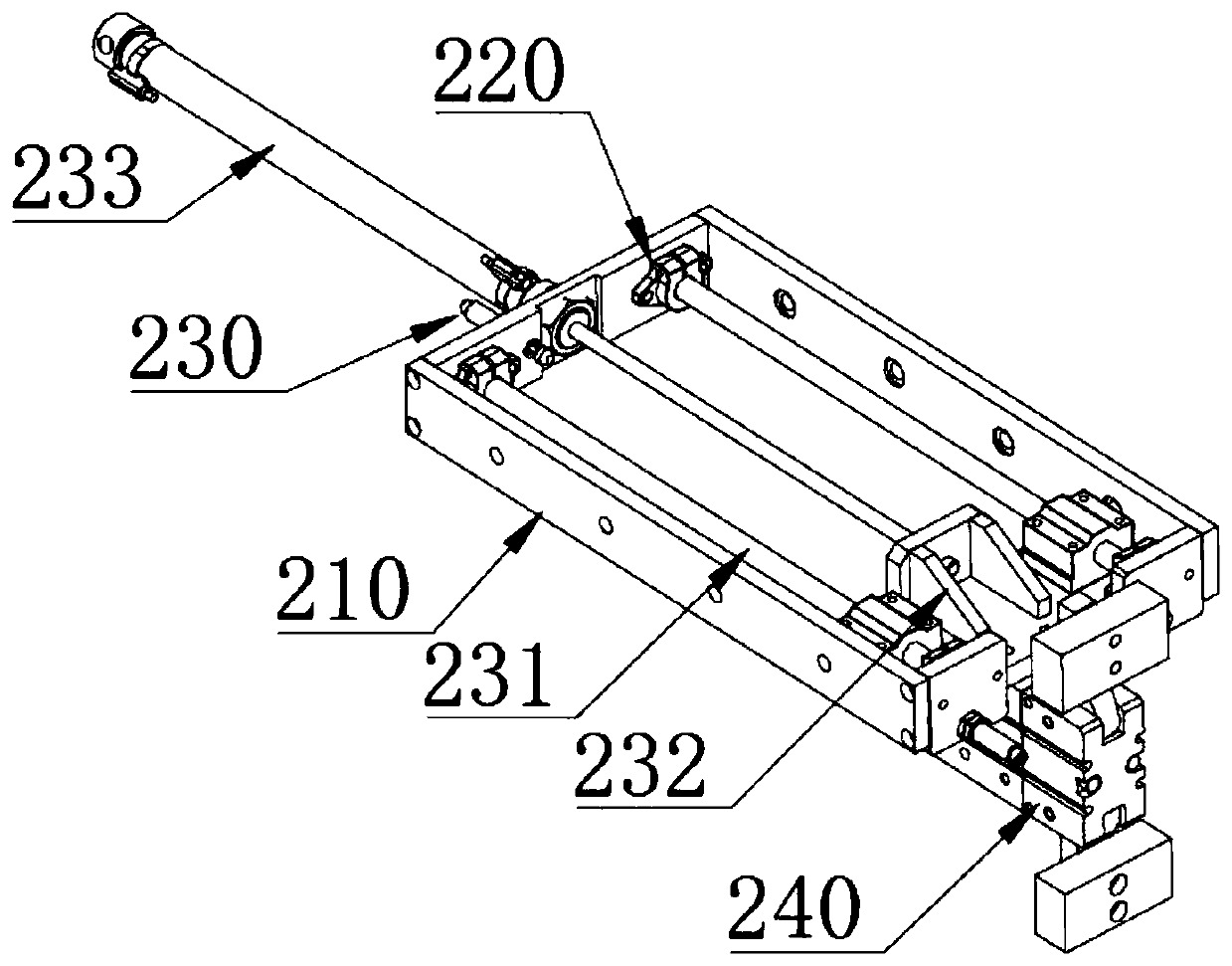

Adjustable-type precise sorting fixture

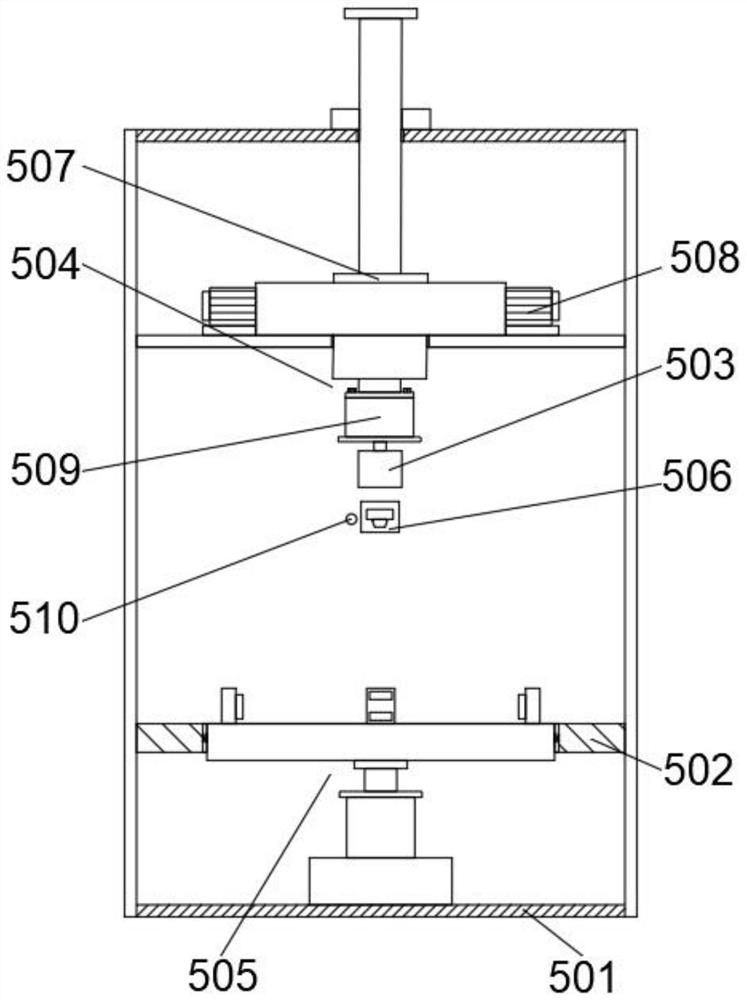

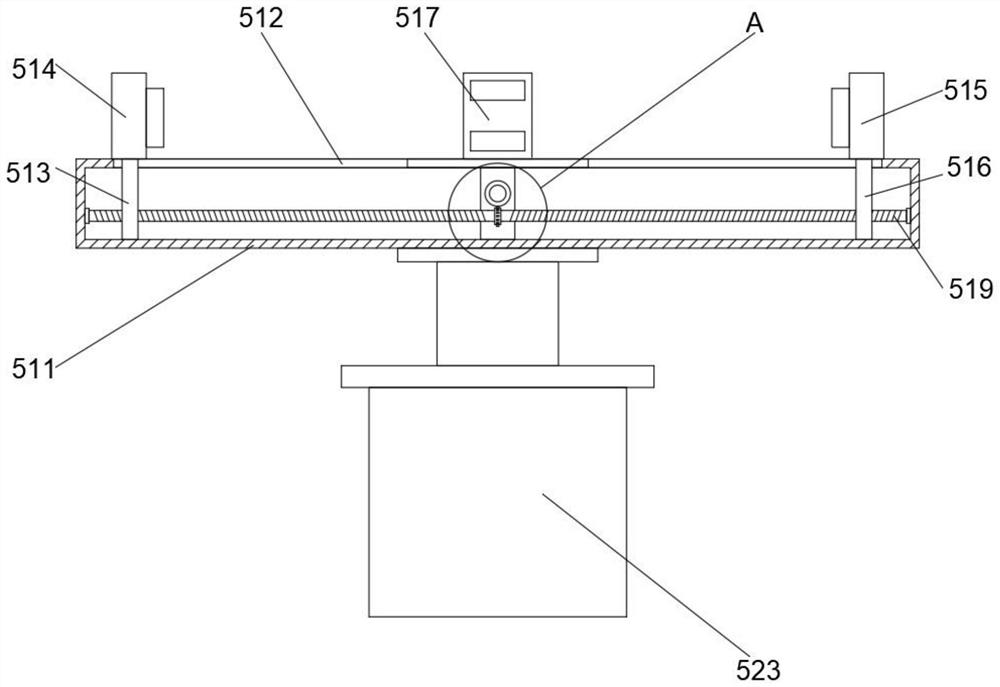

PendingCN108326842AAdapt effectivelyImprove general performanceProgramme-controlled manipulatorGripping headsTraction - actionEngineering

The invention relates to an adjustable-type precise sorting fixture. The adjustable-type precise sorting fixture comprises a fixture loading plate, a driving mechanism, an adjusting mechanism and twoor more grabbing units, wherein the driving mechanism, the adjusting mechanism and the two or more grabbing units are arranged on the fixture loading plate. The driving mechanism is arranged on the fixture loading plate. The adjusting mechanism comprises a guiding plate sliding on the fixture loading plate. The driving mechanism drives the guiding plate to slide along the Z axis in a reciprocatingmode. Each grabbing unit comprises a transplanting bracket sliding on the fixture loading plate. The guiding plate is provided with guiding grooves matched with the grabbing units. The transplantingbrackets are provided with adjusting action parts. The adjusting action parts slide in the guiding grooves in a reciprocating mode. When the guiding plate slides along the Z axis, one or more grabbingunits simultaneously slide along the Y axis in the same direction under the traction action of the guiding grooves on the adjusting action parts, and all the grabbing units are close to or away fromone another. According to the adjustable-type precise sorting fixture, all the grabbing units can simultaneously slide in the same direction, the position adjustment effect that the grabbing units areclose to or away from one another is achieved, the adjustable-type precise sorting fixture can effectively adapt to different types of workpieces, and universality and practicability are high.

Owner:广东埃华路机器人工程有限公司

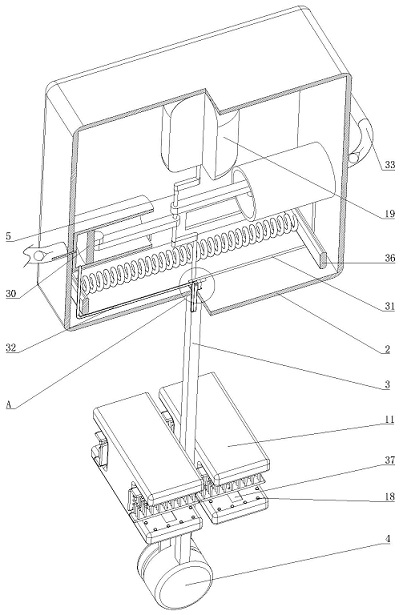

Mobile steam type hang ironing machine

InactiveCN107385841AImprove continuityImprove ironing efficiencyIroning apparatusTextiles and paperEngineeringThreaded rod

The invention discloses a mobile steam type hang ironing machine which comprises a base. A hollow mounting seat is fixed to the top of the base, an ironing shell is fixed to the top of the hollow mounting seat and comprises a back panel, a cross mounting shell is fixed on the back panel of the ironing shell, a second driving motor is fixed in the cross mounting shell, the output shaft of the second driving shell is fixed with a gear sleeved in the cross mounting shell, the gear is connected with a gear ring in an engaged manner, and a second thread rod is sleeved in the inner side of the gear ring in a threaded manner. By cooperative use of the cross mounting shell, the second driving motor, the gear, the gear ring, the second thread rod, a C-shaped connecting rod and the like in structure, clothes on a support rod can pass through the interior of the ironing shell, continuous hanging and taking out operations of the clothes can be performed, good continuity in clothes ironing is achieved, and the hang ironing machine is flexible in use.

Owner:合肥赛格汽车服务有限公司

Strain bag automatic capping unit

ActiveCN104488566BLess susceptible to infectionSimple structureCultivating equipmentsMushroom cultivationPulp and paper industryBelt conveyor

The invention relates to an automatic strain bag covering unit and belongs to the technical field of edible fungus production. The automatic strain bag covering unit aims at solving the technical problems of low production efficiency and low automation degree existing in the prior art are solved and is high in automation degree and remarkably-improved in production efficiency. According to the technical scheme, the automatic strain bag covering unit comprises a belt conveyor for conveying strain bags, wherein strain bag baffles are installed on two sides of the belt conveyor, a ring sleeving machine for strain bags to be sleeved with rings is further installed on the belt conveyor, a bag opening folding mechanism for folding the openings of the strain bags is arranged at the rear portion of the ring sleeving machine, and a covering machine for the strain bags to be covered is arranged at the rear portion of the bag opening folding mechanism. The automatic strain bag covering unit is widely used for ring sleeving and covering of the strain bags.

Owner:ZHANGZHOU CITY XINGBAO MACHINERY

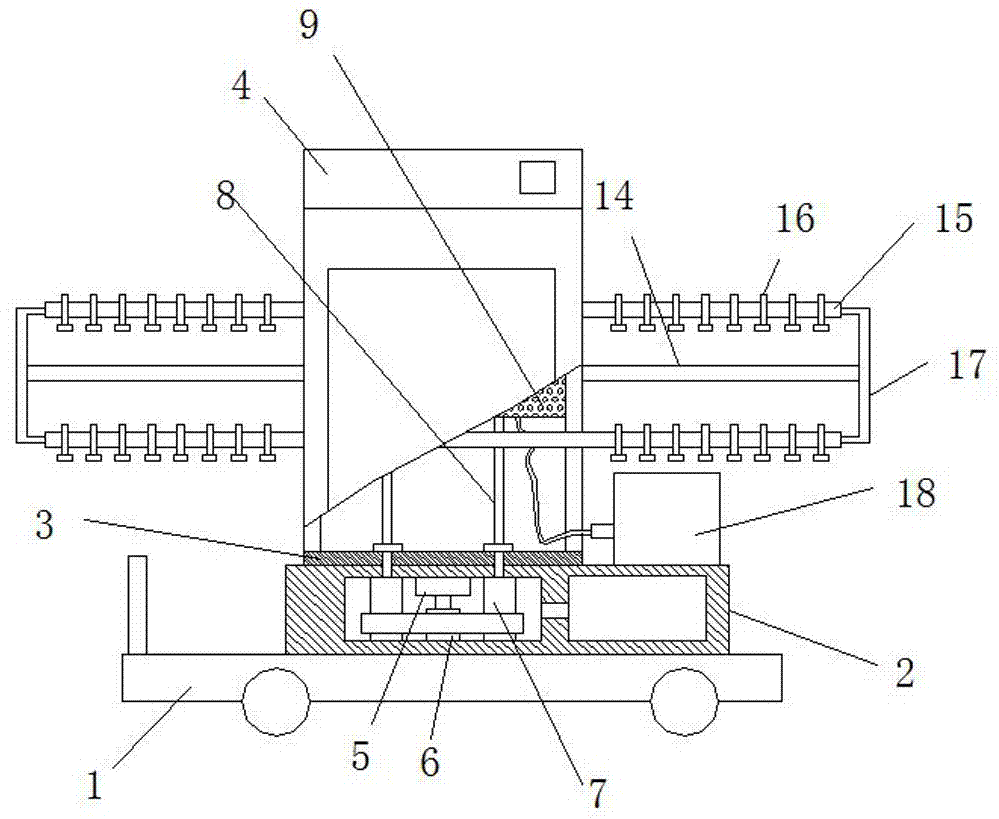

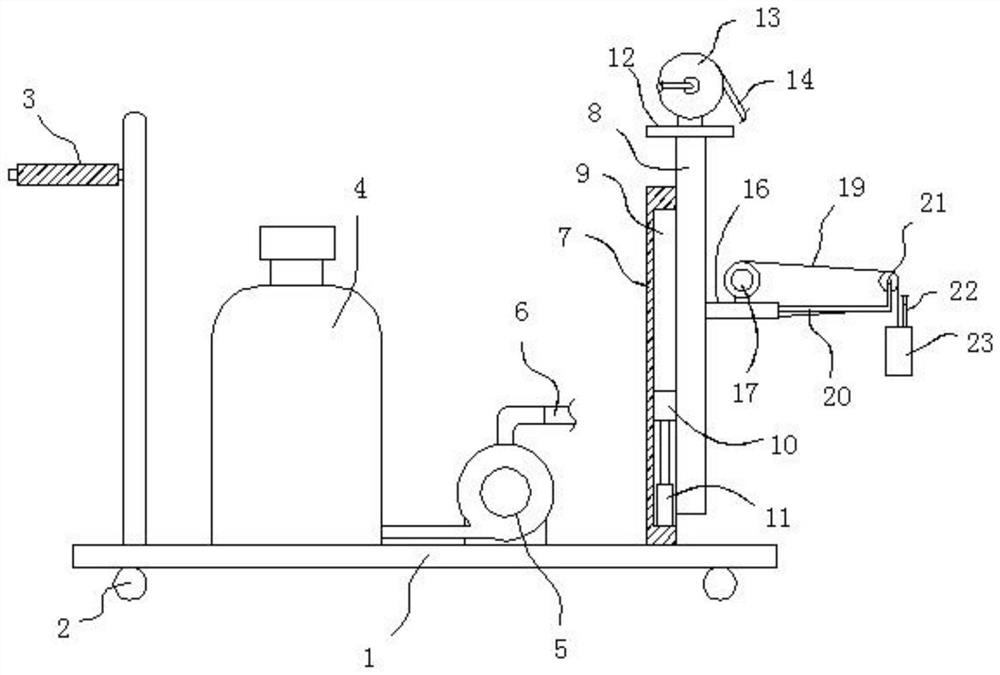

On-site water spraying detection equipment for performance of external doors and windows of building

PendingCN114034434AManual operation is not requiredSpray evenlyFluid-tightness measurement using fluid/vacuumArchitectural engineeringWindow detection

The invention belongs to the technical field of door and window detection, and particularly relates to on-site water spraying detection equipment for performance of external doors and windows of a building which comprises a base, a handle, a water tank, a liquid pump and a fixing plate are sequentially and fixedly mounted at the top of the base from left to right, and a lifting plate is connected to the right side wall of the fixing plate. The equipment moves to a windowsill through a pushing device, then a water spraying pipe extends out of a window, and then a second electric push rod and a third electric push rod are started according to the width of the window, so that a first spraying pipe and a second spraying pipe extend outwards, the length is adjusted, and the equipment adapts to the width of the window; then a first motor is started to discharge a water pipe, meanwhile, a second motor is started to pay off, so that a spray pipe descends, a liquid pump is started to pump water in a water tank, and the water is sprayed to the surface of the window through a spray head for detection, so that the device can adapt to windows of different sizes, manual handheld operation is not needed, and spraying is uniform; meanwhile, the dangerous situation of manual operation is avoided.

Owner:曾斌

Ingot casting device for automatically clearing impurity and finishing appearance

The invention belongs to the field of non-ferrous metal melting equipment, and relates to an ingot casting device for automatically clearing impurity and finishing appearance. The device comprises a casting part, a baffle plate, a scraper assembly, an edge scraping assembly and an ingot mold, wherein the casting part adjusts the flow by using the dynamic balance principle; the scraper assembly removes oxide layers and impurity; and the edge scraping assembly finishes the ingot casting appearance. The device has the advantages that: because of the adoption of the technical scheme, the device automatically controls the flow and the weight, clears the impurity and finishes the appearance by electric and mechanical automatic control combination; and the device replaces manual operation, improves the dangerous and hard working environment of workers, reduces the labor intensity, improves the work efficiency, has a simple structure, and does not use manual operation.

Owner:施长智

An automatic tape wrapping system for gypsum board pads

ActiveCN109693308BRealize automatic receivingAchieve rotationAuxillary shaping apparatusAdhesive beltEngineering

Owner:BEIJING NEW BUILDING MATERIALS PLC +1

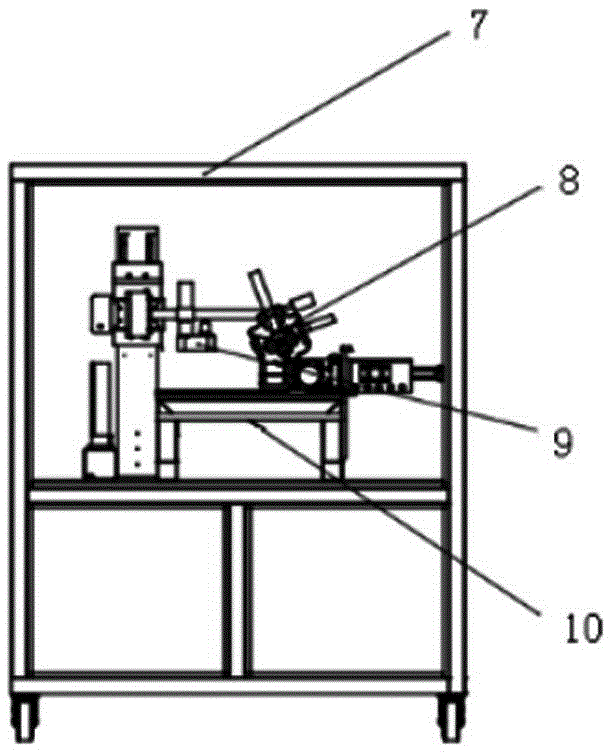

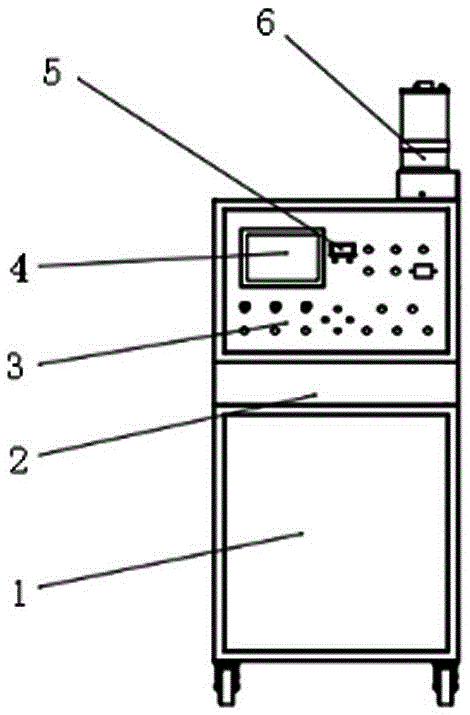

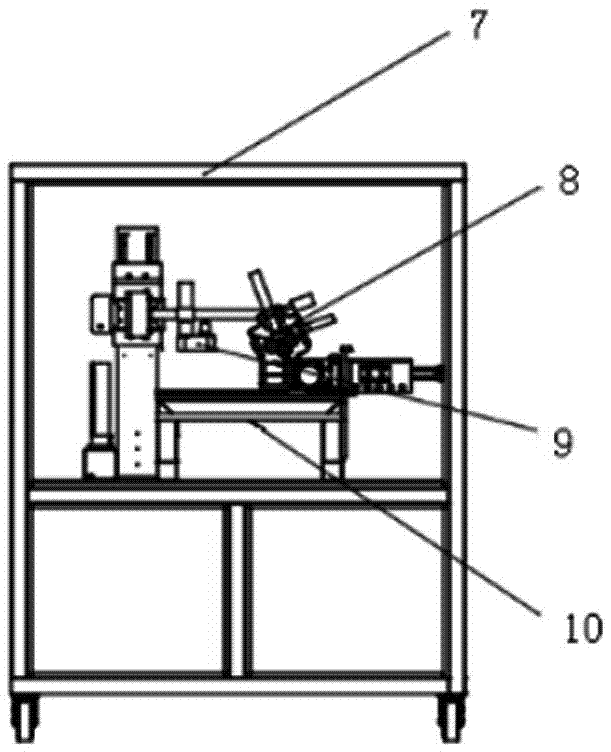

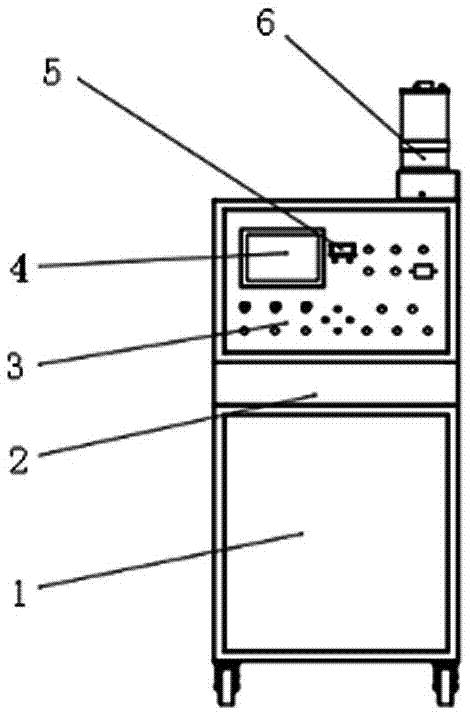

Intelligent metal deposition modular system

ActiveCN105671547AReduce inconsistencyAdd setting functionMolten spray coatingTotal factory controlReal-time dataControl system

The invention discloses an intelligent metal deposition modular system. The intelligent metal deposition modular system comprises a fast insertion-pulling mode power source box, a central control system, an operation interface, a deposition material conveyor, a safety protection box, a material deposition generator and a workpiece tool clamp. A control system and the operation interface are installed on the fast insertion-pulling mode power source box. A man-machine interaction interface and a real-time data display gauge are installed on the front outer face of the operation interface in a nested mode. The deposition material conveyor is installed at the top end of the right side of the operation interface. The workpiece tool clamp is installed in the safety protection box. A temperature collecting device and the material deposition generator are installed on a support of the workpiece tool clamp. According to the intelligent metal deposition modular system, full-automatic operation of the whole processing course is achieved, and manual intervention is not needed, so that the labor cost is reduced, the product production pass rate is increased, and the efficiency is improved.

Owner:开识(上海)自动化科技有限公司

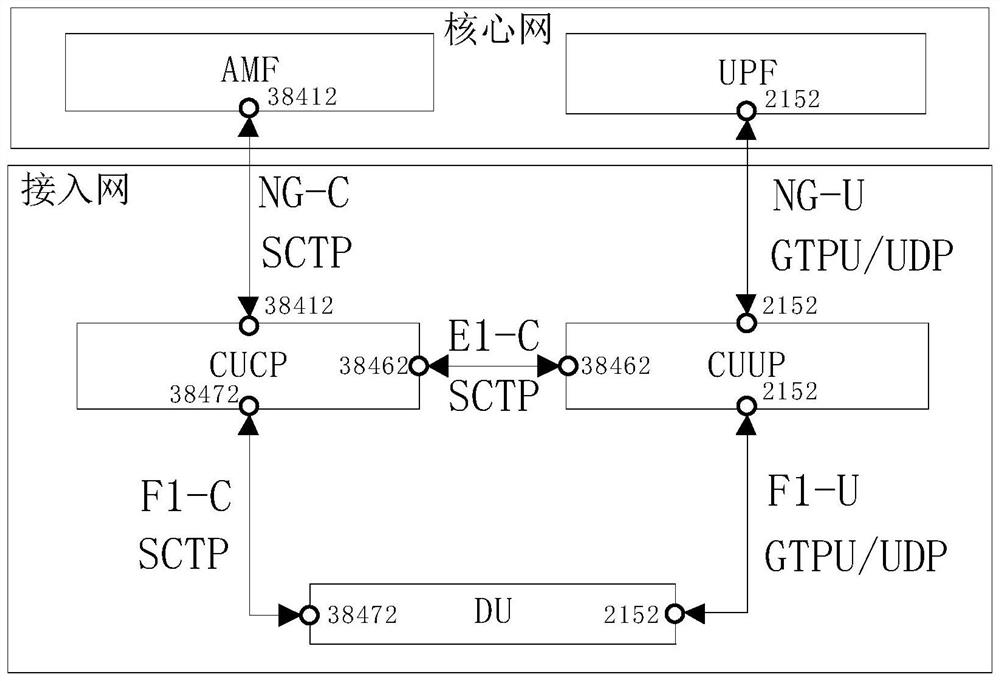

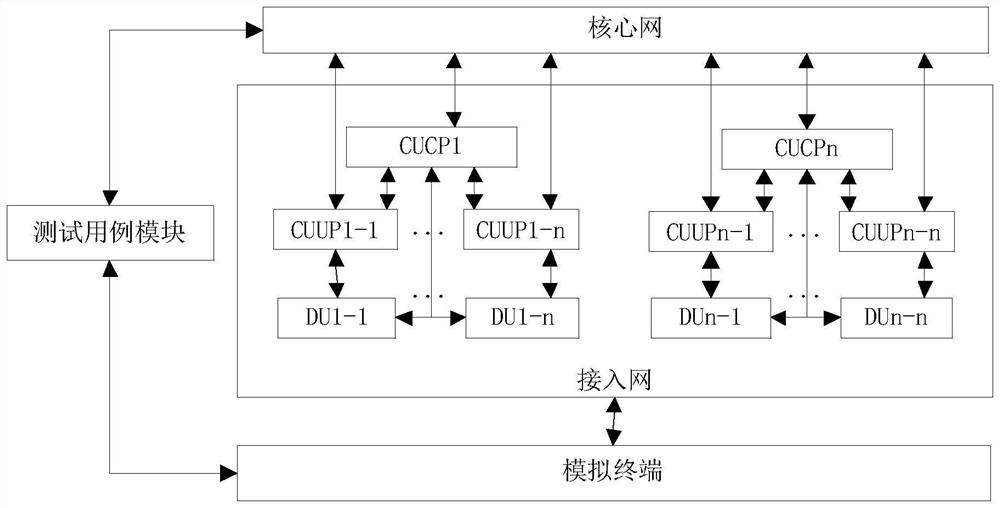

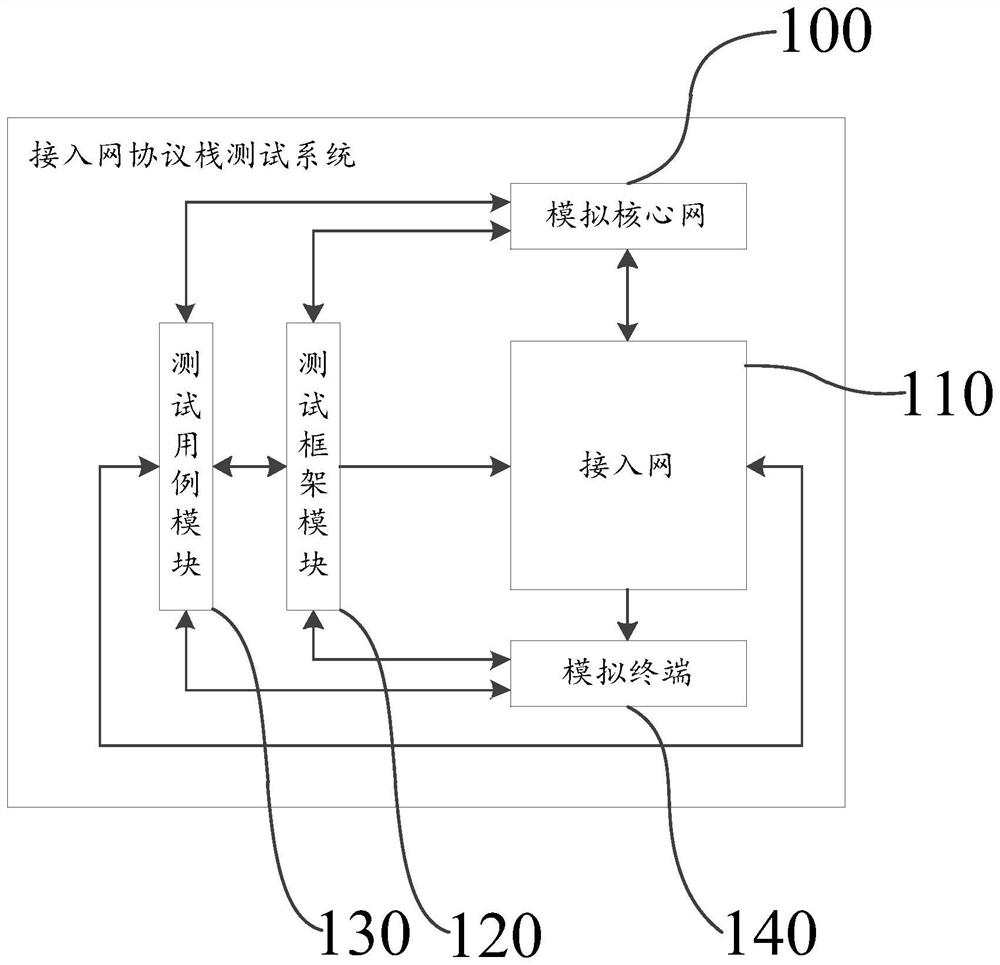

Access network protocol stack test method and system and storage medium

PendingCN114390024ASolve conflictsThe test environment is accurateTransmissionAccess networkOperational system

The invention discloses an access network protocol stack testing method and system and a storage medium, and relates to the technical field of 5G communication. The access network protocol stack test method comprises the following steps: taking over a network service of a preset operating system; intercepting a first communication request of a preset first network element through the taken-over network service; the first communication request comprises a first port number; when the first port number is unavailable, acquiring a preset first available port number, and binding the first available port number with the first network element; searching first identification information corresponding to the first network element, and obtaining a first available port number corresponding to the first identification information; establishing a link between the first network element and the second network element through the first available port number and a preset second port number of the second network element; wherein the second port number is different from the first available port number. According to the access network protocol stack testing method, the problem that the port numbers conflict with one another can be solved, and manual operation is not needed.

Owner:中科南京移动通信与计算创新研究院

Porcelain insulator trimming method and device

InactiveCN102485452BQuality improvementHigh degree of automationCeramic shaping apparatusElectric machineryEngineering

Owner:贵州建新南海科技股份有限公司 +2

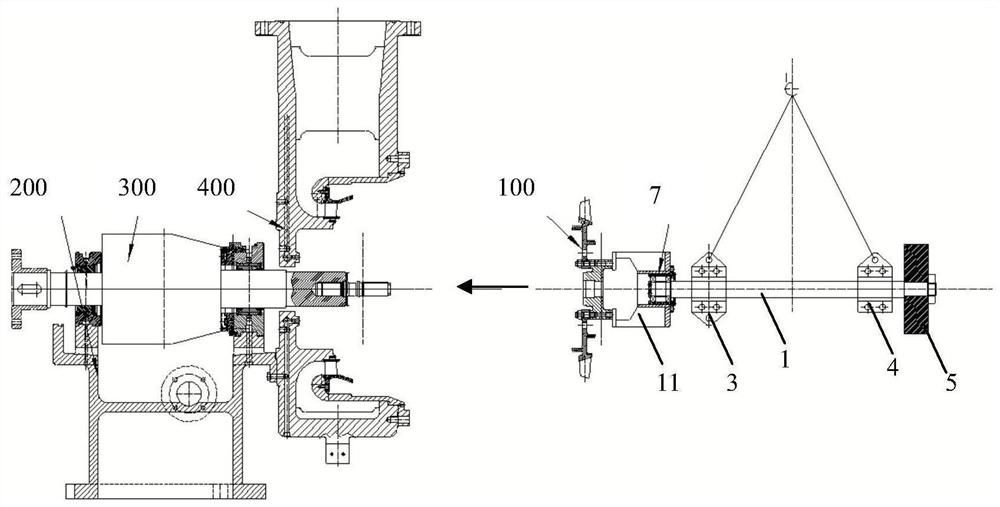

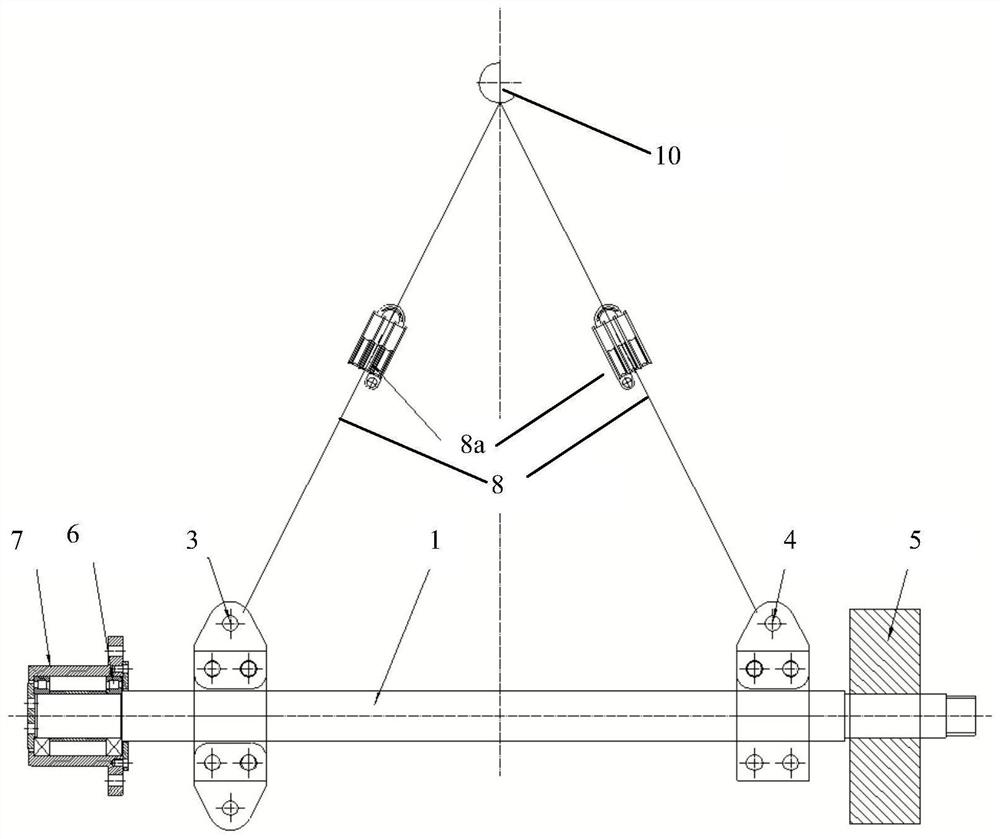

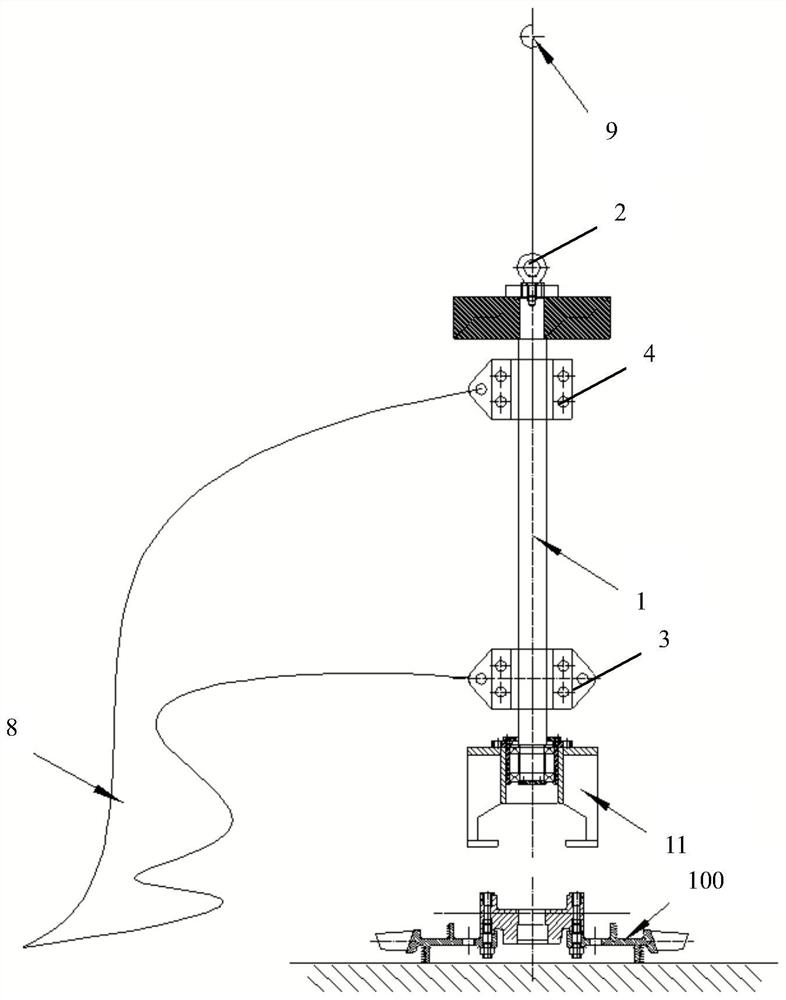

Blade disc hoisting device and method

PendingCN114229673AAchieve circumferential rotationOperation saves time and effortLoad-engaging elementsEngineeringMechanical engineering

The invention discloses a blade disc hoisting device and method, and the hoisting device comprises a hoisting beam; and the rotating part is arranged on the lifting beam and is connected with the blade disc in the lifting process, so that the blade disc can circumferentially rotate around the axis of the lifting beam. The hoisting method comprises the following steps that the hoisting beam is hoisted in a vertical state, the rotating part is located at the bottommost portion of the hoisting beam after hoisting, and the rotating part and the blade disc are aligned in the vertical direction; the rotating part is connected with the blade disc, and the blade disc and the lifting beam are synchronously lifted; the hanging beam is rotated, the hanging beam is rotated from the vertical state to the horizontal state, and the blade disc rotates synchronously; the hanging beam is transversely moved, and the rotated blade disc is conveyed to a mounting position; the blade disc is installed; and after the blade disc is mounted, the rotating part is separated from the blade disc. The blade disc can circumferentially rotate around the lifting beam in the air, the lifting process is faster and more efficient, and meanwhile the assembly precision is improved.

Owner:SHENYANG TURBO MASCH CORP

Full-automatic blanking device for quantitative cutting of alloy bars

PendingCN113695668ARealize blankingFacilitate automatic processingConveyor partsShearing machine accessoriesHydraulic cylinderSuperalloy

The invention relates to the field of high-temperature alloy machining, in particular to a full-automatic blanking device for quantitative cutting of alloy bars. The device comprises a pressing and breaking device and a truss manipulator, the truss manipulator is located on the side, where a material bearing groove is located, of the pressing and breaking device, and the truss manipulator corresponds to a bar in the material bearing groove through a pneumatic claw on the truss manipulator; a roller conveying line is installed on a bearing base, a first hydraulic cylinder and a second hydraulic cylinder are installed on a press frame in the vertical direction, a fixed pressing head is installed at the output end of the lower portion of the first hydraulic cylinder, and a breaking pressing head is installed at the output end of the lower portion of the second hydraulic cylinder; and the material bearing groove is installed at the tail end of the roller conveying line, an air cylinder is installed at the bottom of the material bearing groove, two sets of proximity switches are arranged below the material bearing groove, the proximity switches judge whether incoming materials are excess materials or finished products, and the incoming materials are grabbed to corresponding stations through the truss manipulator. According to the full-automatic blanking device, full-automatic breaking and blanking after grooving of the alloy bar are achieved, the labor cost is saved, and the product quality and the production efficiency are greatly improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Welding and fixing device for automobile front suspension component

PendingCN114406582AImprove stabilityPlay a protective effectWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryEngineering

The invention discloses an automobile front suspension component welding fixing device which comprises a workbench and a welding gun located above the workbench, a bottom plate is fixed to the lower portion of the inner wall of the workbench, a protection fixing mechanism is arranged between the bottom plate and the workbench, guide grooves are formed in the two sides of the top of the workbench, and the guide grooves are connected with the welding gun. A folding frame is arranged between the inner surfaces of the two guide grooves in a sliding mode, and a welding adjusting mechanism is arranged between the folding frame and the welding gun. The invention relates to the technical field of automobile front suspension part machining. According to the welding and fixing device for the automobile front suspension component, power output is provided through the first motor, through the rotating process of the rotating disc, the lower connecting plate is pushed or pulled through the connecting plate, and the sliding block and the upper connecting plate are matched, so that the rapid fixing process during welding of the automobile front suspension component can be achieved, stability is high, and practicability is high. And meanwhile, a hydraulic rod, a protection plate and a moving groove are arranged, so that the protection effect can be achieved when the automobile front suspension component is welded, sparks are prevented from splashing during welding, and the protection effect is good.

Owner:湖北鼎林五金制品有限公司

An intelligent metal deposition modular system

ActiveCN105671547BReduce inconsistencyAdd setting functionMolten spray coatingTotal factory controlOperator interfaceReal-time data

Owner:开识(上海)自动化科技有限公司

Special-shaped glass bottle double-sided trademark offset printing device

ActiveCN103935115BPrecise positioningGuaranteed positive contactTransfer printingProduction lineEngineering

The invention discloses a special-shaped glass bottle double-sided brand offset printing device which comprises a working table. A rotating disc and a cam indexer are arranged on the working table. A plurality of special-shaped bottle clamping mechanisms are evenly distributed on the edge of the rotating disc. Each special-shaped bottle clamping mechanism comprises a horizontally-moving air cylinder, wherein a bottle body containing base frame is arranged on the horizontally-moving air cylinder, a bottle body turning shaft and a bottle bottom bearing bottom plate are installed at the tail end of the bottle body containing base frame, a pit is formed in the bottle bottom bearing bottom plate, a bottle opening bearing frame is arranged on the bottle body containing base frame, a turning driving device is connected with the outer end of the bottle body turning shaft, an ejecting air cylinder and an ejecting head are arranged at the front end of the bottle body containing base frame, and thermal printing units are correspondingly arranged at the fixed positions of the two special-shaped bottle clamping mechanisms on the working table respectively. By means of the special-shaped glass bottle double-sided brand offset printing device, manual operation is greatly reduced, production efficiency is high, the percent of pass is greatly increased, energy consumption is low, the quality is controllable, labor intensity of workers is low, and the device is suitable for automatically controlling a production line and easy to popularize.

Owner:SHANDONG HAIDA ROBOT TECH CO LTD

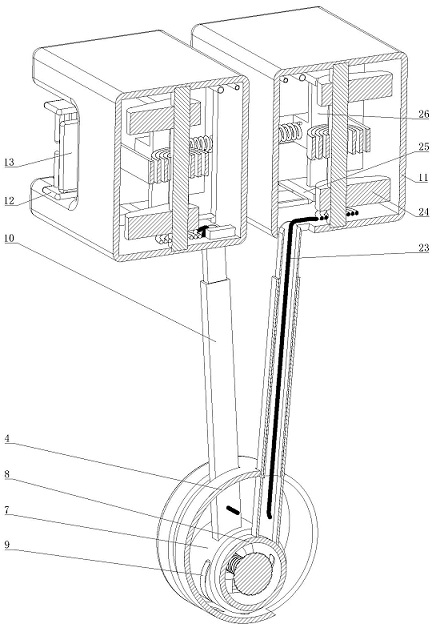

A disassembly device and disassembly method for plastic-steel busway

ActiveCN109244929BStable supportNo manual liftingCable installation apparatusHydraulic cylinderCoupling

The invention discloses a disassembling device for a plastic steel bus slot, which includes a substrate, a universal wheel is connected to both side of that bottom of the base plate through leg, the notches on both sides of the substrate are connected with collecting grooves through springs, two group of first hydraulic cylinders symmetrically arrange are mounted on the base plate att one side ofthat collection groove; the top plate is connected to that middle position of the top of the support plate through the two output ends of first cylinders arranged symmetrically, that top of the top plate is connected with a rotary table through a rotary shaft which is rotatably connected, the motor output ends on both sides of the rotary table are respectively driven and connected with a cutting sheet and a grinding wheel sheet through a coupling, A support groove is movably connected at both sides of that first cylinder on the support plate through the output end of the second cylinder whichis movably connected. The invention provides a stable support function during the disassembly and assembly process, improve the safety of the disassembly and assembly, avoids scattering parts everywhere, facilitates the subsequent recycling and use, does not require manual hand-held operation, saves manpower, and improves the disassembly and assembly efficiency.

Owner:石狮嘉鸿电气有限公司

An automatic sorting and decoding workstation for coal sample barrels

ActiveCN113770055BRealize sorting and batch testingReduce error rateSortingPasswordProcess engineering

The invention discloses an automatic sorting and decoding workstation for coal sample collection barrels, which relates to the technical field of coal sample collection sorting and decoding, and includes a support chassis, a rotary roller line, an L-shaped barrel discharge roller line, a password sample collection barrel, a sorting The selection of workstations and straight line in and out of the roller line realizes the sorting and batch detection of a large number of multi-batch password collection sample barrels, reduces the error rate, reduces manual contact operations, and can automatically sort the code collection sample barrels The sorting and batching detection does not require manual operation, which improves the work efficiency and solves the problem that the traditional relying on manual sorting and batching of a large number of cipher set sample barrels is prone to errors and low efficiency.

Owner:HUAIBEI MINING IND

Automatic sorting and decoding workstation for coal sample collecting barrels

The invention discloses an automatic sorting and decoding workstation for coal sample collecting barrels, and relates to the technical field of coal sample collecting, sorting and decoding, the automatic sorting and decoding workstation comprises a supporting bottom frame, a rotary roller line, an L-shaped barrel outlet roller line, password sample collecting barrels, a sorting workstation and a linear type inlet and outlet roller line, and sorting and blending detection of a large number of multi-batch password sample collecting barrels are achieved. The error rate is reduced, manual contact operation is reduced, sorting and blending detection can be automatically carried out on the password sample collecting barrels, manual operation is not needed, the working efficiency is improved, and the problems that a large number of password sample collecting barrels are sorted and blended manually in the prior art, errors are prone to occurring, and the efficiency is too low are solved.

Owner:HUAIBEI MINING IND

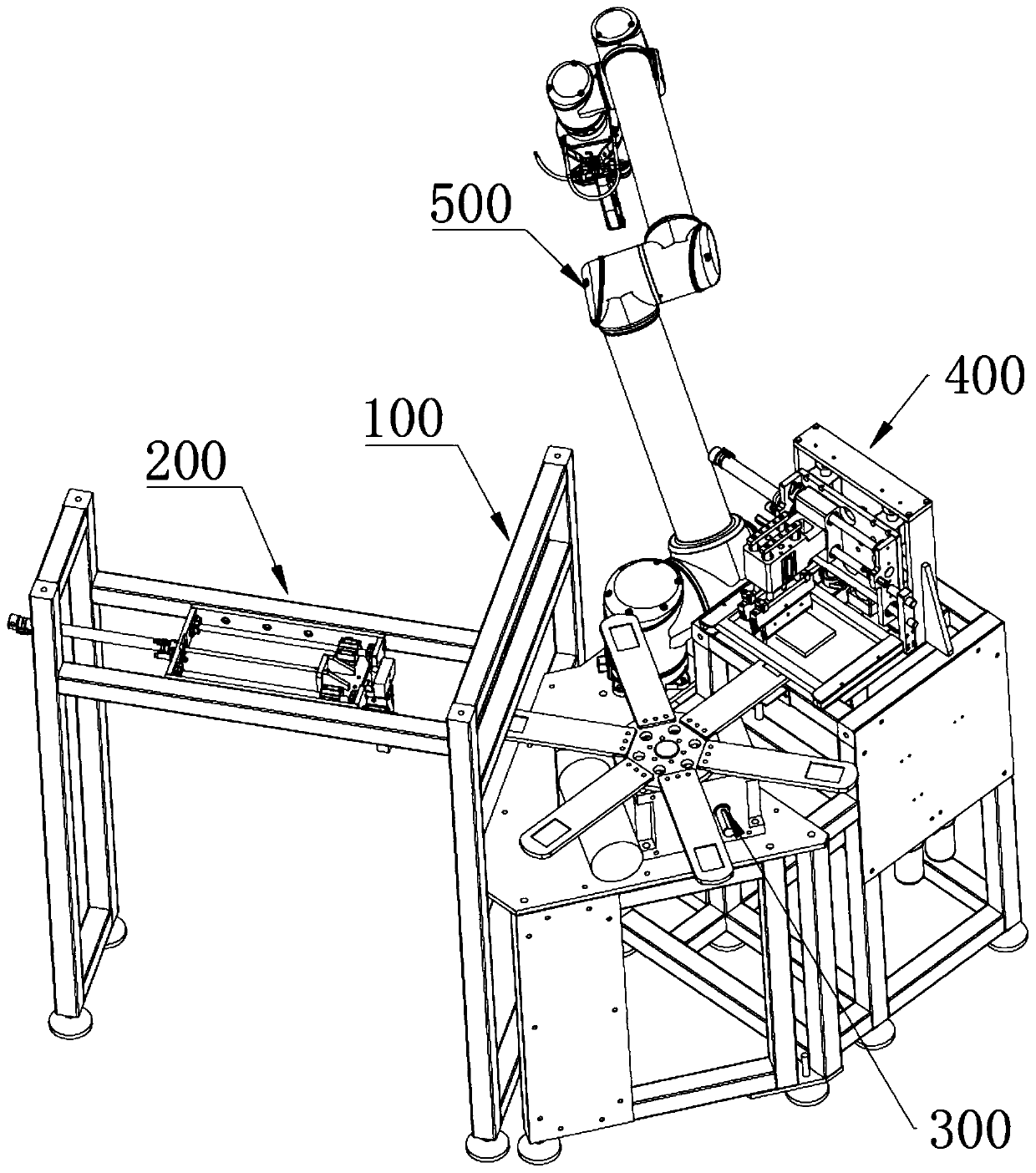

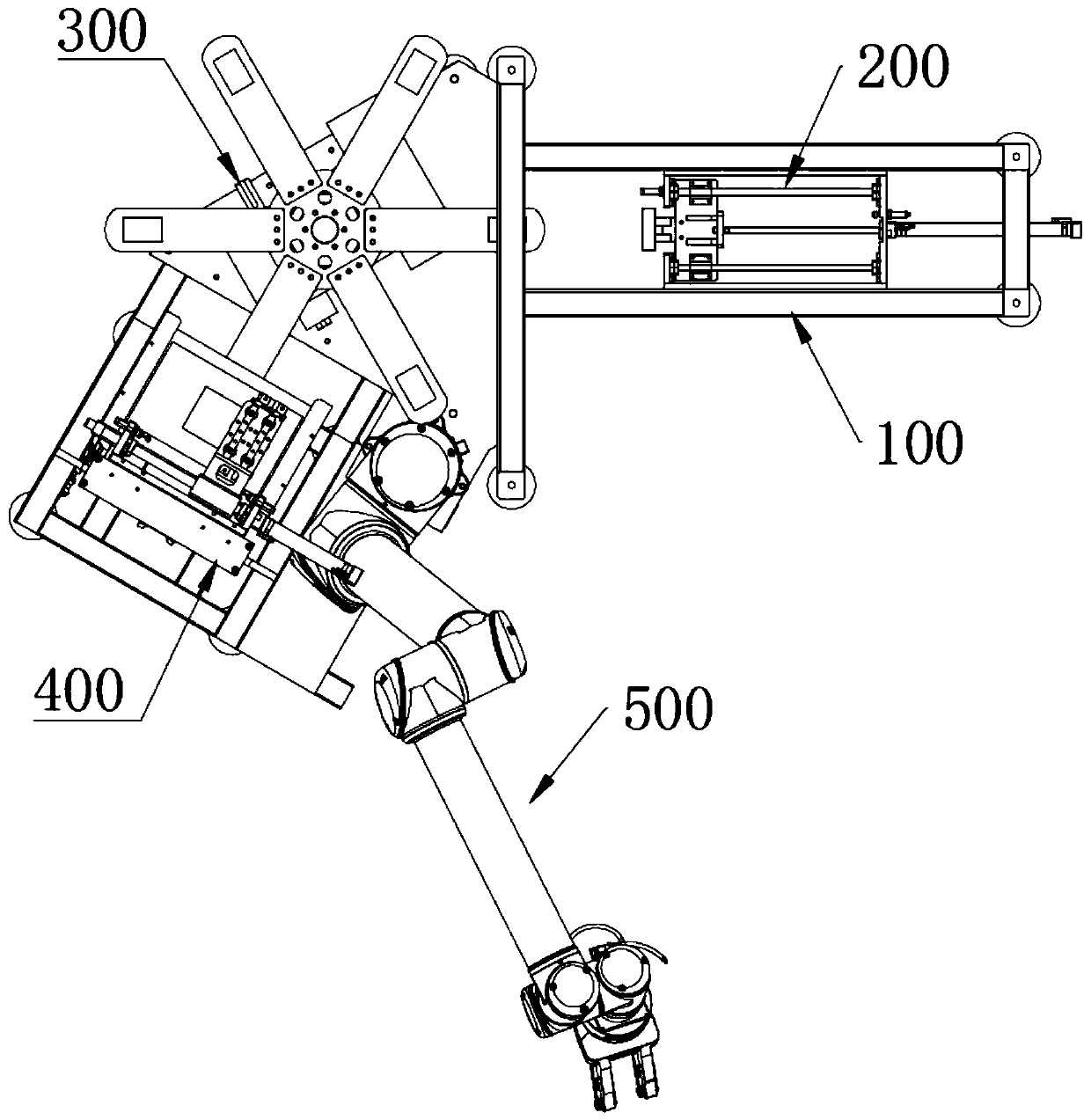

Silk-screen printing equipment based on automatic ink jetting of manipulator

InactiveCN111003499ARealize manual operationRealize fully automatic inkjet screen printingScreen printersConveyor partsScreen printingEngineering

The invention relates to the technical field of silk-screen printing equipment, and particularly relates to silk-screen printing equipment based on automatic ink jetting of a manipulator. The silk-screen printing machine comprises a rack, a feeding device which is arranged on one side of the rack and used for feeding products, a turntable device which is installed on the rack and used for bearingthe products fed by the feeding device, a silk-screen printing device which is installed on the rack, located on one side of the turntable device and used for conducting silk-screen printing on the products, and an automatic manipulator which is installed on the rack and capable of operating on the turntable device and the silk-screen printing device. According to the invention, automatic feedingis realized; the product is transferred through the turntable after feeding, silk-screen printing is conducted through the silk-screen printing structure, the product is grabbed and discharged throughthe automatic manipulator after silk-screen printing is completed, the automatic manipulator can be used for grabbing printing ink at the same time, the printing ink is poured into the silk-screen printing structure for silk-screen printing, manual operation is not needed, and thus the working efficiency is improved.

Owner:东莞市摩克电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com