Multi-factory cooperative scheduling optimization method during equipment manufacturing

A manufacturing process and collaborative scheduling technology, applied in the field of automation, can solve the problems of unreasonable use of resources, difficulty in achieving the optimal overall performance of the product manufacturing process, etc., and achieve the effect of reducing network load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0107] Below in conjunction with accompanying drawing, the present invention will be further described:

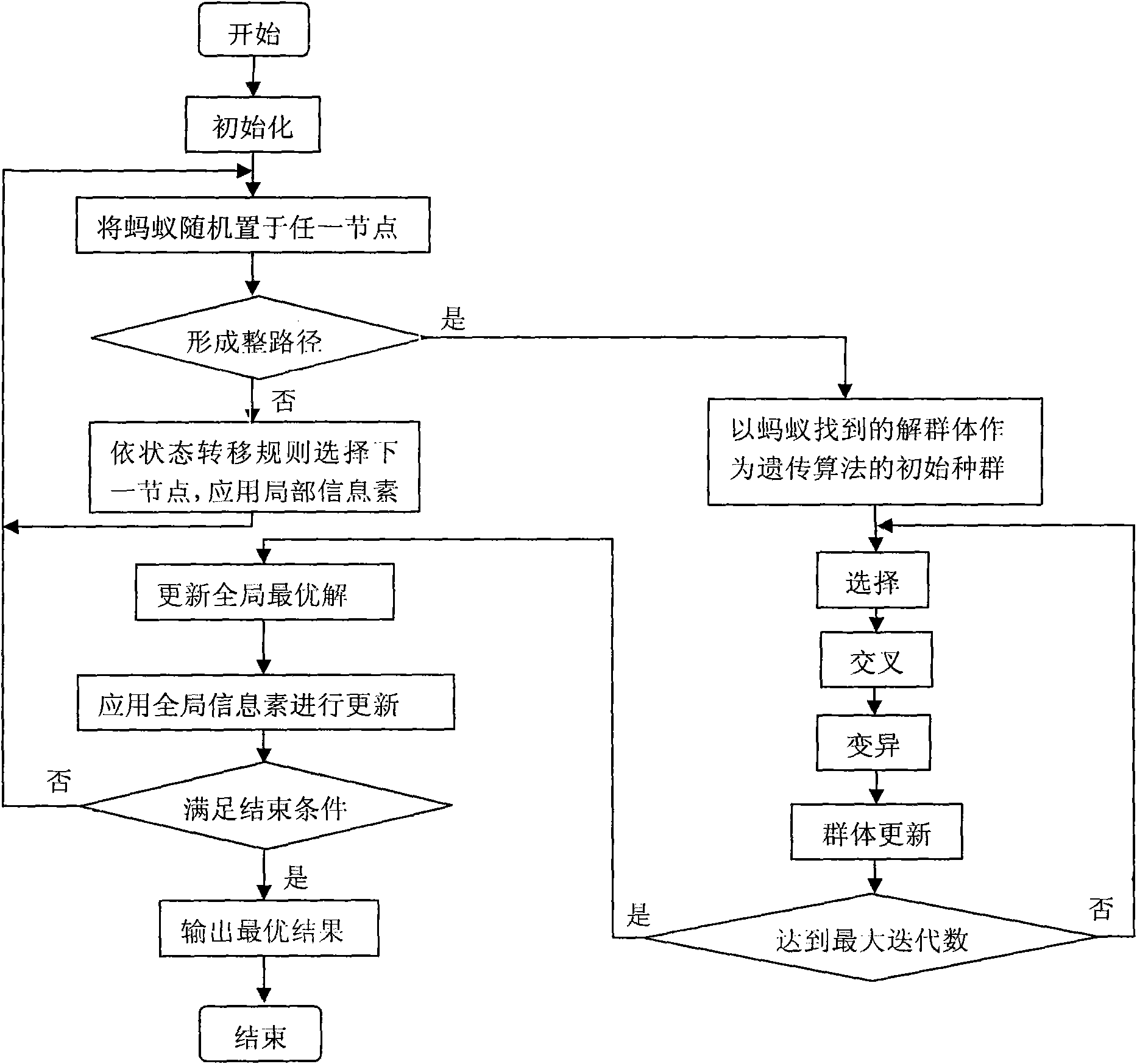

[0108] The present invention provides a multi-factory collaborative scheduling optimization method in the equipment manufacturing process, which is characterized in that: the method consists of the following steps:

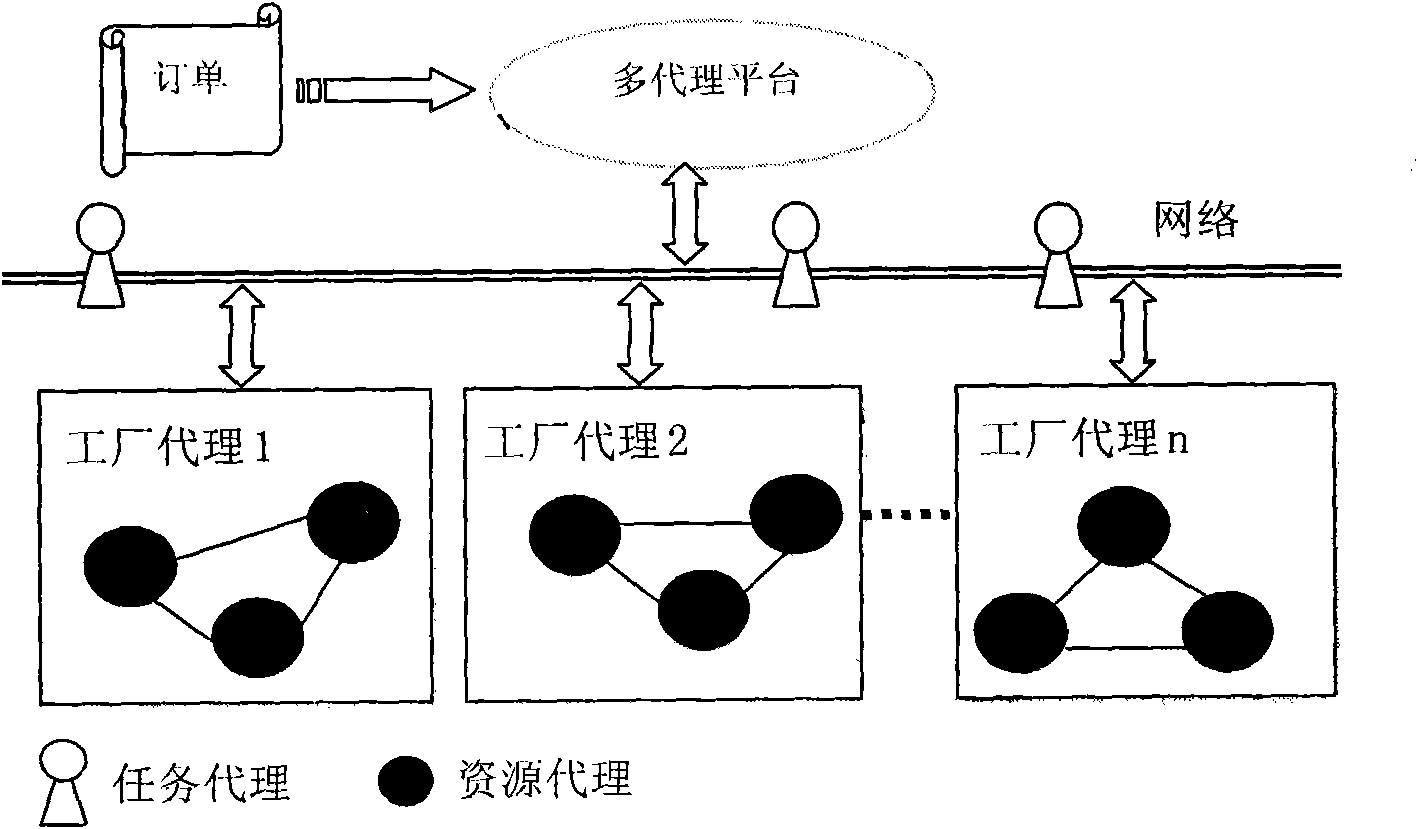

[0109] (1) Establish a multi-agent-based scheduling system model

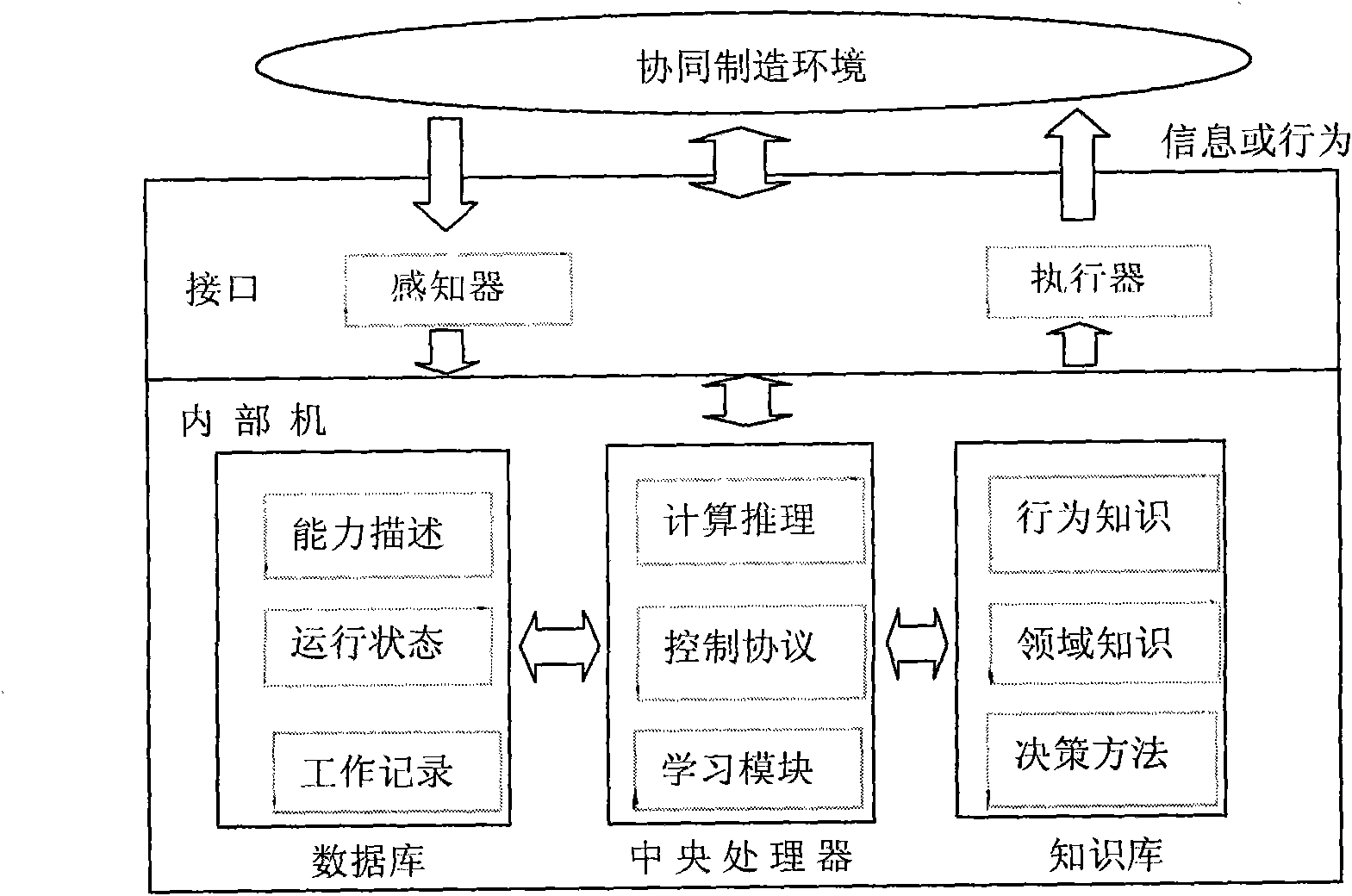

[0110] Establish a multi-agent system model for the multi-factory scheduling system, set up a task agent as the interface between the factory scheduling system and the production planning system to receive tasks, and be responsible for the allocation and decomposition of tasks; set up a resource agent corresponding to each production facility, and manage the information of each machine tool ; Set up a management agent to be responsible for coordinating conflicts between agents (Agents), and to implement scheduling; wherein:

[0111] Management agent (Manager Agent, MA) is responsible for the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com