Low-yield higher-alcohol saccharomyces cerevisiae engineering bacterium and construction method thereof

A technology of Saccharomyces cerevisiae and higher alcohols, which is applied in the field of bioengineering, can solve the problems of high content of higher alcohols, and achieve the effects of not being easy to reverse mutations, wide application prospects, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Construction of Saccharomyces cerevisiae Engineering Bacteria with Low Yield and Higher Alcohol

[0023] (1) Construction of genetic engineering strains

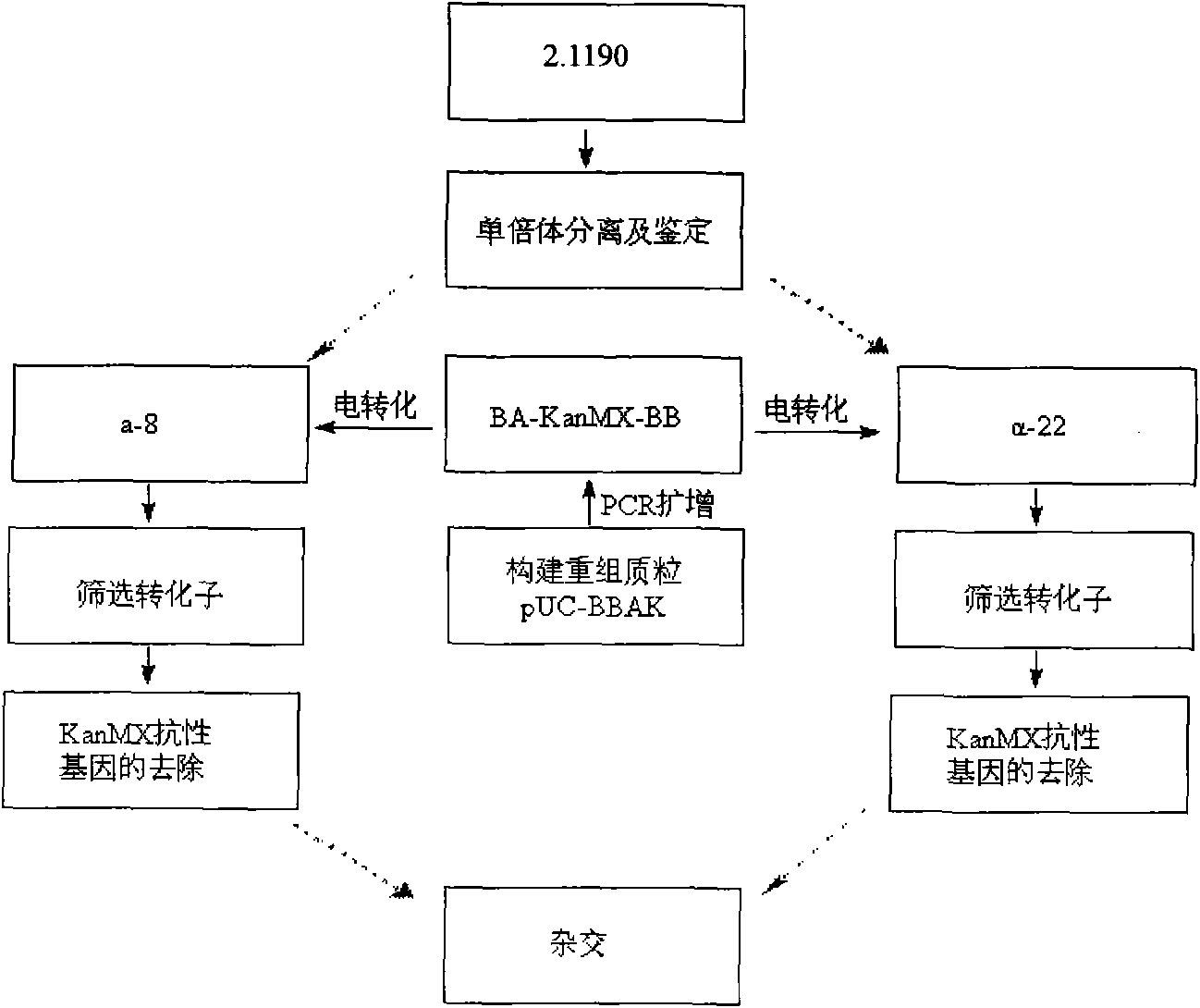

[0024] The construction process of genetically engineered strains is as follows: figure 1 shown. Diploid 2.1190 was haploidized to generate haploid strains a-8 and α-22, and genetically engineered haploid strains were constructed by two homologous recombination methods, and the KanMX resistance gene was removed and the haploid strains were hybridized , to generate diploid genetically engineered strains.

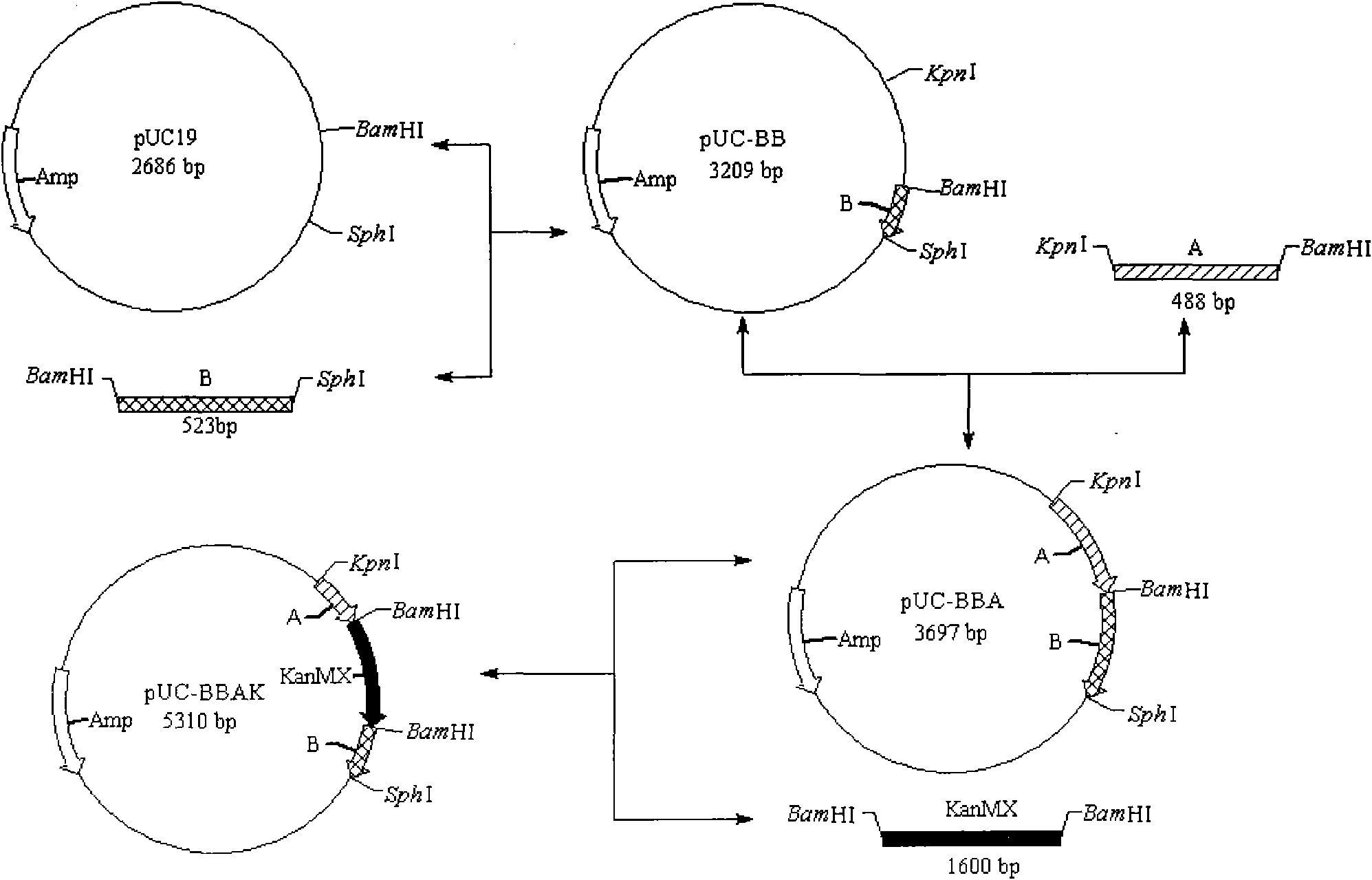

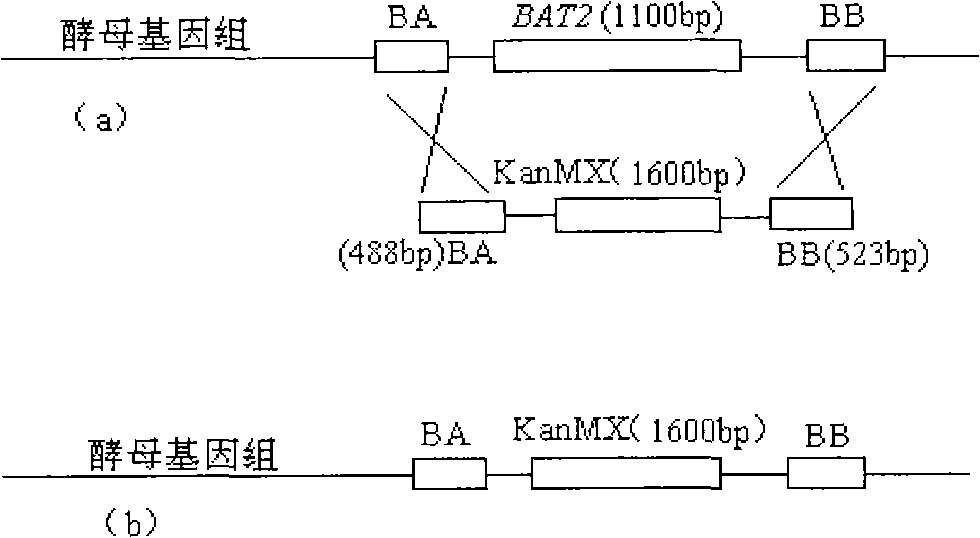

[0025] The construction process of the recombinant plasmid pUC-BBAK is as follows: figure 2 shown. By PCR amplification technology, the sequence BA and BB fragments on both sides of the BAT2 gene for homologous recombination to knock out the gene and the KanMX resistance gene from the pUG6 plasmid were amplified, and the three fragments were amplified in accordance with the pUC19 plasmid as a vector. ...

Embodiment 2

[0034] Embodiment 2: Saccharomyces cerevisiae engineering strain fermentation experiment

[0035] (1) Fermentation experiments of transformants and haploid parents

[0036]Parents a-8 and α-22 and their corresponding BAT2 gene complete deletion transformants were fermented with alcohol thick mash at the same time. After the fermentation, the fermentation performance and higher alcohol production of the strains were measured. The results are shown in Table 1. The results showed that the isobutanol, isoamyl alcohol and higher alcohol contents of parent a-8 were 70.37 mg / L, 208.33 mg / L and 312.93 mg / L respectively, and the isobutanol, isoamyl alcohol and The total contents of higher alcohols were 35.37mg / L, 137.62mg / L and 204.13mg / L respectively, that is, the isobutanol, isoamyl alcohol and higher alcohols of the a-8 transformant were reduced by 49.74% and 33.94% respectively compared with the parent a-8 and 34.77%; the isobutanol, isoamyl alcohol and higher alcohol content of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com