Safety evaluation method for preventing delayed fracture of high strength bolt below M100mm

A technology for high-strength bolts and safety assessment, applied in the direction of screws, threaded fasteners, connecting components, etc., can solve problems such as difficult determination, delayed fracture, and inappropriate high-strength bolts, and achieve reliable methods, simple calculations, and safety assessment accurate effect

Inactive Publication Date: 2010-12-15

LUOYANG SUNRUI SPECIAL EQUIP

View PDF1 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

① Most of them adopt strength check, and design high-strength bolts by increasing the strength safety factor. However, due to the problem of delayed fracture, it is not suitable for high-strength bolts of grade 12.9 and above;

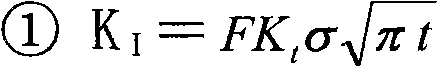

However for K I value, K I The value is difficult to determine, so far no theoretical solution has been found

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

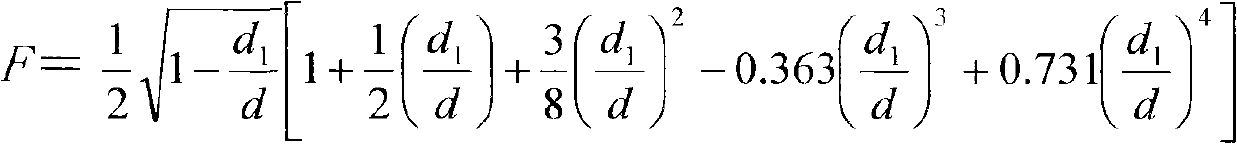

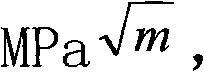

The invention relates to a safety evaluation method for preventing delayed fracture of a high strength bolt below M100mm, which comprises the steps of: finding out a relationship between the root arc radius r of threads of the high strength bolt and the thread depth t of the high strength bolt by a finite element simulation design; determining a stress concentration factor Kt of the high strength bolt by establishing the relationship; introducing Kt into a formula to obtain a stress strength factor of the high strength bolt; and finally obtaining K1c or K1scc>=nK1 and K1c or K1scc<nK1 according to decision principle of linear elastic fracture mechanics K1c or K1scc>=K1. The safety evaluation method is theoretic. Because the finite element simulation design is adopted, the method has the characteristics of scientificity, systematicness, simplicity and practicality, and is more economical than test of mechanical performances, such as strength and toughness of the high strength bolt.

Description

technical field The invention belongs to the technical field of bolt safety assessment, in particular to a safety assessment method for preventing delayed fracture of high-strength bolts below M100mm for bolts of grade 12.9 or above used in atmosphere, marine atmosphere and seawater environment. Background technique For bolts of grade 12.9 and above used in the atmosphere, marine atmosphere and seawater environment, due to the deterioration of the use environment, the problem of delayed fracture of the bolts is very prominent. Delayed fracture refers to a phenomenon in which a bolt under static stress suddenly undergoes brittle failure of its material structure after a certain period of use. This phenomenon is a kind of environmental embrittlement caused by material-environment-stress interaction, and it is a form of hydrogen-induced material deterioration (or hydrogen damage or hydrogen embrittlement). When the tensile strength of the bolt is greater than 1200MPa, its sens...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16B35/00

Inventor 陈继志刘军宁天信

Owner LUOYANG SUNRUI SPECIAL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com