Non-sticky coating applied to ceramic water closet and coating method thereof

A technology of non-stick coating and toilet, which is applied in the field of non-stick coating, which can solve the problems of odor, easy to stick to the surface of the urinal, difficult to remove urine stains and feces, etc., and achieve the effect of no peculiar smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] It consists of the following raw materials in parts by weight: 1 gram of water-based varnish, 1 gram of water-based curing agent, 3 grams of polytetrafluoro latex, 3 grams of water-based varnish and 2 grams of distilled water.

[0025] A method for coating a non-stick coating applied to a ceramic toilet, comprising the steps of:

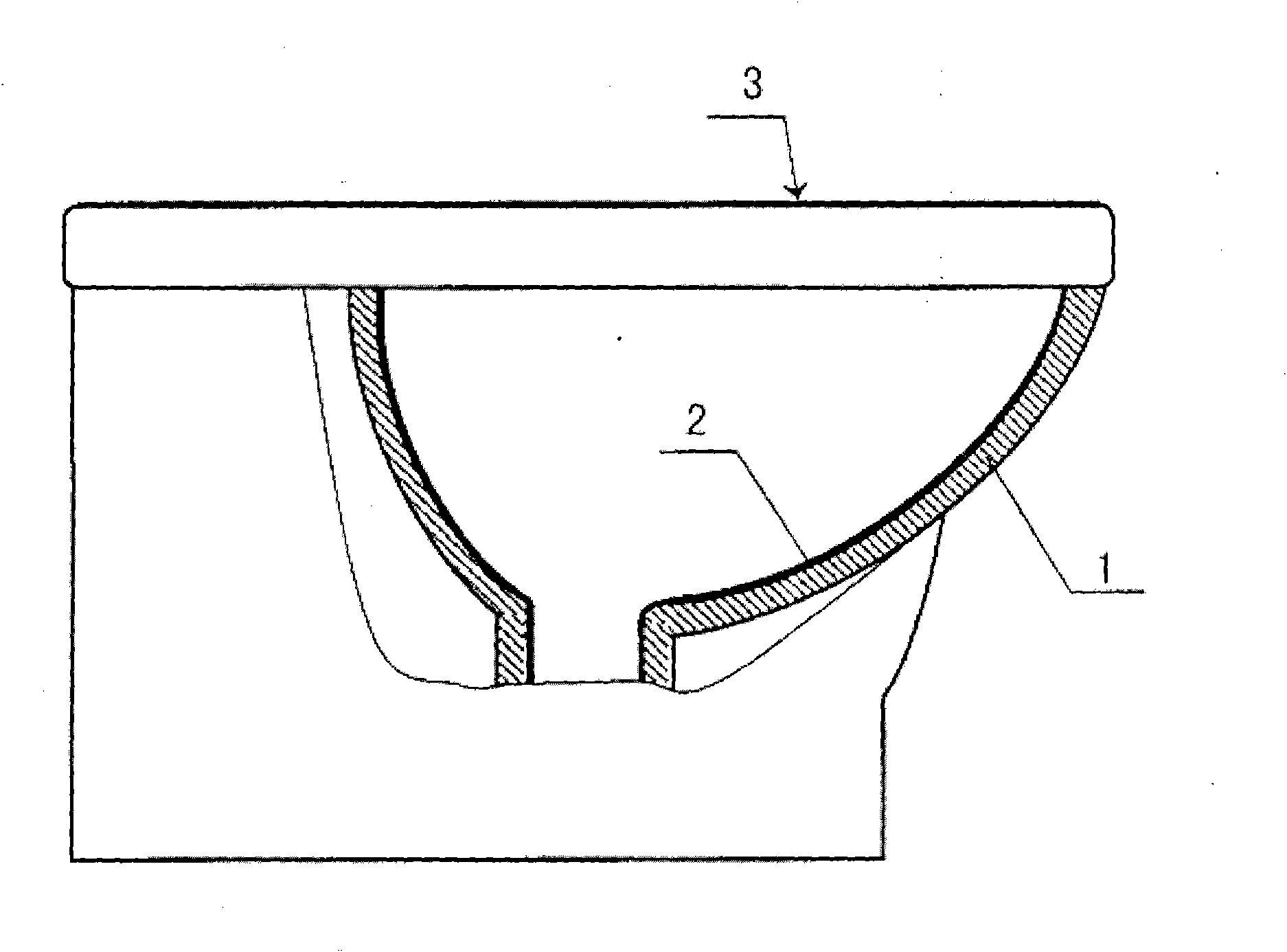

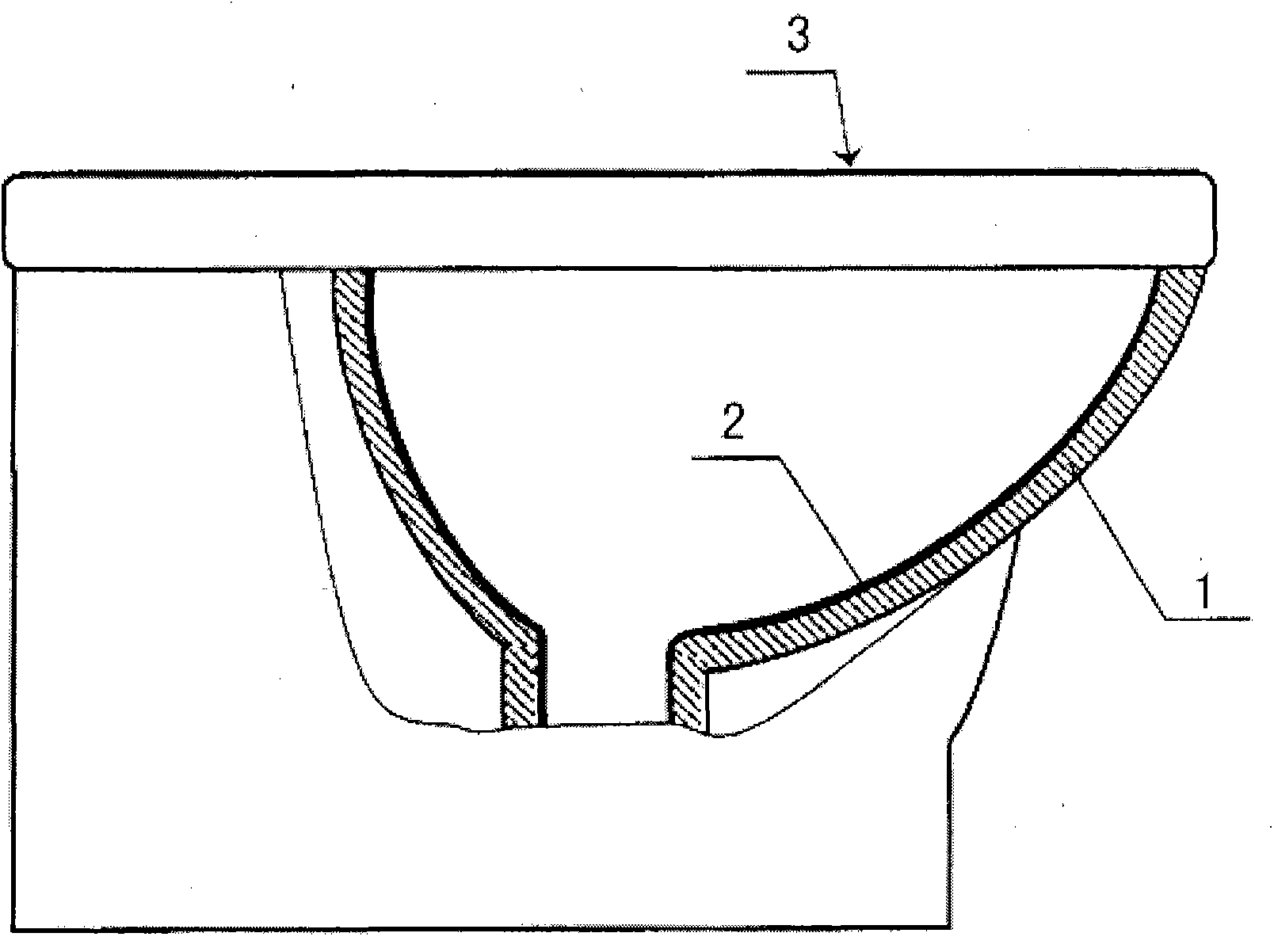

[0026] 1. Wipe the base layer 1 on the surface of the ceramic toilet to avoid water and dust;

[0027] 2. Mix 1 gram of water-based varnish, 1 gram of water-based curing agent, 3 grams of PTFE latex, 3 grams of water-based varnish and 2 grams of distilled water;

[0028] 3. Spray evenly the mixture uniformly mixed in the above step 2 on the base layer 1 on the surface of the ceramic toilet bowl wiped clean in the above step 1, and the thickness of the base layer 1 sprayed on the surface of the ceramic toilet bowl by the mixture is 0.35 mm;

[0029] 4. Seal the base layer 1 on the surface of the ceramic toilet bowl evenly sprayed in step 3 and...

Embodiment 2

[0032] It consists of the following raw materials in parts by weight: 2 grams of water-based varnish, 2 grams of water-based curing agent, 6 grams of polytetrafluoro latex, 6 grams of water-based varnish and 4 grams of distilled water.

[0033] A method for coating a non-stick coating applied to a ceramic toilet, comprising the steps of:

[0034] 1. Wipe the base layer 1 on the surface of the ceramic toilet to avoid water and dust;

[0035] 2. Mix 2 grams of water-based varnish, 2 grams of water-based curing agent, 6 grams of PTFE latex, 6 grams of water-based varnish and 4 grams of distilled water;

[0036] 3. Spray evenly the mixture uniformly mixed in the above step 2 on the base layer 1 on the surface of the ceramic toilet bowl wiped clean in the above step 1, and the thickness of the base layer 1 sprayed on the surface of the ceramic toilet bowl by the mixture is 0.35 mm;

[0037] 4. Seal the base layer 1 on the surface of the ceramic toilet bowl evenly sprayed in step 3...

Embodiment 3

[0040] It consists of the following raw materials in parts by weight: 3 grams of water-based varnish, 3 grams of water-based curing agent, 9 grams of polytetrafluoro latex, 9 grams of water-based varnish and 6 grams of distilled water.

[0041] A method for coating a non-stick coating applied to a ceramic toilet, comprising the steps of:

[0042] 1. Wipe the base layer 1 on the surface of the ceramic toilet to avoid water and dust;

[0043] 2. Mix 3 grams of water-based varnish, 3 grams of water-based curing agent, 9 grams of PTFE latex, 9 grams of water-based varnish and 6 grams of distilled water;

[0044] 3. Spray evenly the mixture uniformly mixed in the above step 2 on the base layer 1 on the surface of the ceramic toilet bowl wiped clean in the above step 1, and the thickness of the base layer 1 sprayed on the surface of the ceramic toilet bowl by the mixture is 0.35 mm;

[0045] 4. Seal the base layer 1 on the surface of the ceramic toilet bowl evenly sprayed in step 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com