Electric contact material friction arc burning loss in-situ test device and test method thereof

A technology for in-situ testing of electrical contact materials, applied to measuring devices, material analysis through electromagnetic means, and material analysis, etc., can solve the problem of inability to effectively reflect the arc energy of electrical contact materials, the inability to effectively remove the negative effects of wear debris, and the inability to conduct electricity. Arc resistance performance evaluation of contact materials and other issues to achieve the effects of avoiding burning interference, accurate safety evaluation, and good feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] In some preferred embodiments, the preparation method further includes: after the test is completed, calculating the ablation mass, and measuring the ablation depth and ablation volume.

[0060] In some preferred embodiments, the in-situ test method for triboelectric arc burning of electrical contact materials further includes: before testing, grinding and cleaning the surface of the sample to be tested;

[0061] Preferably, the cleaning agent used in the cleaning includes deionized water and absolute ethanol.

[0062] This method is not only applicable to the in-situ test of samples of this specification, but also can be used for strip and block materials of other different sizes and specifications.

[0063] The process parameters of this experiment can not only adjust the power pulse width and frequency, but also can achieve this effect by changing the friction frequency.

[0064] Among them, in some more specific implementation cases, the in-situ test device and tes...

Embodiment 1

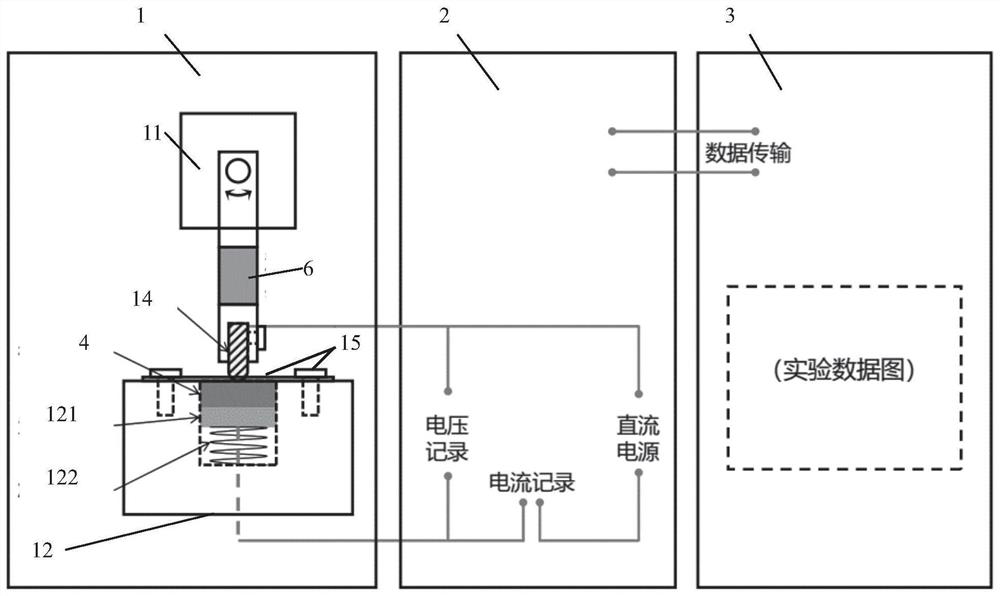

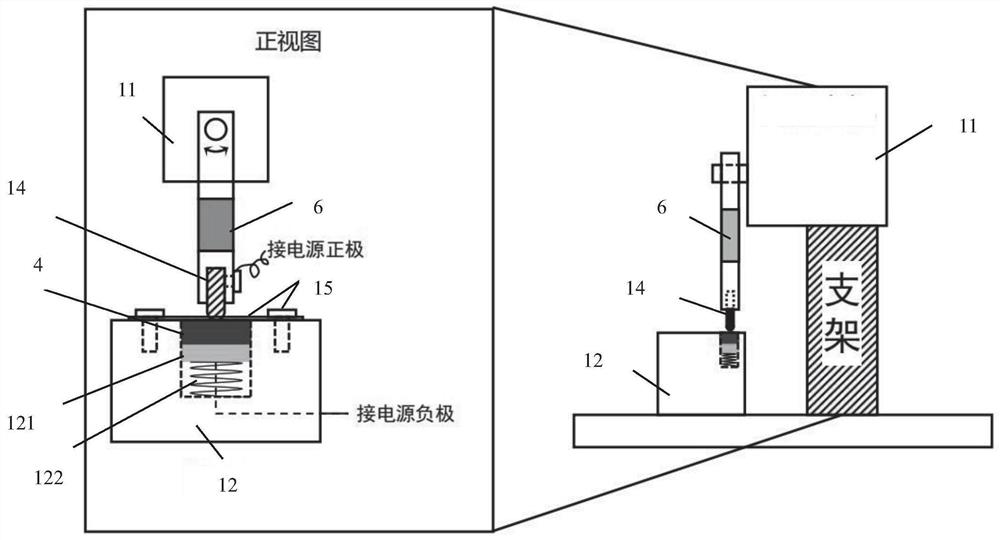

[0071] refer to figure 1 , the embodiment of the present invention provides an in-situ test device for frictional arc burning of electrical contact materials, including a test unit 1, a data acquisition unit 2 and a data processing unit 3, wherein the data acquisition unit 2 is connected to the data processing unit 3 , the test unit 1 is electrically connected with the data acquisition unit 2, specifically, as figure 1 and 2 As shown, the test unit 1 includes an adjustable speed motor 11, a tungsten electrode 14, a sample stage 12 and a DC power supply for at least placing the sample 4 to be tested, wherein the sample stage 12 has a negative electrode contact point 121 and a DC power supply arranged from top to bottom. Damping spring 122; the tungsten electrode 14 is fixedly connected with the adjustable speed motor 11, the tungsten electrode 14 is arranged above the sample 4 to be tested, and the tungsten electrode 14 can be in contact with the sample 4 to be tested and gene...

Embodiment 2

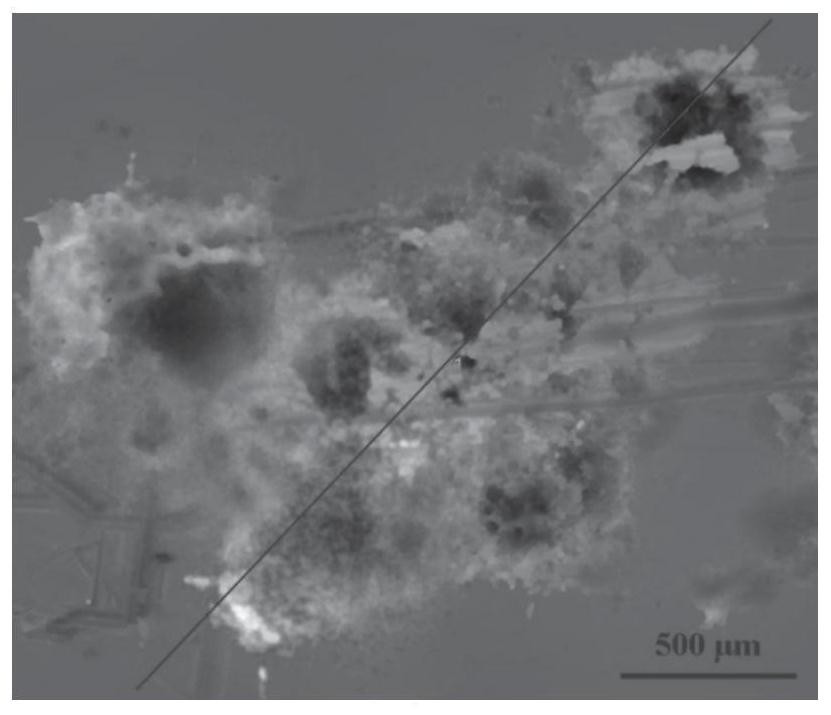

[0075] Tested by the in-situ test device for frictional arc burning of electrical contact materials in Example 1, the sample to be tested 4 is a cast Cu-Te alloy, first cut out from the ingot with a length, width and height of 45 mm by wire electric discharge cutting ×16mm×8mm block sample, then use sandpaper to grind the surface to be tested and then polish it, then wash and dry it with deionized water and absolute ethanol in turn, weigh it and wait for the test.

[0076] The sample is clamped and fixed on the sample stage 12 and the sample to be tested is connected to the negative pole of the power supply, and the clamping tungsten electrode 14 device is connected to the positive pole of the power supply. Turn on the power, set the voltage, the voltage can be adjusted according to the actual needs, the actual needs include whether to start arc, arc energy and application environment considerations, etc. In this embodiment, the voltage is set to 10V. Turn on the power supply...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com