Reciprocating type hydrodynamic force water drawing rotating machinery power converting machine

A rotating machinery and hydrodynamic technology, which is applied in the field of reciprocating hydrodynamic pumping and rotating machinery power converters, can solve problems such as large waste of water energy, and achieve the effects of low layout requirements, low water flow requirements, and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

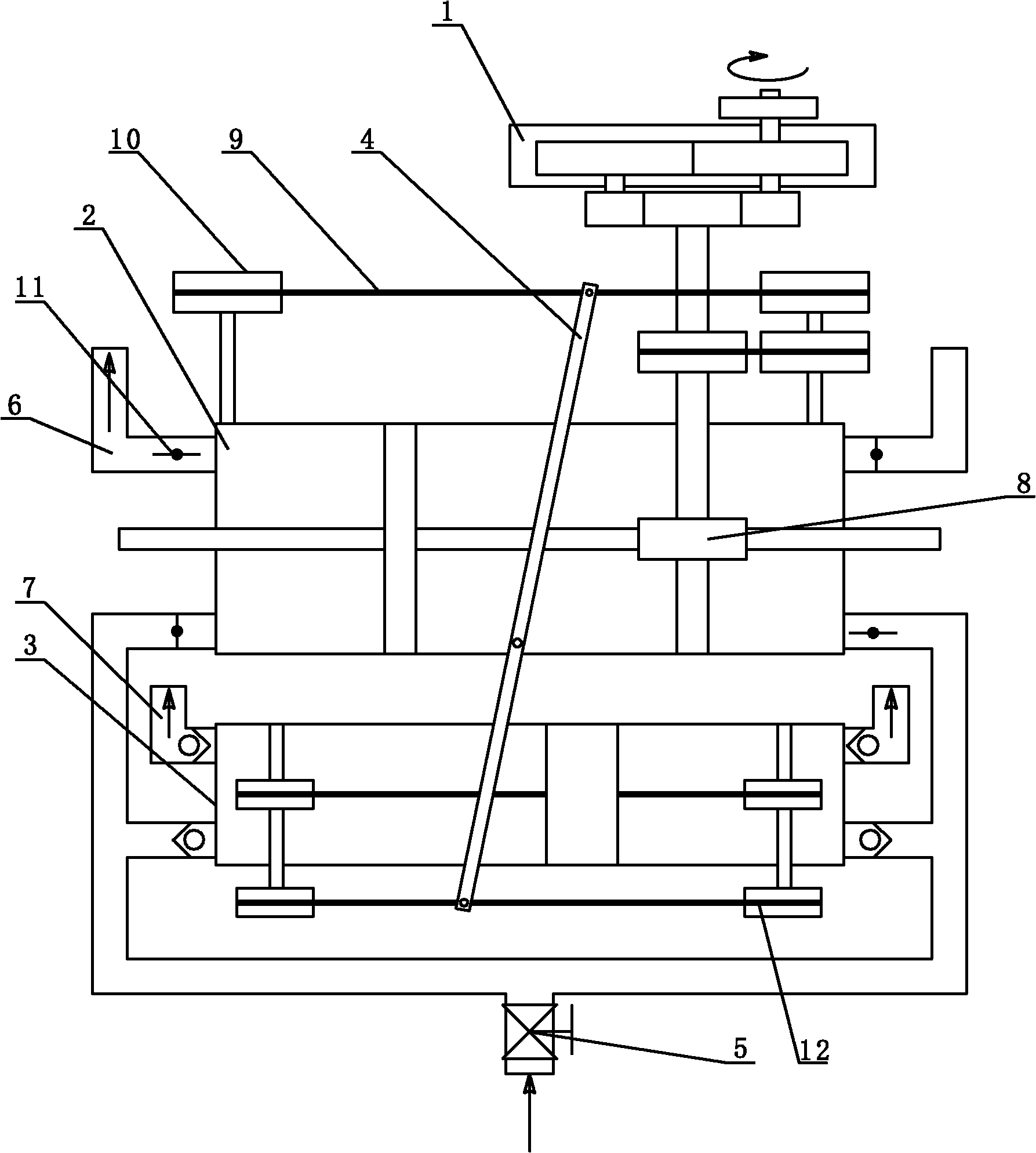

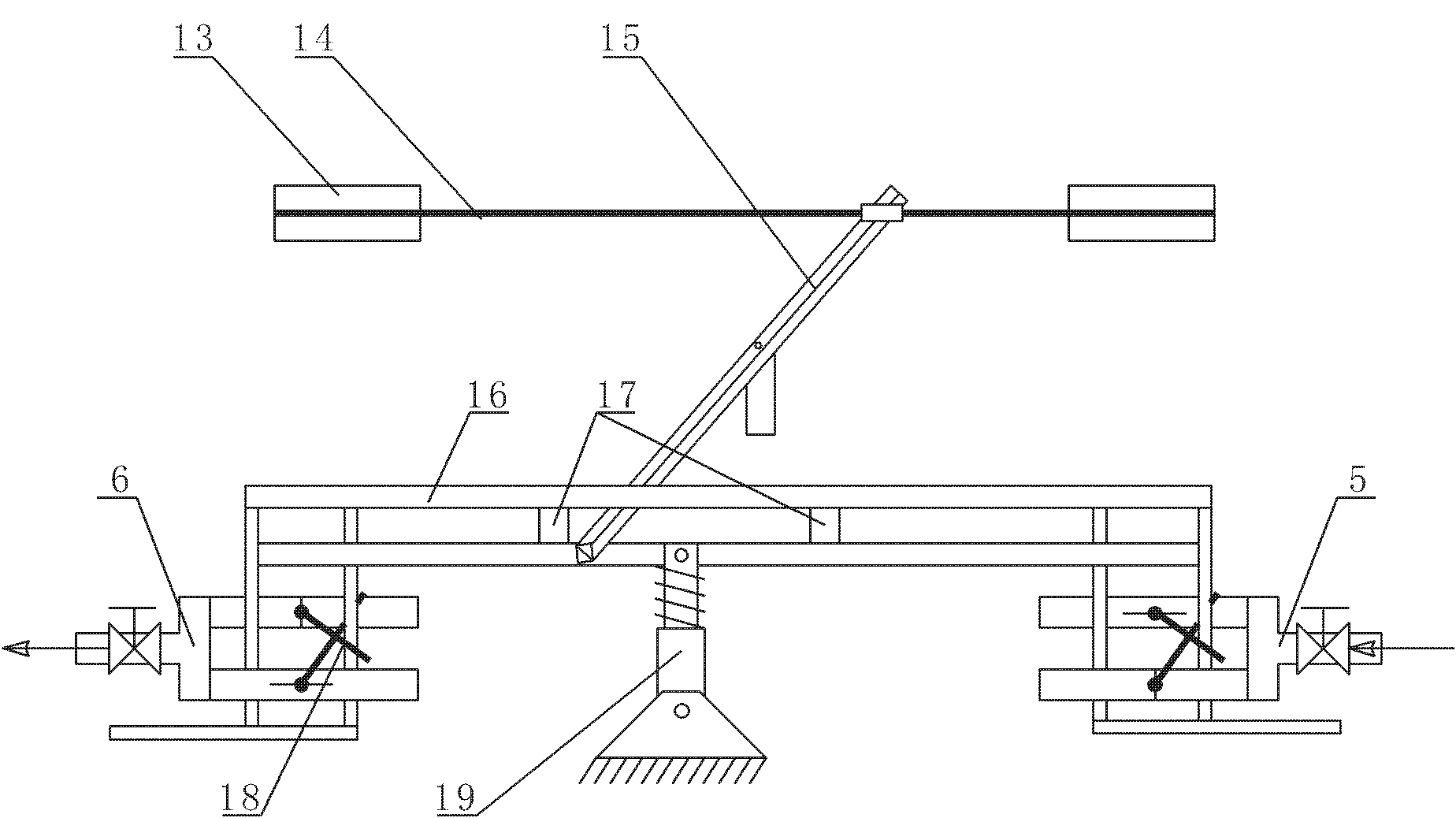

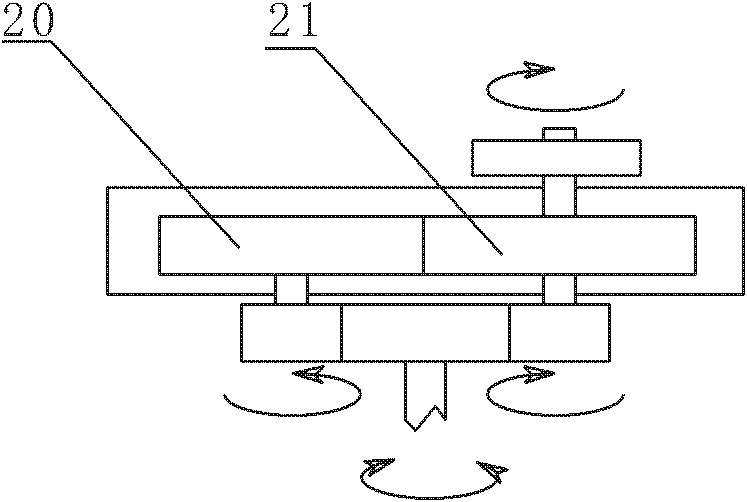

[0014] Such as figure 1 In, a reciprocating hydrodynamic pumping rotary mechanical power conversion machine, the piston rod of the driving cylinder 2 is connected to the conversion device 1 through the rack and pinion mechanism 8; in the conversion device 1, the reverse transmission wheel 20 and the forward transmission The wheel 21 is connected, and the reverse transmission wheel 20 and the forward transmission wheel 21 are provided with a ratchet mechanism in the opposite direction. Such as image 3 In the rack and pinion mechanism 8, the shaft is connected to the reverse transmission wheel 20 and the forward transmission wheel 21 at the same time, and the reverse transmission wheel 20 and the forward transmission wheel 21 are also connected to each other. Due to the built-in ratchet mechanism, the input The torque of the reciprocating rotation is converted into the torque of one direction rotation. Specifically, when the input is counterclockwise rotation, the forward trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com