Strain bag capping machine

A strain bag and capping machine technology, applied in horticulture, botanical equipment and methods, packaging, etc., can solve the problems of low production efficiency and easy infection of miscellaneous bacteria, and achieve high production efficiency, low infection of miscellaneous bacteria, easy operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

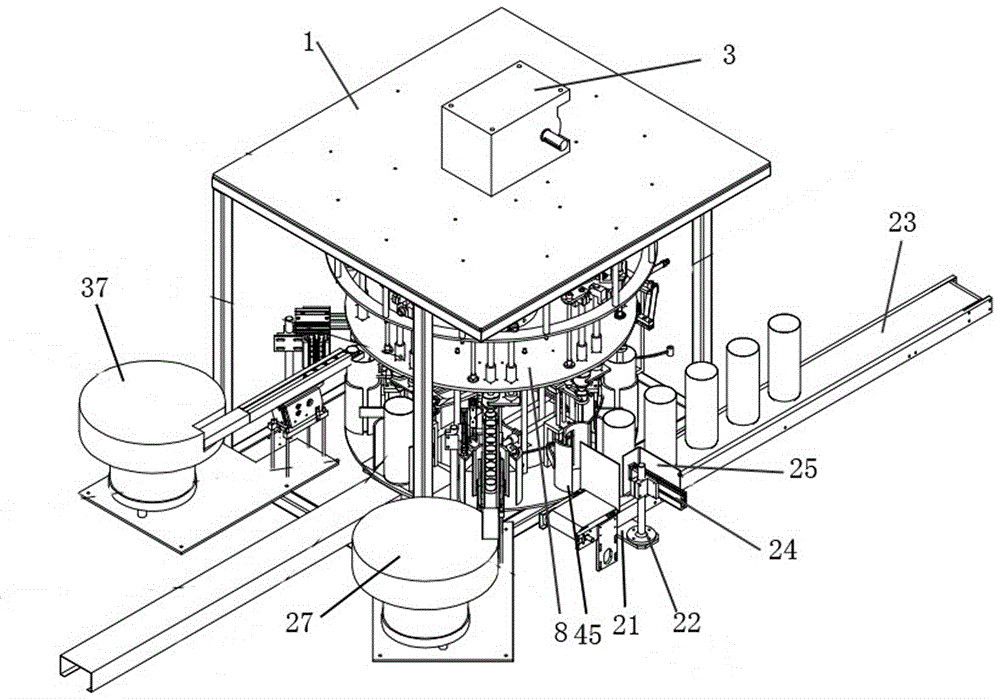

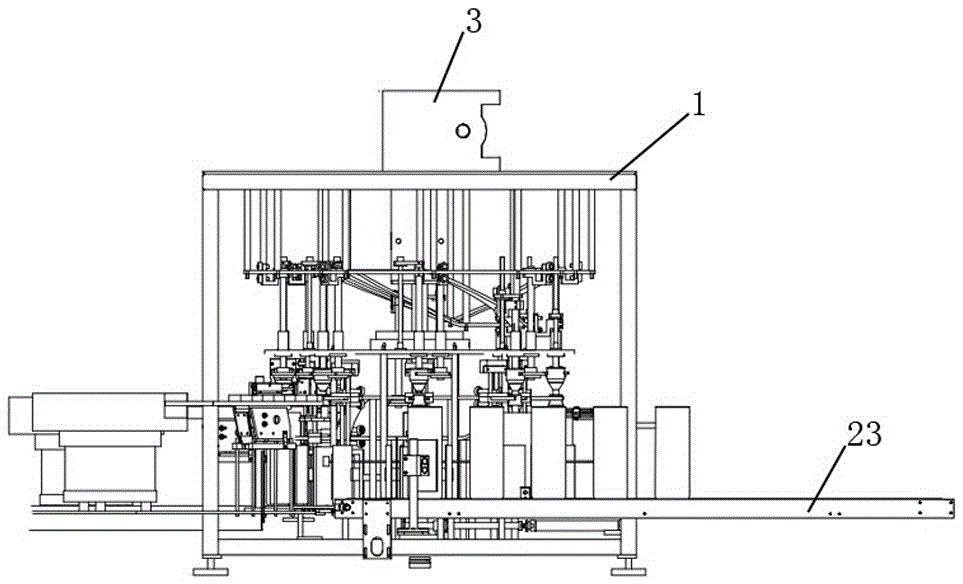

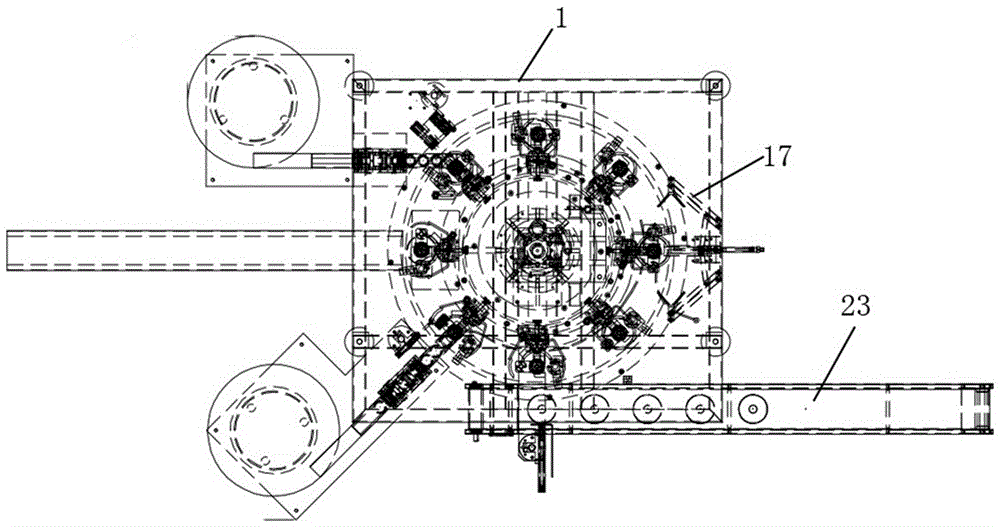

[0024] Such as Figure 1 to Figure 10 As shown, the bacterial strain bag cover machine includes: a frame 1, a central axis 2 is installed in the center of the frame 1, and a divider 3 is installed on the top of the frame 1, and the output of the divider 3 is connected to the central axis. 2 are connected, and the frame 1 is also equipped with an outer cam ring 4, an inner cam ring 5, a lifting cam ring 6 and a pocket cam plate 7, and the outer cam ring 4, the inner cam ring 5 and the lifting cam ring 6 are all The rim with ups and downs, wherein the rim can preset the height track according to the different needs of each station, the outer cam ring 4 and the inner cam ring 5 are concentrically arranged and fixed on the top of the frame 1, and the lifting cam ring 6 Set coaxially with the inner cam ring 5, the lifting cam ring 6 is located b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com