Low-frequency multiferroic particle magnetic-electric composite material and preparation method thereof

A magnetoelectric composite material and composite material technology are applied in the field of low-frequency multiferroic nanoparticle magnetoelectric composite materials and their preparation, which can solve the problems of easy shedding and aging, environmental pollution, and difficulty in long-term preservation and use, and achieve practicality. The effect of strong, low bias magnetic field and large magnetoelectric coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following description is a specific description of the present invention, and should not be regarded as a limitation of the present invention.

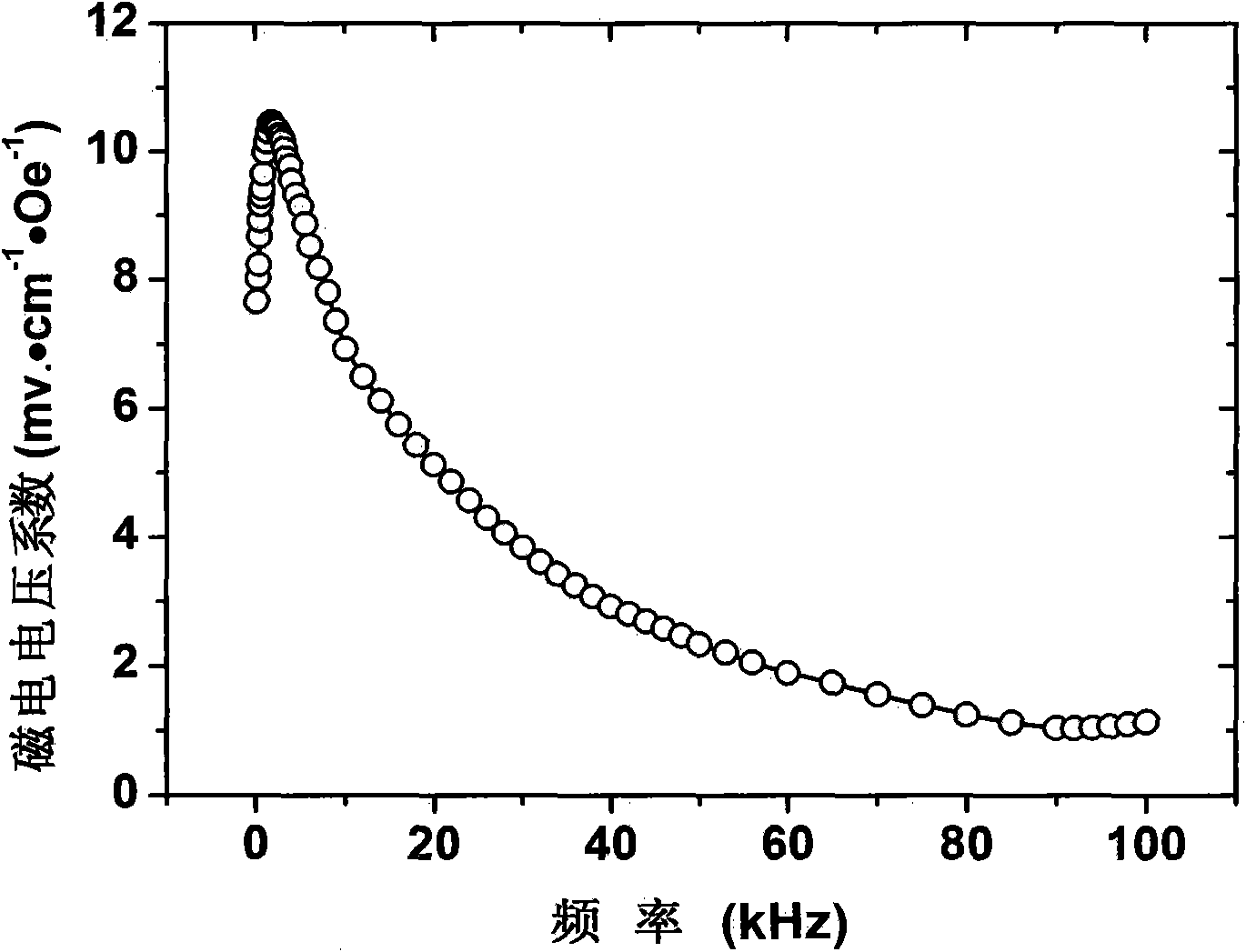

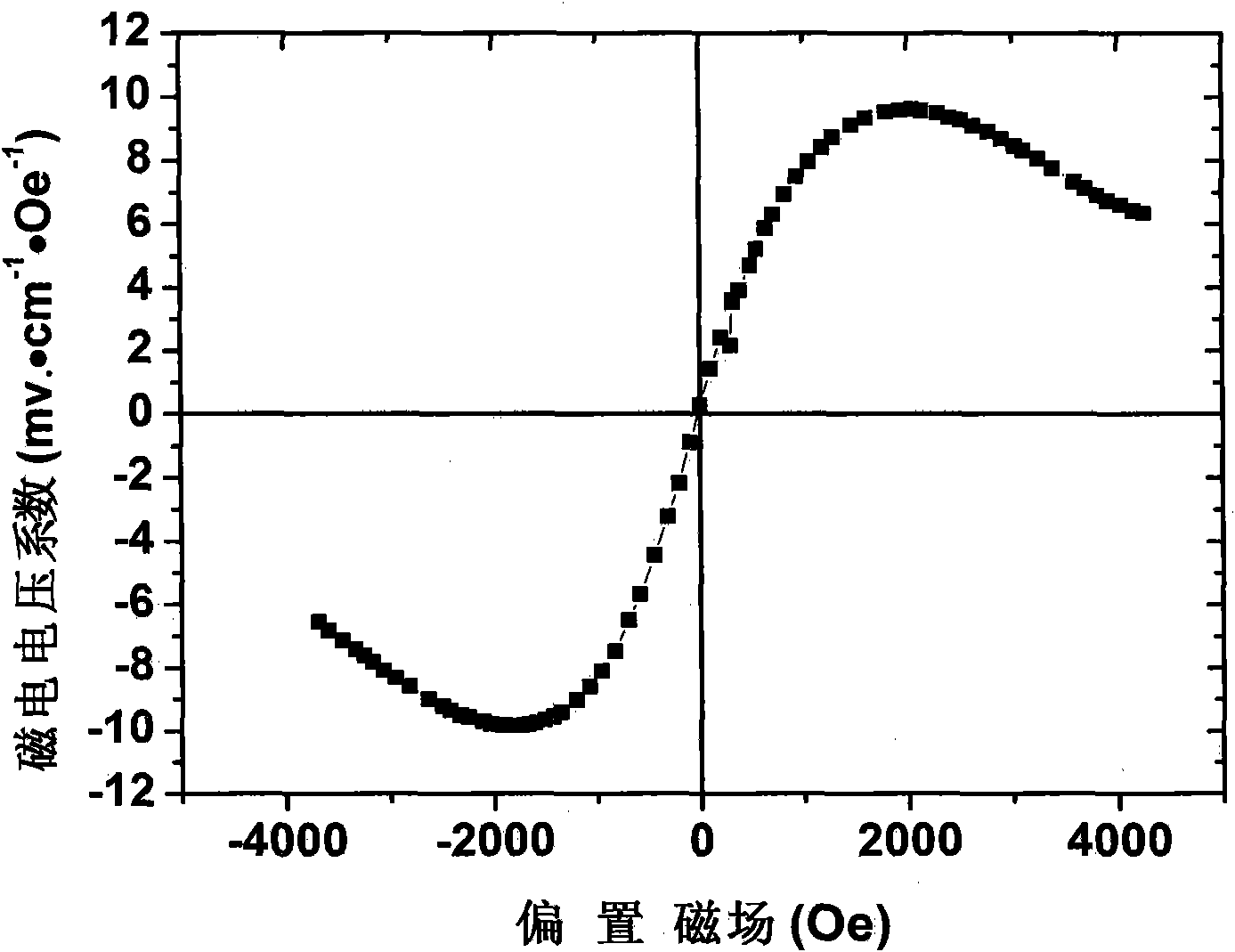

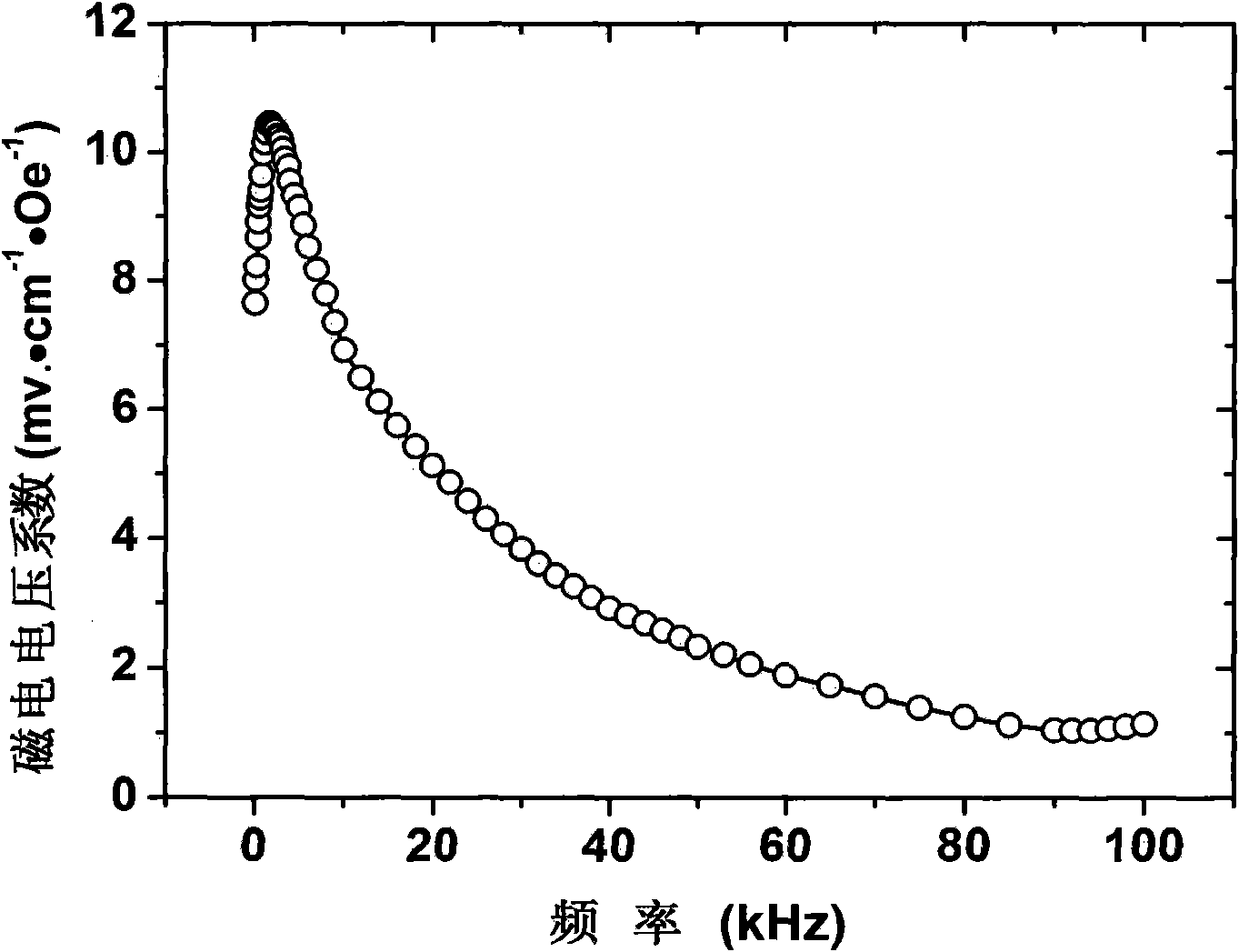

[0019] The molecular formula of the multiphase nanoparticle composite material with magnetoelectric coupling effect of the present invention is xCoFe 2 o 4 -(1-x)[0.948(K 0.5 Na 0.5 )NbO 3 -0.052LiSbO 3 ], where x=0.3 mol. The main phase of the composite nanoparticle mixed multiferroic material is 0.948 (K 0.5 Na 0.5 )NbO 3 -0.052LiSbO 3 , the doped phase is CoFe 2 o 4 . The multiphase nanoparticle mixed multiferroic material is made of raw materials of metal elements, and the raw materials are oxides and inorganic salts containing K, Na, Nb, Li, Sb, Co and Fe metal elements. The production process of the multiphase nanoparticle mixed multiferroic material includes selecting components, preparing the main phase component and the mixed component respectively, and finally mixing, grinding and firing the main phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com