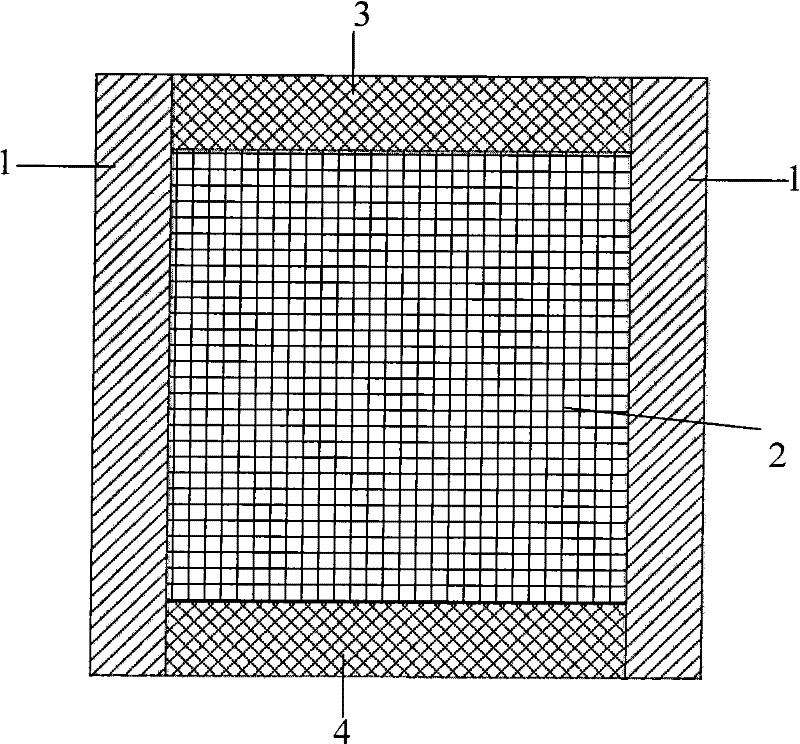

Three-dimensional barcode label and manufacturing method thereof

A barcode label and barcode technology, applied in the field of barcodes, can solve the problems of poor anti-damage ability and limited information capacity space of two-dimensional codes, and achieve the effects of strong anti-distortion ability, lower requirements, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

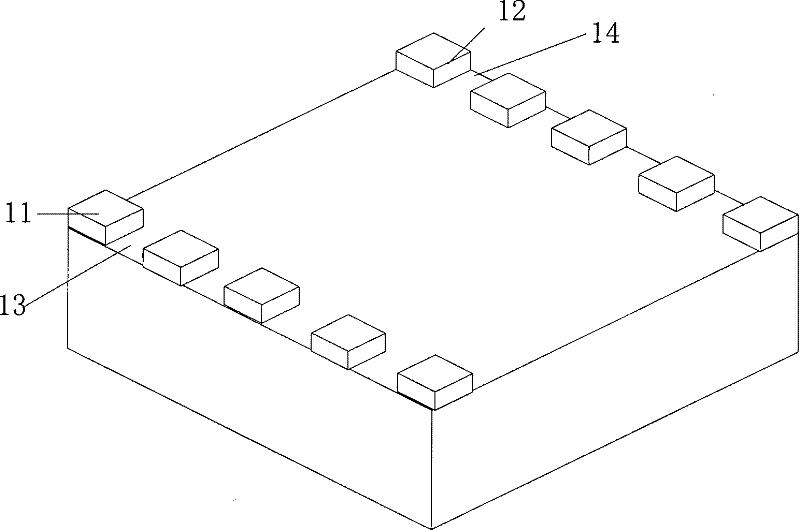

Embodiment 1

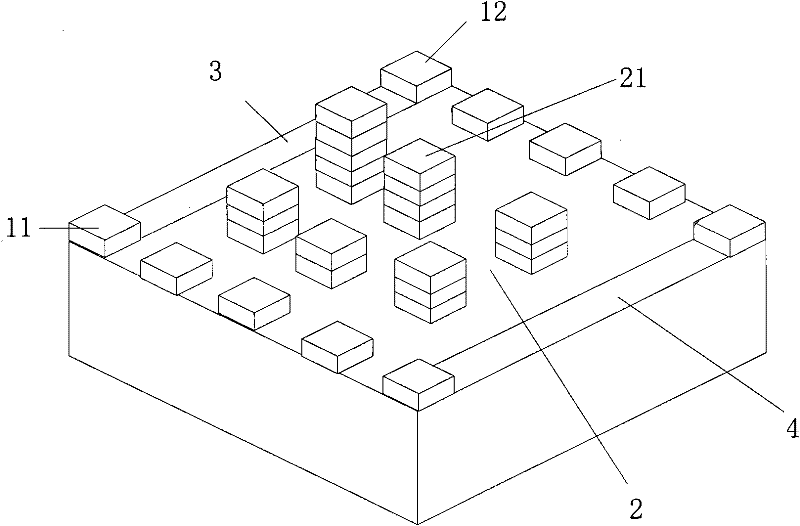

[0031] The making material of the barcode label of the present embodiment is a photosensitive polymer, and each height unit of the information storage unit 21 of the design barcode is divided into eight heights (see Figure 4 ), the first height is 000, the second height is 001, the third height is 010, the fourth height is 011, the fifth height is 100, the sixth height is 101, the seventh height is 110, and the eighth height is 111. The difference of each height is 0.1mm, and each height represents 3 bits respectively.

[0032] The three-dimensional solid model of the barcode label is processed layer by layer, and the generated layer format files are format converted to form a series of bitmap files. The series of bitmap files are imported into the three-dimensional barcode inkjet printer layer by layer, and printed layer by layer, that is The three-dimensional bar code label of the present invention is made.

Embodiment 2

[0034] Each height unit of the information storage unit 21 represents 2 bits, and the others are the same as in the first embodiment. Compared with Embodiment 1, the information density of the label in this embodiment is relatively low, and the area of the barcode label expressing the same information is relatively large, so it is suitable for occasions where the requirement for information storage capacity is not high.

Embodiment 3

[0036] Each height unit of the information storage unit 21 is divided into eight heights, but the difference between each height is 1.0 mm, and the others are the same as in Embodiment 1. The height difference of each unit in this embodiment is relatively large, and it is easy to be distorted during the printing process, so it is not suitable for occasions requiring high precision in label production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com