Pneumatic engaging and disengaging device for overhead cigarette carton conveying line

A technology of clutch device and conveying line, applied in the direction of conveyor, transportation and packaging, can solve the problems of unstable current and voltage of electromagnetic clutch, overload, burning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

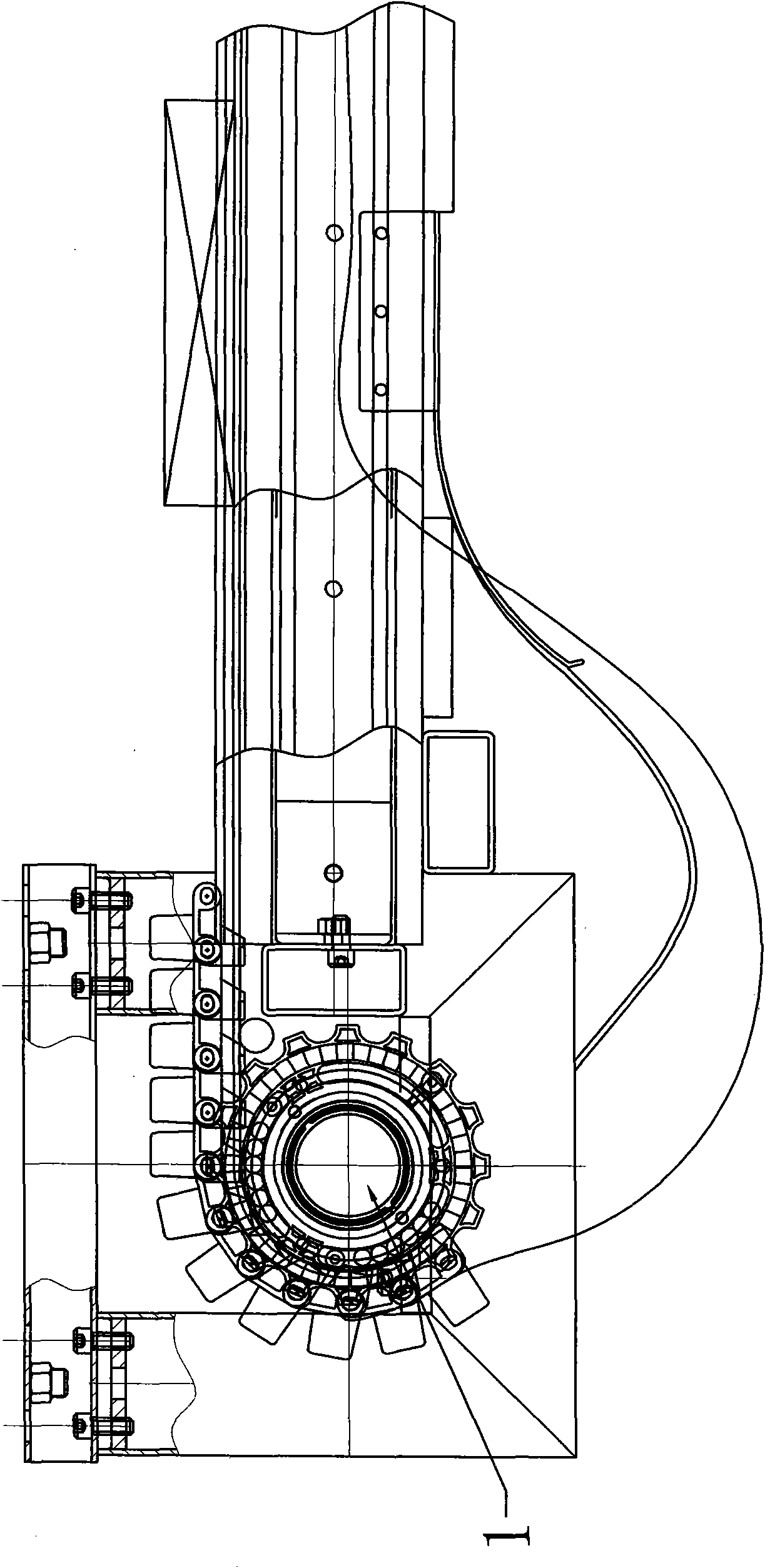

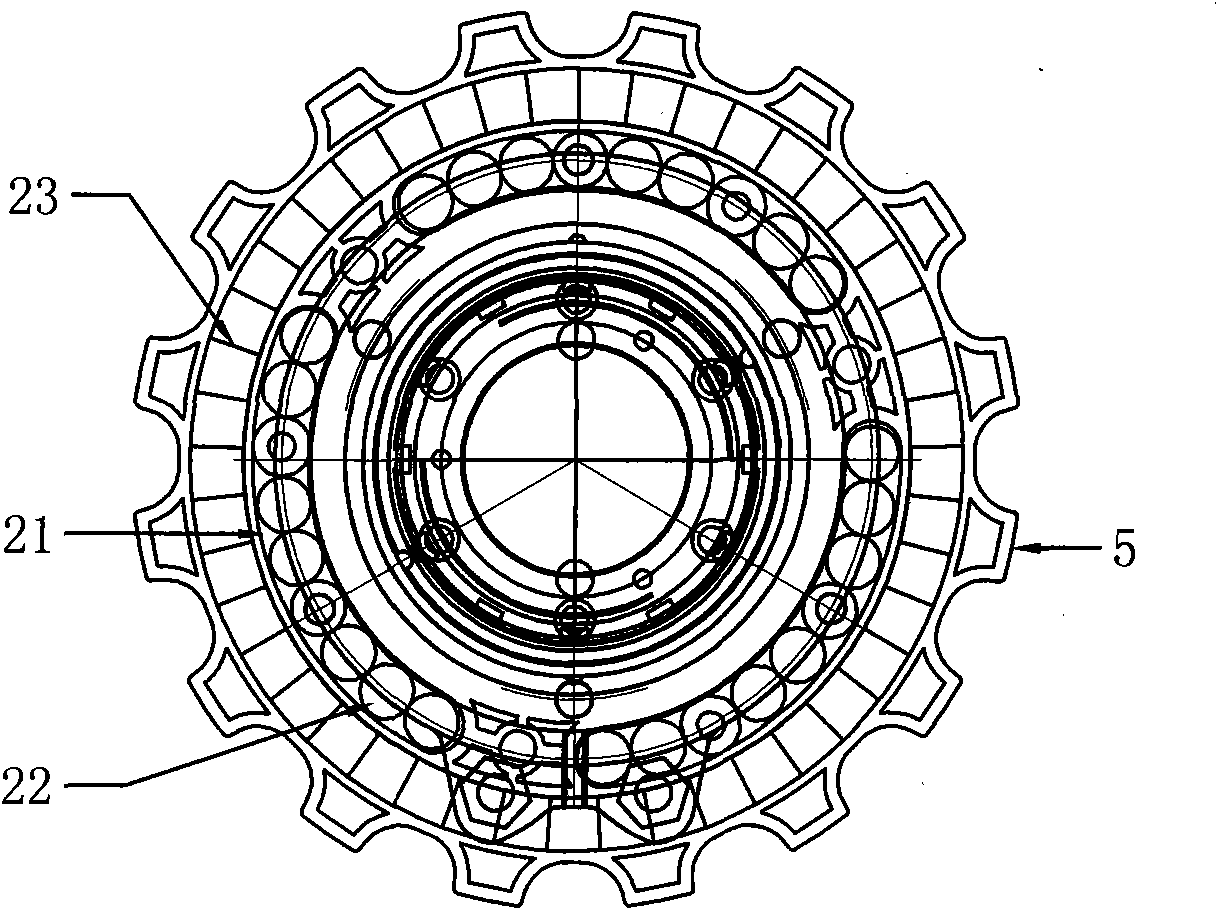

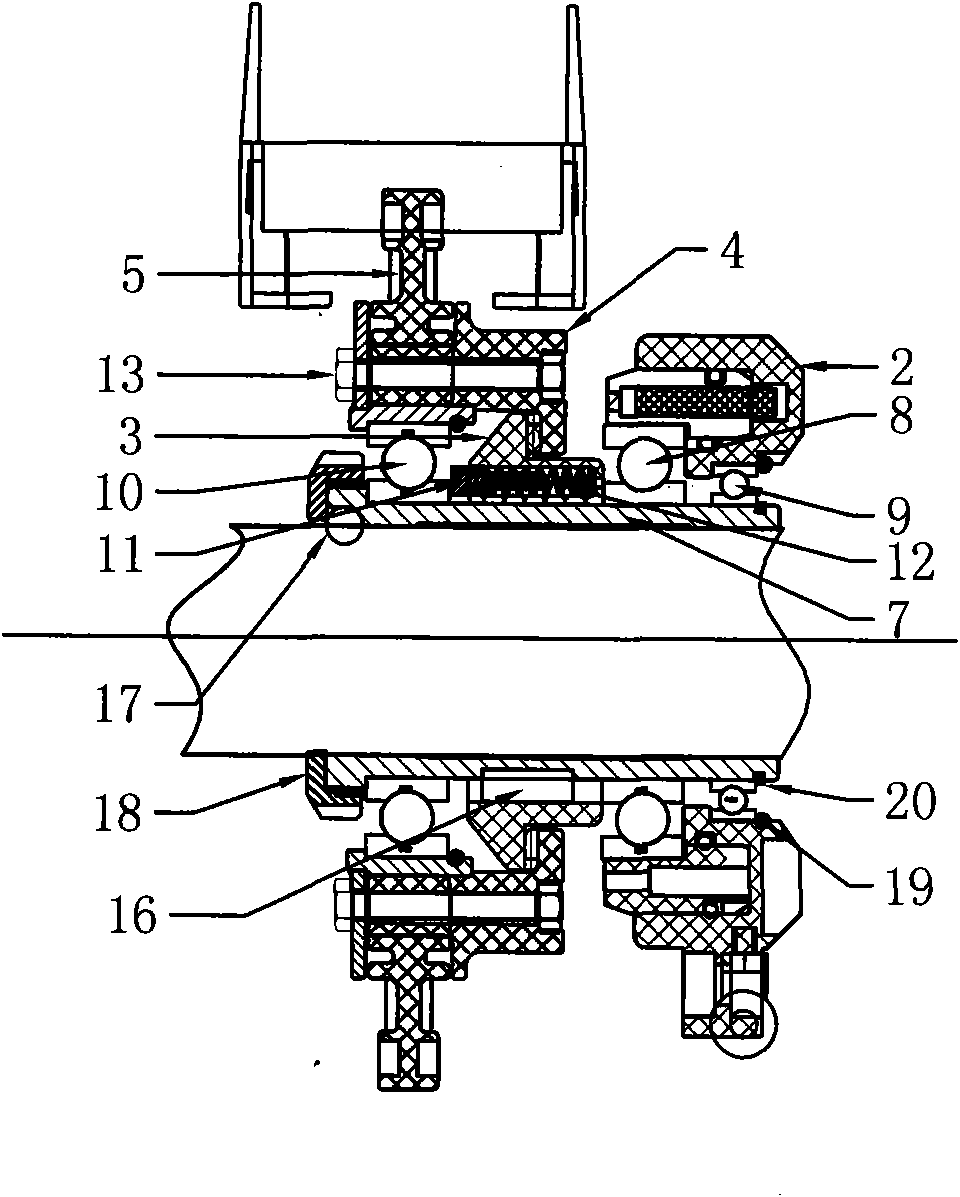

[0025] Attached below figure 1 to attach Figure 7 To further explain the present invention, the preferred embodiment of the present invention is: a pneumatic clutch device used on the elevated conveying line of tobacco rods described in this embodiment, the pneumatic clutch device is sleeved on the main shaft through the steel sleeve 7 1, the steel sleeve 7 is fixed on the main shaft 1 through the main shaft sleeve 18, and a positioning steel ball 17 is arranged between the steel sleeve 7 and the main shaft 1, which includes a plastic annular cylinder 2, a plastic movable gear 3, and a plastic fixed gear 4, plastic sprocket wheel 5, spring top 11, spring 12, forward buffer device 21, reverse buffer device 6, wherein, plastic ring cylinder 2 is assembled on the steel sleeve 7 by cylinder large bearing 8, cylinder small bearing 9, ( see Figure 6 , Figure 7 ) The plastic annular cylinder 2 includes a cylinder body 24 and an annular piston 25, wherein a U-shaped groove 26 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com