Machining device and method for machining material

A processing equipment, processing head technology, applied in the direction of metal processing equipment, analysis materials, welding equipment, etc., to achieve cost-effective and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

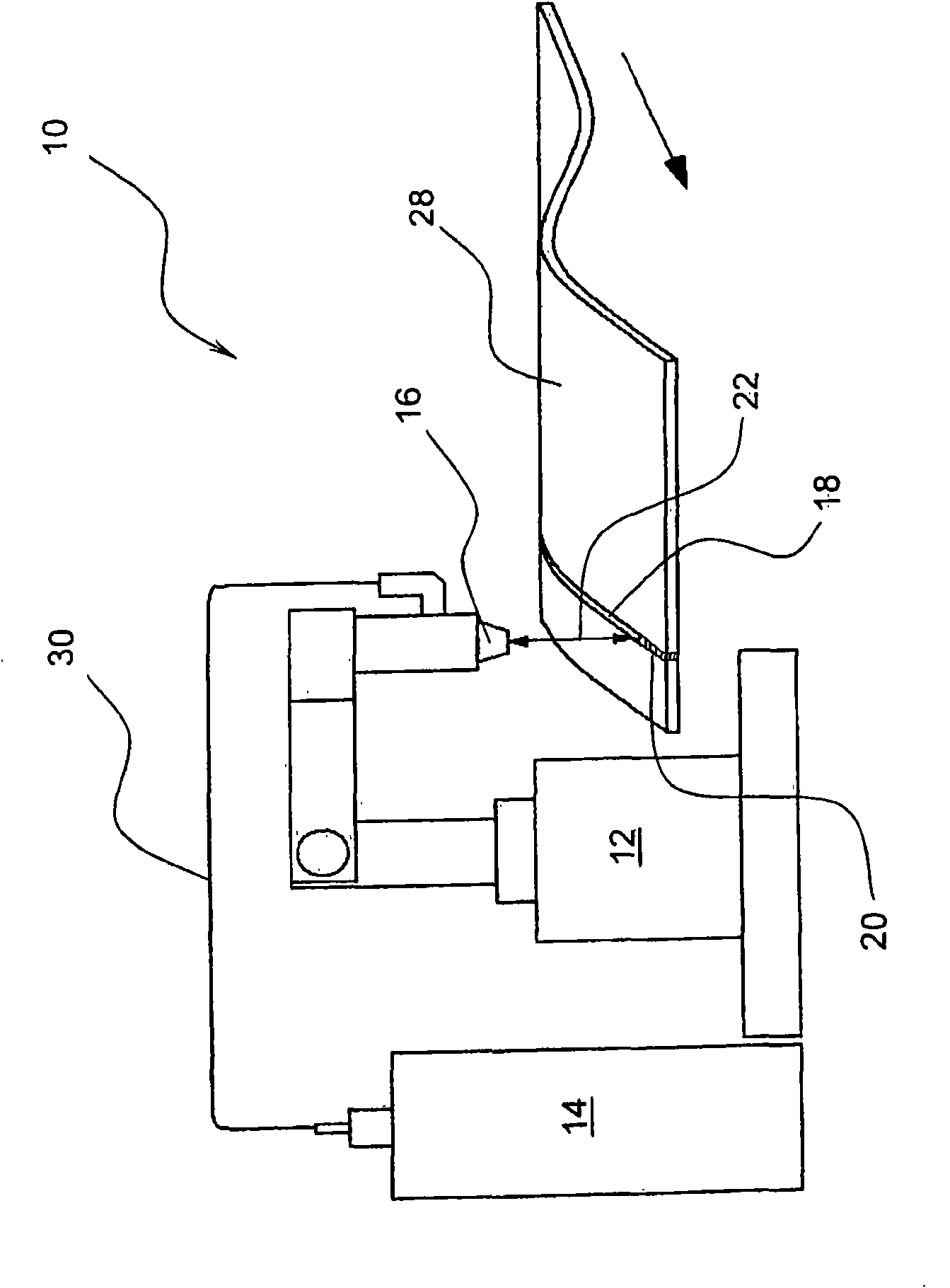

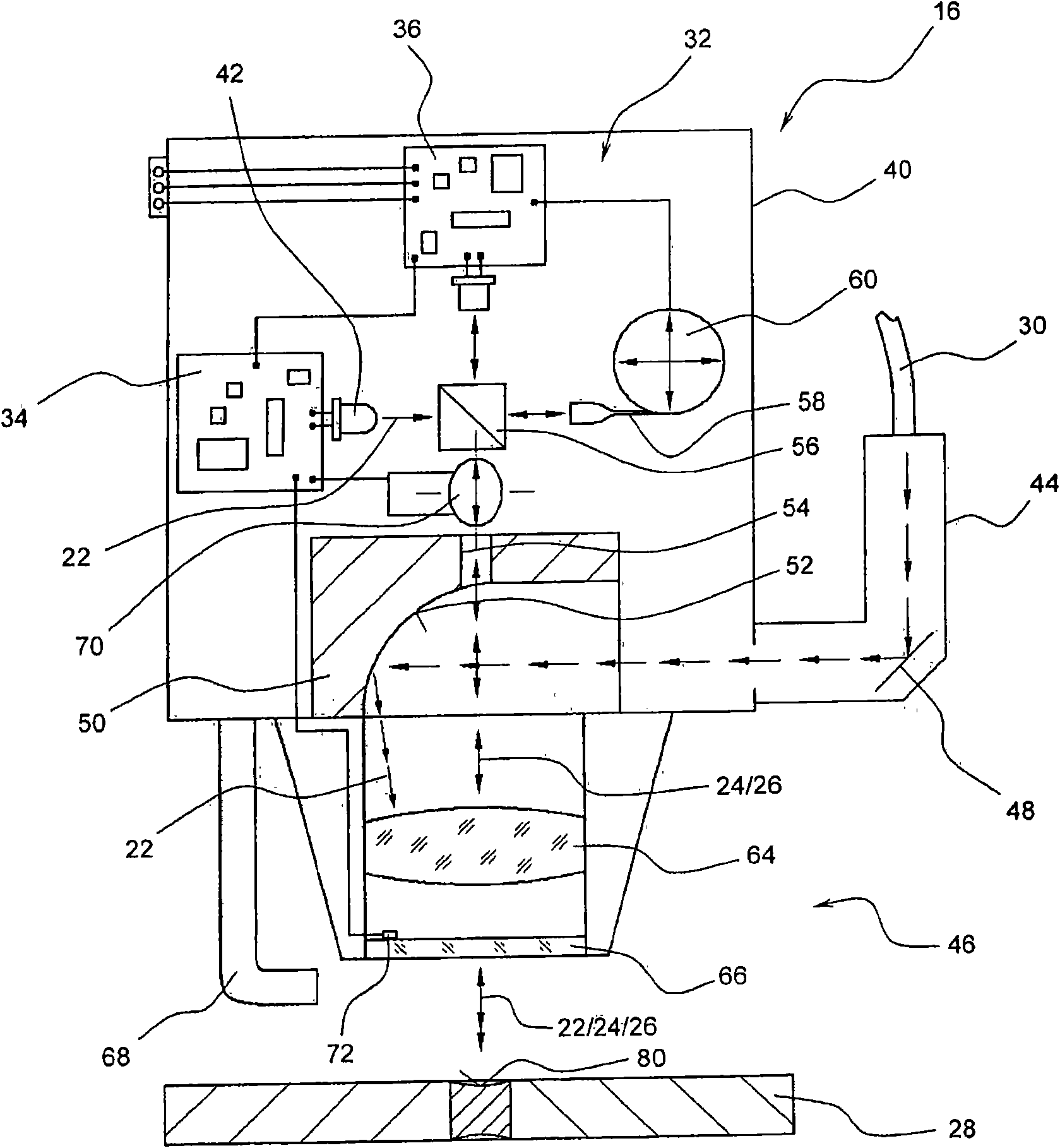

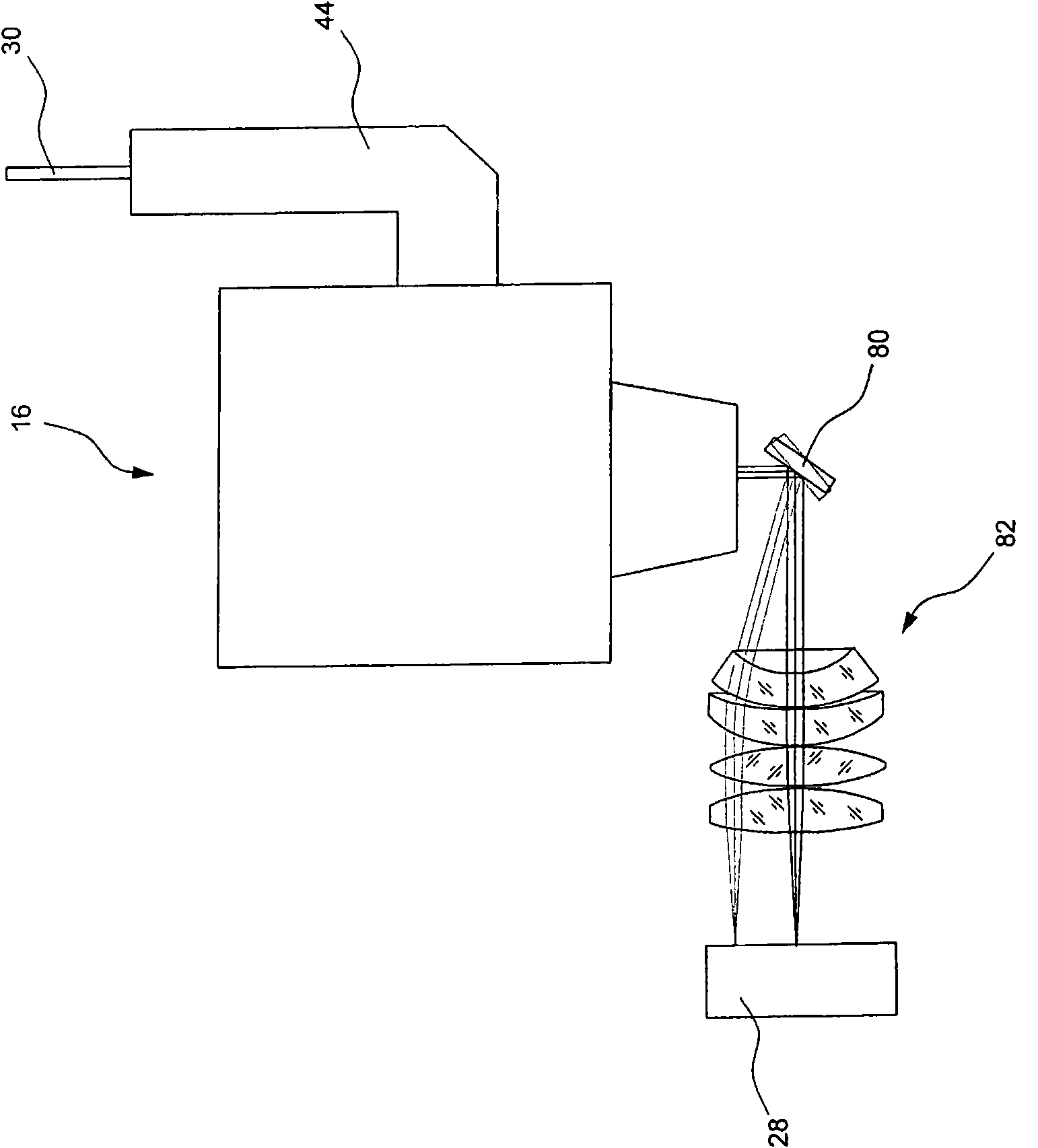

[0035] exist figure 1 A processing device 10 is shown in , which mainly consists of an industrial robot 12 , a laser source 14 and a processing head 16 carried by the industrial robot 12 . The industrial robot 12 is a multi-axis robot which can bring the machining head to different spatial positions relative to the workpiece 28 in order to ensure favorable machining of the workpiece 28 . The laser source 14 is connected to the processing head 16 by means of a bendable fiberglass line 30 . Here, the laser light generated by the laser source 14 is input to the processing head 16 provided in the figure 2 The optical system is shown in detail in . The laser output from the optical system is aimed at the workpiece 28 as a high-energy machining beam 22 .

[0036] In the processing head 16, in addition to the optical system for the high-energy processing beam 22, there are also figure 2 An optical coherence tomography device 32 , shown in detail in , is used to determine the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com