Preparation method of 2,3,3,3-tetrapion propylene

A technology of tetrafluoropropene and tetrafluoropropane, which is applied in the preparation of dehydrohalogenation, organic chemistry, etc., can solve the problems of easy coking and deactivation of catalysts, frequent regeneration of catalysts, short continuous production cycle, etc. The effect of continuous production cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

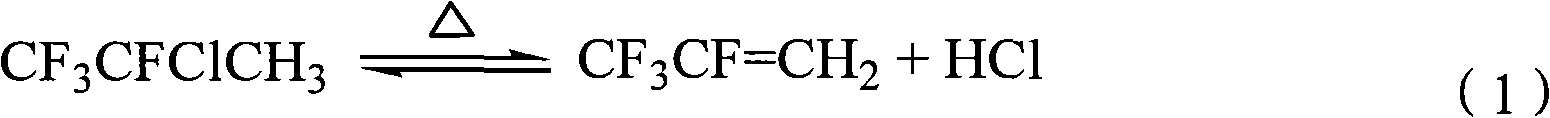

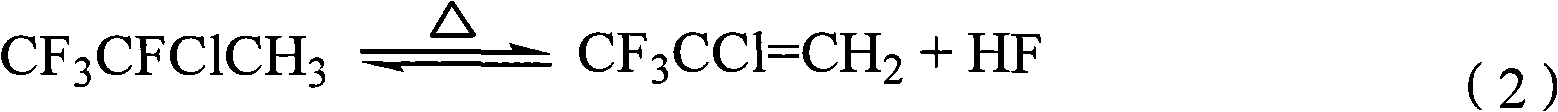

Method used

Image

Examples

Embodiment 1

[0019] HCFC-244bb is thermally cracked under the conditions of normal pressure, reaction temperature 450°C, and residence time 60 seconds. The conversion rate of HCFC-244bb is 90.3%, the selectivity of HFO-1234yf is 32.2%, and the selectivity of HFO-1233xf is 57.7% %.

Embodiment 2

[0021] The same operation as in Example 1, except that the reaction temperature is 900° C., the residence time is 0.01 second, the conversion rate of HCFC-244bb is 99.5%, the selectivity of HFO-1234yf is 63.4%, and the selectivity of HFO-1233xf is 15.7%.

Embodiment 3

[0023] The same operation as in Example 1, except that the reaction temperature is 750° C., the residence time is 0.1 second, the conversion rate of HCFC-244bb is 97.8%, the selectivity of HFO-1234yf is 58.5%, and the selectivity of HFO-1233xf is 28.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com