Adhesive tape winding drum for belt conveyer

A technology of belt conveyor and reel, which is applied in the field of belt conveyor, can solve the problems of cumbersome fixing release process, laborious rolling and rewinding, and large reel volume, so as to save labor intensity, facilitate transportation, and flexibly assemble and disassemble Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

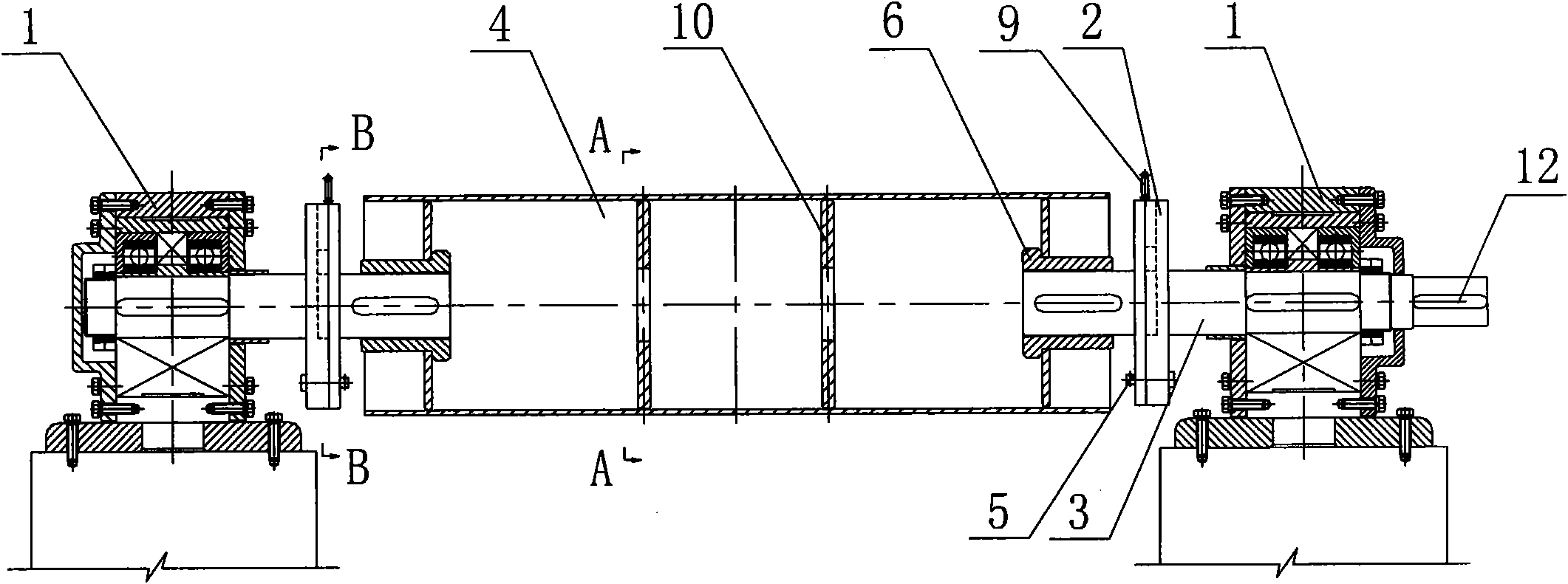

[0017] See figure 1 , belt conveyor tape rewinding reel, including reel 4, half shaft 3, bearing seat 1, the two ends of reel 4 are respectively connected with bearing seat 1 through half shaft 3, and the half shaft 3 is a split type Structure, a pair of slotted discs 2 divide the half shaft 3 into two parts, and the slotted discs 3 are connected together by a fixed pin shaft 5 . One side axle end is provided with keyway 12 and can be connected with power mechanism such as motor.

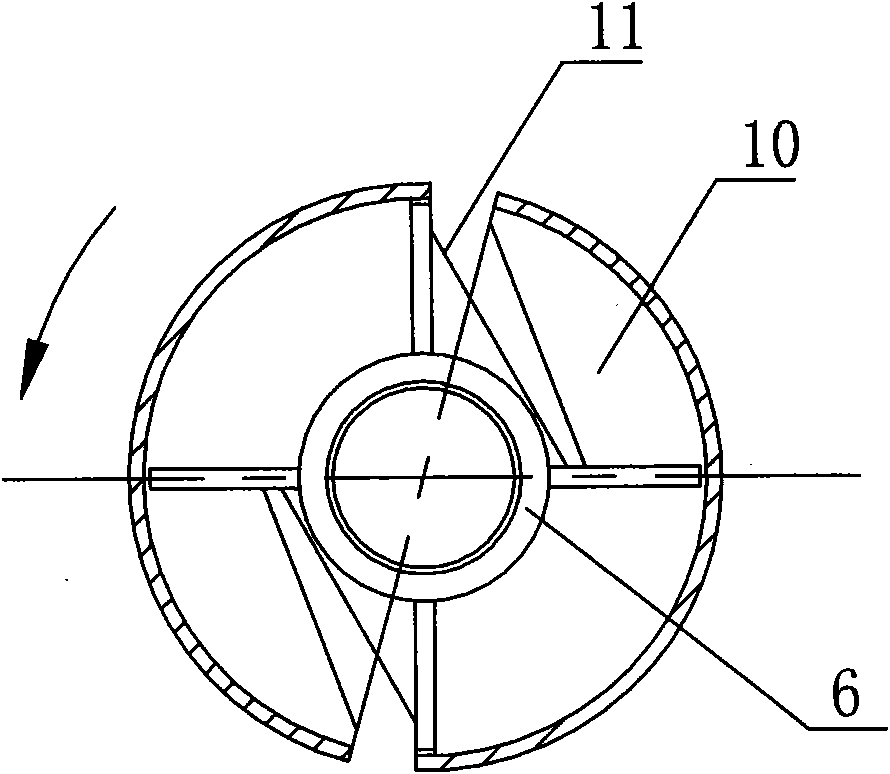

[0018] See figure 2 , is a cross-sectional view of the reel 4. The reel 4 is a hollow cylinder with several ribs 10 inside, and bushes 6 are arranged on both sides. The ribs 10 are provided with wedge-shaped grooves 11. The direction of rotation of the cylinder 4 is opposite.

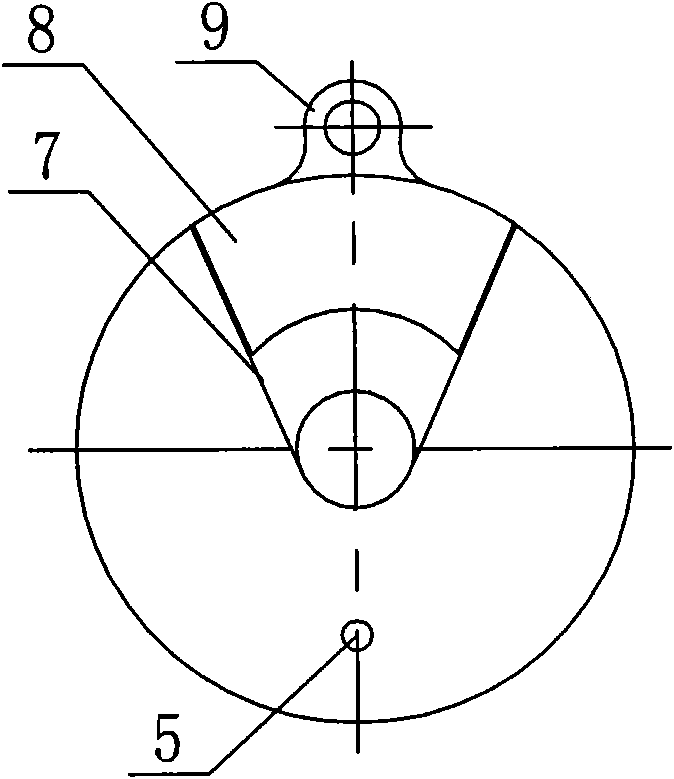

[0019] See image 3 , is a schematic diagram of the structure of the slotted disc 2, on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com