Paper discharge mechanism of paper feedback device

A paper-feeding and one-feeding paper technology, which is applied in the directions of transportation and packaging, sending objects, thin material handling, etc., can solve the problems of complicated paper structure components, difficult assembly operations, and high cost of parts and components, and achieve simple structure and low cost of parts and components. Less, the effect of reducing the assembly cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

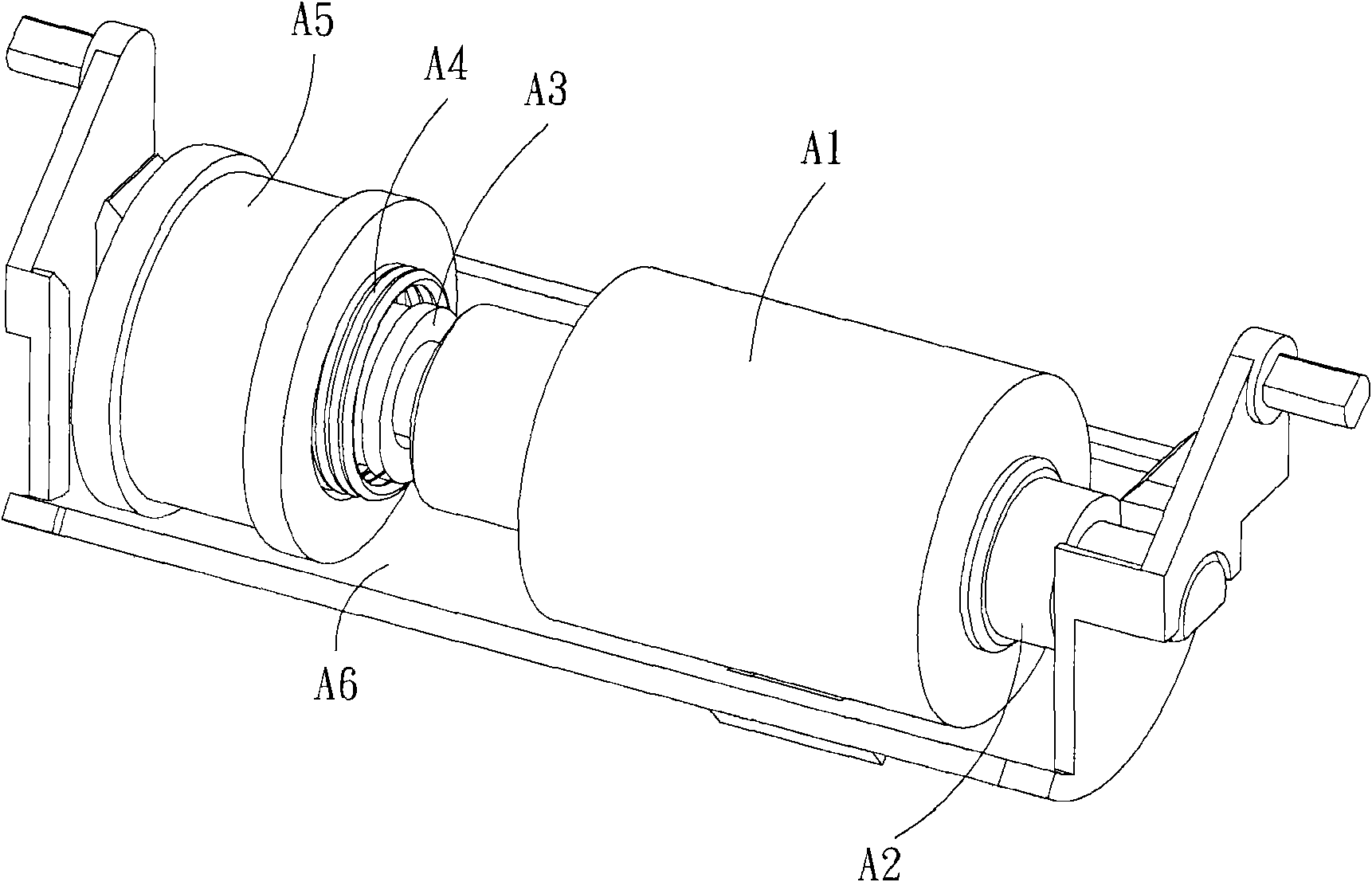

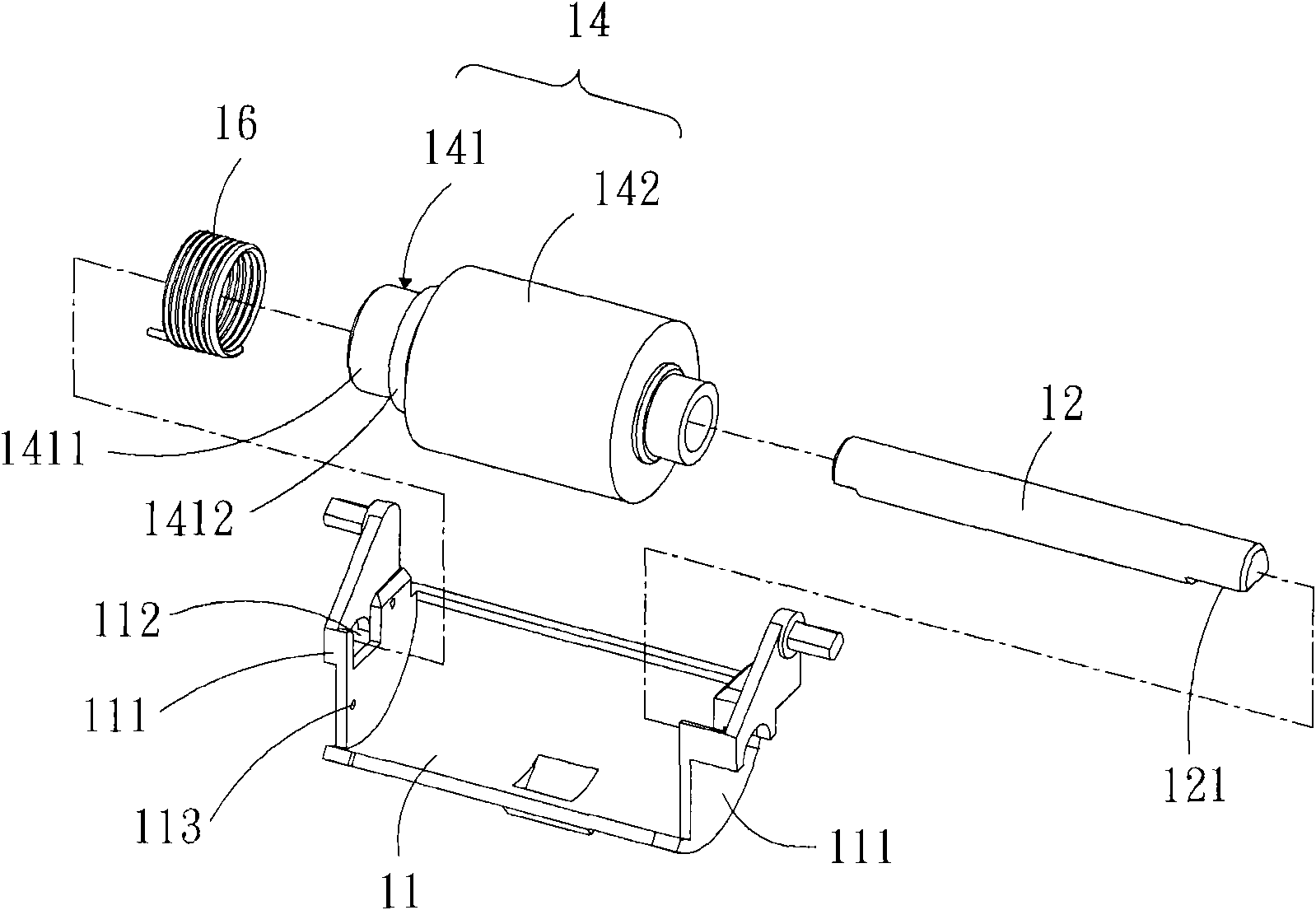

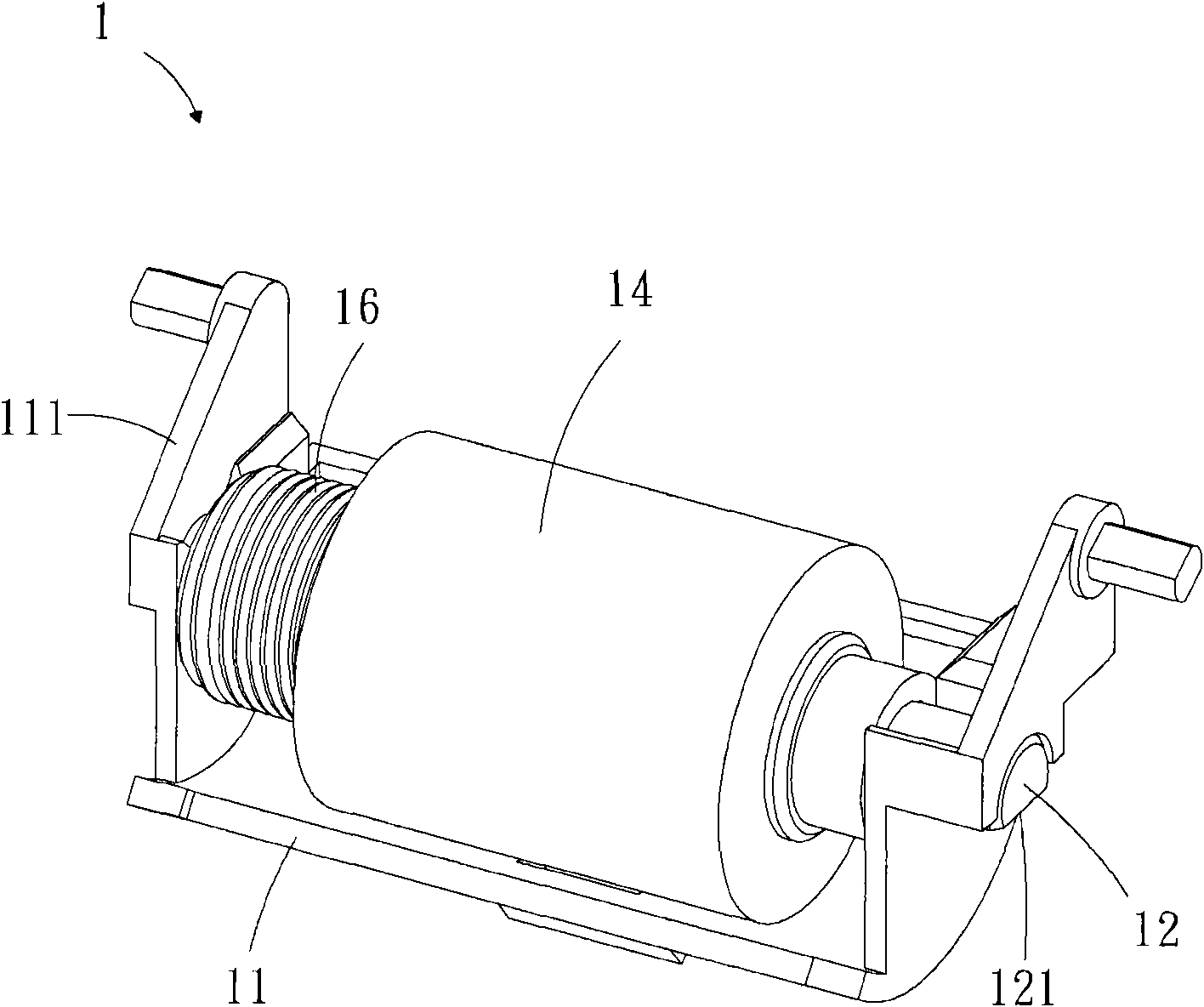

[0017] Please refer to figure 2 and image 3 It is the paper output mechanism of the paper feeding device disclosed in the first embodiment of the present invention.

[0018] The paper output mechanism 1 of the paper feeding device includes: a seat body 11 , a connecting shaft 12 , a paper feeding roller 14 , and an elastic component 16 .

[0019] The seat body 11 is a roughly hollow container body, the bottom of which is an arc-shaped plate body, and side wall surfaces 111 are respectively extended on both sides, and accommodating holes 112 are arranged on the side wall surfaces 111, and one of the side wall surfaces 111 is provided with Positioning holes 113 are provided.

[0020] The connecting shaft 12 is a roughly elongated rod body, and its two ends are respectively passed through the accommodation holes 112 of the seat body 11, wherein, a chamfered surface 121 may preferably be provided in the direction of the long axis of the connecting shaft 12, Viewed from its si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com