Glass for manufacturing micro-channel plate glass matrix

A technology of glass substrate and micro-channel plate, which is applied in the field of glass for manufacturing glass substrate of micro-channel plate, can solve problems such as difficulties, and achieve the effects of good aperture precision and good structural uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

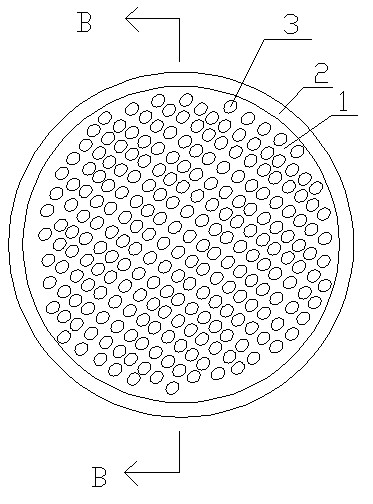

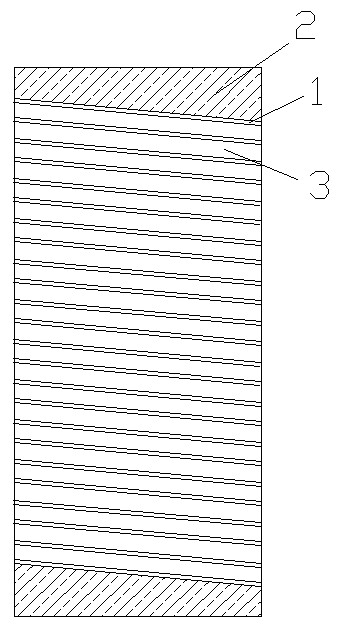

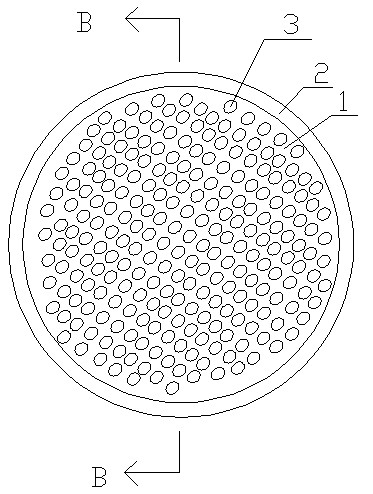

Image

Examples

Embodiment Construction

[0052] Leather glass of the present invention comprises by weight parts:

[0053] SiO 2 47-50.0 servings

[0054] Al 2 o 3 0.5-2.0 parts

[0055] PbO 28-30.0 parts

[0056] Bi 2 o 3 7.0-10.0 servings

[0057] ∑(K 2 O+Rb 2 O+C S2 O) 5-6.5 parts

[0058] ∑(BaO+CaO) 6-9.0 parts

[0059] ∑(As 2 o 3 +Sb 2 o 3 ) 0.5-1.0 parts;

[0060] The softening point Tf of leather glass is 580-590°C, and its thermal expansion coefficient α at 20°C-300°C is (68-75)×10 -7 / °C;

[0061] Correspondingly, the core glass comprises by parts by weight:

[0062] SiO 2 20-27.0 servings

[0063] B 2 o 3 12-18.0 servings

[0064] Al 2 o 3 1-2.0 servings

[0065] ∑(BaO+CaO) 30-40 parts

[0066] La 2 o 3 10-20 servings

[0067] ∑(ZnO+MgO) 2-3 parts.

[0068] The softening point Tf of the core glass is 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com