Electromagnetic wave absorption material

A technology for absorbing materials and electromagnetic waves, used in the preparation of materials, composite materials that can absorb electromagnetic waves, and materials that can absorb electromagnetic waves, can solve problems such as inability to use, application limitations, and large matching thickness, to eliminate electromagnetic interference and meet absorption requirements. , to meet the effect of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0022] a. First smelt the rare earth element, iron, and ferroboron into an alloy under the protection of an inert gas, then anneal the alloy for a week under vacuum, and then pulverize it into powder under the protection of a protective agent.

[0023] b. Mix the prepared rare earth transition group intermetallic compound powder with the uncured bonding material with a volume ratio of 1~9:9~1 and put it into a mold made of non-magnetic material, place it in 10 -4 In a magnetic field of ~10T (Tesla), the mold is rotated at a speed of 1 ~ 200 rpm in the magnetic field at the same time until the bonding material is solidified.

[0024] The preferred material preparation method of the present invention is that mold is placed in 10 -4 ~10T (Tesla) magnetic field, the mold rotation speed is 1~200 rpm.

[0025] Below are two preferred embodiments of the present invention:

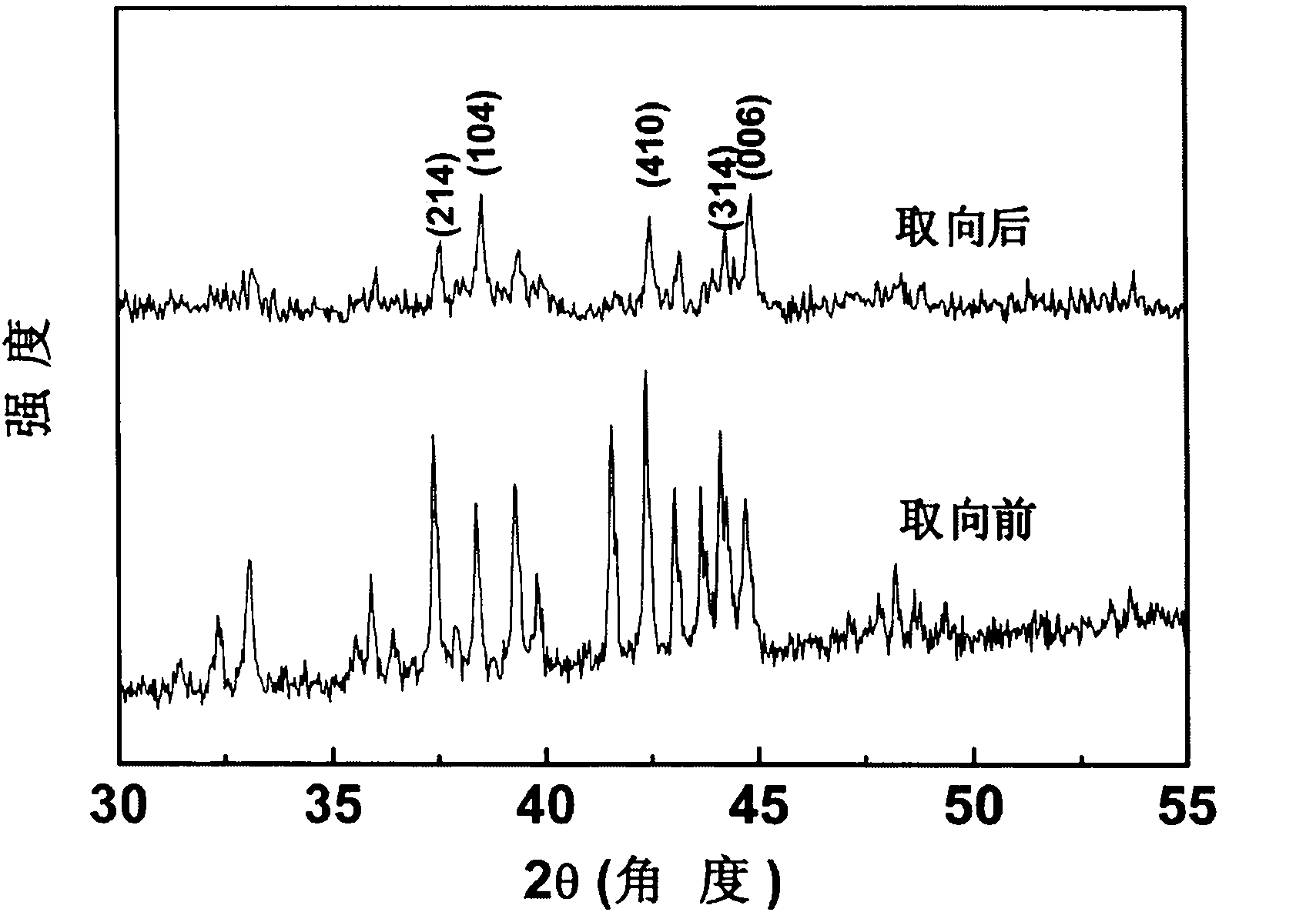

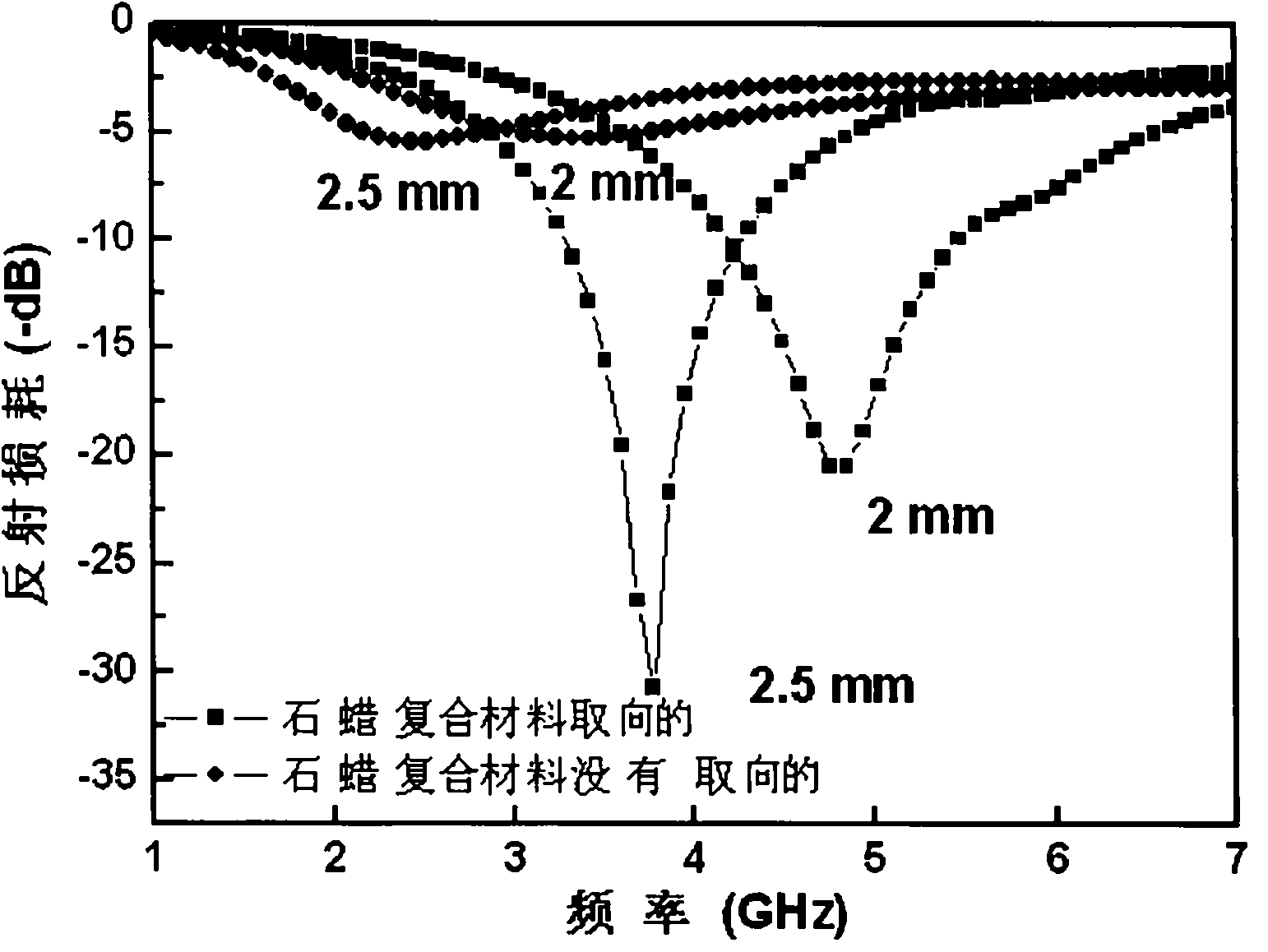

Embodiment 1

[0027] Weigh 1.837g of neodymium, 1.128g of samarium, 6.789g of iron, and 0.510g of ferroboron, and melt them into ingots under the protection of argon. Annealed in a vacuum quartz tube at 1000 °C for one week. Grind the annealed ingot into particles of about 70 microns with an agate mortar, then wet-mill the particles with a planetary ball mill by adding 100ml of isopropanol and 0.2ml of phthalate coupling agent, the ball-to-material ratio is 20:1, and ball mill The speed is 200 rev / min, adopt the mode of forward and reverse ball milling, the time interval is 1 hour, the total time of ball milling is set as 8 hours, finally the sample is dried to obtain (Nd 0.66 SM 0.34 ) 2 Fe 14B material. Then the samples were compounded in three situations: (1) mixed evenly with the paraffin wax diluted with n-hexane at a volume ratio of 35:65, and put it into a mold (with an inner diameter of 3.04mm and an outer diameter of 7.00mm) after drying , Pressed and molded under 1Mpa pressur...

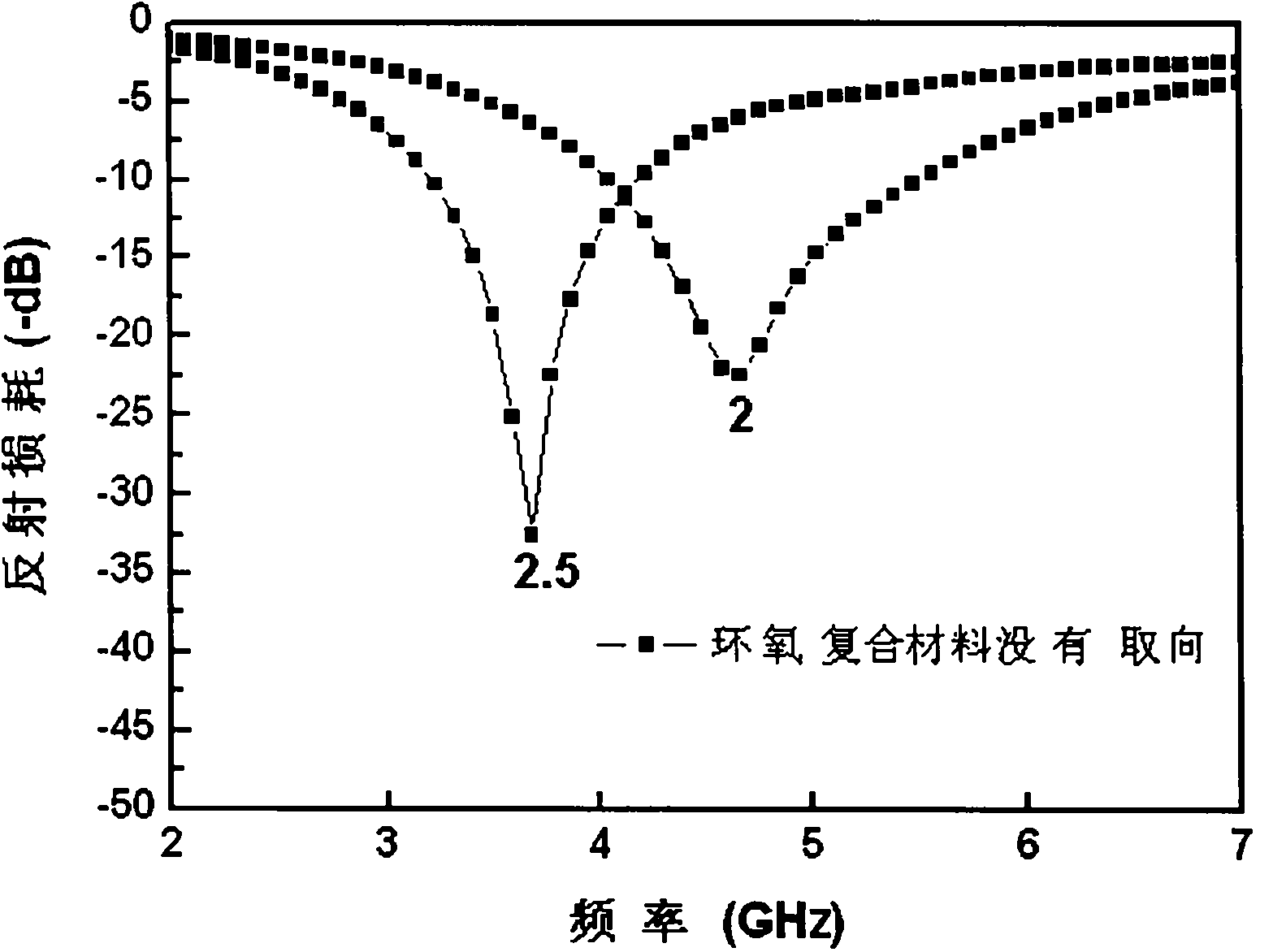

Embodiment 2

[0032] Weigh 1.393 g of neodymium, 1.659 g of samarium, 6.781 g of iron, and 0.509 g of ferroboron, and melt them into ingots under the protection of argon. Annealed in a vacuum quartz tube at 1000 °C for one week. The annealed ingot was ground into particles of about 70 microns with an agate mortar, and then the particles were wet-milled with a planetary ball mill by adding 100 ml of isopropanol and 0.2 ml of phthalate coupling agent, with a ball-to-material ratio of 20:1. The ball milling speed was 200 rev / min, and the mode of forward and reverse ball milling was adopted, the time interval was 1 hour, the total time of ball milling was set as 8 hours, and finally the sample was dried to obtain (Nd 0.54 SM 0.46 ) 2 Fe 14 B material. Then the samples were compounded in three situations: (1) mixed with paraffin wax diluted with n-hexane at a volume ratio of 35:65, dried and placed into a mold (with an inner diameter of 3.04 mm and an outer diameter of 7.00 mm) , pressed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com