Electric screw press and limit method thereof

An electric screw and motor technology, applied in the direction of presses, punching machines, manufacturing tools, etc., can solve the problems of uncertain stop position of the slider and component failure, and achieve the effect of enhancing reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

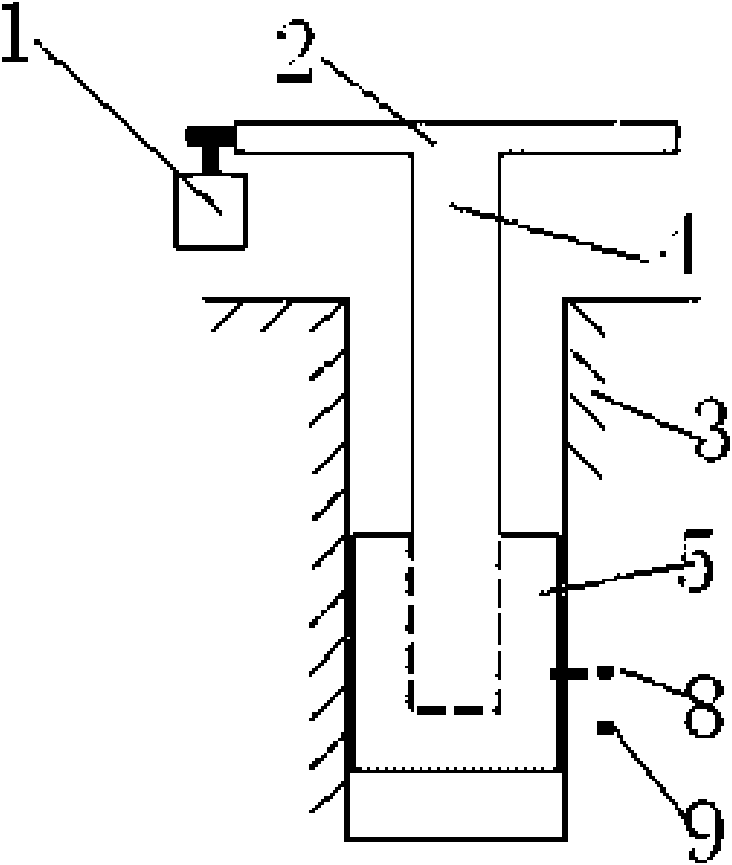

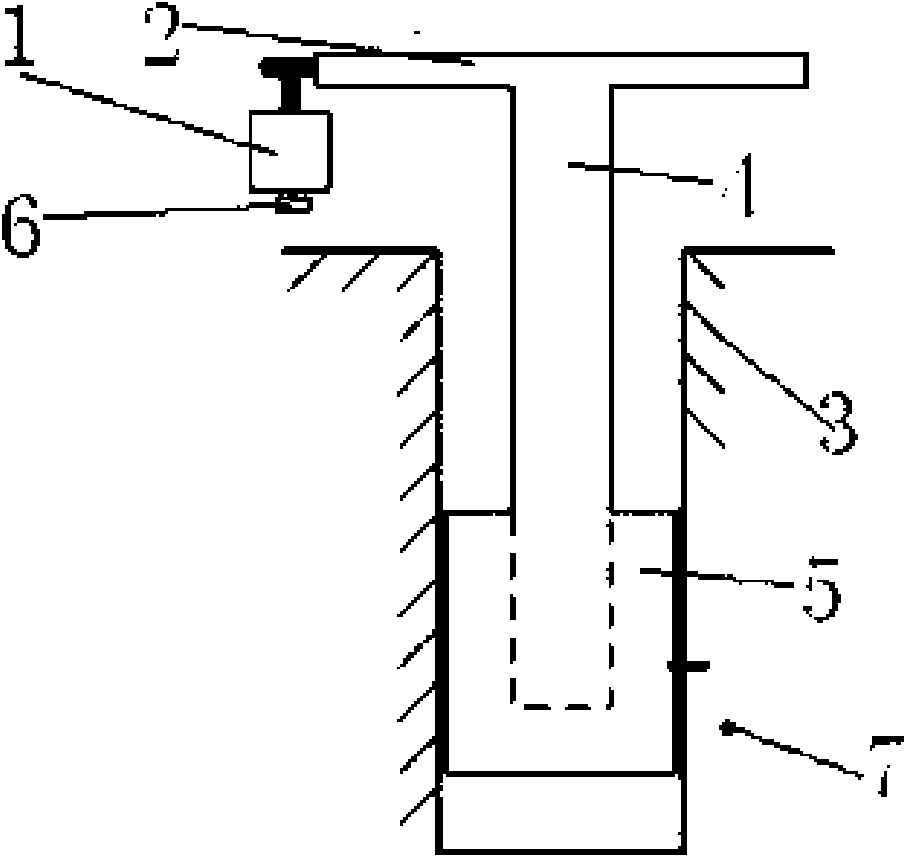

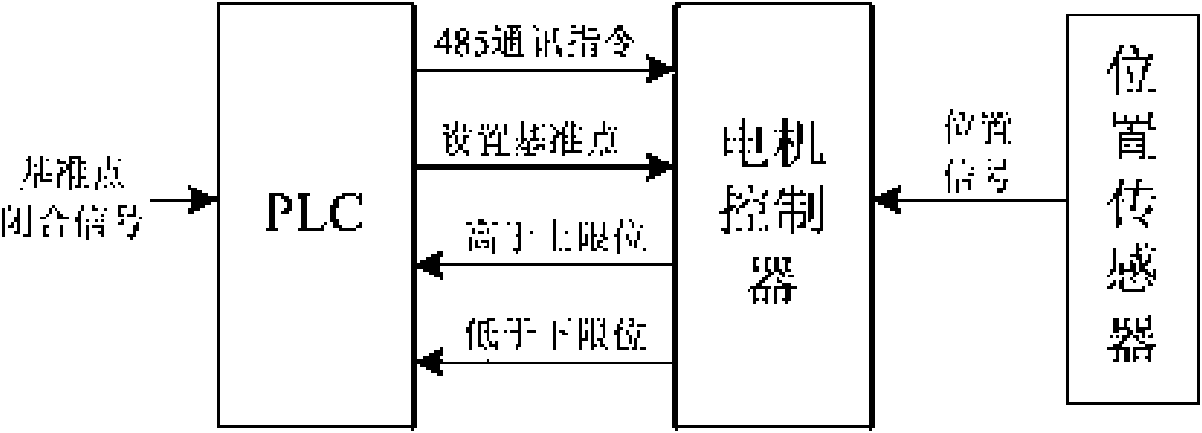

[0024] Such as figure 2 As shown, an electric screw press of the present invention includes a motor 1, a flywheel 2 and a frame 3, the motor is connected to the flywheel through a transmission, the flywheel is connected to a screw 4, and the bottom end of the screw is threaded Connect a slide block 5, the screw rod and the slide block extend into the frame and move up and down in the frame, the motor is a switched reluctance motor, and a position sensor 6 is installed on the switched reluctance motor, the position sensor Connected to the limit control function module, the control principle block diagram of the limit control function module is as follows image 3 As shown, the limit control function module has the functions of countin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com