Ultrasonic inspecting and scanning device of welding line

A scanning device and ultrasonic testing technology, applied in measuring devices, analyzing solids using sonic/ultrasonic/infrasonic waves, and using sonic/ultrasonic/infrasonic waves for material analysis, etc. problems, improve the detection rate, and improve the effect of detection quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

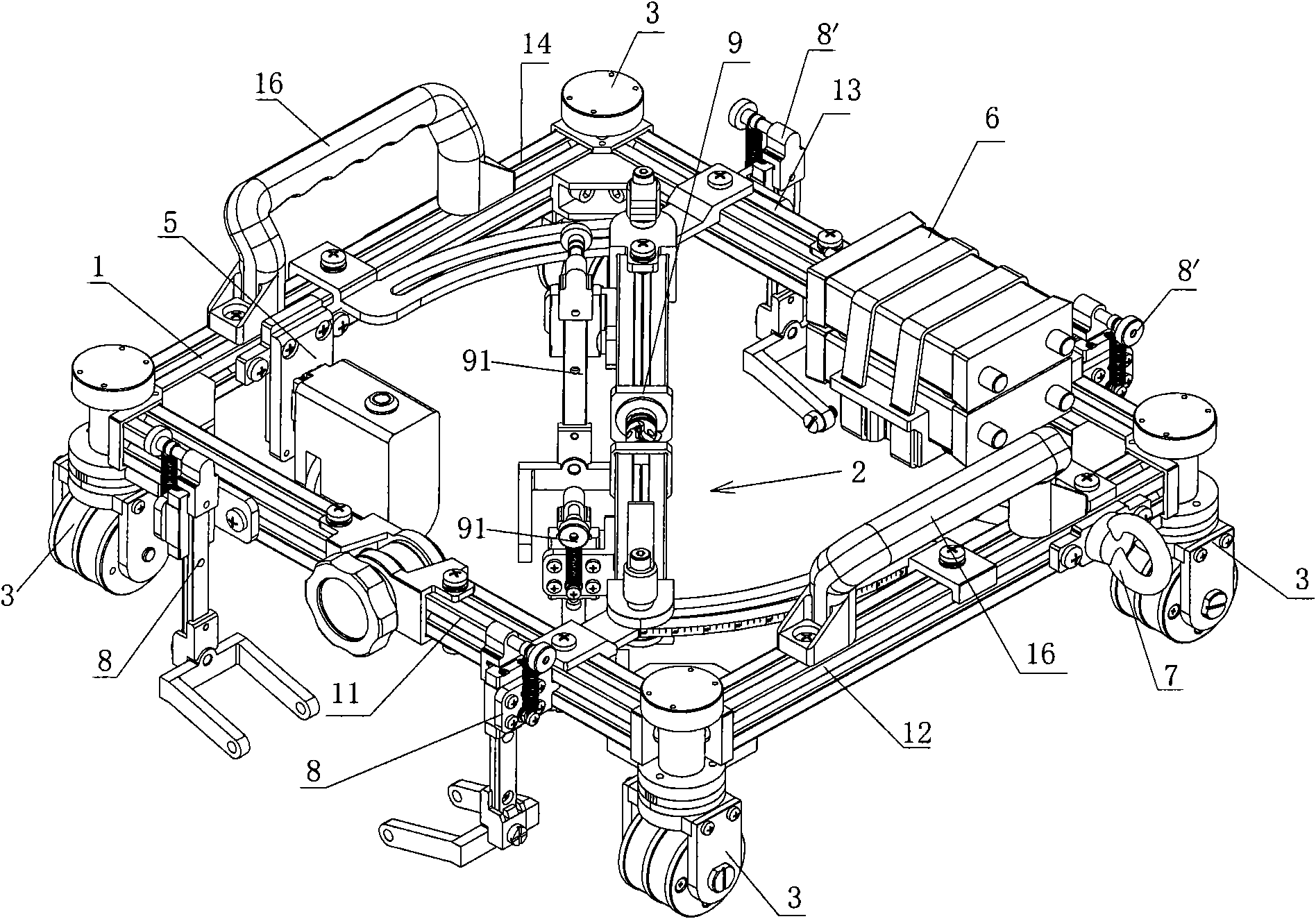

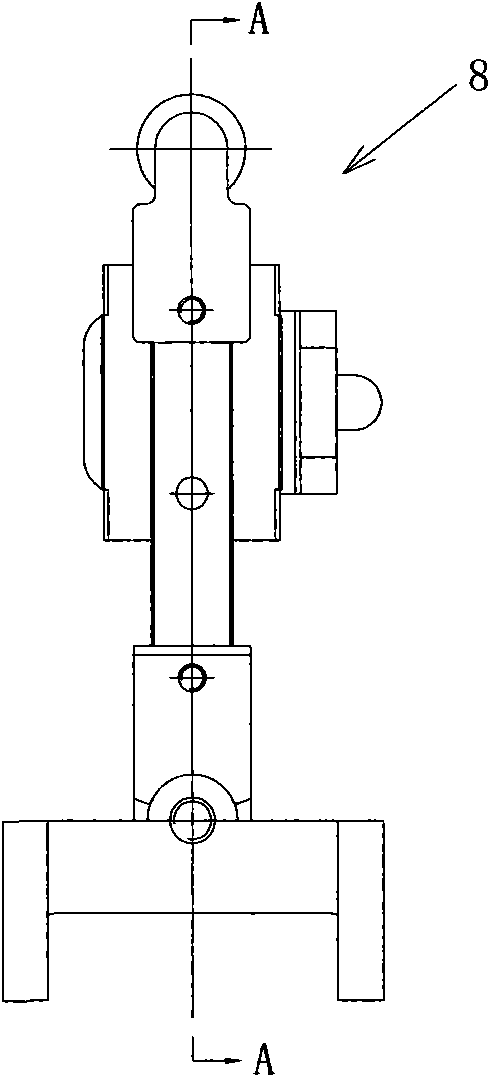

[0040] Such as figure 1As shown, the present invention provides a scanning device for ultrasonic detection of welds, including: a main frame 1, a scanning mechanism 2 arranged on the main frame 1, a roller mechanism 3 connected to the main frame 1, an encoder mechanism 5, The preamplifier mechanism 6, the cable suspension ring 7, etc., the improvement of the present invention is: except that the scanning mechanism 2 includes the existing horizontal scanning arm 8, it also includes an oblique scanning mechanism 9, the oblique scanning The mechanism 9 has an oblique scanning arm 91 arranged obliquely relative to the weld to be inspected, so that the probe loaded by the oblique scanning mechanism 9 is Welds are scanned obliquely, which can effectively reduce the missed detection of transverse defects. Each component is described in detail below.

[0041] (1) Main frame 1

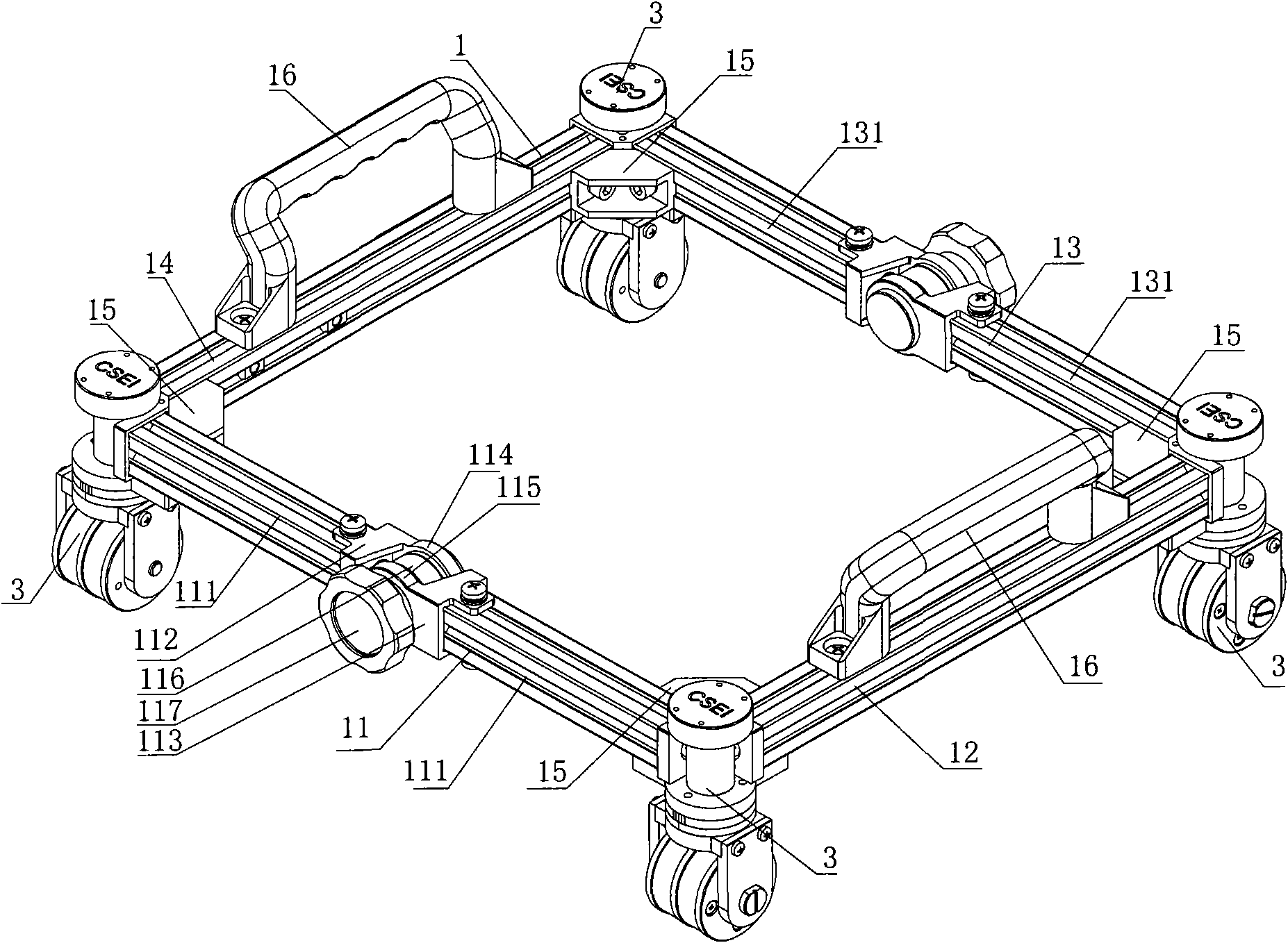

[0042] Such as figure 1 , 2 As shown, the main frame 1 is rectangular, and the four sides of the rectan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com