Cradle head fault detecting method and device

A fault detection and PTZ technology, applied in image data processing, TV, instruments, etc., can solve problems such as single function, reducing the effectiveness of automatic inspection of PTZ faults, and poor adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

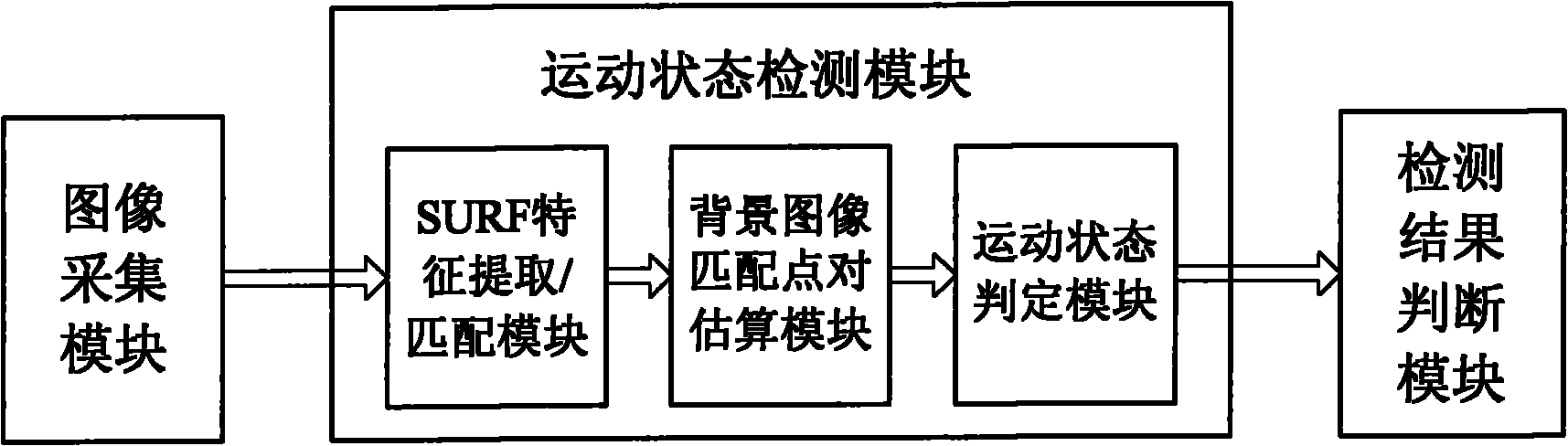

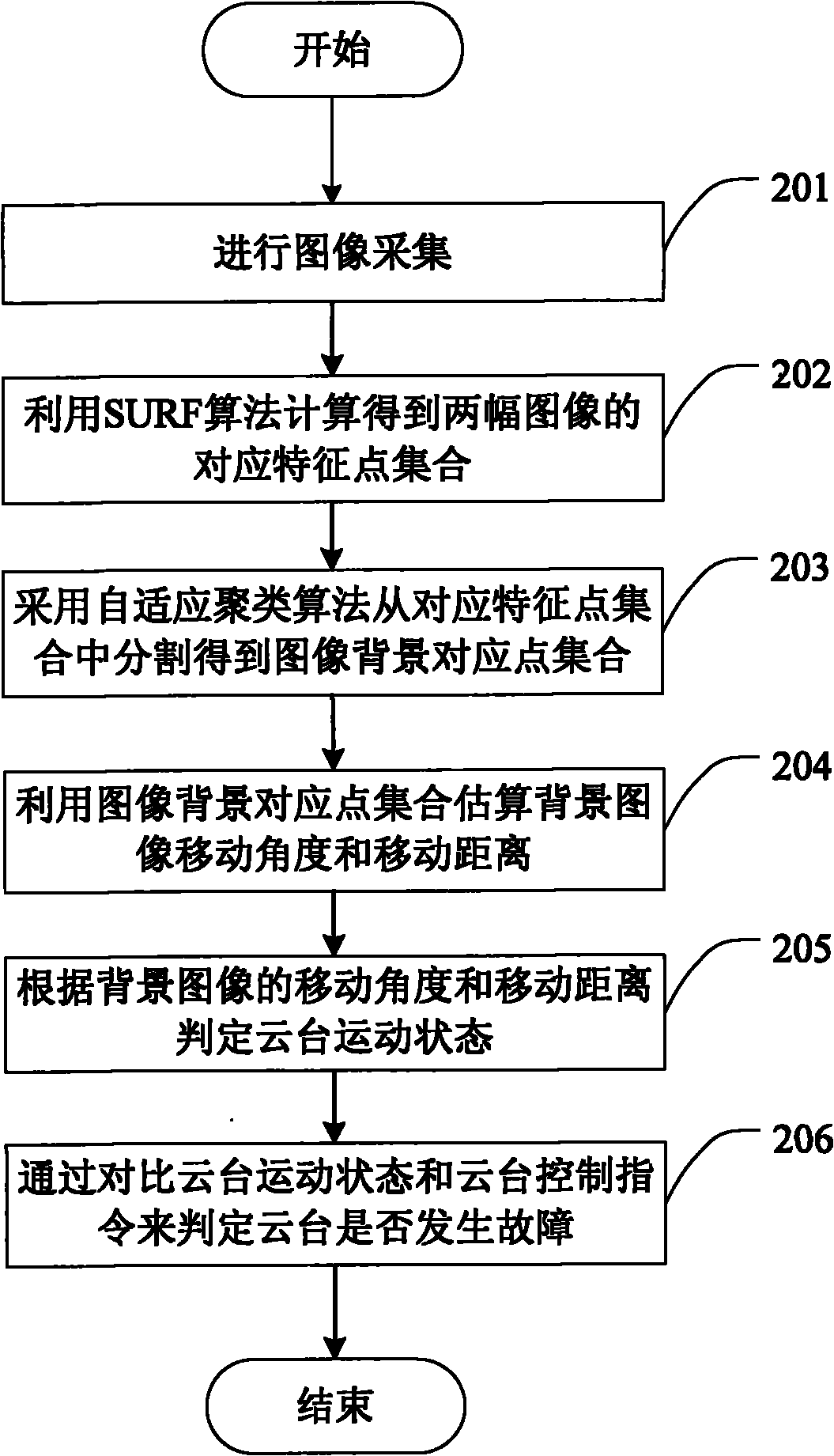

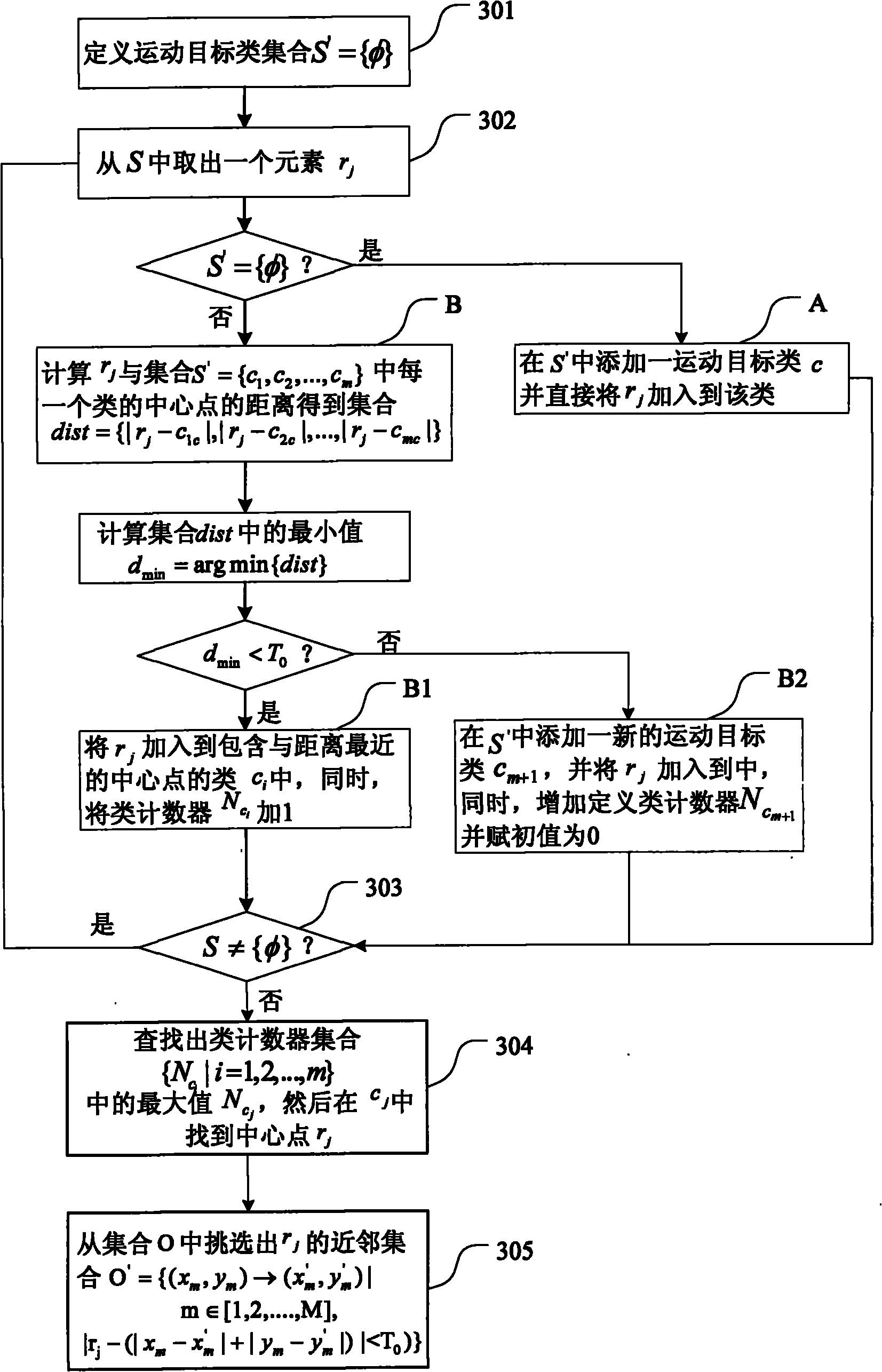

[0061] The core idea of the present invention is: when needing to carry out inspection, send the cloud platform control instruction (the kind of instruction comprises five kinds of upward, downward, leftward, rightward, stop) to the cloud platform to be tested, simultaneously, on the cloud platform The video equipment continuously collects a series of images as the image to be analyzed; then, the SURF algorithm is used to extract the features of the image to be analyzed, and the change state of the background image is calculated through these features, and then the change state of the pan / tilt to be measured is determined accordingly ( Including the change of the cloud platform to be measured from the static state to the motion state, the change from the motion state to the static state, and the direction of motion and the speed of motion under the motion state); at last, the change state of the cloud platform to be measured is compared with the above cloud If the two are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com